Movable hanging and hoisting construction method for steel structure fabricated wallboard

A construction method and prefabricated technology, applied in structural elements, building components, building structures, etc., can solve the problems of wall panel shaking, construction period extension, and high difficulty of wall panel hoisting, so as to achieve the effect of smooth lowering and reduced friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

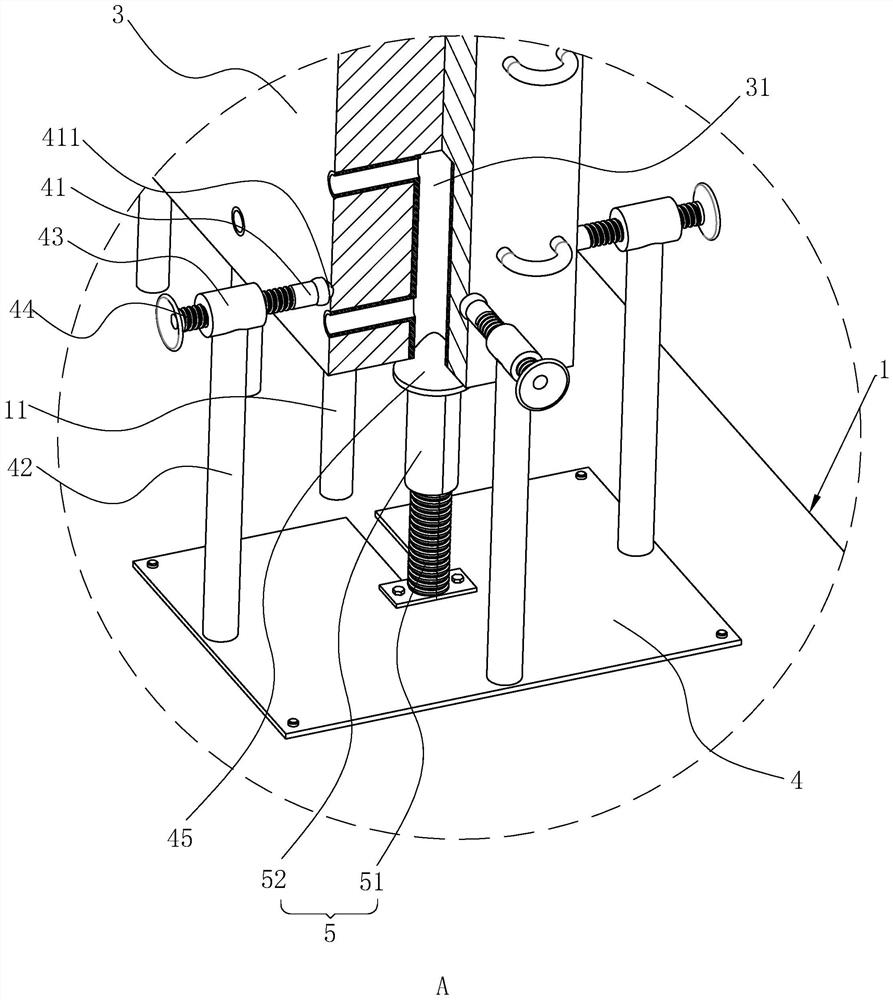

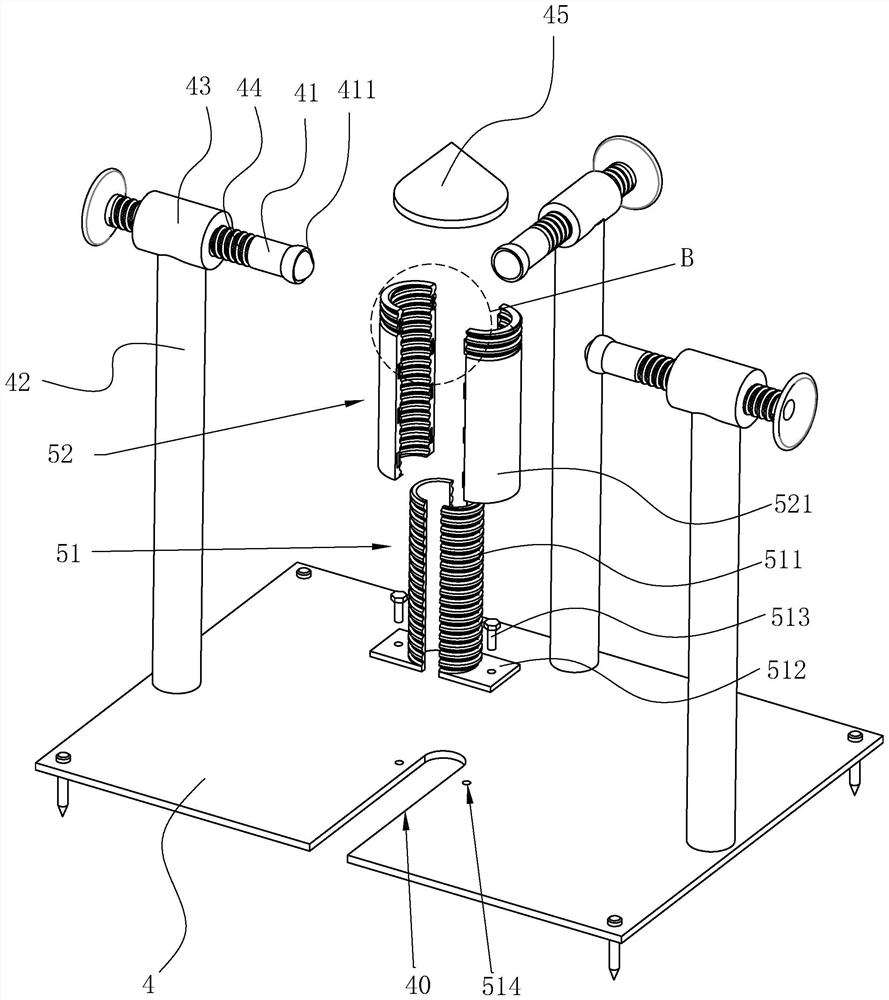

[0042] The following is attached Figure 1-6 The application is described in further detail.

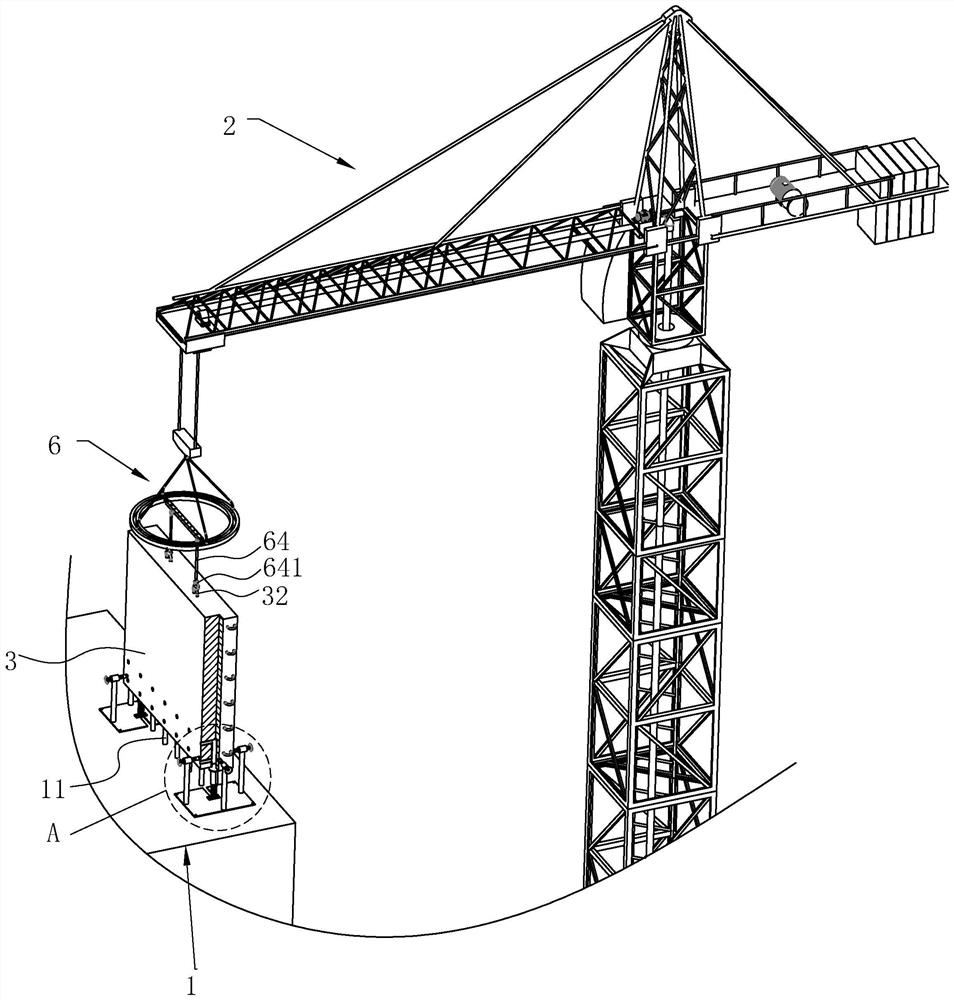

[0043] The embodiment of the present application discloses a construction method for movable suspension and hoisting of steel structure assembled wall panels, refer to figure 1 and figure 2 , including the following steps:

[0044] S1: Prefabricated wall panel 3, the wall panel 3 is a prefabricated reinforced concrete structure, two sets of lifting rings 32 are pre-embedded at the top of the wall panel 3; There is a one-to-one correspondence with several connecting steel bars 11 on the joint surface 1 .

[0045] The hanger 6 is prefabricated, and the hanger 6 is provided with two sets of connecting ropes 64, and the ends of the two sets of connecting ropes 64 far away from the hanger 6 are provided with hooks 641, and the two sets of hooks 641 are respectively used to hook up the two sets at the top of the wall panel 3. Lifting ring 32, in the present embodiment, two groups of c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com