Patents

Literature

79results about How to "Reduce field work time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

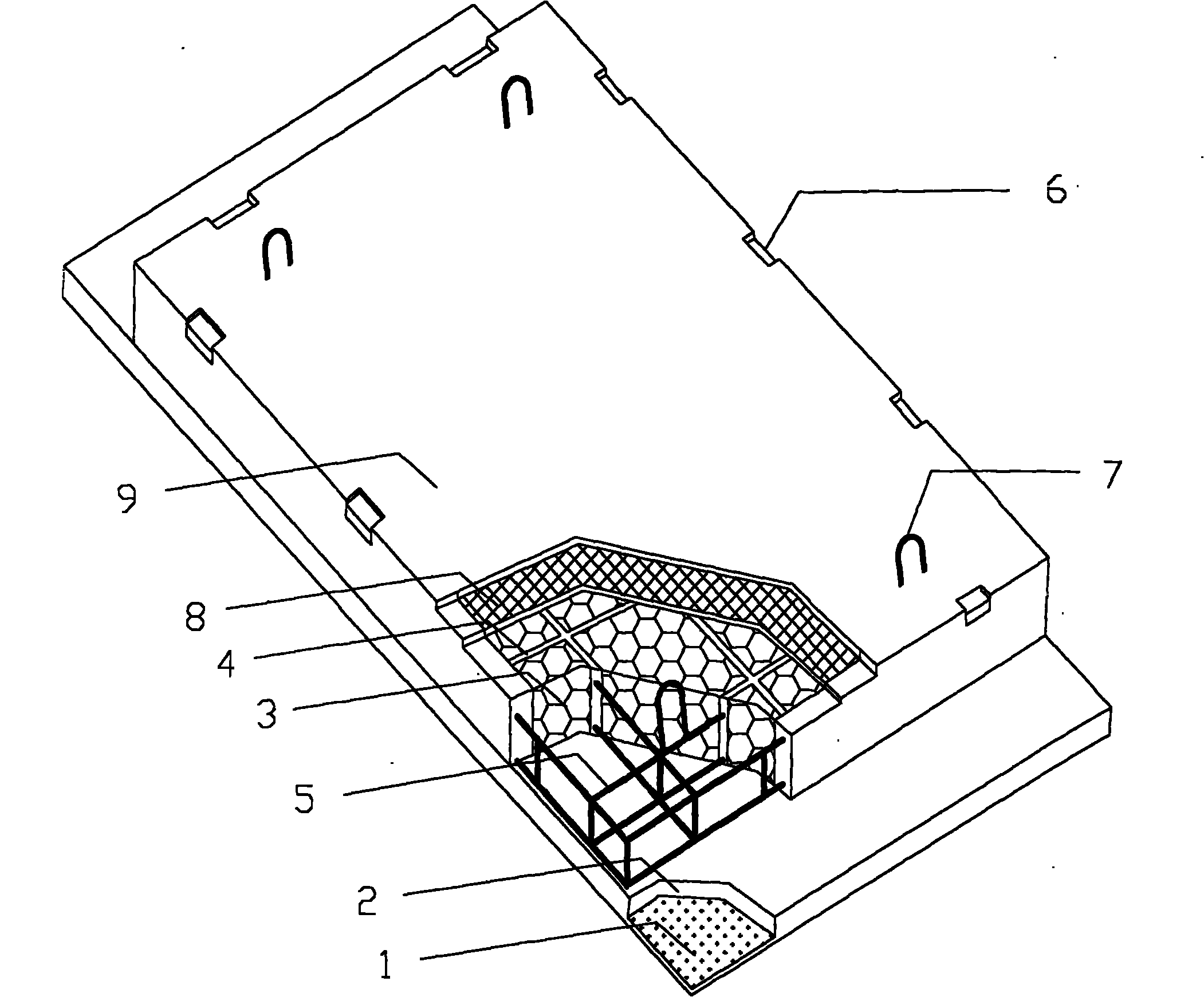

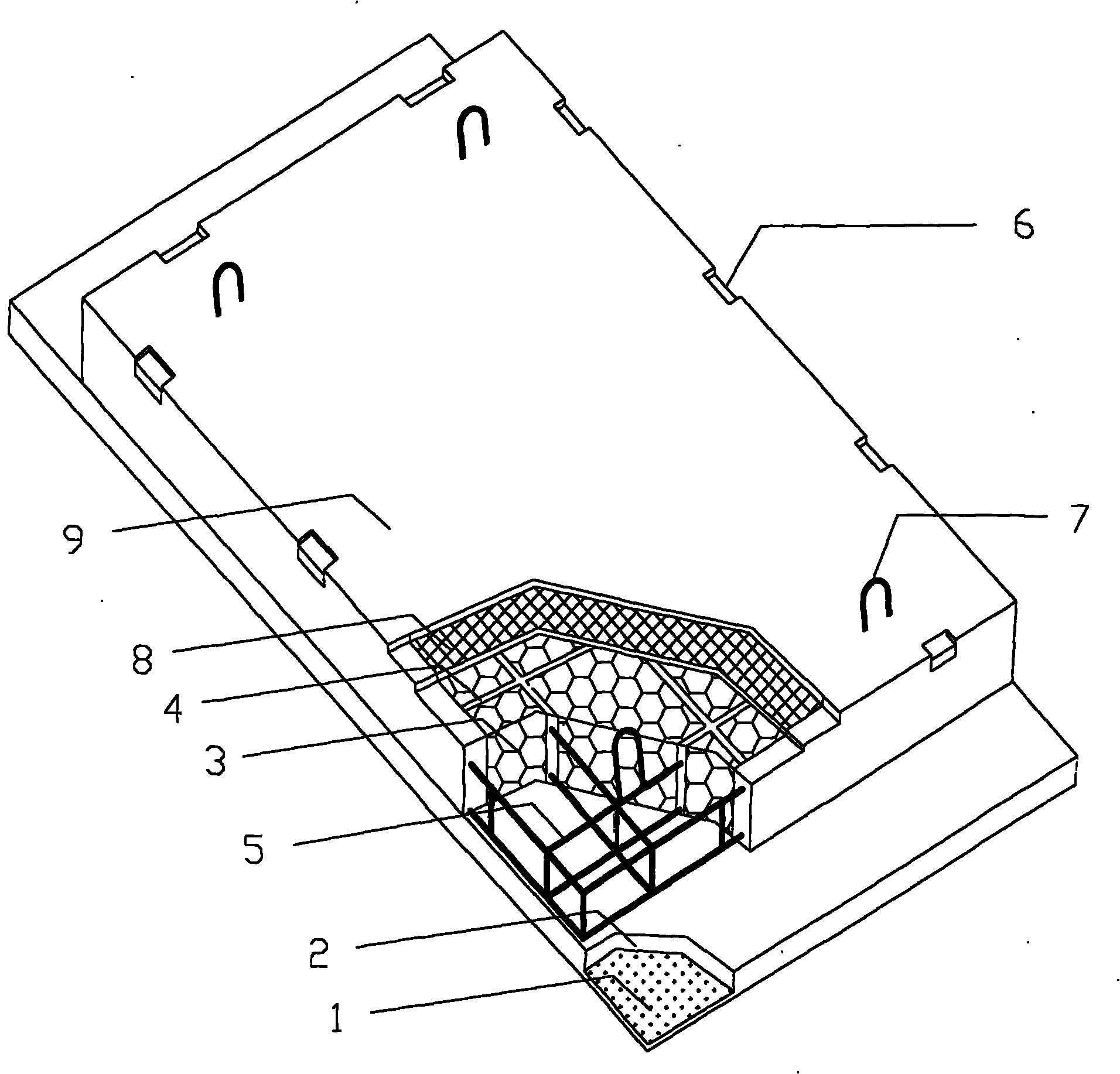

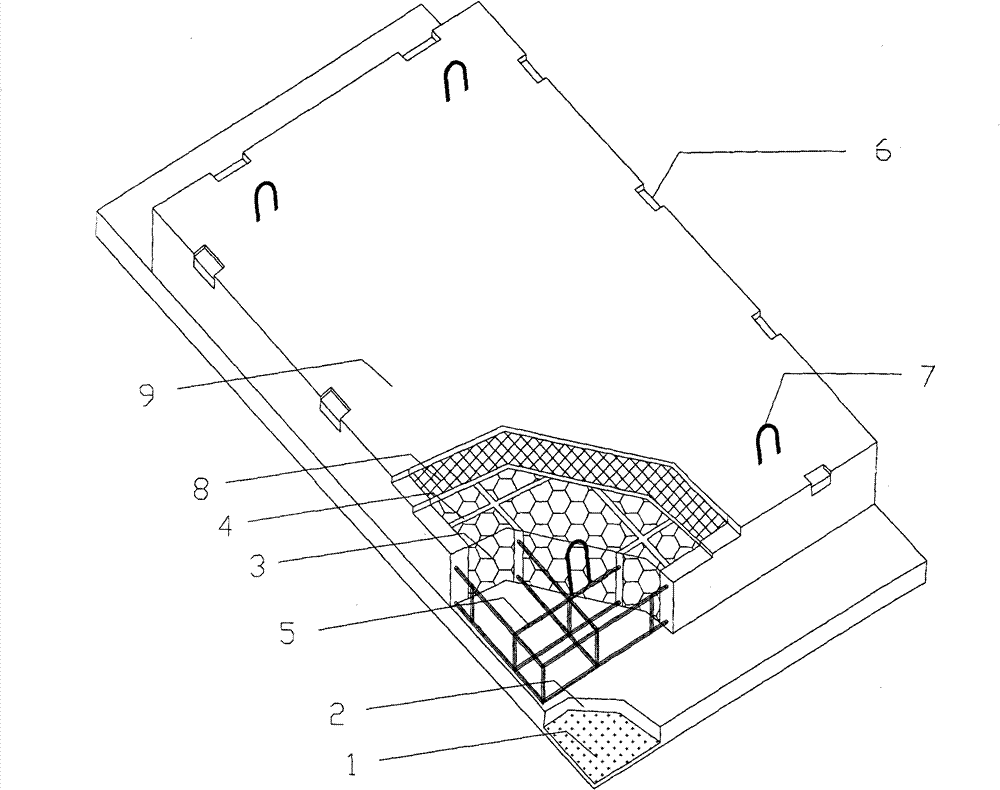

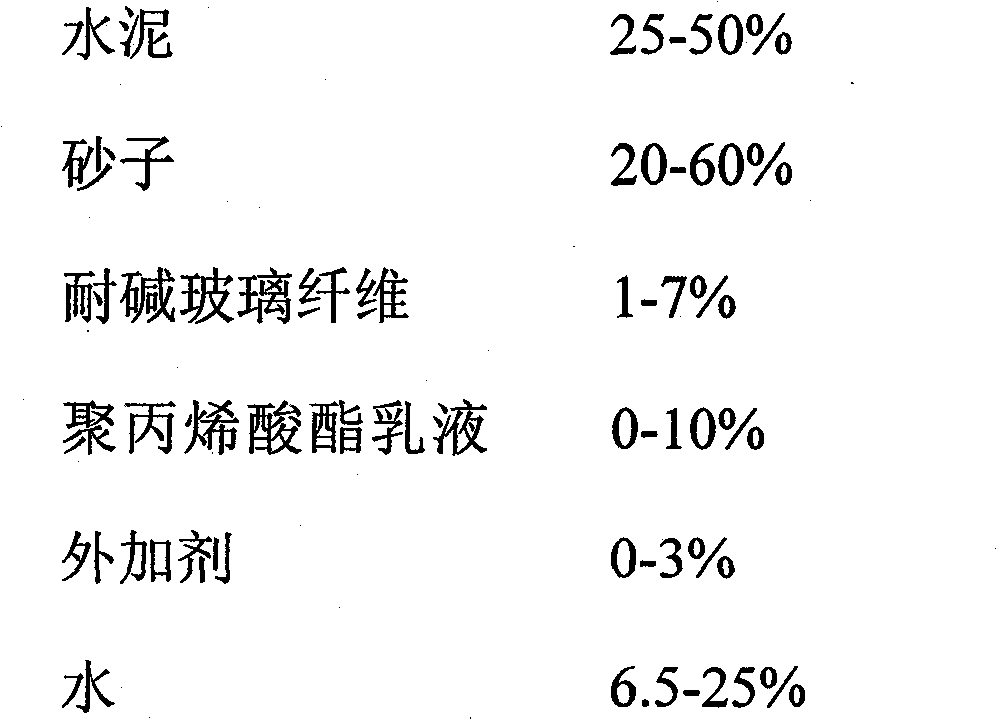

Glass fiber reinforced cement (GRC) insulation decorative wallboard and production method thereof

InactiveCN102094501AReduce pollutionReduce on-site workCovering/liningsCeramic shaping apparatusGlass fiberSteel frame

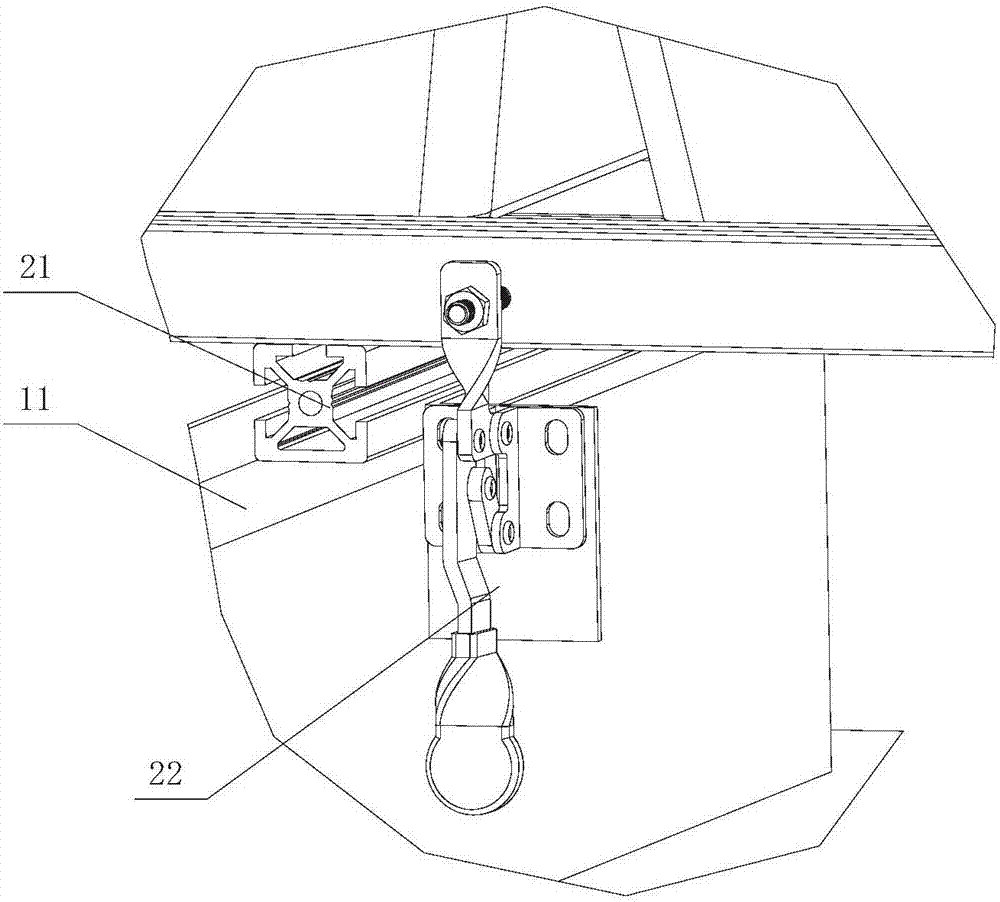

The invention relates to a glass fiber reinforced cement (GRC) insulation decorative wallboard and a production method thereof, which are applicable to structural envelope, heat insulation and decoration of an external wall for a building of a frame structure. The GRC insulation decorative wallboard comprises a decorative layer, a GRC structural layer I, a GRC structural layer II, an insulating layer, a GRC reinforcing rib, steel frames, an installation connection piece, a lifting ring and an anti-cracking material, wherein, the GRC structural layer I is compounded on the decorative layer andis equipped with the insulating layer; the GRC structural layer II is arranged on the insulating layer, and the GRC reinforcing rib is arranged in the insulating layer; the GRC structural layer I is connected with the GRC structural layer II through the GRC reinforcing rib; the steel frames are arranged in the GRC structural layer I, the GRC structural layer II and the reinforcing rib; and the anti-cracking material is laid in the GRC structural layer II.

Owner:NANJING BEILIDA NEW MATERIAL SYST ENG

Structural plane measuring method based on three-dimensional laser scanning technique

InactiveCN104482922AReduce field work timeNo need for manual measurement one by onePhotogrammetry/videogrammetryPoint cloudLaser scanning

The invention relates to the structural plane measuring technique in the engineering geological investigation field and discloses a structural plane measuring method based on the three-dimensional laser scanning technique. The structural plane measuring method solves the problems that working time is long and efficiency is low in rock mass structural plane measuring modes in the prior art. Investigation window rock mass surface laser-point clouds are obtained through the three-dimensional laser scanning technique, rock mass surface true color digital photos are obtained through a digital camera, structural planes are recognized through the three-dimensional laser-point clouds and the true color digital photos, the occurrence of the structural planes is worked out, the exposing lines of the structural planes are generated, and the length and persistence ratio of the structural planes and the distance between the structural planes and the like are measured. The method is suitable for rock mass structural plane measuring.

Owner:POWERCHINA CHENGDU ENG

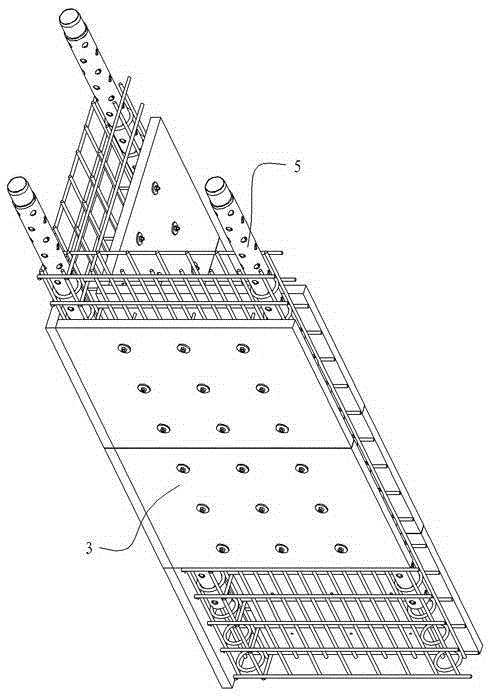

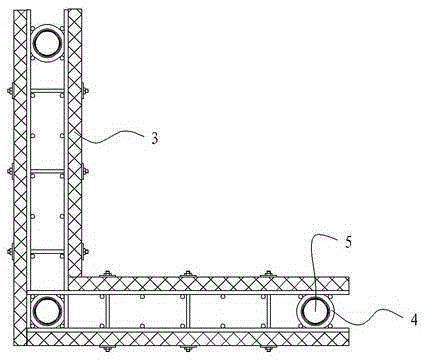

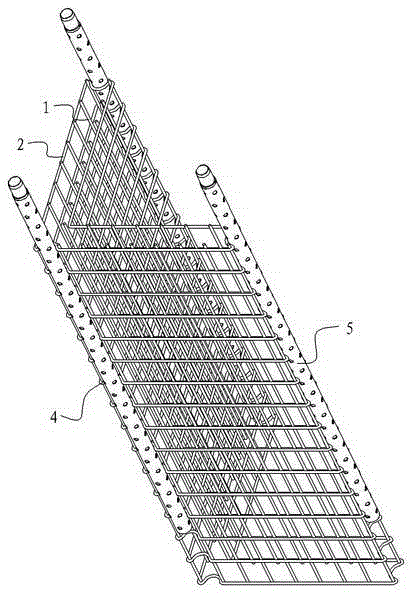

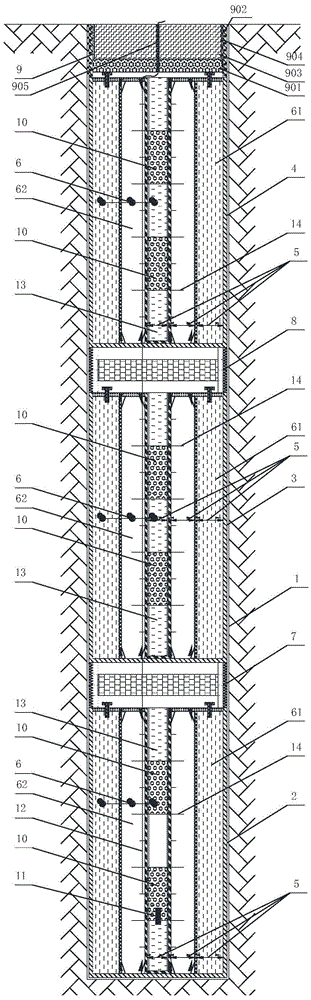

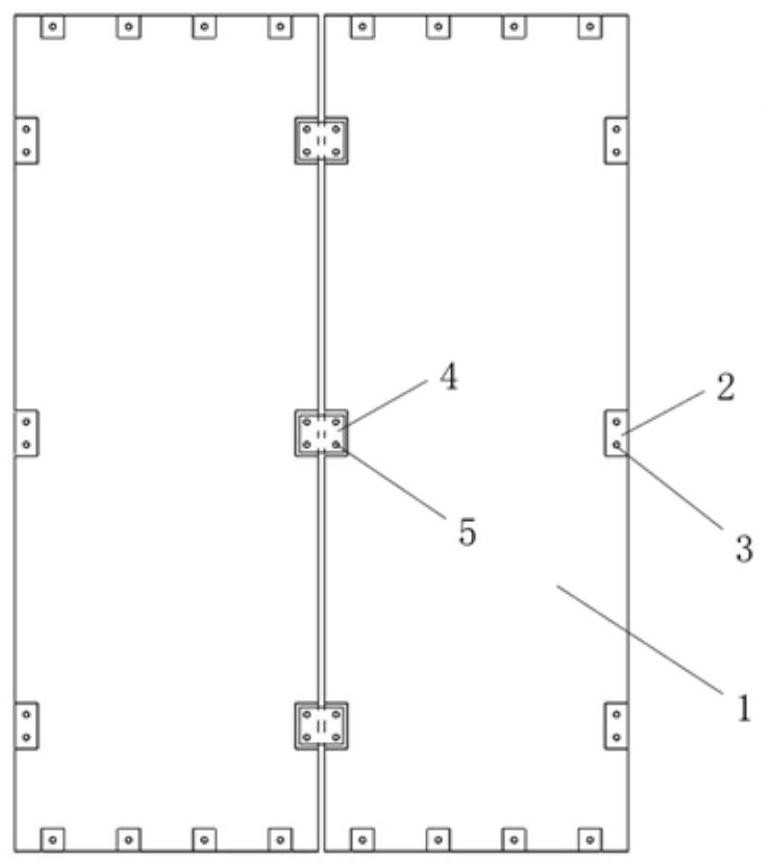

Prefabricated wall, prefabricated wallboard, construction method of prefabricated wall and production method of prefabricated wallboard

ActiveCN105317137AReliable qualityReduce field work timeWallsCeramic shaping apparatusSteel tubeRebar

The invention relates to a prefabricated wall, a prefabricated wallboard, a construction method of the prefabricated wall and a production method of the prefabricated wallboard, belonging to the technical field of building walls. The prefabricated wall comprises steel reinforcement cages arranged at floors, wherein each steel reinforcement cage comprises longitudinal main reinforcements and reinforcement stirrups fixedly arranged on the main reinforcement; the outer surface of each steel reinforcement cage is fixedly provided with two first dismounting-free heat insulation template; each steel reinforcement cage is internally provided with a limiting ring and a locating steel tube extending along the length direction of the main reinforcement; the locating steel tubes are arranged in the limiting rings; the locating steel tubes in the steel reinforcement cages at an upper floor are connected with the adjacent locating steel tubes in the steel reinforcement cages at a lower floor through locating tube sleeves; the mutually-abutted main reinforcements of the steel reinforcement cages at the upper floor and at the lower floor are welded together fixedly; and cast-in-place concrete is solidified in the steel reinforcement cages and holes of the locating steel tubes. The prefabricated wall, the prefabricated wallboard, the construction method of the prefabricated wall and the production method of the prefabricated wallboard have the advantages that the structure is reasonable and rapid construction and installation are conveniently realized.

Owner:史世英

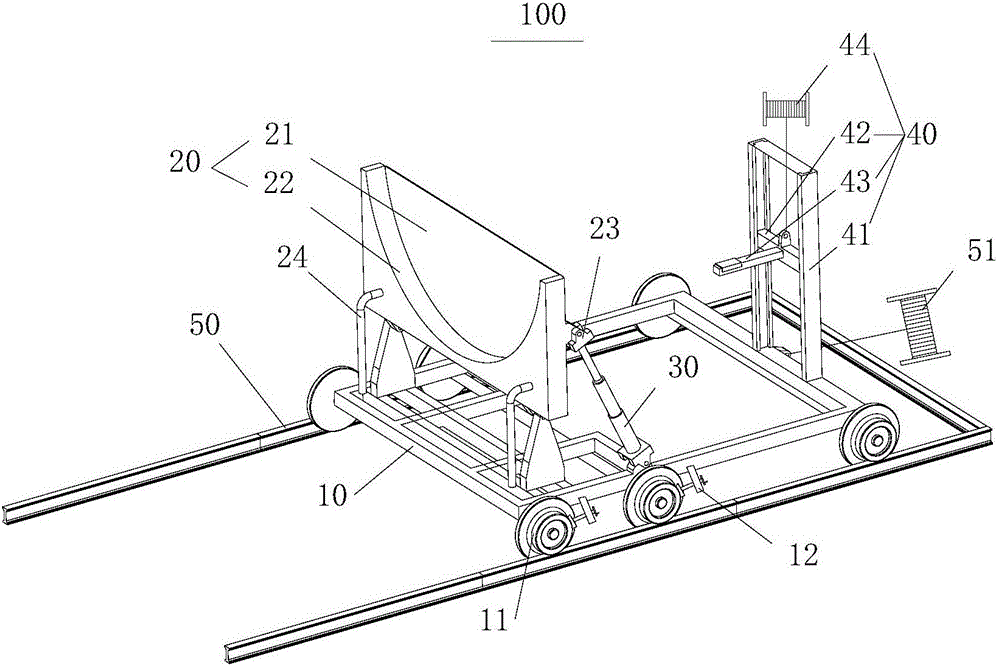

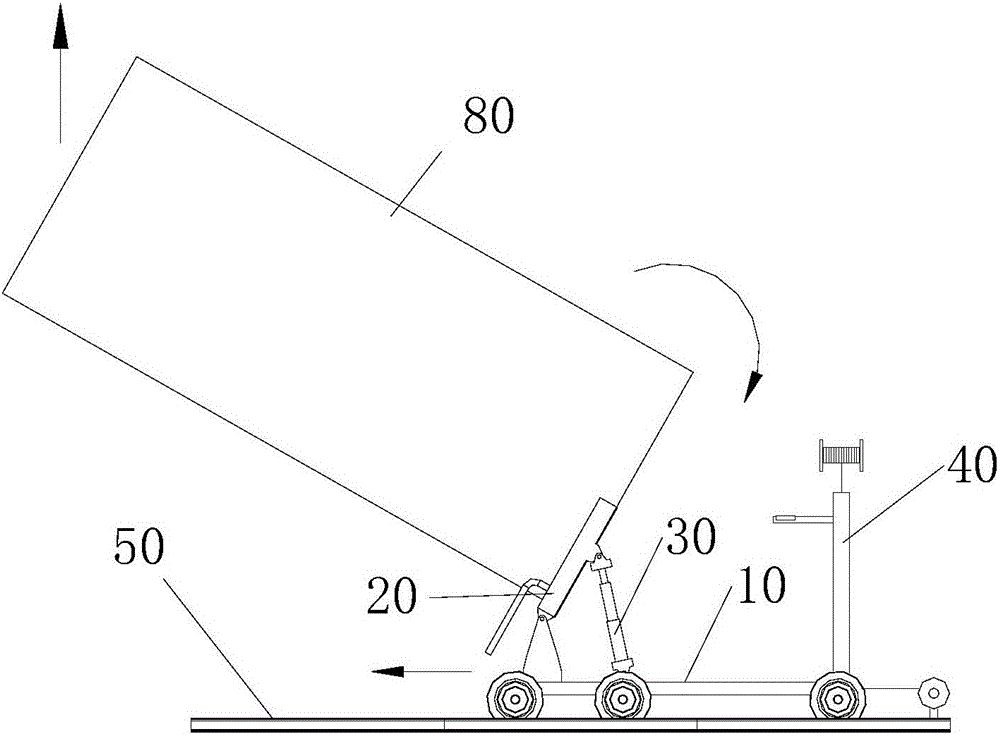

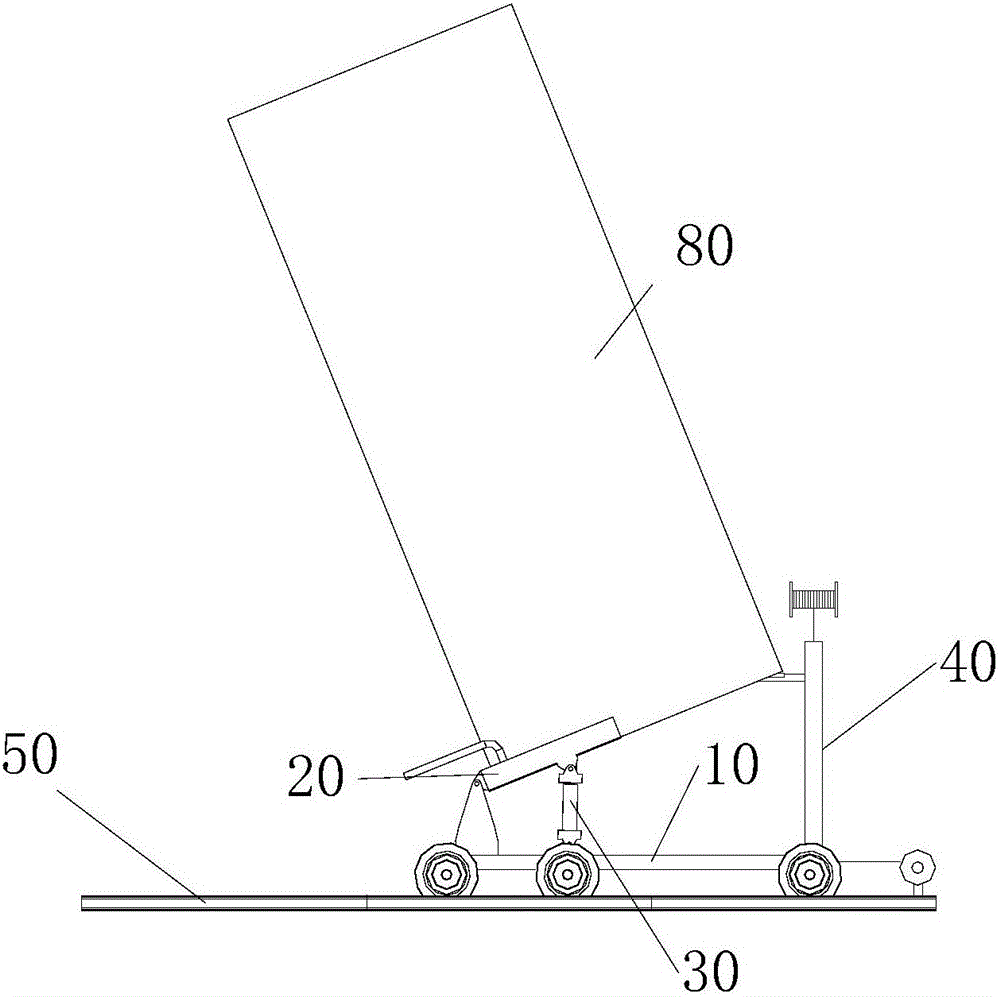

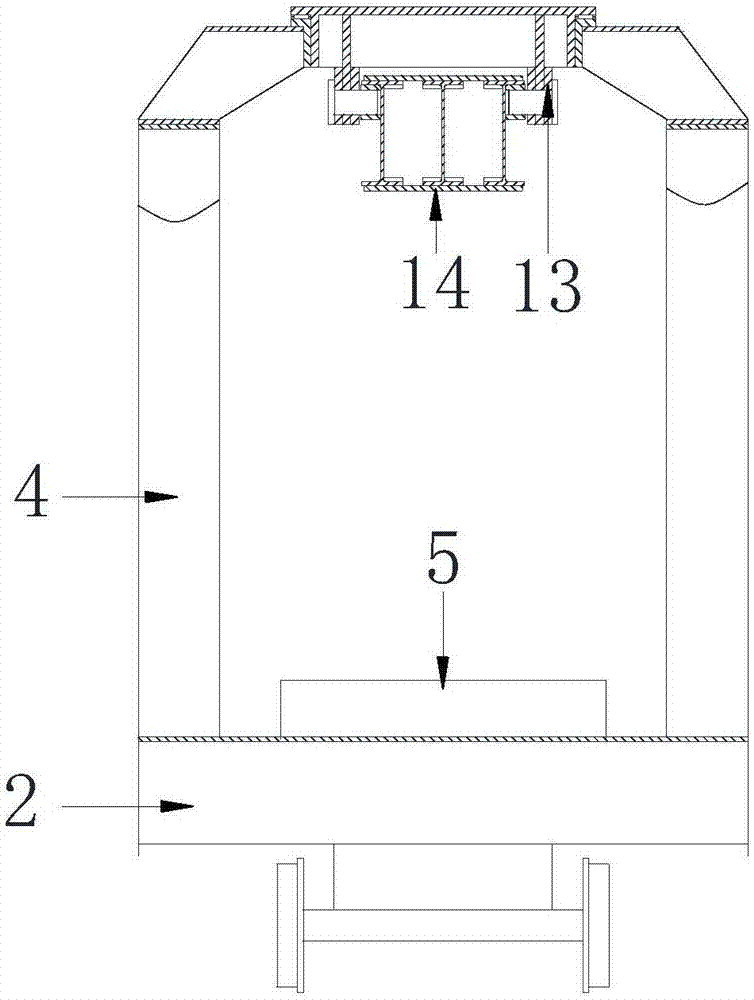

Tower cylinder overturning device and hoisting method for tower cylinder

ActiveCN106744312ASave installationEliminates disassembly workWind motor assemblyTowersPulp and paper industryTower

The invention provides a tower cylinder overturning device and a hoisting method for a tower cylinder. The tower cylinder overturning device comprises a base, an overturning bracket and a hydraulic supporting device. One end of the overturning bracket is in pivot connection with the base, and the overturning bracket can be overturned to a horizontal state from a vertical state. The overturning bracket comprises a supporting plate supporting part and a side supporting part. The upper surface of the bracket supporting part is used for supporting the bottom of the tower cylinder in the axial direction, and the side supporting part is used for supporting the side wall of the tower cylinder in the radial direction. According to the tower cylinder overturning device, the bracket supporting part supports the bottom of the tower cylinder, the side supporting part supports the side wall of the tower cylinder, after the tower cylinder overturning device is connected with the bottom of the tower cylinder in a butting manner, by means of the action of a crane, the tower cylinder can be hoisted into the vertical state from the horizontal state, and then the crane hoists and installs the tower cylinder.

Owner:XINJIANG GOLDWIND SCI & TECH

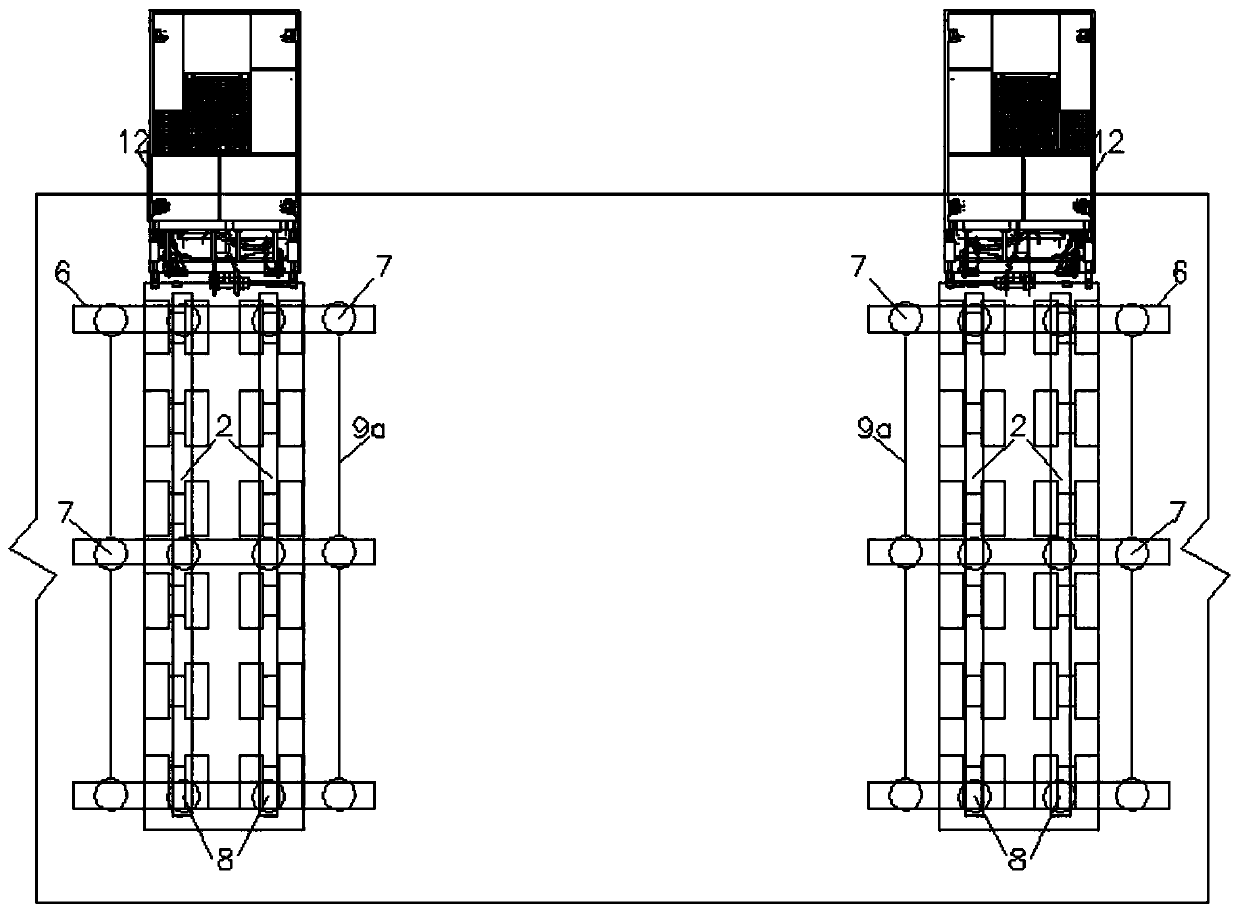

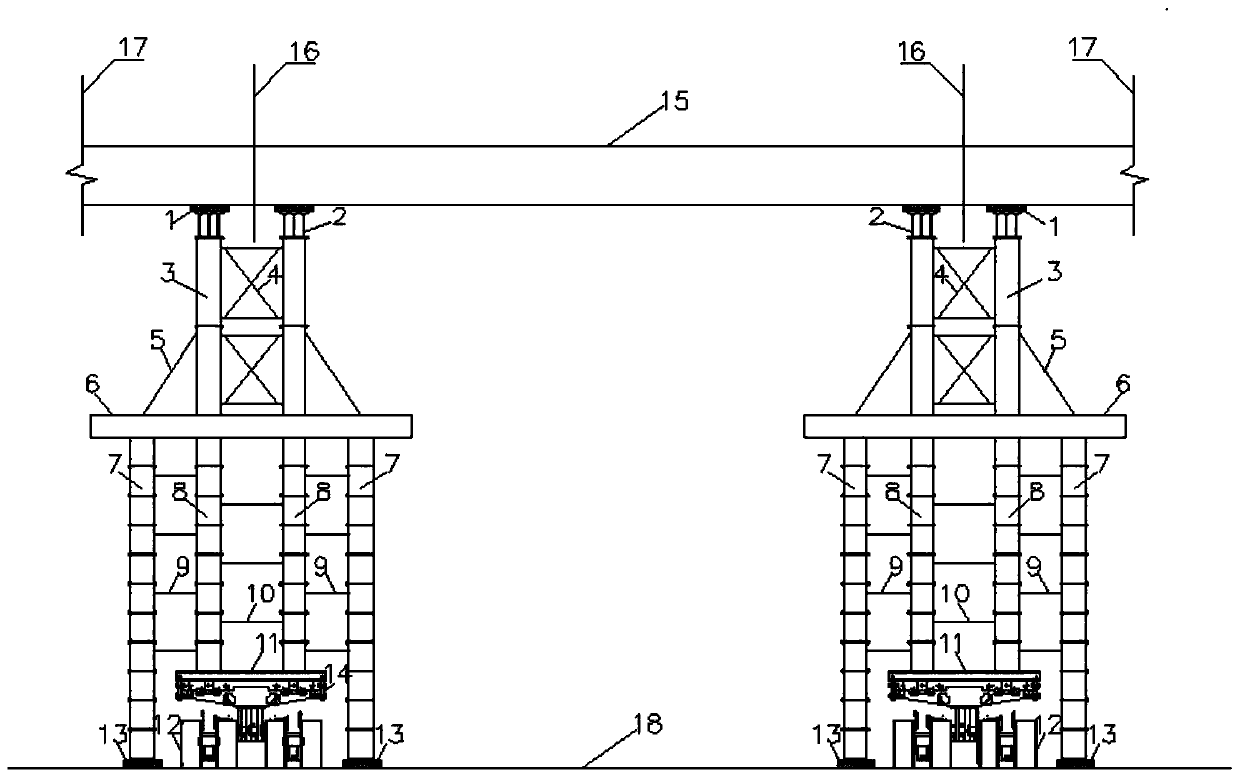

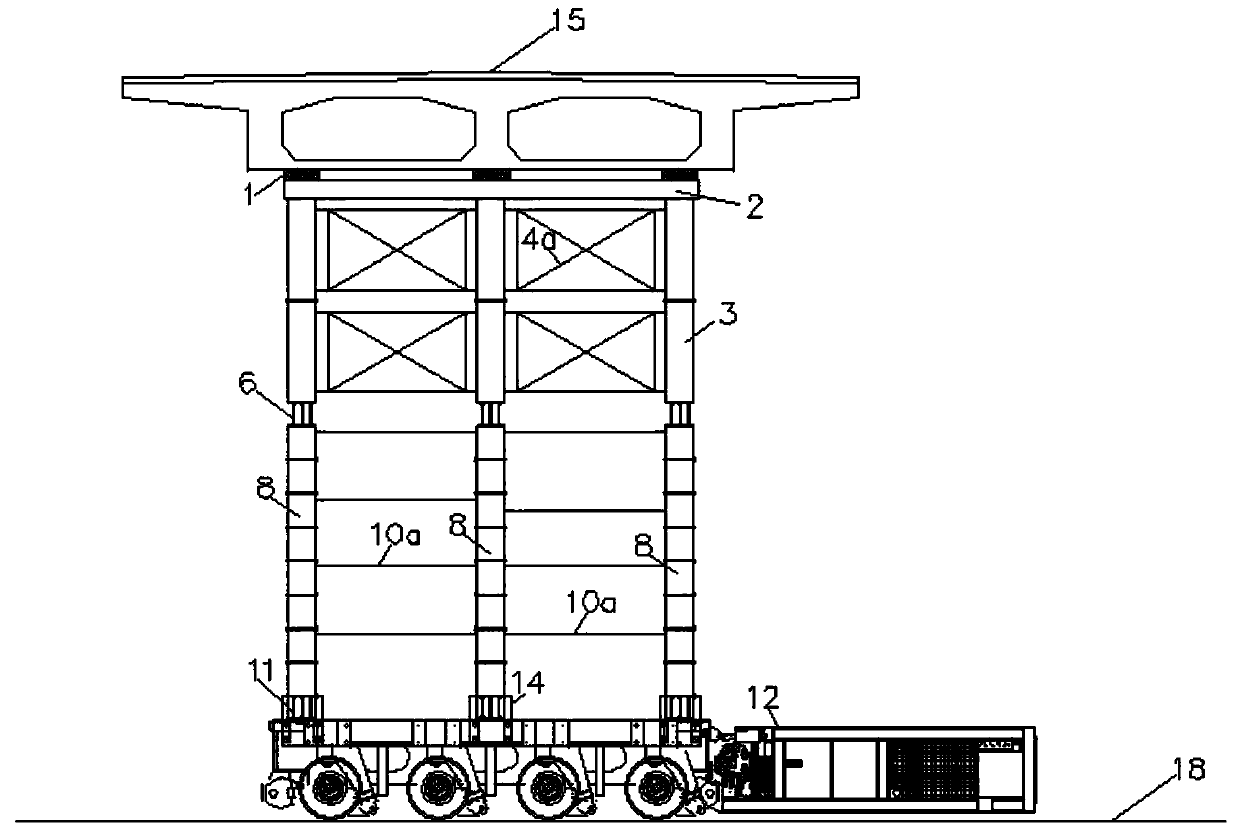

Bridge big-height lifting displacement equipment based on vehicle set and construction method thereof

ActiveCN110528405ASimple structureEasy to assembleBuilding repairsBridge erection/assemblyStructural engineeringMulti beam

Owner:CCCC ROAD & BRIDGE SPECIAL ENG

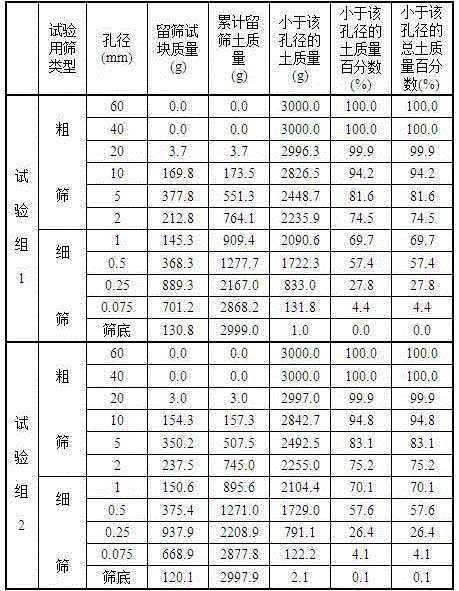

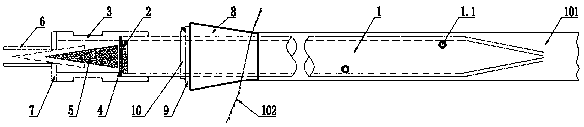

Water-air combined medium non-coupled rapid explosive charging device for tunnel extra-large cross section deep-hole rock blasting fragmentation

Disclosed is a water-air combined medium non-coupled rapid explosive charging device for tunnel extra-large cross section deep-hole rock blasting fragmentation. The device comprises a drilled hole, a first mixing explosive-charging system, a second mixing explosive-charging system, a third mixing explosive-charging system, structural cavity systems, combined medium systems, a first connecting sleeve, a second connecting sleeve, a combined blocking system, explosive, detonators and leading wires. The water-air combined medium non-coupled rapid explosive charging device for tunnel extra-large cross section deep-hole rock blasting fragmentation is provided by the invention, has the characteristics of low cost, high efficiency, reliable performance and good shock absorption and dust prevention effects and also has the following advantages that rapid explosive charging is achieved; the explosive-charging structure is accurate; the length of deep holes is accurately measured; and shock absorption, high energy utilization rate, good reliability, low cost and the like are achieved.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

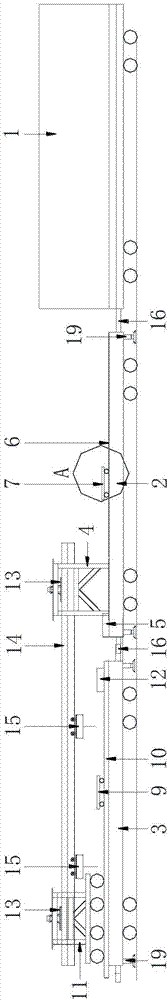

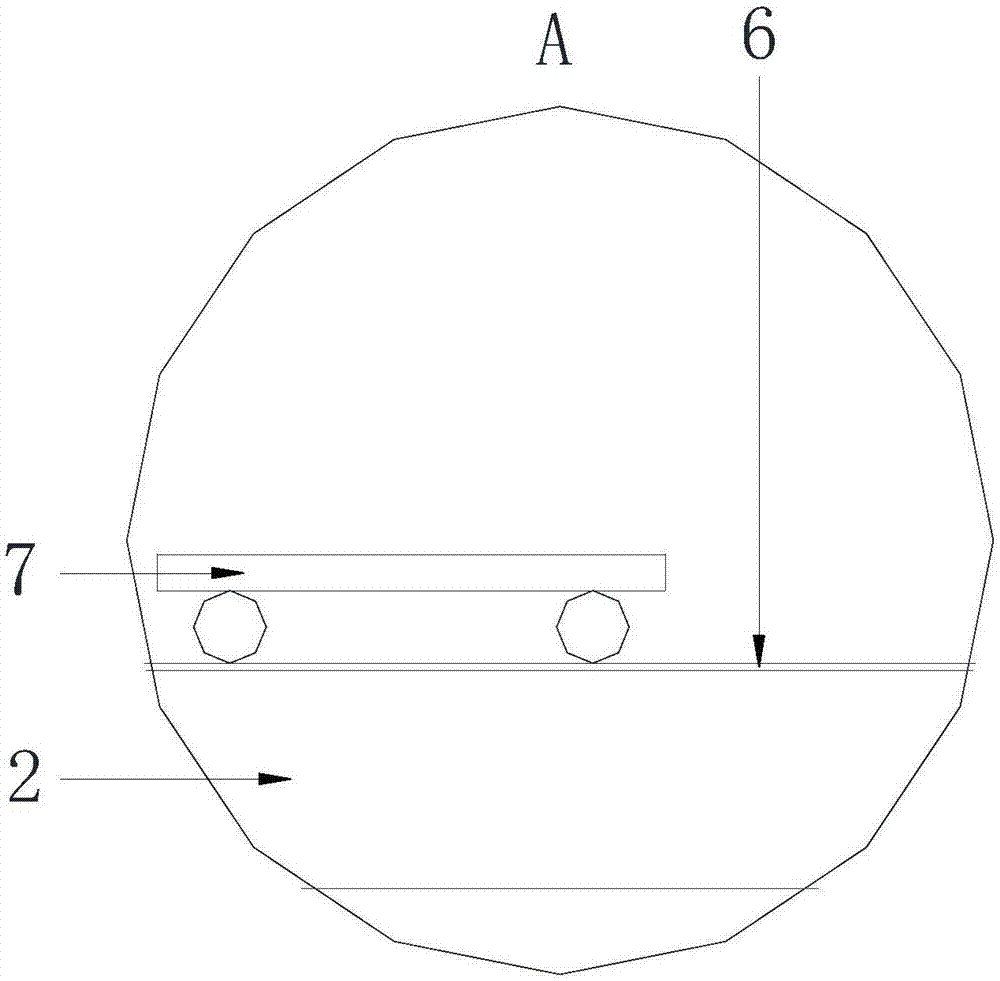

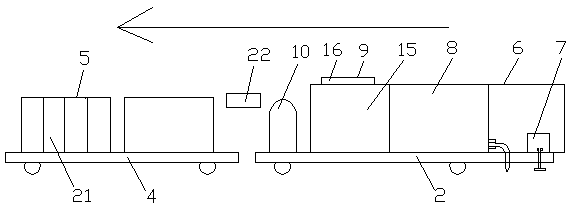

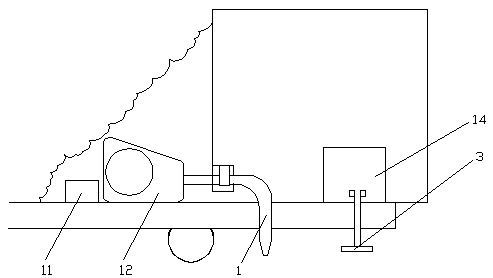

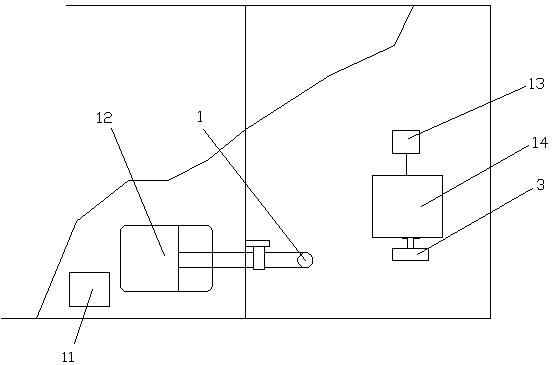

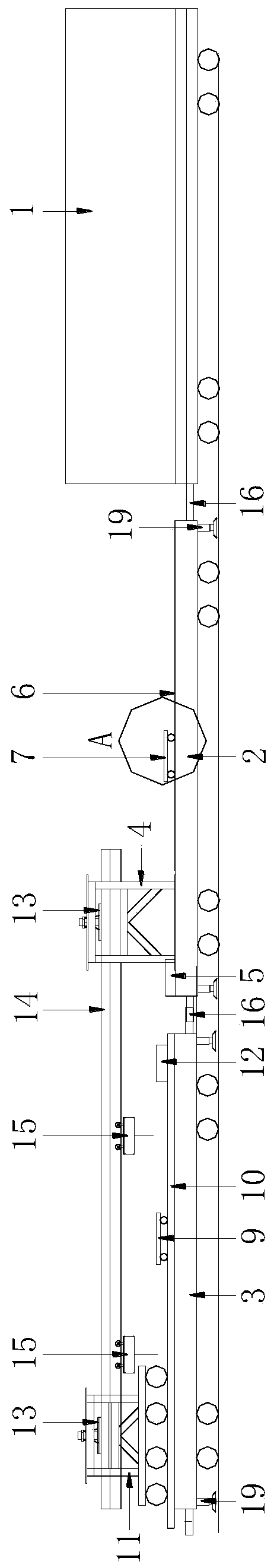

Hoisting vehicle and method for replacing of long and heavy parts of high-speed railway turnout

ActiveCN107476146AReduce field work timeReduce equipment investmentTrack superstructureRailway track constructionAutomotive engineeringPortal frame

The invention discloses a hoisting vehicle and method for replacing of long and heavy parts of a high-speed railway turnout. The hoisting vehicle comprises a rail vehicle body, a fixed portal frame flat vehicle body and a moveable portal frame flat vehicle body which are connected end to end through hooks. The method for replacing of the long and heavy parts of the high-speed railway turnout comprises the following steps that 1, the new long and heavy parts of the high-speed railway turnout are hoisted and fixed; 2, the fixed portal frame flat vehicle body and the moveable portal frame flat vehicle body are unfolded and fixed; 3, the used long and heavy parts of the high-speed railway turnout are hoisted and fixed; 4, the new long and heavy parts of the high-speed railway turnout replace the used long and heavy parts of the high-speed railway turnout; and 5, the fixed portal frame flat vehicle body and the moveable portal frame flat vehicle body are folded. The hoisting vehicle and method have the advantages that according to the mechanical device designed special for the long and heavy parts of the high-speed railway turnout, the current defect of secondary hoisting of the new and used long and heavy parts of the high-speed railway turnout is overcome, and thus the site operation time is saved greatly. In the safety aspect, the operation range of the equipment is below that of a lifting beam, so that the hidden danger that the equipment collides a contact net is avoided. In the aspect of comparing the equipment cost, the equipment investment of the newly-proposed method is quite low, and thus popularization is easy.

Owner:蔡钟博

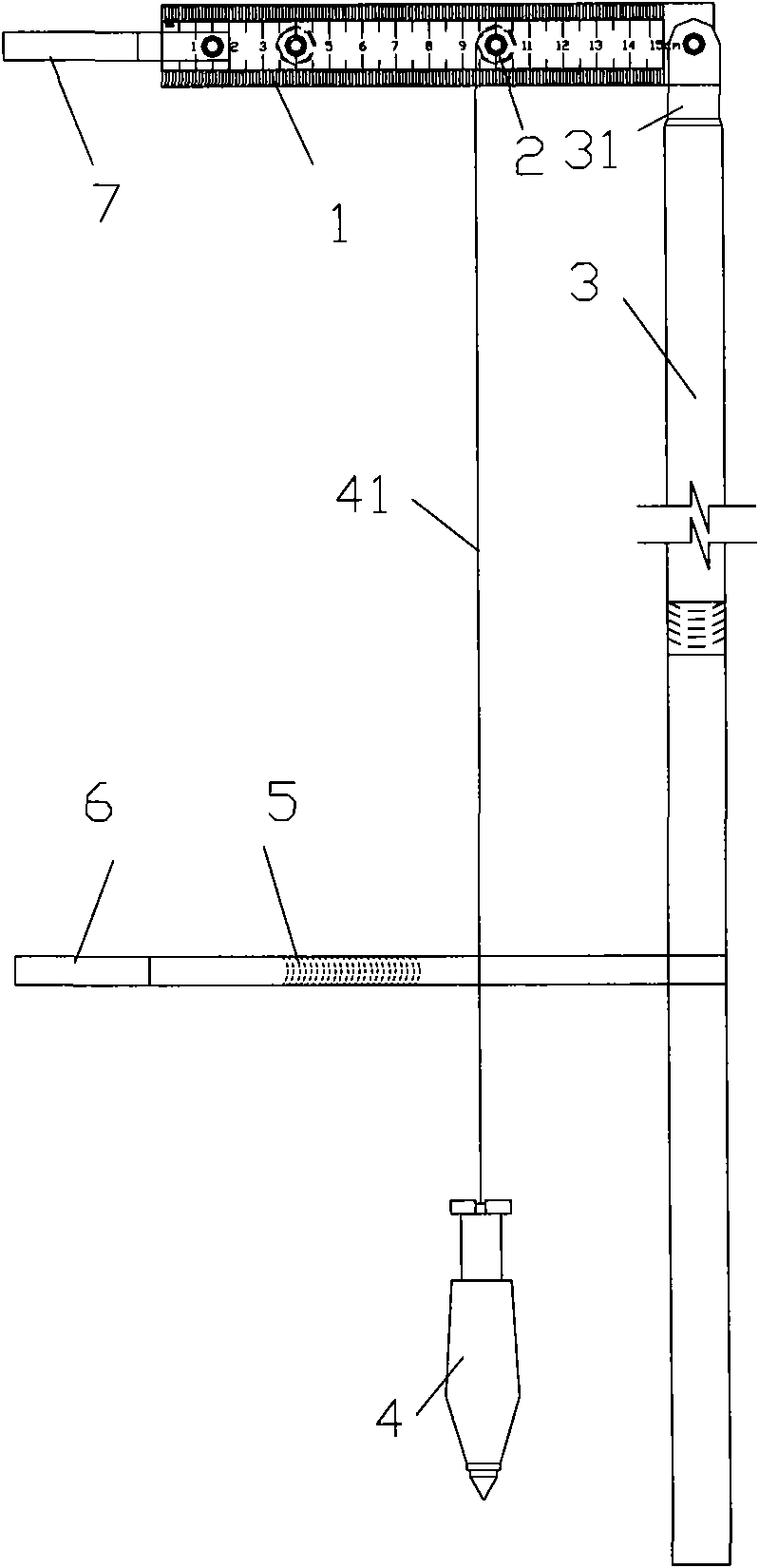

Column gradient measuring device and measuring method thereof

InactiveCN101586955AReduce field work timeReduce the number of operatorsIncline measurementPlumb bobScrew cap

The invention relates to a measuring tool, in particular to a column measuring tool. A column gradient measuring device comprises a straight steel ruler provided with scales, an upright post, two screw bolts, a telescopic sleeve tube and a tup, wherein the top of the upright post is provided with a joint fixedly connected with one end with large scales of the straight steel ruler; each screw bolt is provided with a screw cap and a spacing piece; the two screw bolts are fixedly connected and penetrates through the straight steel ruler, one screw bolt approaches the end with small scales of the straight steel ruler, and the other screw bolt is positioned on the middle section of the straight steel ruler; the telescopic sleeve tube is arranged in parallel with the straight steel ruler, and one end is fixedly connected with the lower section of the upright post; and the tup is hung on the screw bolt positioned on the middle section of the straight steel ruler through a hanging rope. The invention ensures that operators can fast, conveniently and accurately carry out column gradient measuring work in a complex environment in the field, shortens field work time, reduces the operators, and obviously enhances the efficiency of the measuring work.

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE

Method for cladding steel rail with alloy without cooling rate control

InactiveCN107999980AImproved corrosion and wear resistance propertiesImprove wear and corrosion resistanceWelding apparatusConstant speedCooling rates

The invention discloses a method for cladding a steel rail with an alloy without cooling rate control. The method is characterized by comprising the following steps that a, a steel rail cladding machine is put on the steel rail, a plasma welding gun moves at a constant speed, and the upper portion of the to-be-cladded portion is cladded with the alloy; b, a formed alloy strip is located on the inner side of the center of the tread face of the rail head of the steel rail, the width of the alloy strip ranges from 4 mm to 40 mm, and the thickness of a heat affected zone of the steel rail is controlled to range from 0.3 mm to 30 mm; c, a flame head is arranged above the alloy strip, liquefied gas and oxygen are directly mixed on the flame head, after the alloy strip obtained after cladding issubjected to standing for 2 s to 180 s, the flame head is started to move in the X-axis direction at a constant speed to carry out heating, and the fact that the structure of the heat affected zone ofthe heated steel rail is tempered sorbite or tempered sorbite and tempered troostite or tempered troostite is taken as the standard. By means of the method, the cladding applicability and cladding efficiency can be improved, and it can be guaranteed that the mechanical performance of the structure of the heat affected zone meets steel rail use after field steel rail cladding.

Owner:CHENGDU ZHONGGUI TECH CO LTD

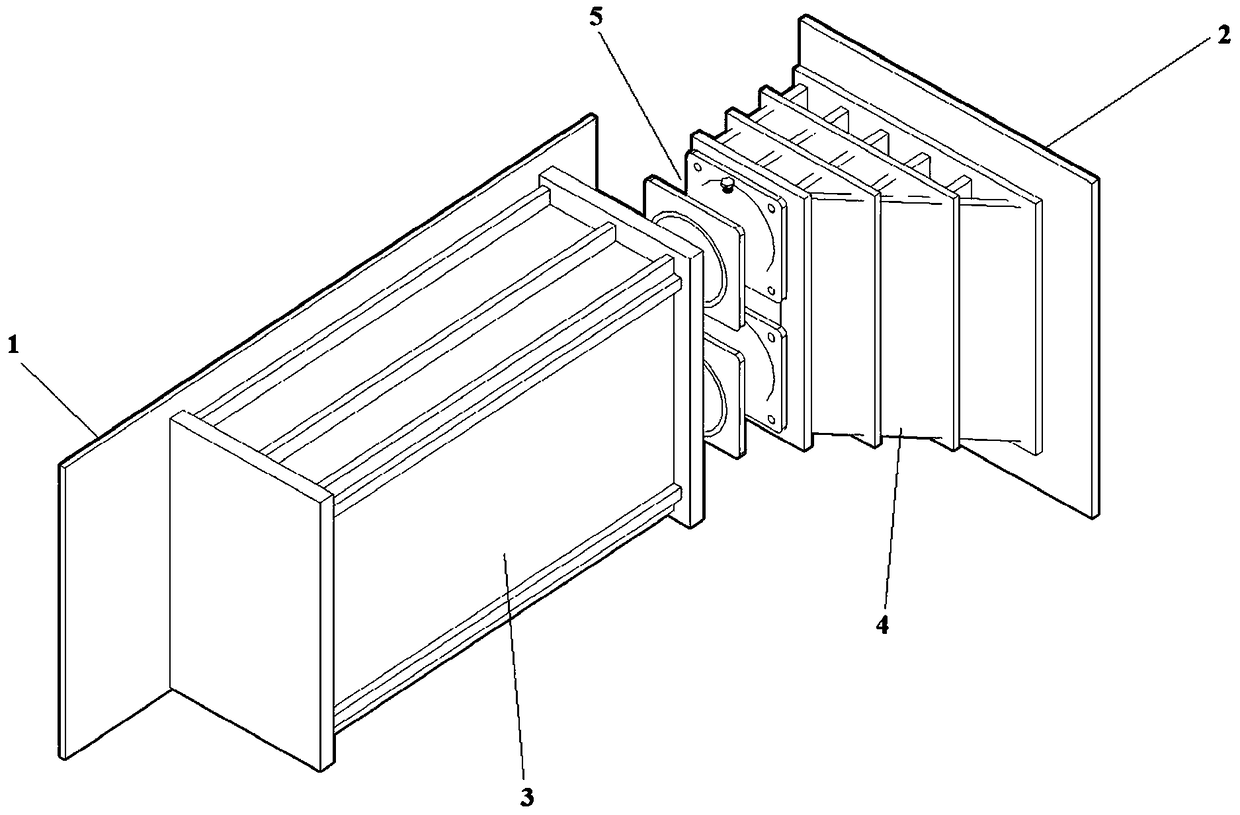

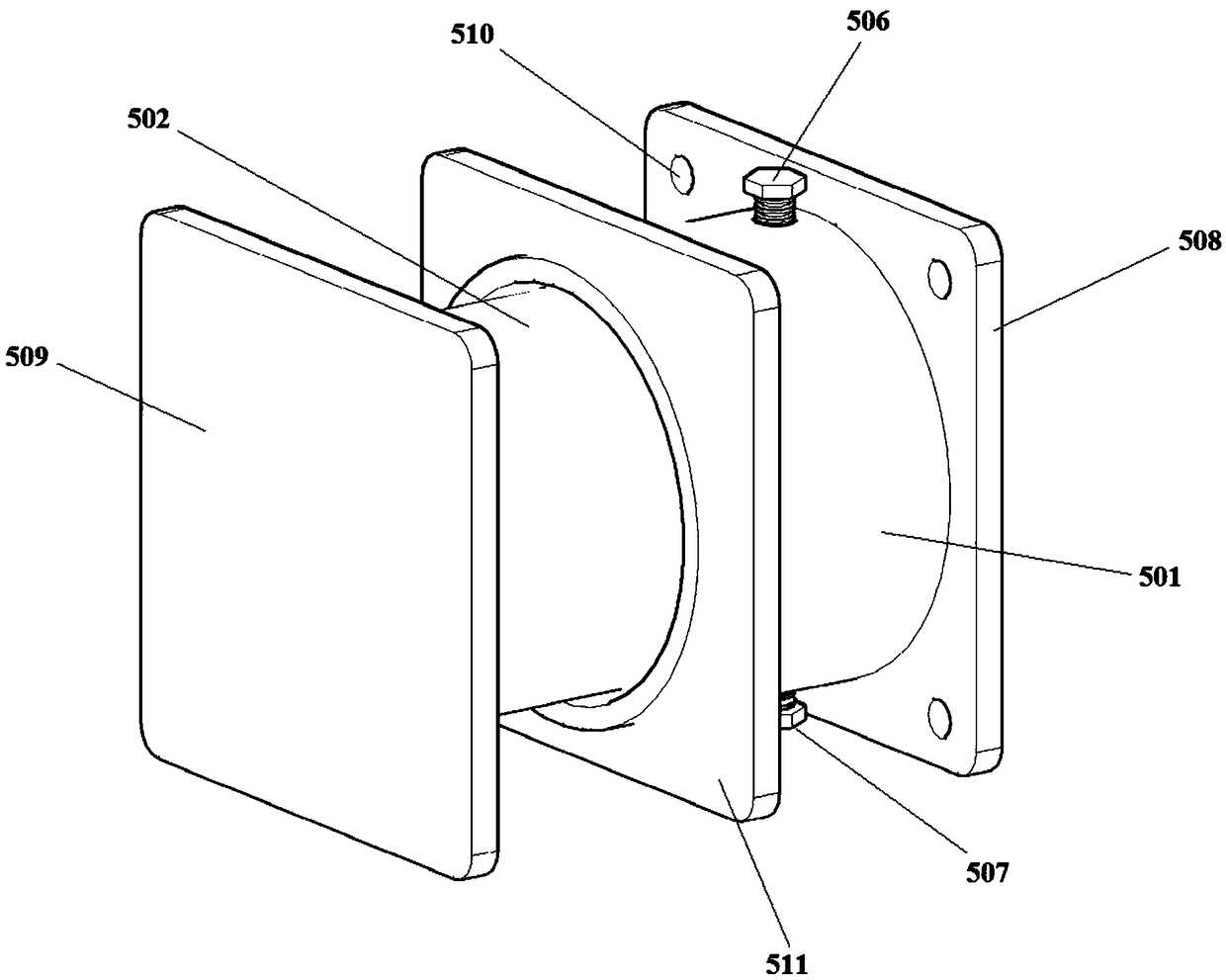

Integral mounting-dismounting method and platform of circuit breaker

ActiveCN107134733AOptimize working proceduresImprove work efficiencySwitchgearLoad lossCircuit breaker

The invention relates to an integral mounting-dismounting method of a circuit breaker. A mounting-dismounting platform is used, phase-splitting assembling, inflation and high-voltage test are carried out in advance, and the circuit breaker is hoisted and replaced integrally onsite; and the workload of onsite replacement is reduced effectively. Power failure time is shortened from 3 days originally to 1 day, and the load loss is reduced greatly. The platform is movable, and can be used onsite conveniently. Wear-resistant universal wheel are used in the bottom of the mounting-dismounting platform, and it is ensured that the circuit breaker is installed beyond a site, and can be pushed to the working site during use via the platform. Thus, the onsite work time is shortened effectively, the efficiency is improved, time that people may make contact with a live line portion is reduced, the working safety is ensured, and a safety coefficient is improved.

Owner:CHAOYANG POWER SUPPLY COMPANY OF STATE GRID LIAONING ELECTRIC POWER SUPPLY +1

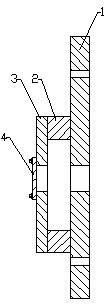

An external prestressed anchorage device and rapid reinforcement method for concrete bridges

ActiveCN102286945ANo fatigueSimplify the installation processBridge erection/assemblyBridge strengtheningPre stressPre stressing

The invention relates to an external pre-stressed anchoring device for a concrete bridge body and a rapid strengthening method. The anchoring device comprises two anchoring pieces with symmetrical structures, wherein the anchoring pieces are arranged at two sides of the concrete bridge body; an anchor cable is arranged between the left anchoring piece and the right anchoring piece; a steering gear is arranged on the anchor cable; each anchoring piece comprises a base plate, connection plate fixedly arranged on the base plate and an ear plate fixedly arranged on the connection plate; a half-round groove is arranged at one end of the connection plate; and a baffle is arranged on a pin hole. The strengthening method provided by the invention comprises the following steps of: anchoring piece processing, bridge body polishing, installing, glue pouring and tensioning. The device and the method which are provided by the invention have the advantages that: the installation process is simple and rapid; the traffic needs not to be interrupted during installation; the construction period of installing the device provided by the invention is short; and the volume of the device is small and the device is flexible to ensure that the requirements for rapid strengthening construction can be satisfied.

Owner:SHIJIAZHUANG TIEDAO UNIV

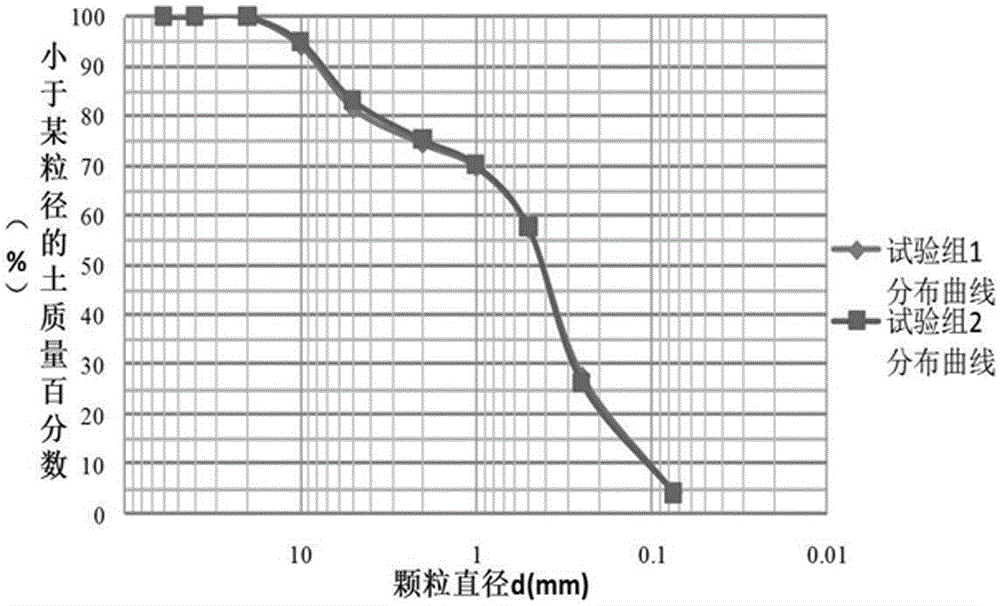

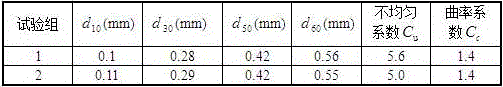

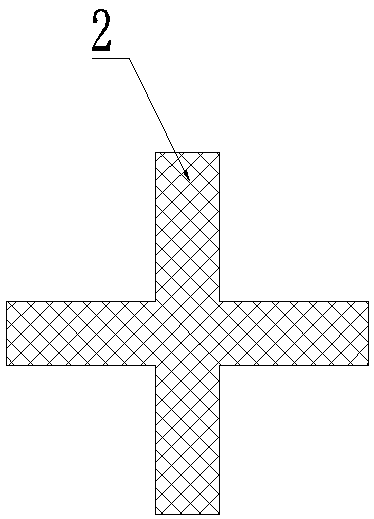

Detection method for anti-filtration capability of vegetation concrete

InactiveCN105738258AEasy to operateThe test data is accurateParticle size analysisVegetationSoil science

The invention discloses a detection method for the anti-filtration capability of vegetation concrete. The method comprises the following specific steps: 1, selecting and drying soil on a bank slope; 2, pouring dry soil test blocks into test sieves, sufficiently jolting the test sieves on a standard jolting sieve shaker, weighing the mass of the soil left on the test sieves of each aperture stage, and calculating the accumulated mass of the soil left on the test sieves, the mass percentages of the soil smaller than the apertures and the total mass percentages of the soil smaller than the apertures; 3, drawing a soil particle size distribution curve chart according to the test data, and calculating a uniformity coefficient and curvature coefficient of soil particles according to the soil particle size distribution curve chart; 4, estimating the anti-filtration capability; 5, performing data analysis. The method is scientific in principle, easy to operate and accurate in test data, site construction links can be reduced, site operation time can be shortened, adaptability to various site construction conditions can be ensured, construction quality and engineering effects can also be improved, and popularization of an ecological concrete bank protection technology is facilitated.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

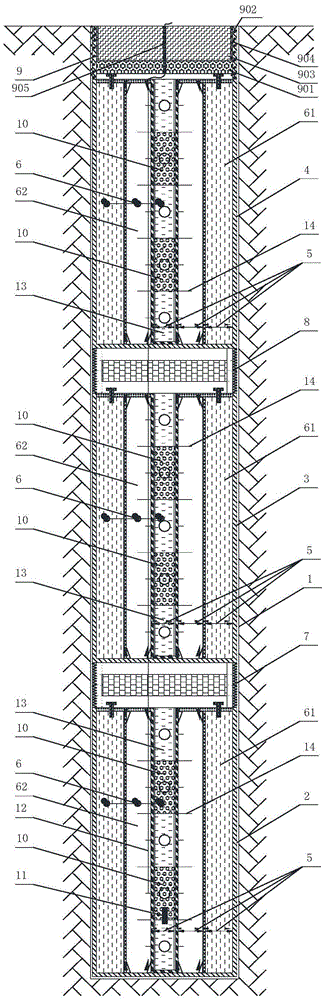

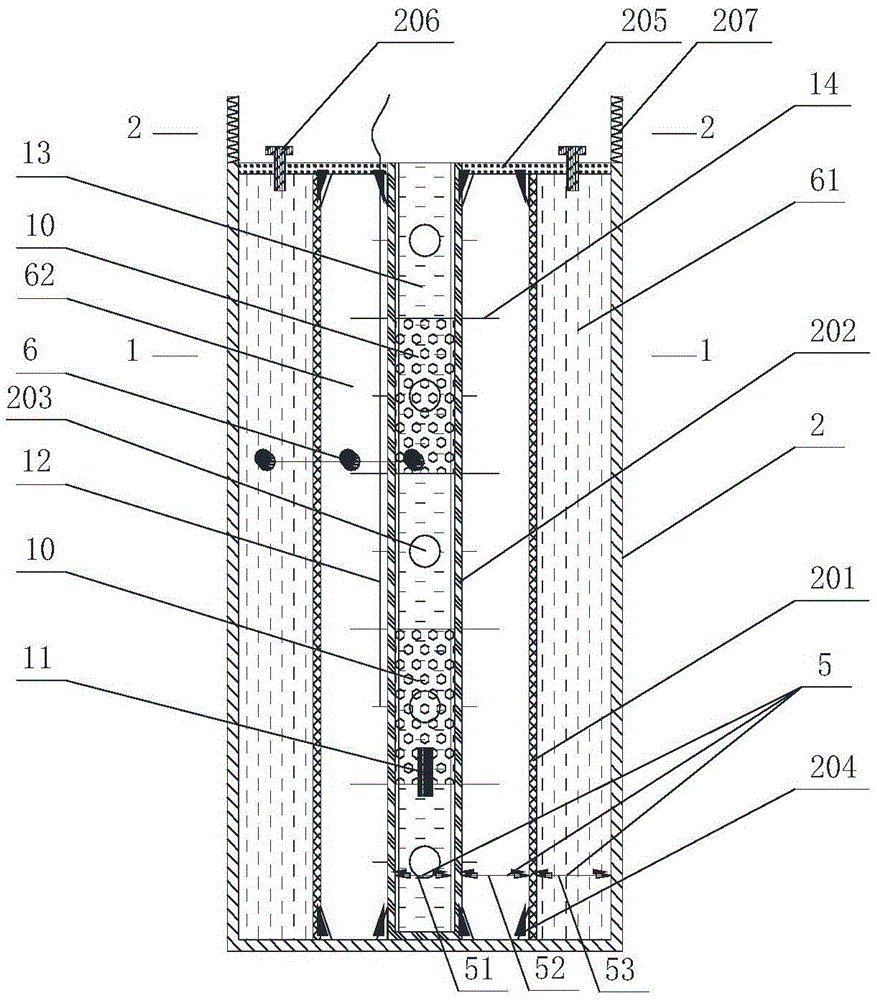

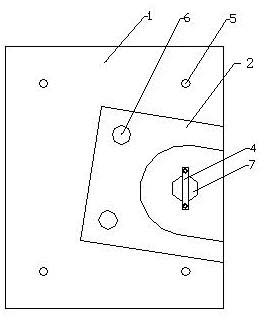

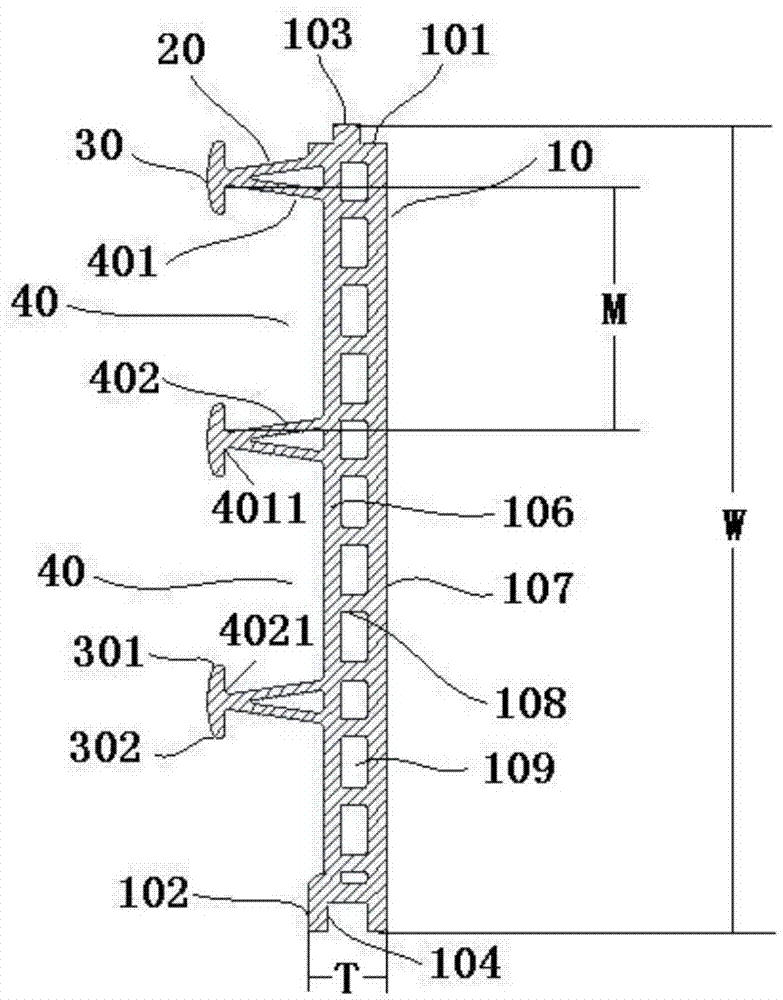

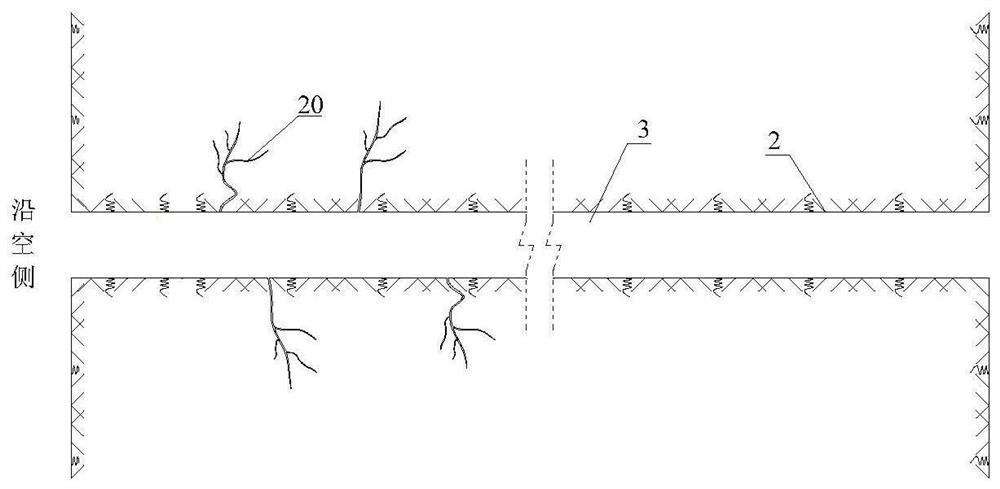

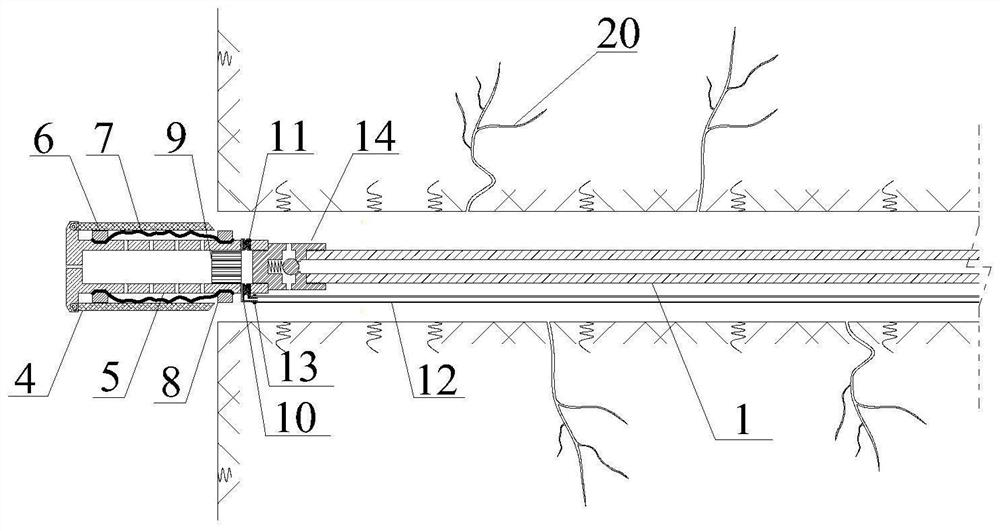

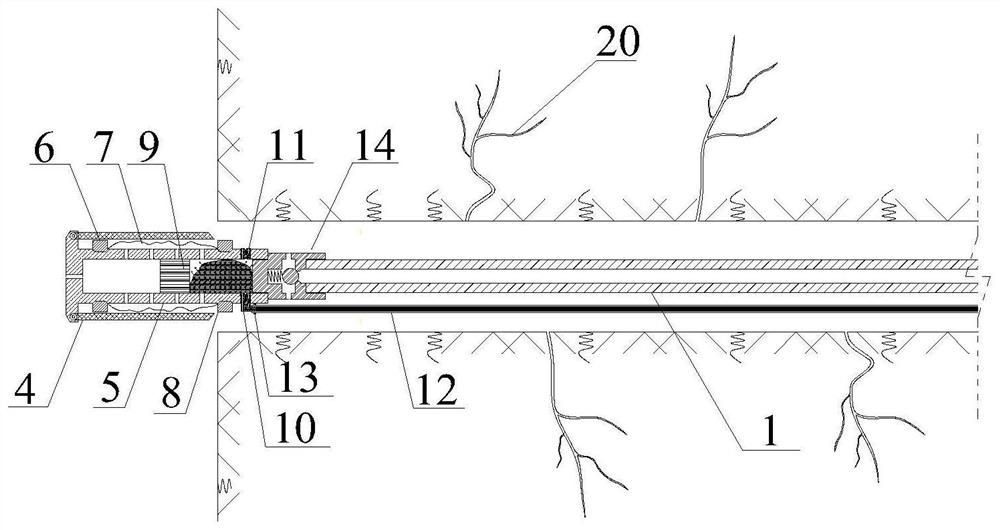

Self-grouting-stopping device of assembly type grouting guiding pipe

PendingCN109707337APrevent outflowReduce field work timeUnderground chambersSealing/packingSlurryStops device

The invention provides a self-grouting-stopping device of an assembly type grouting guiding pipe,and belongs to the technical field of geotechnical engineering and particularly belongs to undergroundconstruction guiding pipe grouting construction. The self-grouting-stopping device of the assembly type grouting guiding pipe comprises a grouting guiding pipe, a sleeving pipe, a sealing ring, a check plug and a grouting connecting pipe, wherein a separating grid is arranged on a slurry inlet of the grouting guiding pipe, outer threads are arranged on the outer wall of the slurry inlet, a ring-shaped sealing plate is arranged at the inlet end of the sleeving pipe, a ring-shaped groove is formed in the inner wall of the outlet end, the ring-shaped groove is provided with inner threads, the sealing ring is arranged between the end surface of the ring-shaped groove and the end surface of the slurry inlet of the grouting guiding pipe, the grouting connecting plate is fixed to the sealing plate, and the check plug is a cone and is arranged in the sleeving pipe and the grouting connecting pipe. According to the self-grouting-stopping device of the assembly type grouting guiding pipe, the grouting guiding pipe, the sleeving pipe, the check plug and the grouting connecting pipe are all prefabricated by a factory and can be quickly assembled and used in an engineering field, a grouting andgrout-stopping device is not required to be machined on the construction site, site operating time is shortened, and potential safety hazards caused by electrical welding or cutting operation are avoided.

Owner:CHINA RAILWAY 12TH BUREAU GRP +2

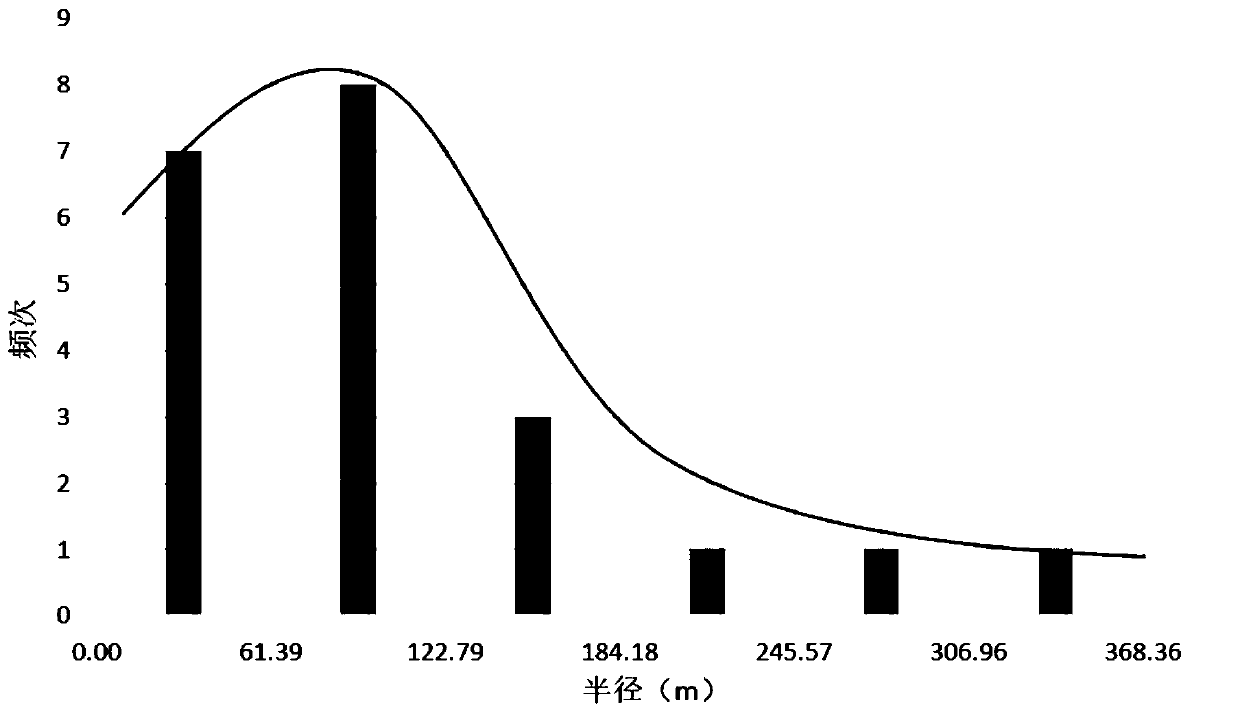

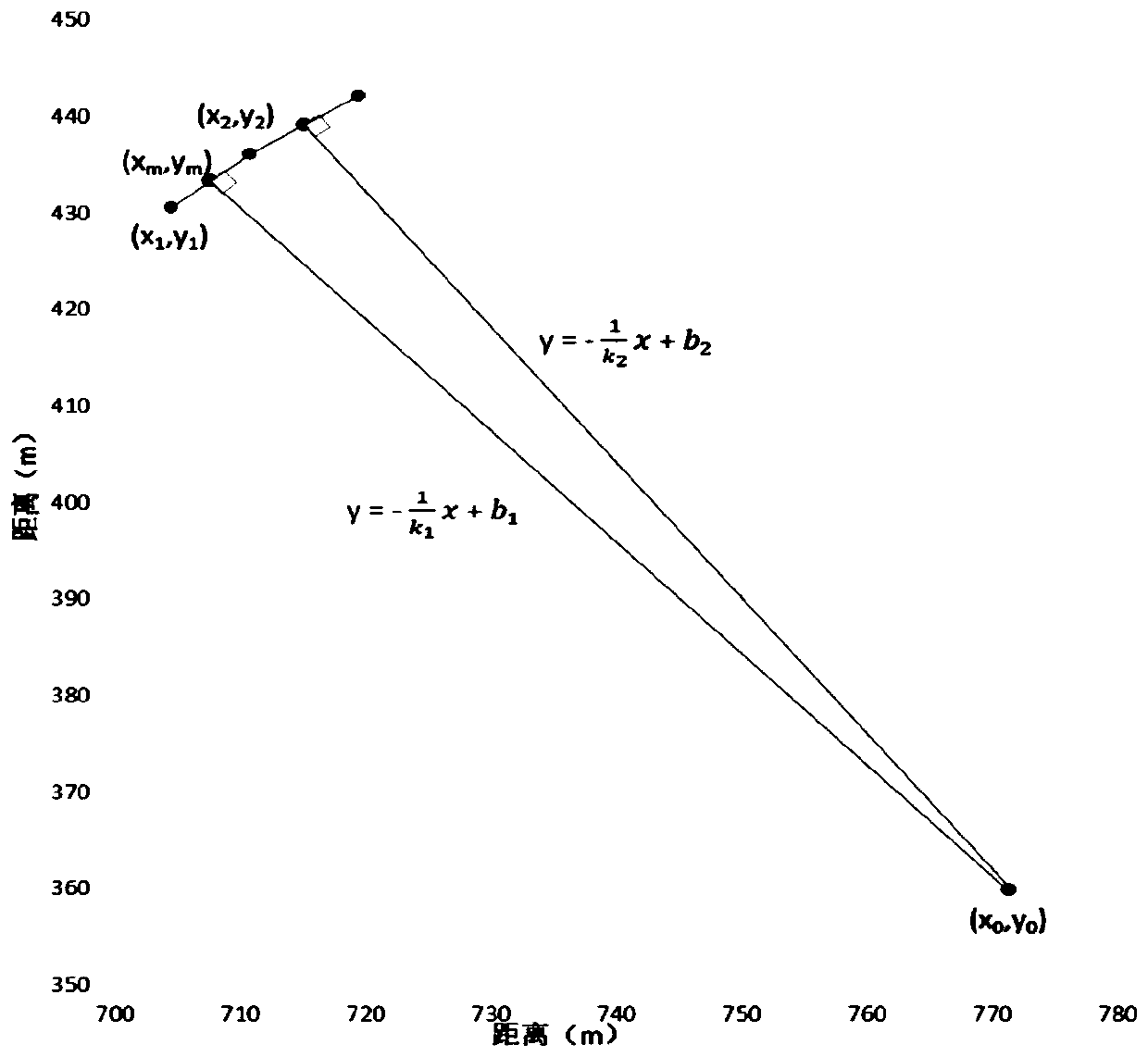

Method for determining circular curve radius of road and driving sight distance based on GPS motion camera data

ActiveCN107121115ADoes not affect normal trafficReduce field work timeOptical rangefindersUsing optical meansOrthogonal coordinatesRoad surface

The invention relates to a method for determining a circular curve radius of a road and a driving sight distance based on GPS motion camera data. A GPS point coordinate point of a driving track is transformed into a corresponding two-dimensional orthogonal coordinate; according to the geometrical principle, calculation is carried out by using each three coordinate points as one group successively to obtain track line radiuses, wherein the mode of the multiple path radiuses is a circular curve radius of a corresponding lane; and then a road circular curve radius is obtained based on a corresponding position relation. Track lines moving to a road central line are moved left and right in a translation manner at distances being the half of the roadbed width; after the translation, track points fall at edges lines of the pavement; and a sight distance is calculated by using the conventional measuring method. The method has high advancement and exploitativeness. When the method is implemented, normal traffic of the road is not affected, so that the field working time can be shortened, the measuring efficiency can be improved, and the needed manpower and materials can be reduced.

Owner:ZHENGZHOU UNIV

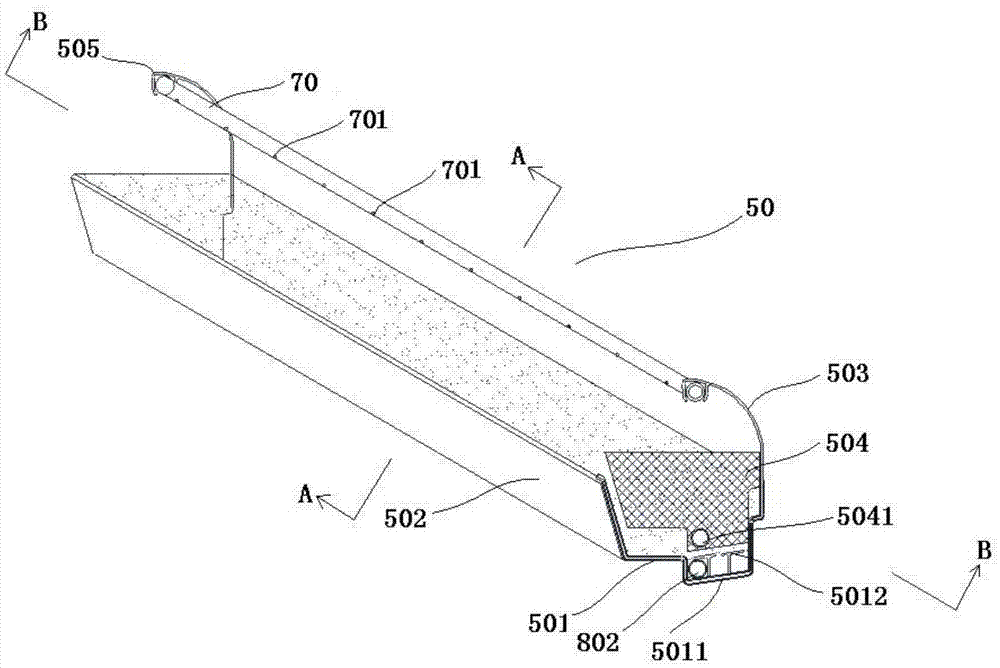

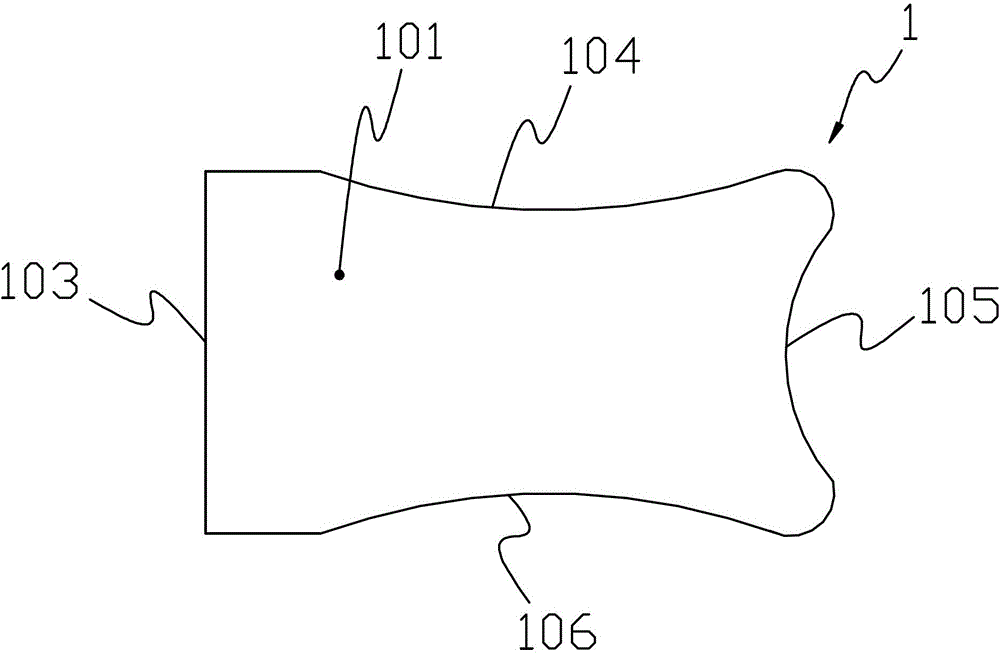

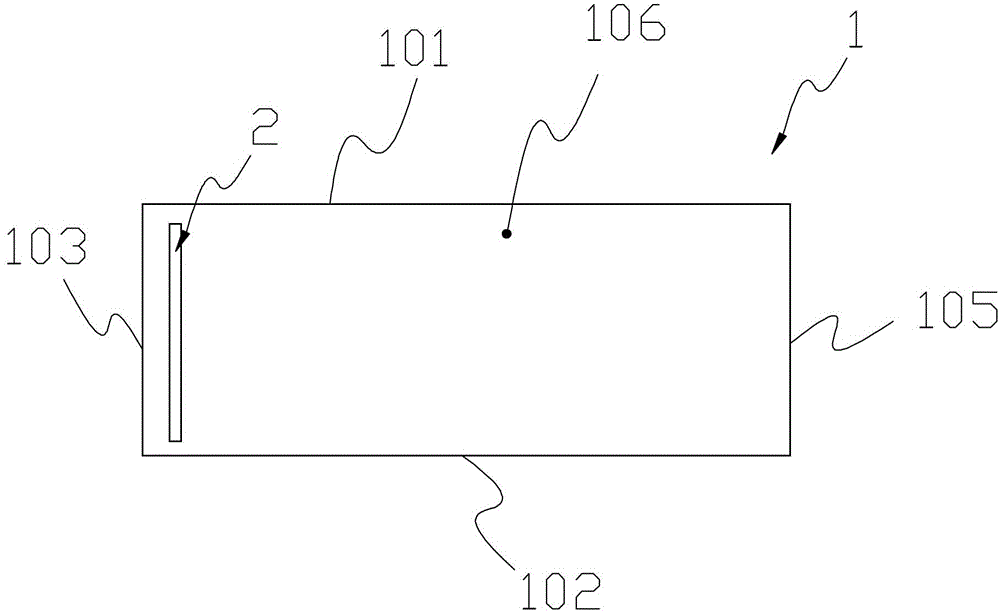

Wallboard provided with greening planting system and greening planting system installed on wallboard

InactiveCN107090942ASimple structureImprove compactnessWatering devicesPressurised distribution of liquid fertiliserEngineeringBuilding construction

The invention discloses a wallboard provided with a greening planting system and the greening planting system installed on the wallboard. The wallboard provided with the greening planting system comprises a board body, limiting supports and an isolation belt, one end of each limiting support is arranged on an outer surface of the board body, the other end of each limiting support is connected with the isolation belt, and the board body, the limiting supports and the isolation belt form a groove-shaped accommodation part; two adjacent limiting supports constitute the top and the bottom of the accommodation part respectively, the top and the bottom and the isolation belt connected with the top and the bottom constitute an opening of the accommodation part, and the accommodation parts are formed at the outer surface of the board body, and are placed in the length direction of the board body. The wallboard provided with the greening planting system solves the problems that in the prior art, the city greening land is limited, the stereo greening construction is big in difficulty, the cost is high, the landscape effect is not so ideal, plants are short in life, and the maintenance cost is high.

Owner:四川华磷科技有限公司

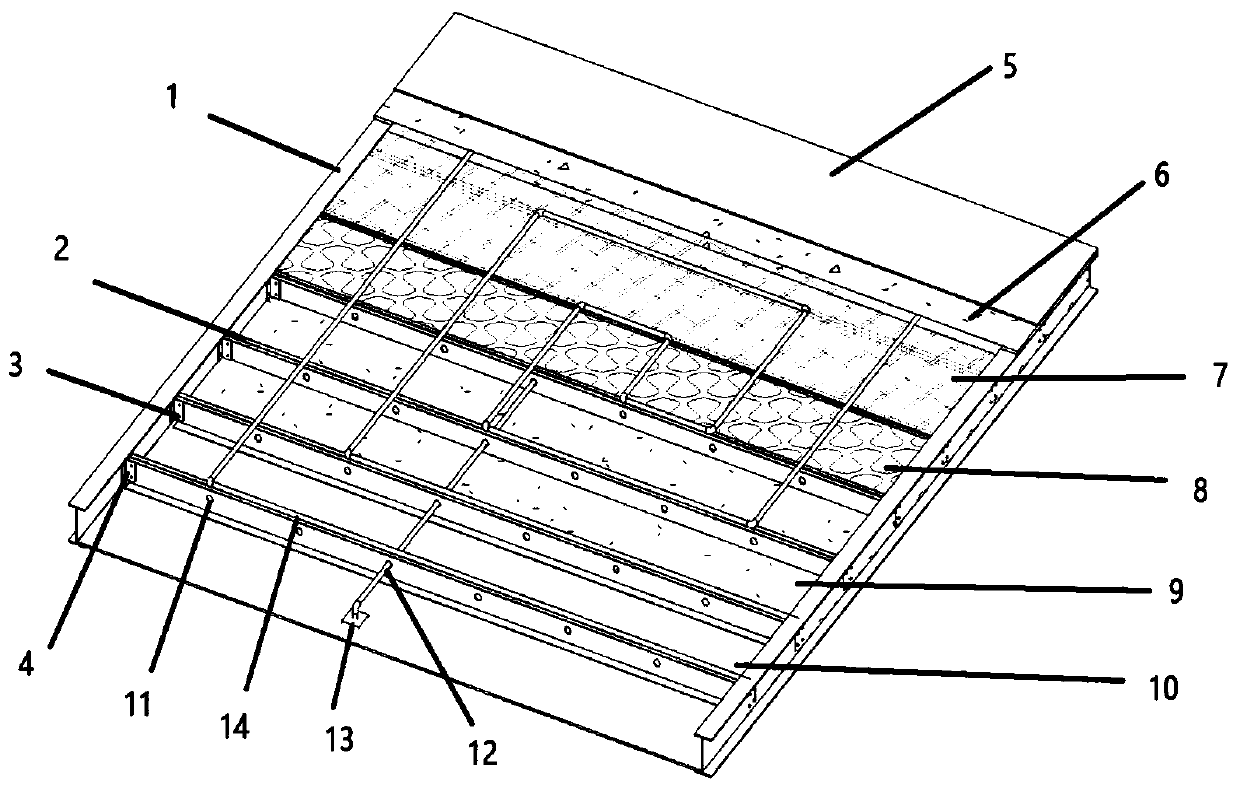

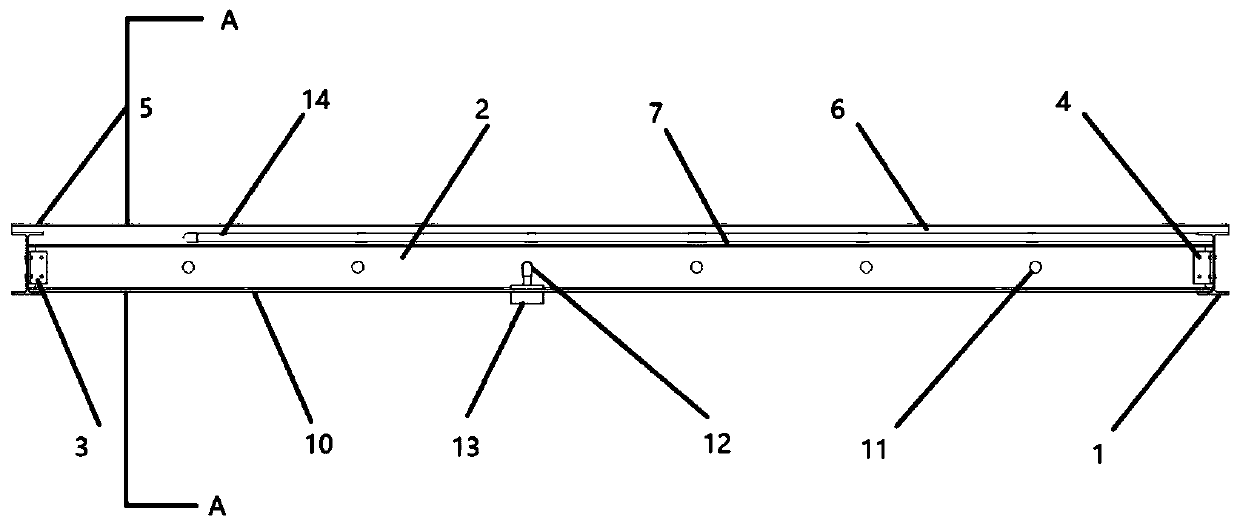

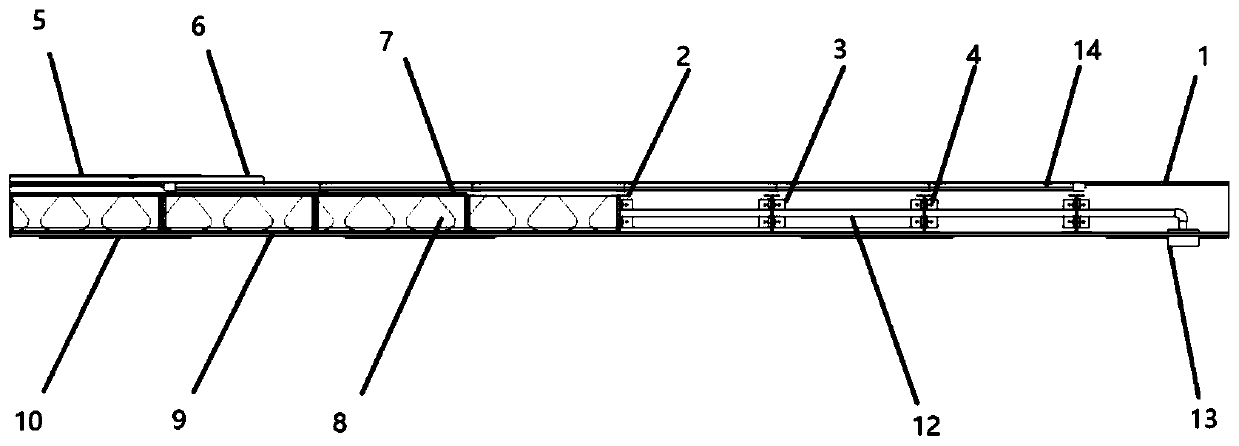

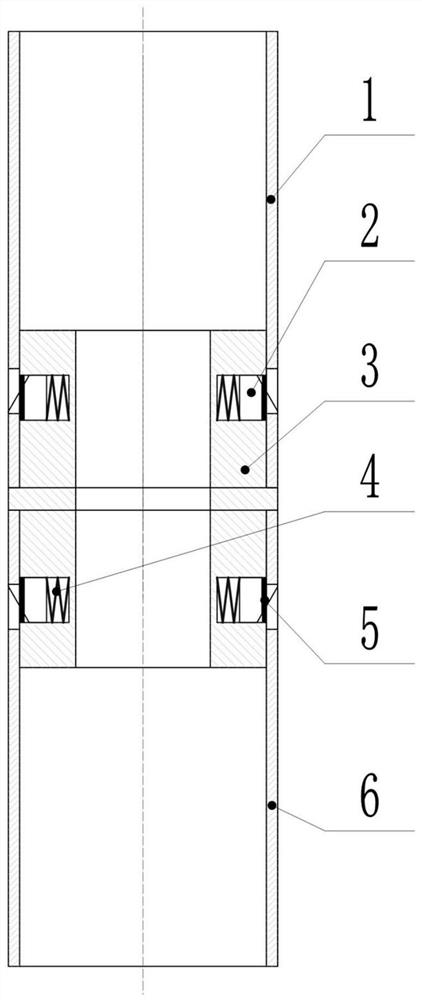

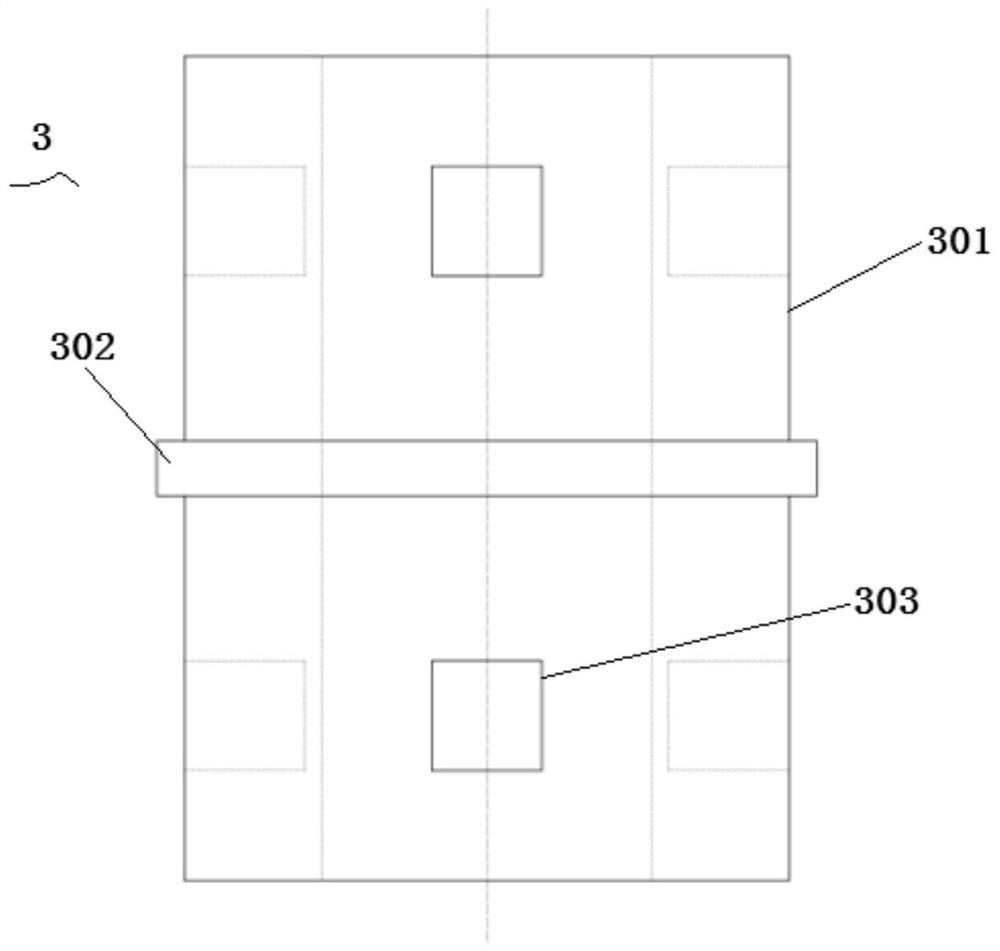

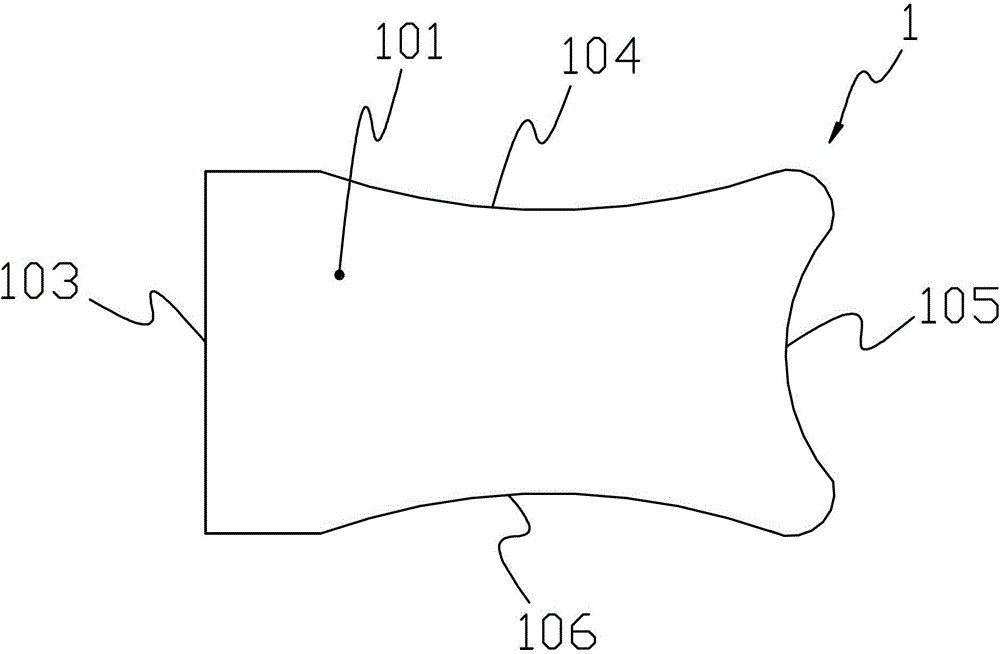

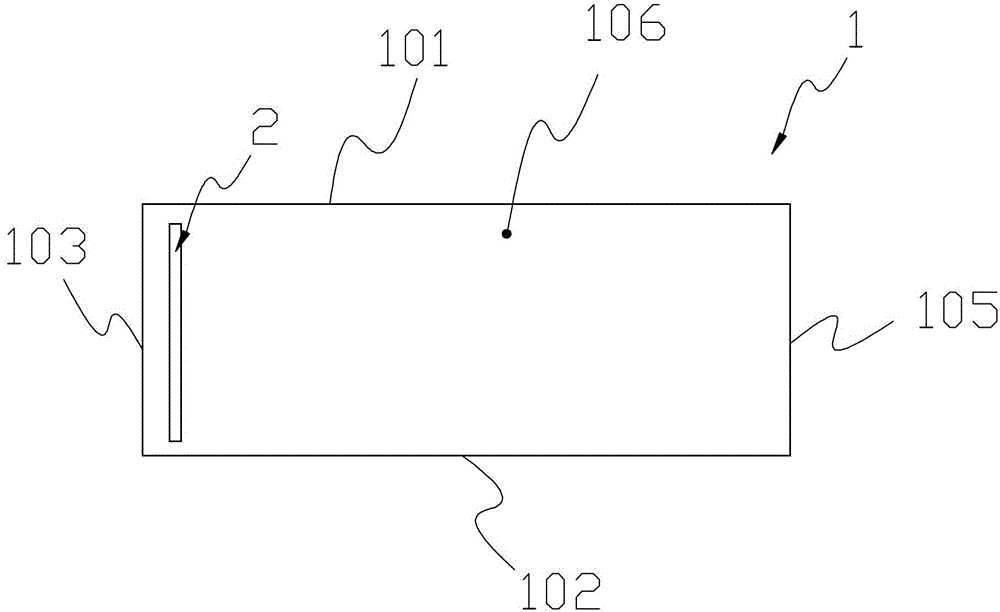

Light assembly type steel structure composite floor slab and implementation method thereof

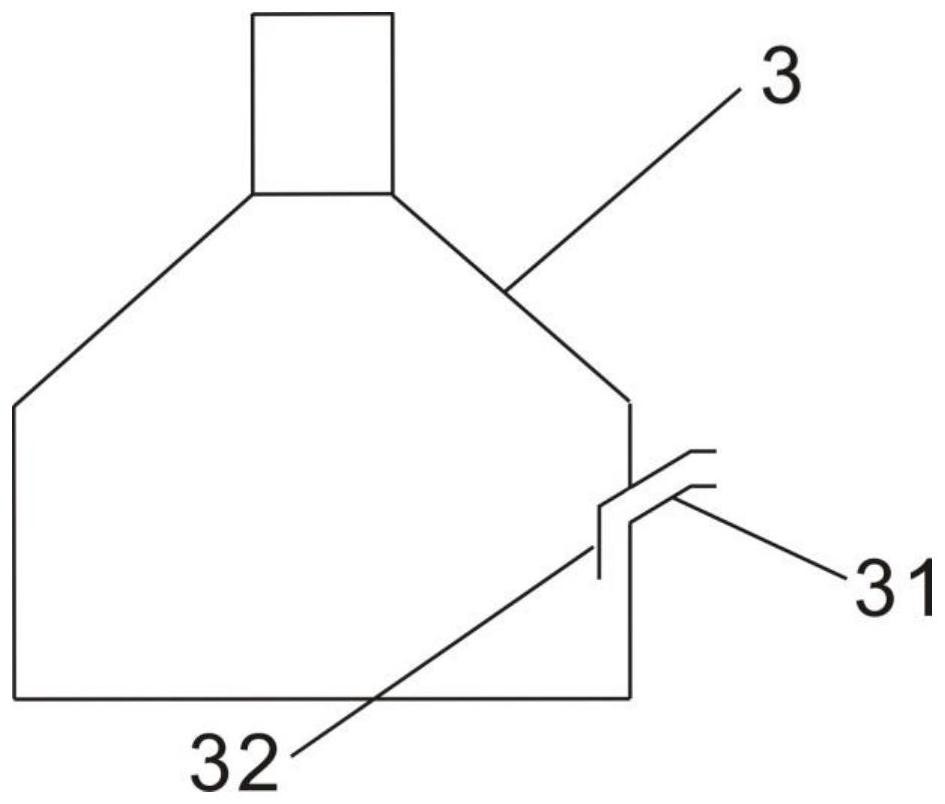

PendingCN111549950AIncrease net heightReduce field work timeFloorsHeat proofingFloor slabInsulation layer

The invention relates to the technical field of steel structure composite floor slabs, and particularly relates to a light assembly type steel structure composite floor slab and an implementation method thereof. An existing steel structure floor slab is large in field wet operation amount, large in weight and insufficient in heat preservation performance, sound insulation performance and anti-seismic performance. The light assembly type steel structure composite floor slab for an assembly type steel structure building comprises a steel frame, pipelines and a light concrete layer. The steel frame comprises a steel beam and a plurality of supporting frameworks, wherein a supporting plate is laid on the lower bottom face of the steel frame, a waterproof film is laid on the upper top face of the steel frame, and a cavity is formed in the steel frame; the cavity is filled with a heat preservation and sound insulation layer; a decoration layer is laid on the surface of the composite floor slab; pipeline holes allowing the equipment pipelines to penetrate through are reserved in webs of the supporting frameworks; and the equipment pipelines are connected with a junction box. The wet operation amount is reduced, the weight of the floor slab is reduced, meanwhile, good heat preservation, sound insulation and flame retardance are achieved, and good development prospects are achieved in the technical field of steel structure composite floor slabs.

Owner:河南省第二建设集团有限公司 +1

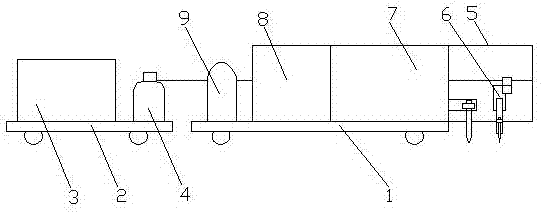

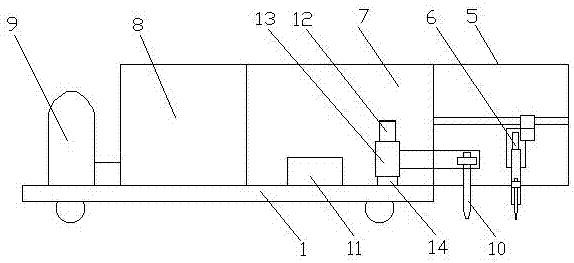

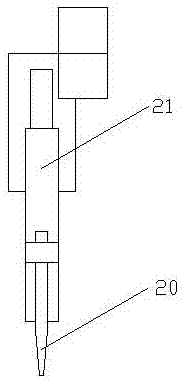

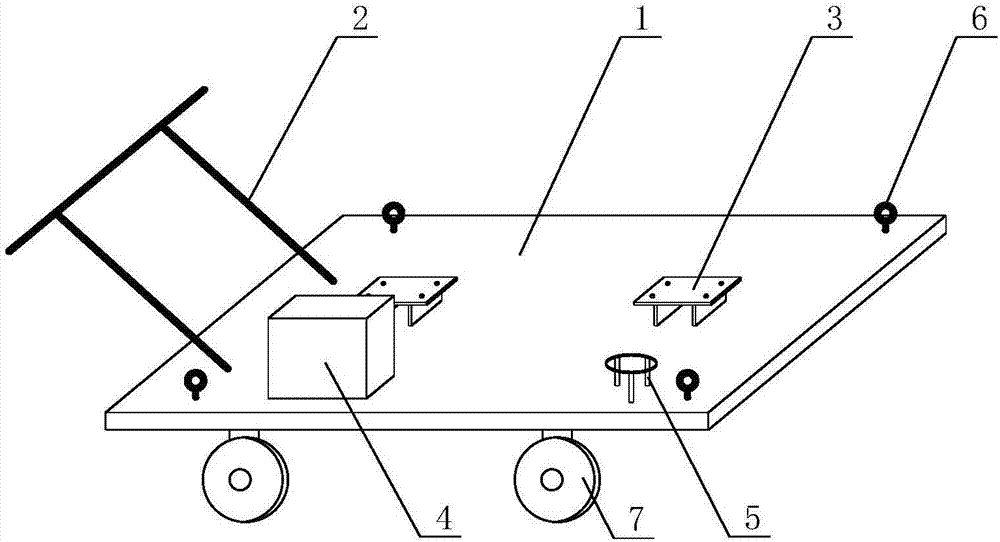

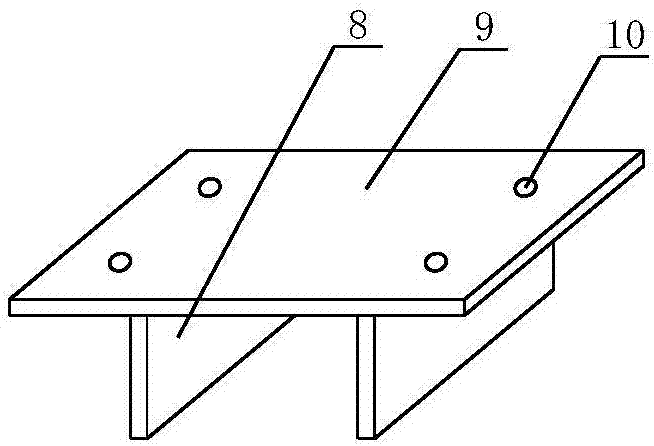

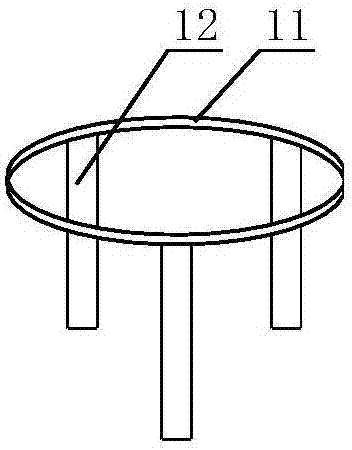

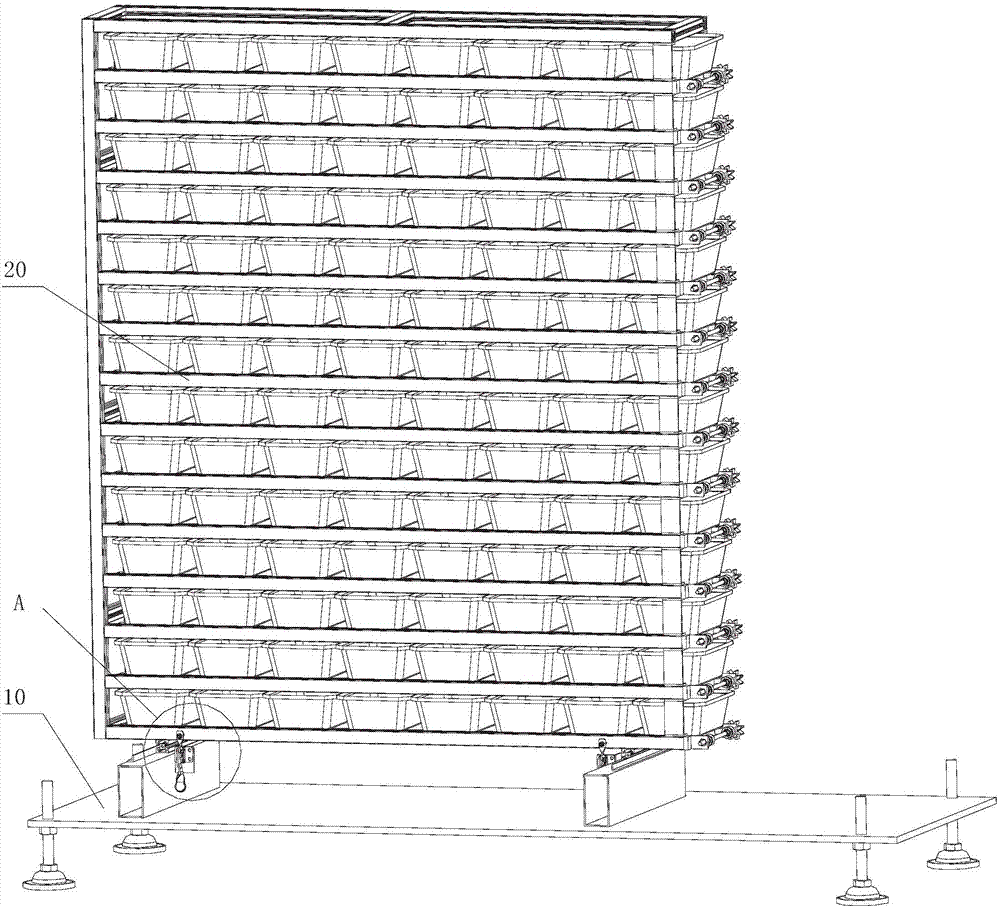

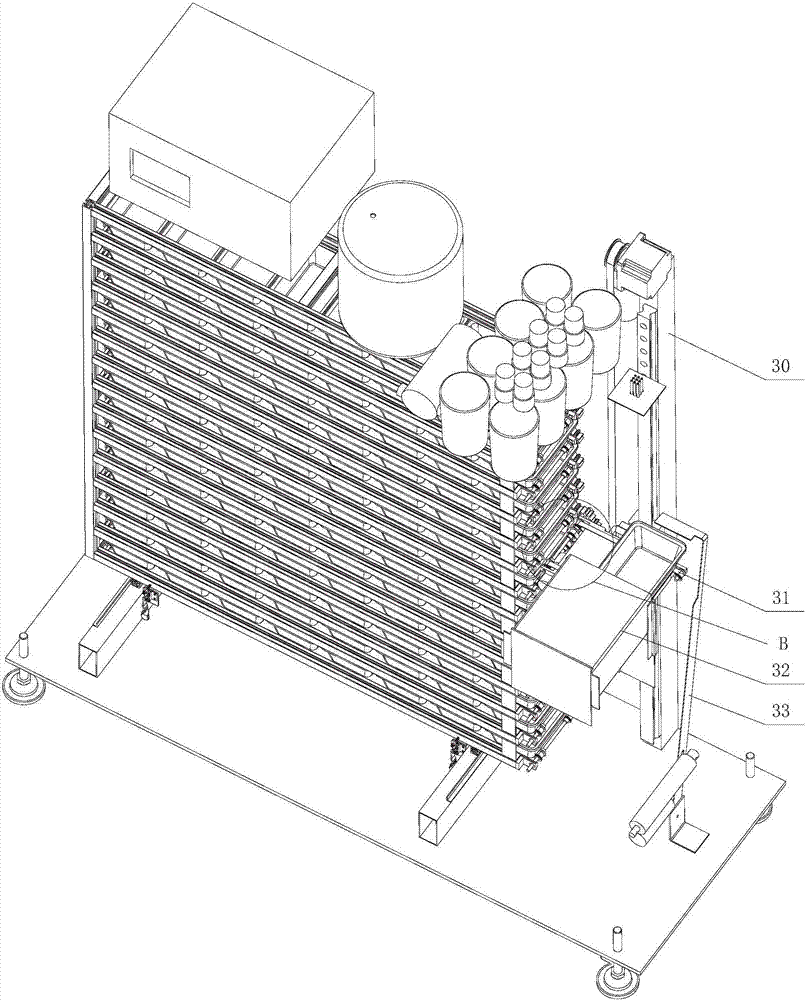

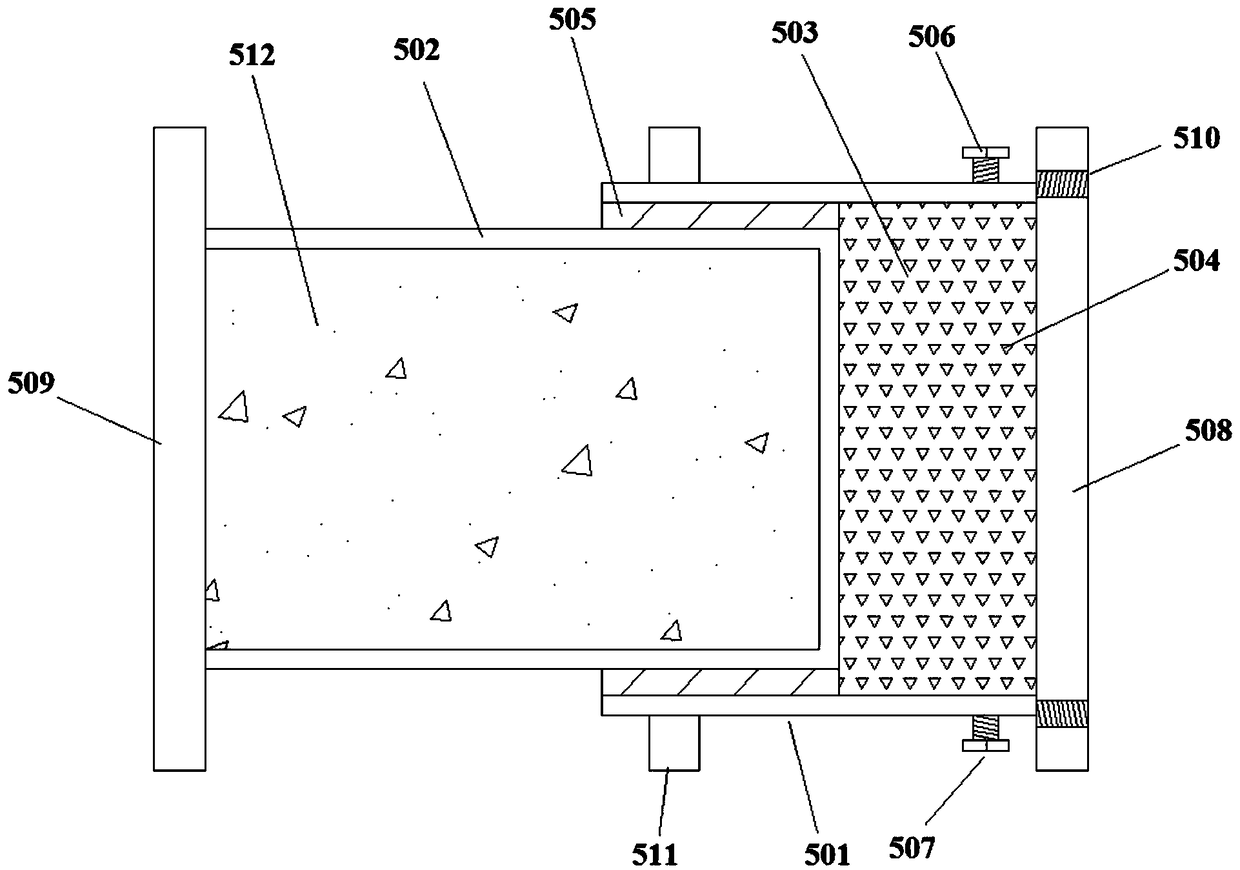

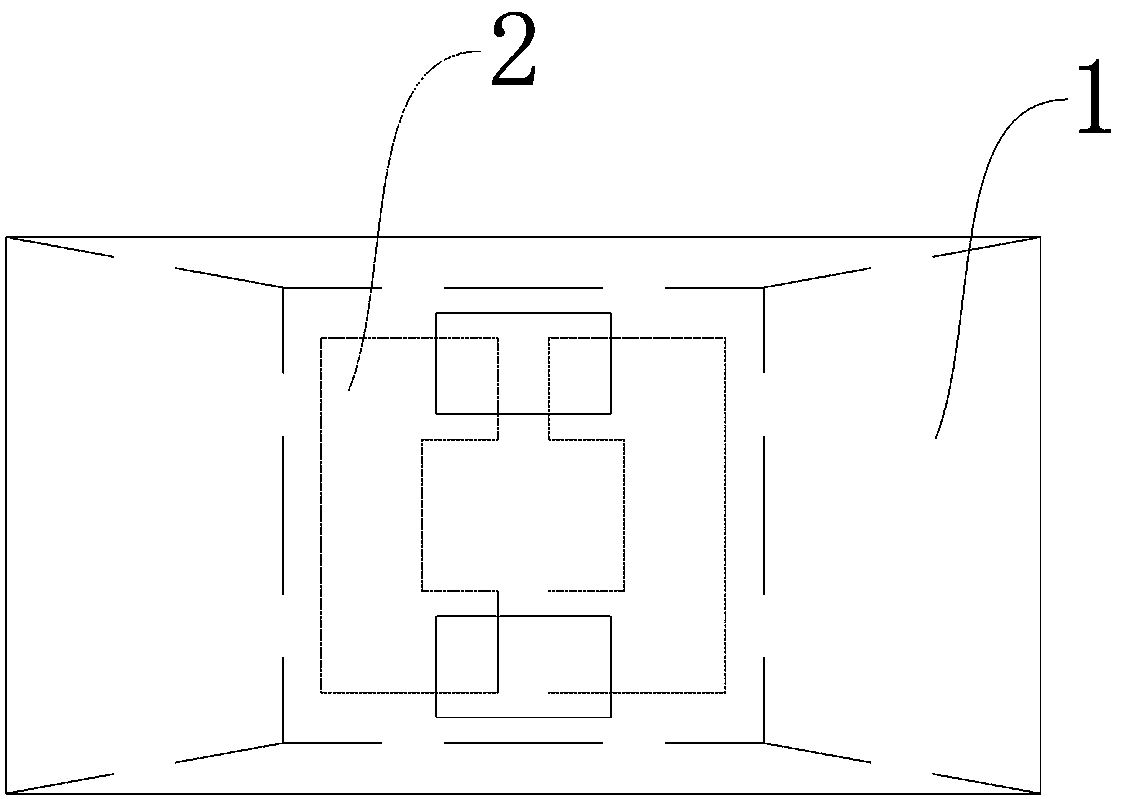

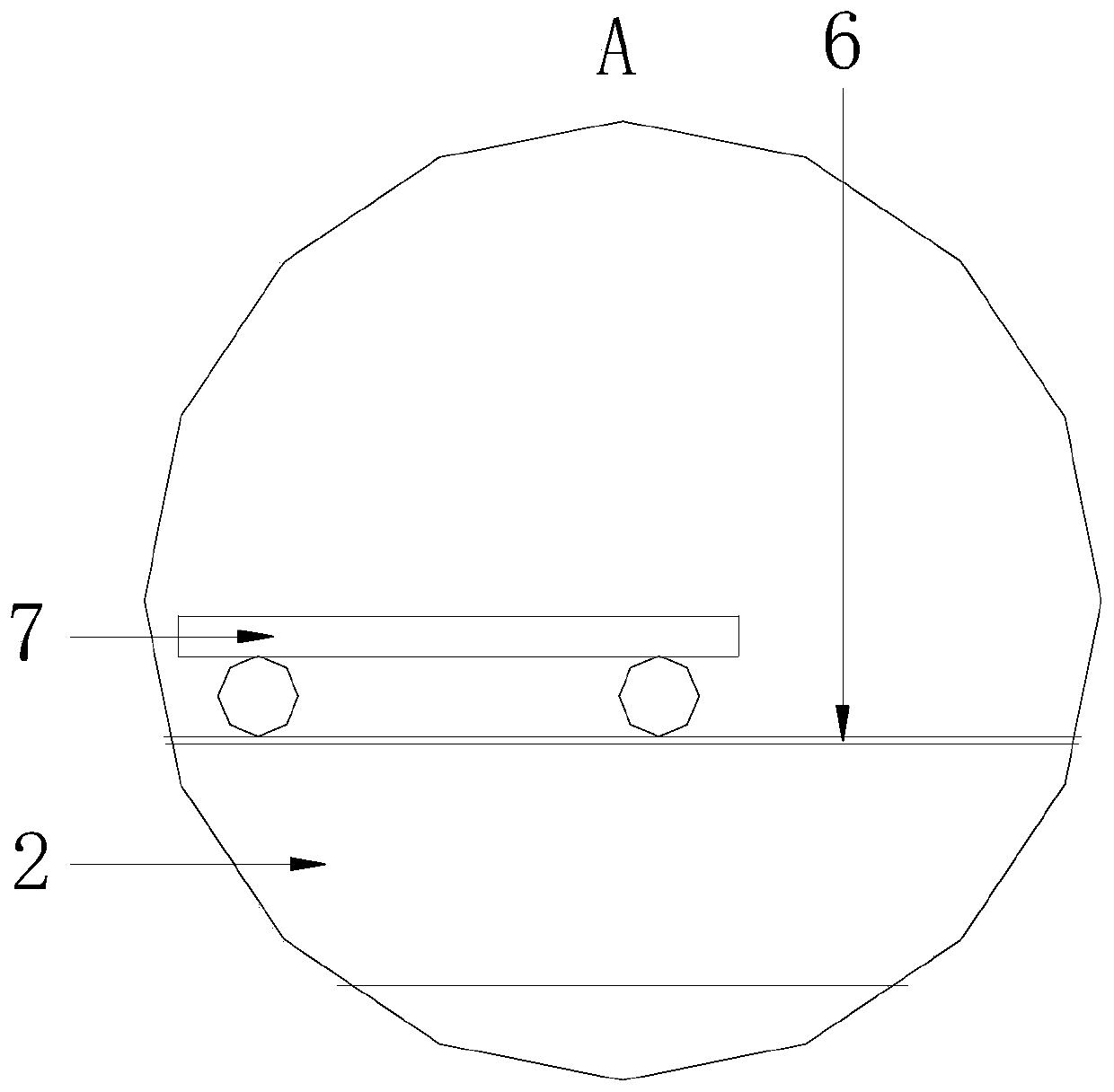

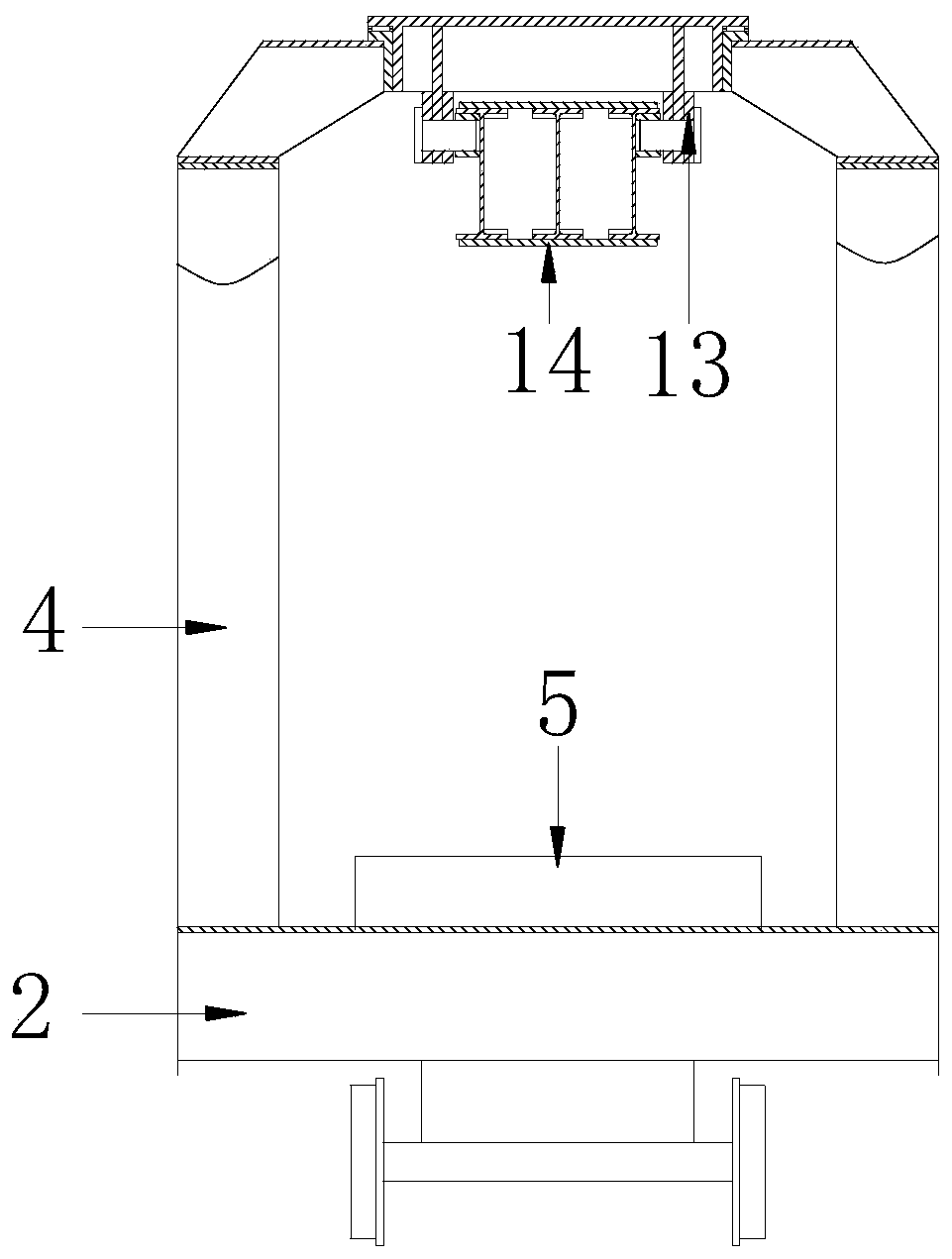

Vending machine

PendingCN107393154AGuaranteed to workReduce field work timeCoin-freed apparatus detailsApparatus for dispensing discrete articlesEngineeringMechanical engineering

The invention discloses a vending machine which comprises a vending machine body, a goods shelf and a good fetching mechanism, wherein the vending machine body comprises a base and a shell disposed on the base; the goods shelf comprises a goods shelf body as well as multiple storage mechanisms which are disposed on the goods shelf body and disposed vertically on the goods shelf body from bottom to top , and the bottom of the goods shelf body is movably disposed on the base along the horizontal direction; and the goods fetching mechanism comprises a support, a lifting table, a goods fetching channel and a connecting rod mechanism, the support is disposed on the base and located on one side of the storage mechanisms, the lifting table is movably disposed on the support along the vertical direction and is in transmission connection with the storage mechanisms, the goods fetching channel is disposed on the lifting table, the connecting mechanism is disposed on the base, and the connecting mechanism and the goods fetching channel are located on two opposite sides of the lifting table. In comparison with the prior art, the vending machine disclosed by the invention is characterized in that the goods shelf body is movably disposed on the base; lunch boxes on the goods shelf body can be replaced as a whole; on-site operation time is saved; working efficiency is increased; and normal work of the vending machine can be ensured.

Owner:SUZHOU JIERUISI INTELLIGENT TECH CO LTD

Reinforcement protective cover cushion block fixing method

InactiveCN102912980AGuaranteed thicknessReduce field work timeBuilding material handlingEconomic benefitsRebar

The invention discloses a reinforcement protective cover cushion block fixing method, which comprises the following steps of: (1) preparing a plurality of cushion blocks with same structures, wherein each cushion block is a hexahedron, upper and lower surfaces and one side wall surface I of each cushion block are planes, a steel tank is embedded on one side of each cushion block close to the side wall surface I, and the other three side wall surfaces of each cushion block are arc surfaces; (2) using adaptive thin steel strips to penetrate through the steel tanks; connecting the cushion blocks in series to form a cushion block string; and pressing and bending steel strips on two sides of each steel tank; and (3) if a reinforcement framework is to be prefabricated, prefixing the cushion block string on a bound reinforcement framework by a steel strip; and then lifting the reinforcement framework into a template. According to the invention, the thickness of a reinforcement protective cover can be guaranteed; as the field bulk binding of the cushion blocks is changed into centralized prebinding, the field operation time can be greatly reduced, obvious technical and economic benefits are obtained, the fixing method is beneficial for accelerating construction progress and project investment is saved. The reinforcement protective cover cushion block fixing method disclosed by the invention is especially suitable for object side surfaces or bottom surfaces with small reinforcement distances and difficulties in binding the cushion blocks.

Owner:SHANDONG HI SPEED QINGDAO HIGHWAY +4

Glass fiber reinforced cement (GRC) insulation decorative wallboard and production method thereof

InactiveCN102094501BReduce pollutionReduce on-site workCovering/liningsCeramic shaping apparatusGlass fiberSteel frame

The invention relates to a glass fiber reinforced cement (GRC) insulation decorative wallboard and a production method thereof, which are applicable to structural envelope, heat insulation and decoration of an external wall for a building of a frame structure. The GRC insulation decorative wallboard comprises a decorative layer, a GRC structural layer I, a GRC structural layer II, an insulating layer, a GRC reinforcing rib, steel frames, an installation connection piece, a lifting ring and an anti-cracking material, wherein, the GRC structural layer I is compounded on the decorative layer andis equipped with the insulating layer; the GRC structural layer II is arranged on the insulating layer, and the GRC reinforcing rib is arranged in the insulating layer; the GRC structural layer I is connected with the GRC structural layer II through the GRC reinforcing rib; the steel frames are arranged in the GRC structural layer I, the GRC structural layer II and the reinforcing rib; and the anti-cracking material is laid in the GRC structural layer II.

Owner:NANJING BEILIDA NEW MATERIAL SYST ENG

Tower-beam thrust connection device and self-anchored suspension bridge rapid construction method

The invention provides a tower-beam thrust connection device and a self-anchored suspension bridge rapid construction method. The beam end resistor is fixedly installed on the beam end reserved steelplate in the tower beam thrust connection device, the tower end resistor is fixedly installed on the tower end pressure-bearing steel plate, and the beam end resistor is connected with the tower end resistor through a thrust conductor. The method comprises the following steps: step 1, synchronously constructing the main girder and the bridge tower of the side span; step 2, installing a tower-beamthrust connection device to temporarily connect the main girder of the side span with the bridge tower; step 3, synchronously constructing the main cable erection and the main beam installation; step4, detaching the tower beam thrust connection device to complete the first system conversion; step 5, pulling the boom, removing the bracket, and completing the second system conversion. The method ofthe invention adopts the tower beam thrust connection device to realize the cooperative installation of the main cable and the main beam safely and economically, thereby greatly saving the field operation time; Its characteristic is to increase the system conversion of the main girder by one time compared with the traditional process.

Owner:CHANGAN UNIV

Method for coating steel rail with alloy by means of arc cladding

ActiveCN107815684AMeet the use requirementsReduce volumeArc welding apparatusMetallic material coating processesHeat-affected zoneInduction heater

The invention discloses a method for coating steel rail with alloy by means of arc cladding and belongs to the field of rail cladding. The method is characterized by comprising the following steps: (a) putting a steel rail cladding machine on the steel rail, moving an arc welding gun at a constant speed, and melting alloy at the upper portion of a to-be-coated position of a tread surface of the railhead of the steel rail; (b) controlling the width of an alloy strip to be 4 mm to 30 mm, and controlling the thickness of a heat affected zone of the steel rail to be 0.6 mm to 6 mm; and (c) arranging an induction heater above the melted alloy strip, stewing the alloy strip for 2 s to 180 s and then moving the induction heater at a constant speed along the length direction of the steel rail so as to perform heating, wherein the tissues in the heat affected zone of the steel rail after heating are considered as tempered sorbite or tempered sorbite + tempered troostite, or tempered troostite.According to the method disclosed by the invention, the cooling speed of the heat affected zone in a cladding process needs not to be controlled, the volume and weight of the steel rail cladding machine can be reduced, the cladding applicability and cladding efficiency can be improved, and the performances of the tissues in the heat affected zone after the steel rail is melted on site are ensuredto meet the use requirements of the steel rail.

Owner:CHENGDU ZHONGGUI TECH CO LTD

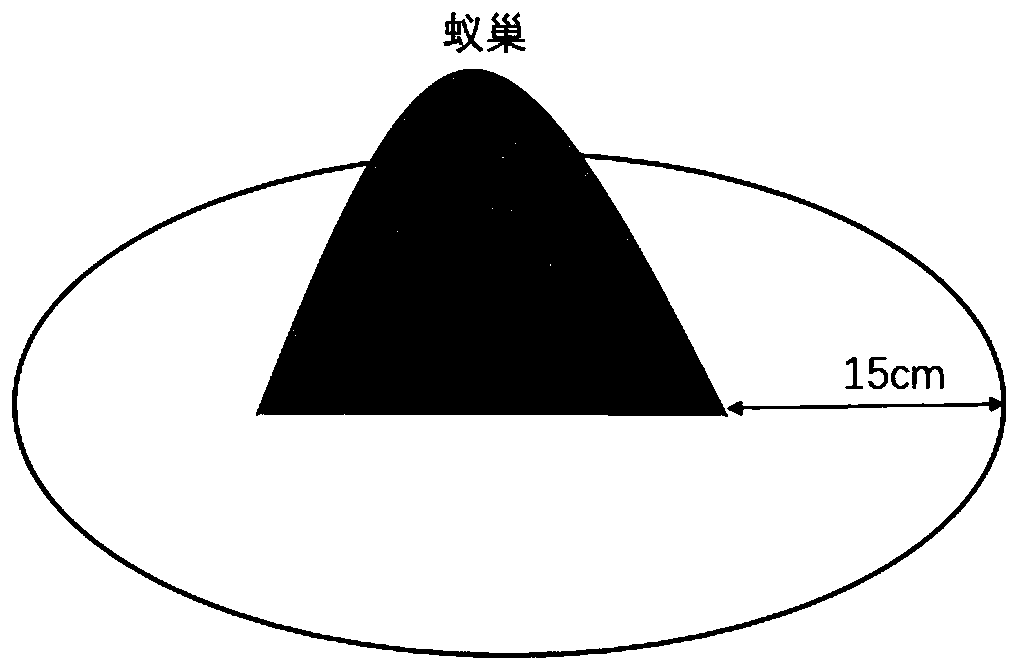

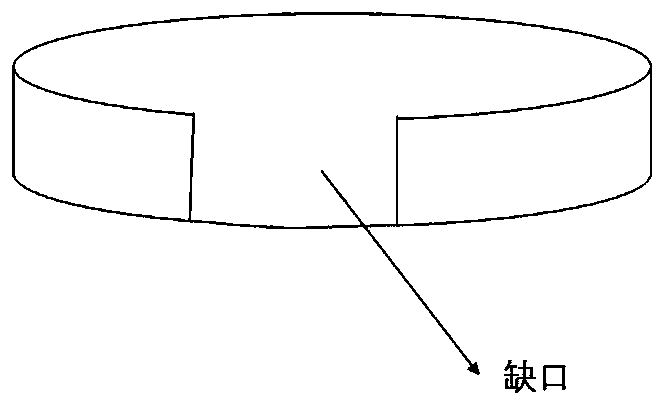

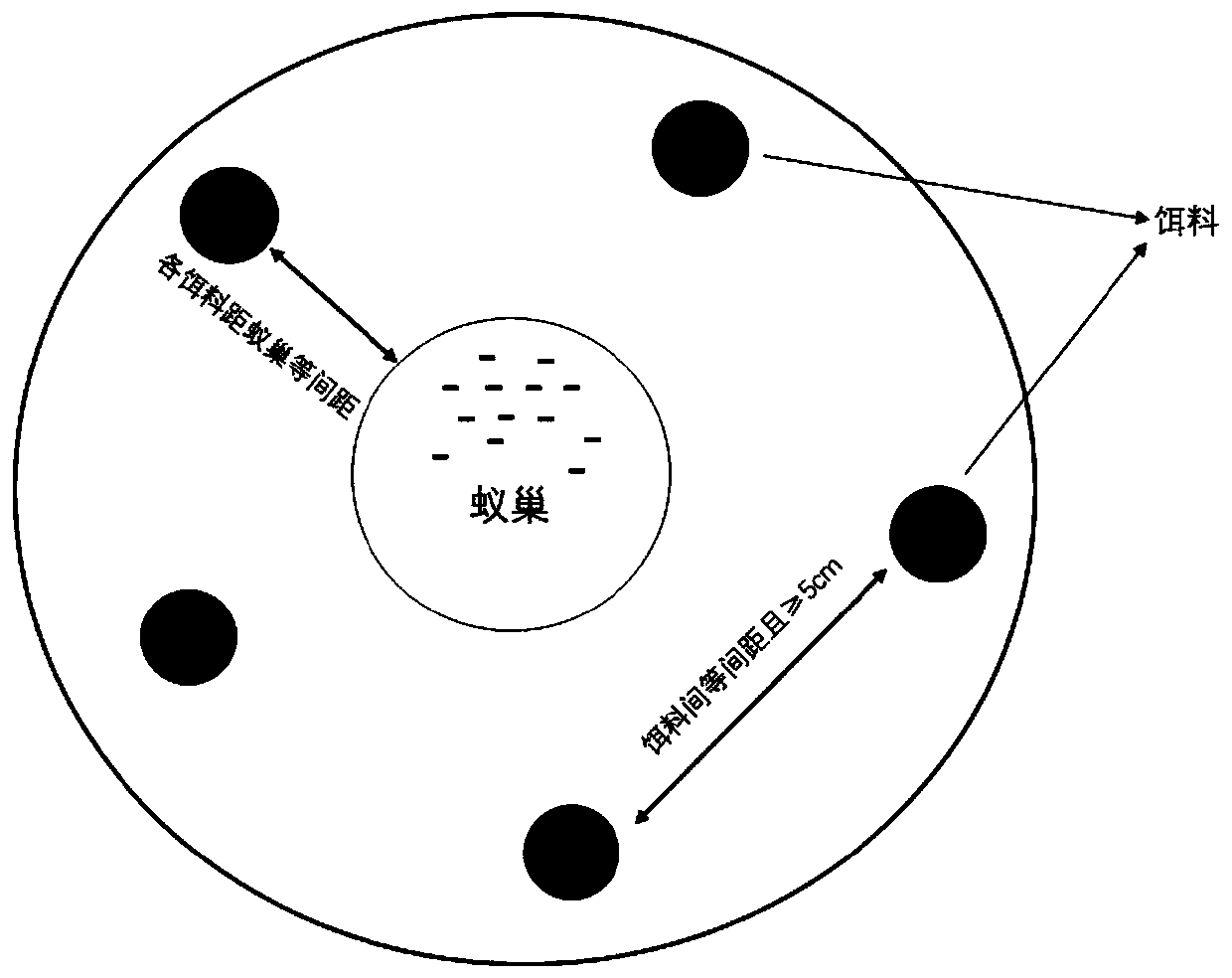

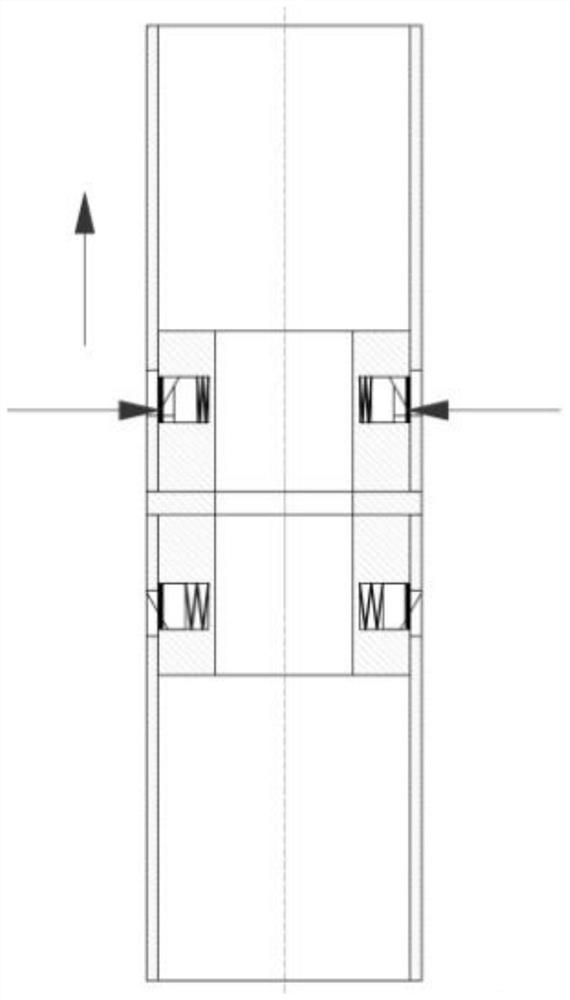

Solenopsis invicta buren bait field evaluation method

The invention discloses a solenopsis invicta buren bait field evaluation method which comprises the steps of solenopsis invicta buren nest field standardization treatment, bait / bait agent placement, data collection, data statistics and evaluation. The method has the advantages that the operation is convenient and fast; the field operation time and the experiment errors are effectively reduced; thescientific evaluation on the attracting effect and the palatability of baits / bait agents on the solenopsis invicta buren is facilitated; and a standardized field operation method is provided for thefield statistics of the solenopsis invicta buren and the evaluation on the bait / bait agent attracting effect.

Owner:INST OF ZOOLOGY GUANGDONG ACAD OF SCI

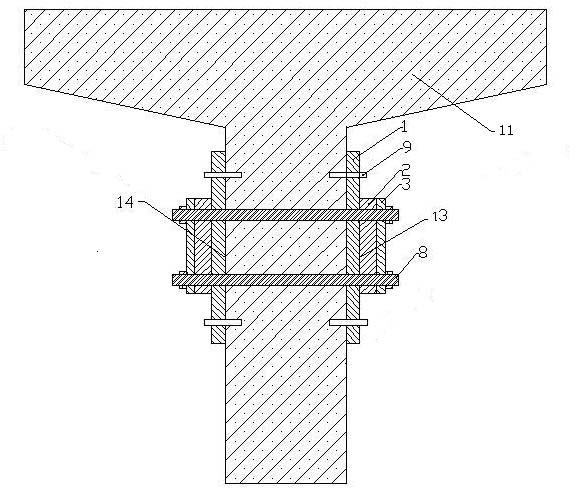

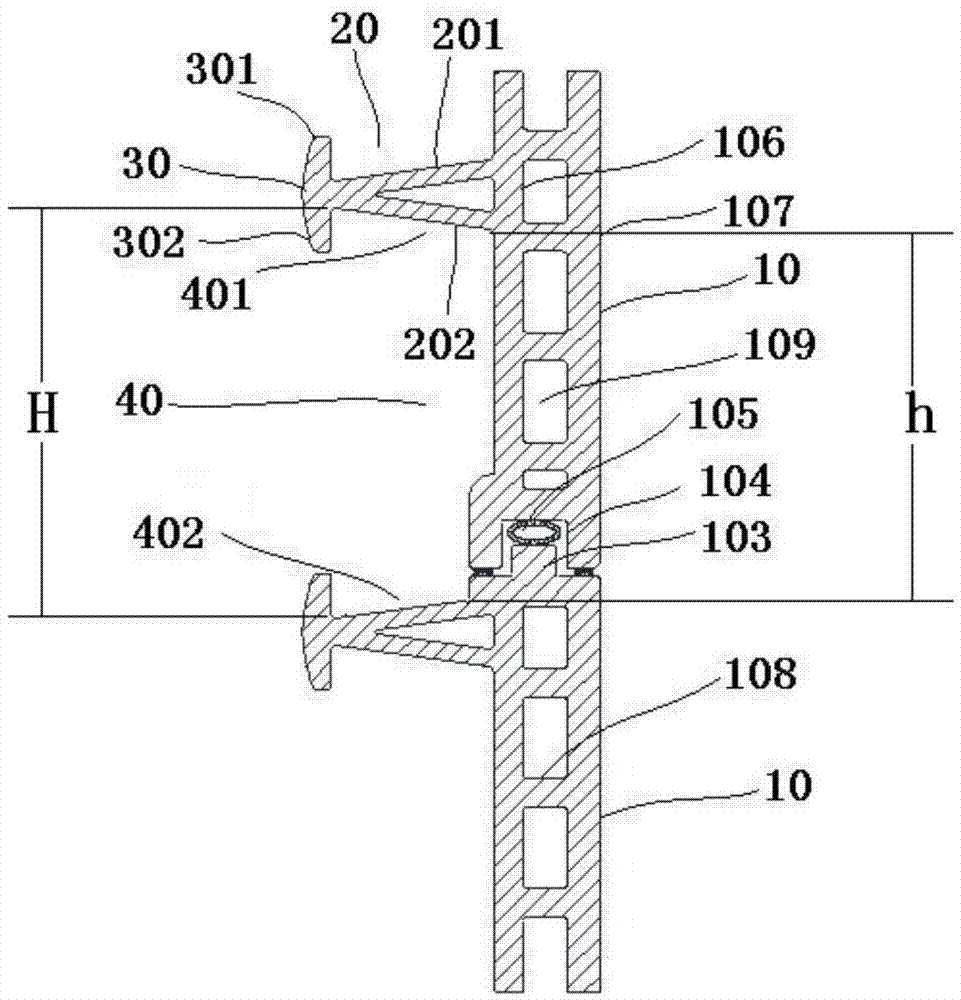

Tubular pile quick connector and method

The invention relates to a tubular pile quick connector and a method. The tubular pile quick connector comprises the following components: a socket pile tongue, reset springs, a locking pin, and check rings; the socket pile tongue is of a cylindrical structure and comprises a socket pile tongue body and an annular protrusion arranged on the peripheral wall of the socket pile tongue body; a plurality of blind holes are uniformly formed in the peripheral walls of the upper end and the lower end of the socket pile tongue body; the blind hole does not penetrate through the inner cylinder wall of the socket pile tongue; the first ends of the reset springs are fixed on the inner walls of the blind holes; the locking pin comprises a locking pin body and a wedge-shaped protrusion arranged on the locking pin body; the locking pin body is fixedly connected with the second end of the reset spring; the wedge-shaped protrusion is a free end; the locking pin body freely slides in the blind holes; a limiting hole matched with the wedge-shaped protrusion is formed in the tubular pile; and the check rings are arranged in the blind holes. According to the connector, the connecting part of tubular pipe pile can be placed in a workshop for production, the field operation time can be shortened, and the field operation efficiency can be improved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

Reinforcement protective cover cushion block fixing method

InactiveCN102912980BGuaranteed thicknessReduce field work timeBuilding material handlingEconomic benefitsRebar

The invention discloses a reinforcement protective cover cushion block fixing method, which comprises the following steps of: (1) preparing a plurality of cushion blocks with same structures, wherein each cushion block is a hexahedron, upper and lower surfaces and one side wall surface I of each cushion block are planes, a steel tank is embedded on one side of each cushion block close to the side wall surface I, and the other three side wall surfaces of each cushion block are arc surfaces; (2) using adaptive thin steel strips to penetrate through the steel tanks; connecting the cushion blocks in series to form a cushion block string; and pressing and bending steel strips on two sides of each steel tank; and (3) if a reinforcement framework is to be prefabricated, prefixing the cushion block string on a bound reinforcement framework by a steel strip; and then lifting the reinforcement framework into a template. According to the invention, the thickness of a reinforcement protective cover can be guaranteed; as the field bulk binding of the cushion blocks is changed into centralized prebinding, the field operation time can be greatly reduced, obvious technical and economic benefits are obtained, the fixing method is beneficial for accelerating construction progress and project investment is saved. The reinforcement protective cover cushion block fixing method disclosed by the invention is especially suitable for object side surfaces or bottom surfaces with small reinforcement distances and difficulties in binding the cushion blocks.

Owner:SHANDONG HI SPEED QINGDAO HIGHWAY +4

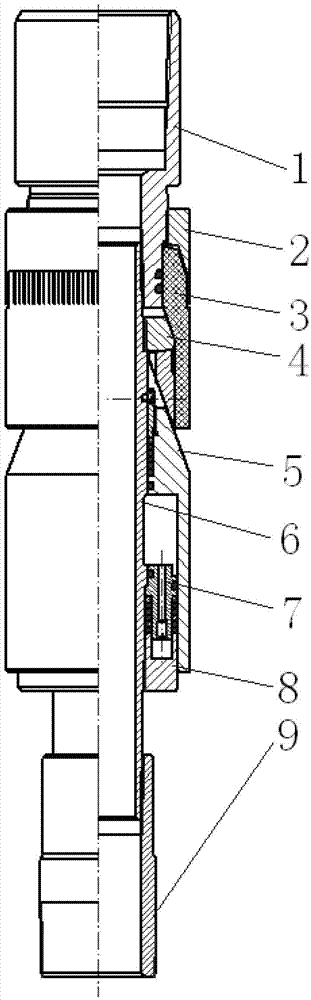

Thick-oil thermal recovery device in oil fieldSelf-sealing type thermal recovery packer.

The invention relates to a thick-oil thermal recovery device in an oil field, in particular to a self-sealing type thermal recovery packer. The thick-oil thermal recovery deviceself-sealing type thermal recovery packer. is characterized in that an upper joint, a central pipe and a lower joint are connected in sequence from top to bottom; a cylinder sleeve is sheathed on the central pipe and is fixedly connected with the central pipe by a pin; expanding liquid is filled in the cylinder sleeve; the lower end of the cylinder sleeve is sealed by a sealing head and a double-pressing cap; the upper end of the cylinder sleeve is provided with a sliding and locking device; and an outer sealing assembly is arranged at the outer side of the sliding and locking device and the inner side of the lower end of a supporting ring. The thick-oil thermal recovery deviceself-sealing type thermal recovery packer. has the advantages that automatic setting is realized, the setting time is short, the setting is durable, the structure is compact, the sealing is excellent, the unsealtting is smooth, the production and operation cost is reduced, and the defects of complex structure, longer size, troublesome operation and easy well blocking in the existing packer are overcome.

Owner:CNPC BOHAI EQUIP MFG

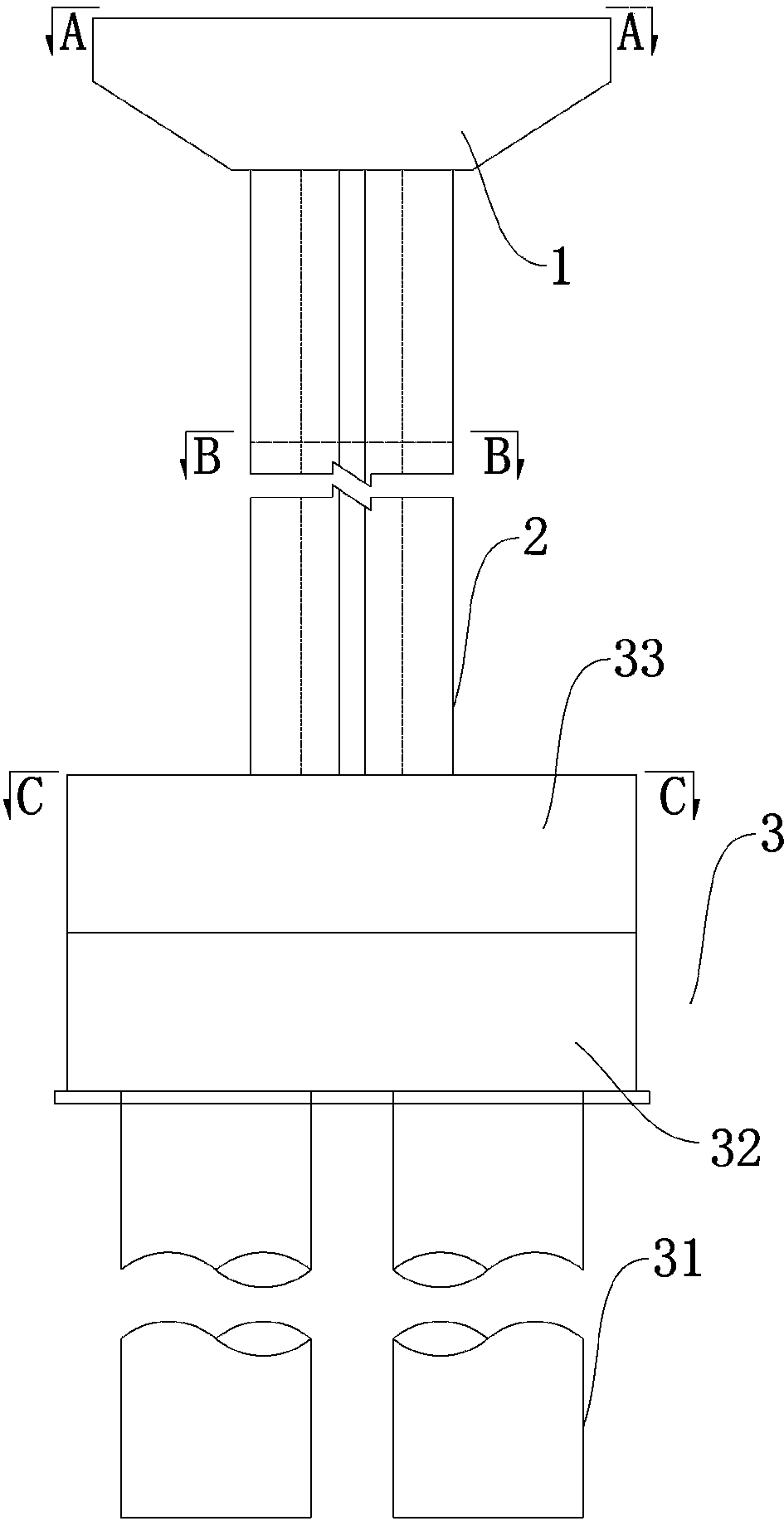

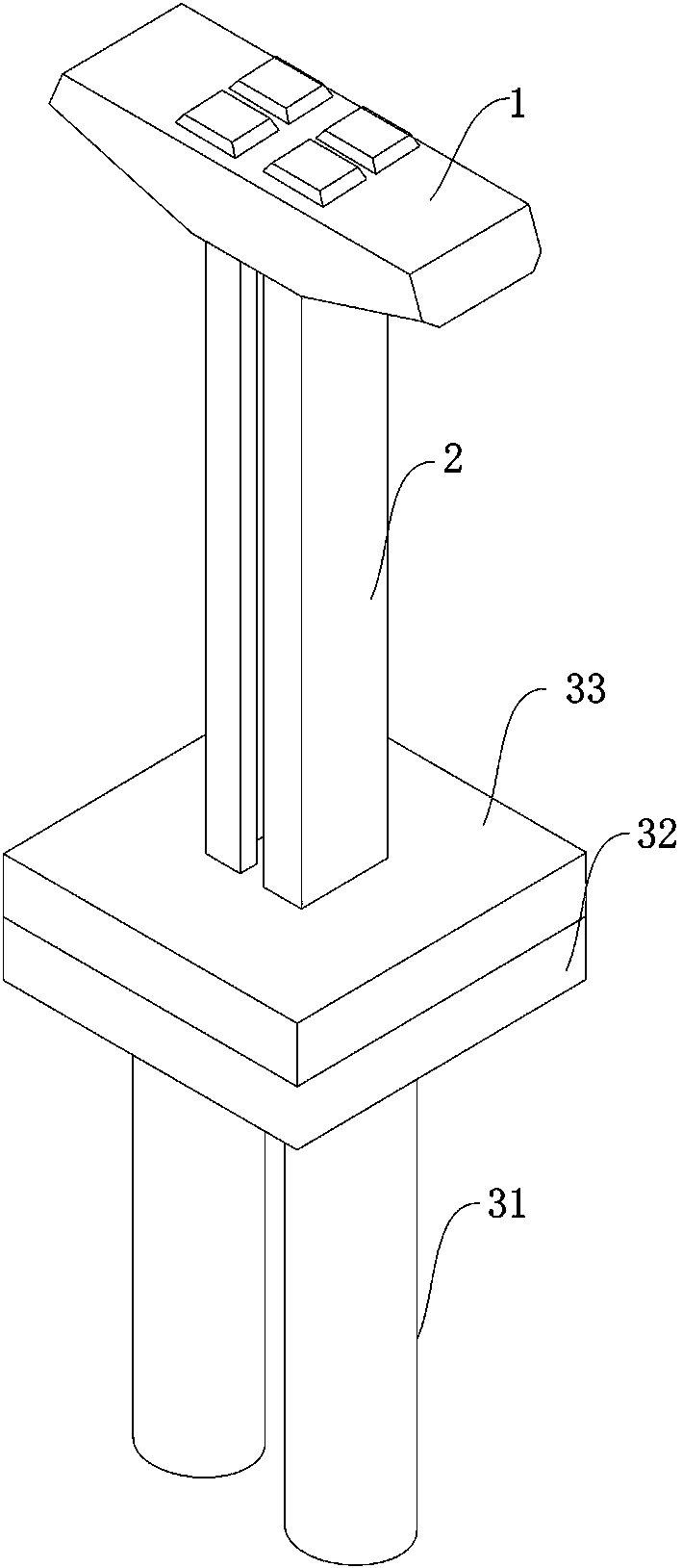

Double-limb thin-wall T-shaped pier

PendingCN111188264AImprove crash performanceEasy to manufactureBridge structural detailsArchitectural engineeringRoad traffic

The invention discloses a double-limb thin-wall T-shaped pier which comprises a bearing platform base, U-shaped columns and a bent cap. The U-shaped columns are arranged between the bearing platform base and the bent cap in pairs, and staggered openings of the U-shaped columns are oppositely formed to form hollow thin-wall pier columns. The double-limb thin-wall T-shaped pier has the beneficial effects that the double-limb thin-wall T-shaped pier is split into the bent cap and the two U-shaped columns, the bent cap and the two U-shaped columns are prefabricated and machined in a factory through mechanical line production, the U-shaped columns can be prefabricated in a supine mode and are convenient to manufacture, store and transport, and the integral double-limb thin-wall T-shaped pier can be assembled in the factory. The bent cap and the U-shaped columns are disassembled, prefabricated and assembled into the hollow component, so that the structural strength of the hollow component isguaranteed, and 30-40% of raw materials are saved. During on-site installation, mechanical hoisting can be adopted, the on-site operation time is less than 3 days, and the on-site operation time is greatly shortened compared with that of an original cast-in-place pier stud bent cap which needs to be operated for more than 25 days, so that the time of road traffic and urban environment influence is reduced.

Owner:重庆单轨交通工程有限责任公司 +1

Narrow coal pillar gob-side entry end self-expansion reinforced anchoring type anchor rod structure and method

The invention discloses a narrow coal pillar gob-side entry end self-expansion reinforced anchoring type anchor rod structure and a method. The narrow coal pillar gob-side entry end self-expansion reinforced anchoring type anchor rod structure and the method are suitable for being used in deep well gob-side entry narrow coal pillars. The narrow coal pillar gob-side entry end self-expansion reinforced anchoring type anchor rod structure comprises a hollow anchor rod, a metal tray, a nut, a stop-grouting plug, a metal porous expansion lock body, a carbon fiber expansible rubber bag, bag passive protection wings, a grouting pipe and a one-way valve body set; during use, the low-pressure grouting is conducted through an expansion end, the carbon fiber expandable rubber bag expands, the bag passive protection wings are unfolded, after slurry in the bag is solidified, the expansion anchoring end is formed, and the anchoring strength of the anchor rod is improved; and the hollow anchor rod is subjected to drilling and high-pressure grouting, so that the mechanical property of the crushed coal and rock mass in the narrow coal pillar is improved, the anchoring length of the narrow coal pillar is increased, the anchor rod supporting effect is improved, stable control of the deep well narrow coal pillar gob-side entry surrounding rock is achieved, and the narrow coal pillar gob-side entry end self-expansion reinforced anchoring type anchor rod structure has the advantages of being economical, reliable, simple in structure and convenient and fast to install.

Owner:CHINA UNIV OF MINING & TECH

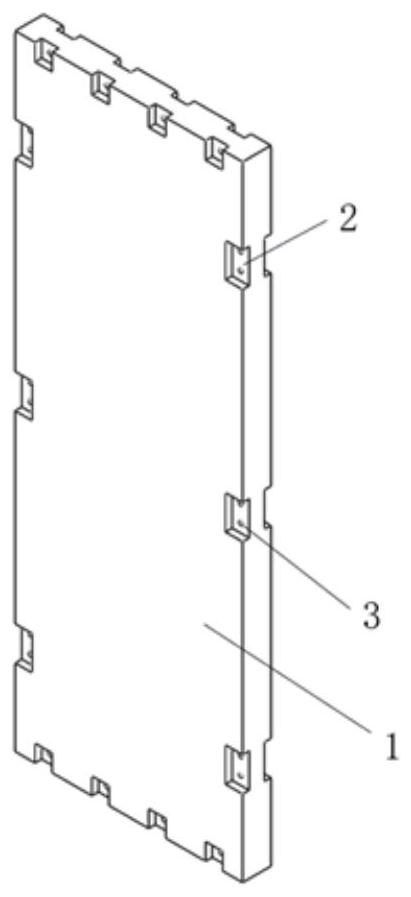

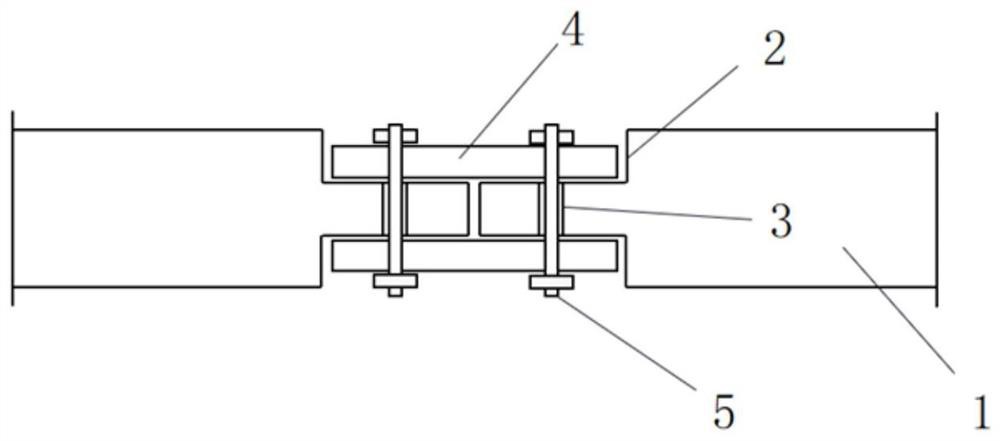

Connecting joint of assembly type concrete prefabricated wallboards and installation method of connecting joint

PendingCN113152659AImprove installation efficiencyRealize completely dry operationBuilding material handlingMechanical engineeringPrecast concrete

The invention provides a connecting joint of assembly type concrete prefabricated wallboards and an installation method of the connecting joint. The connecting joint comprises a plurality of grooves which are formed in the periphery of the prefabricated wallboards, connecting plates and connecting bolts, the connecting plates and connecting bolts are embedded in the grooves, the grooves are symmetrically formed in the two faces of the prefabricated wallboards in the thickness direction, a plurality of through connecting holes are formed in the grooves, through holes corresponding to the positions of the connecting holes in the grooves are formed in the connecting plates, the connecting bolts penetrate through the two connecting plates in the two grooves symmetrically formed in the two faces of the prefabricated wallboards in the thickness direction and the connecting holes in the grooves, the two ends of the connecting bolts are fastened by utilizing nuts, and the connecting joints between the two prefabricated wallboards are connected and fastened by screwing the nuts. According to the connecting joint of the assembly type concrete prefabricated wallboards and the installation method of the connecting joint, through the provided connection mode between the prefabricated concrete wallboards, on-site complete dry method operation can be achieved, the installation efficiency of the prefabricated concrete wallboards is greatly improved, the on-site operation time is shortened, and the standardization degree is high.

Owner:WUHAN UNIV OF TECH

Hoisting vehicle for replacing long and heavy parts of high-speed railway turnout and its replacement method

ActiveCN107476146BOvercoming the defects of secondary hoistingReduce field work timeTrack superstructureRailway track constructionTruckPortal frame

The invention discloses a hoisting vehicle and method for replacing of long and heavy parts of a high-speed railway turnout. The hoisting vehicle comprises a rail vehicle body, a fixed portal frame flat vehicle body and a moveable portal frame flat vehicle body which are connected end to end through hooks. The method for replacing of the long and heavy parts of the high-speed railway turnout comprises the following steps that 1, the new long and heavy parts of the high-speed railway turnout are hoisted and fixed; 2, the fixed portal frame flat vehicle body and the moveable portal frame flat vehicle body are unfolded and fixed; 3, the used long and heavy parts of the high-speed railway turnout are hoisted and fixed; 4, the new long and heavy parts of the high-speed railway turnout replace the used long and heavy parts of the high-speed railway turnout; and 5, the fixed portal frame flat vehicle body and the moveable portal frame flat vehicle body are folded. The hoisting vehicle and method have the advantages that according to the mechanical device designed special for the long and heavy parts of the high-speed railway turnout, the current defect of secondary hoisting of the new and used long and heavy parts of the high-speed railway turnout is overcome, and thus the site operation time is saved greatly. In the safety aspect, the operation range of the equipment is below that of a lifting beam, so that the hidden danger that the equipment collides a contact net is avoided. In the aspect of comparing the equipment cost, the equipment investment of the newly-proposed method is quite low, and thus popularization is easy.

Owner:蔡钟博

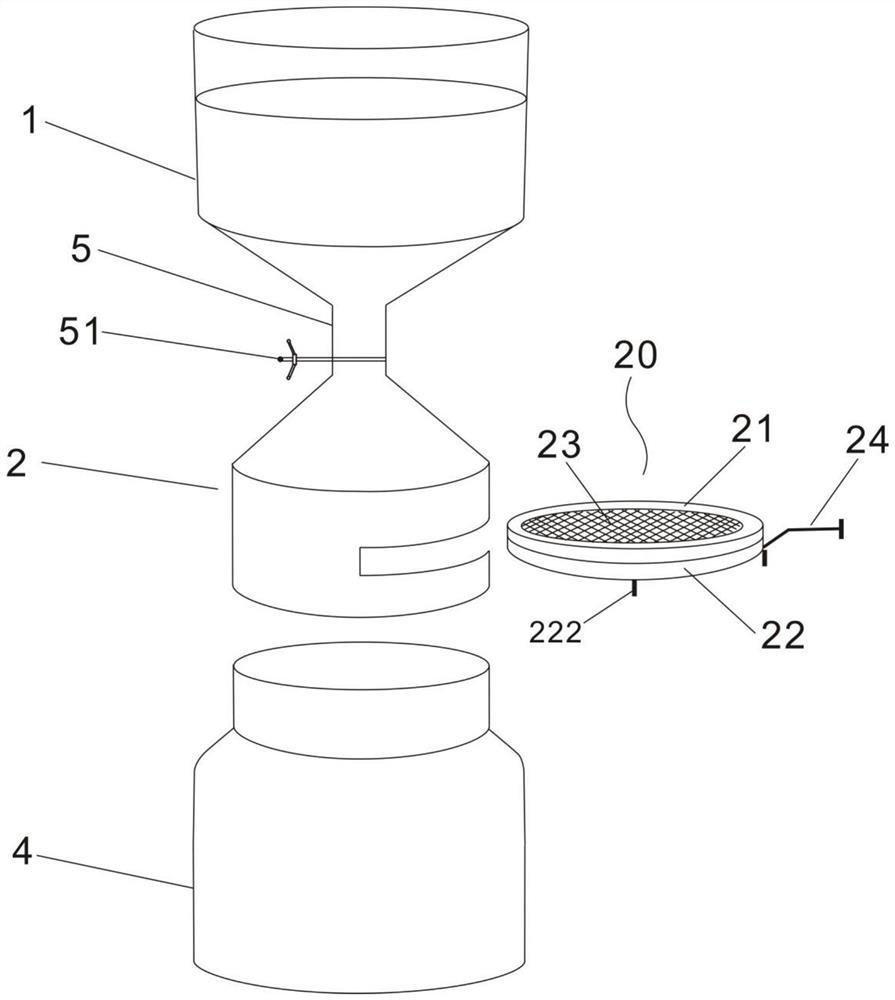

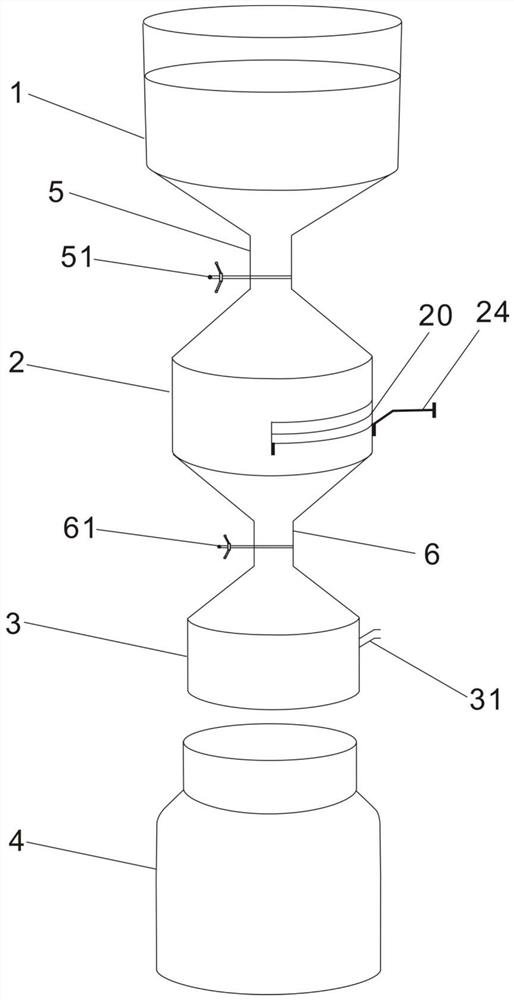

Field natural water sample collection system and method

ActiveCN111855378AQuick changeEasy to operateGeneral water supply conservationPreparing sample for investigationWater qualityProcess engineering

The invention discloses a field natural water sample collection system and method, belongs to the technical field of water quality analysis and testing, and solves the problems that sampling cannot beinterrupted at any time, the replacement speed of a filter membrane is low and the working efficiency is low during existing field water sample collection. The field natural water sample collection system comprises a water containing funnel, a filtering device and a sample collecting bottle, wherein the water containing funnel is used for containing an original field natural water sample, the filtering device is used for filtering impurities in the original natural water sample, and the sample collecting bottle is used for storing the natural water sample filtered by the filtering device; thewater containing funnel, the filtering device and the sample collecting bottle are sequentially connected along the flowing direction of a natural water sample; and the filtering device is detachablyprovided with a filtering assembly. According to the invention, the sampling can be interrupted at any time according to needs, the filter membrane can be rapidly replaced, and the collection efficiency of field natural water samples is greatly improved.

Owner:INST OF KARST GEOLOGY CAGS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com