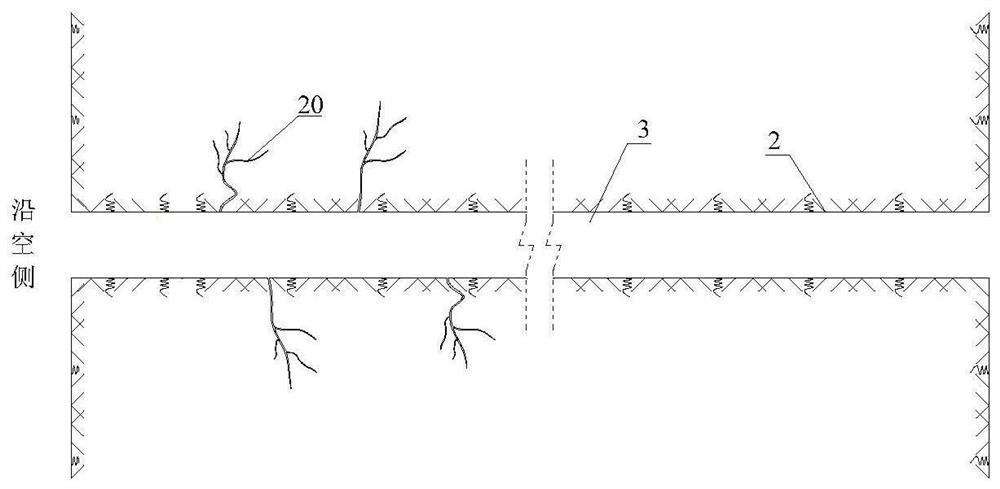

Narrow coal pillar gob-side entry end self-expansion reinforced anchoring type anchor rod structure and method

A narrow coal pillar and self-expanding technology, which is applied to the installation of bolts, earthwork drilling, mining equipment, etc., can solve the problems of insufficient anchorage strength of narrow coal pillars, etc., and achieve a small operating time span and save operating time , Improve the effect of anchoring performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

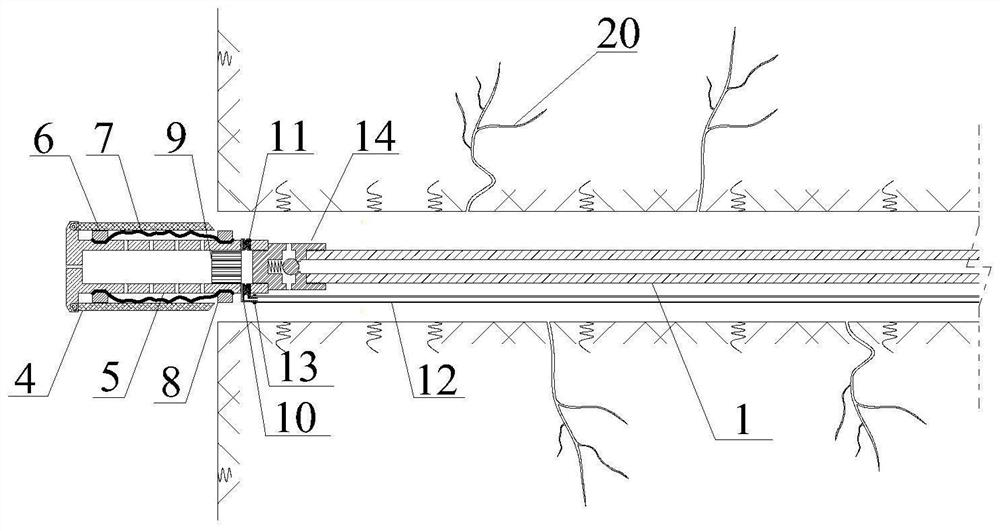

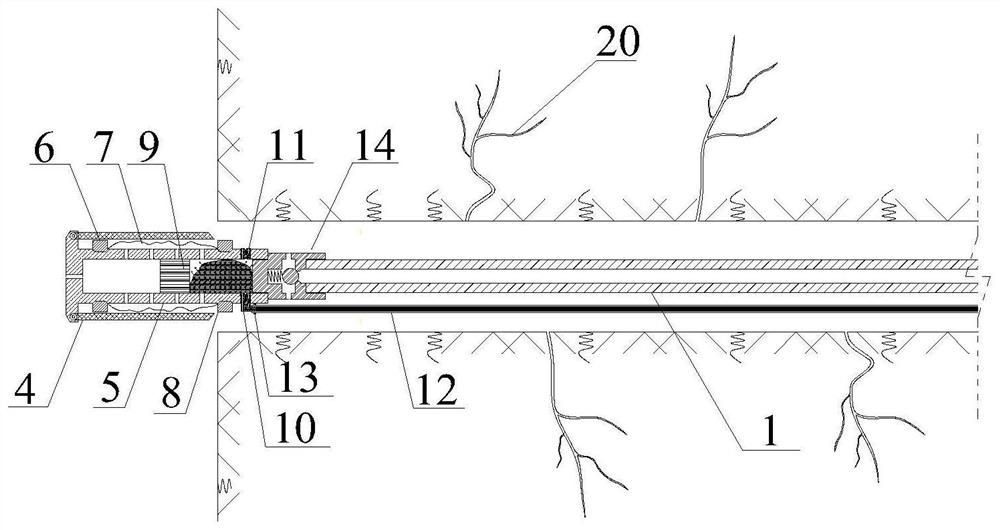

[0045] An anchor hole 3 suitable for the diameter of the metal porous expansion lock body 5 is constructed in the narrow coal pillar, and the residual debris in the hole is cleaned.

[0046]The grouting one-way valve A10 and the pressure relief valve 11 are symmetrically installed on the metal porous expansion lock body 5, and the carbon fiber expandable rubber bladder 7 is passed through the metal porous expansion lock body 5 to the overflow area, and the two ends of the bladder ensure that Cover the groove 52, press the carbon fiber expandable rubber bladder 7 into the reserved groove 52 on the metal porous expansion lock body 5 with the bladder fixing ring a8 and the bladder fixing ring b6, and tighten it with bolts b82 and a62 solid, push the rubber piston 9 into the metal porous expansion lock body 5, and the distance from the end of the metal cylinder is 35-40 mm; connect the grouting check valve B14 with the metal porous expansion lock body 5, and then connect it with th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com