Self-grouting-stopping device of assembly type grouting guiding pipe

A grouting conduit and assembled technology, which is applied in shaft equipment, wellbore lining, tunnel lining, etc., can solve the problems of long working time and high risk on site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

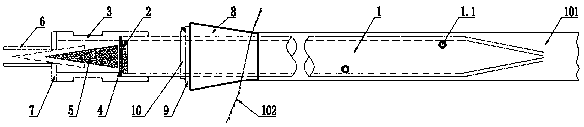

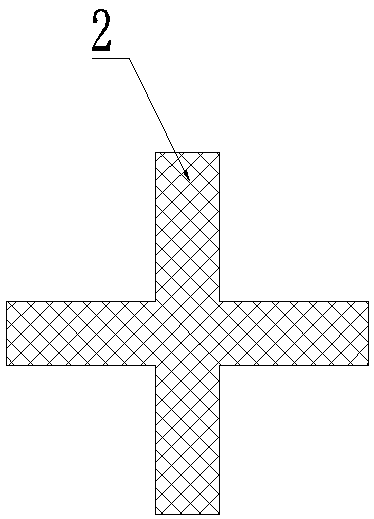

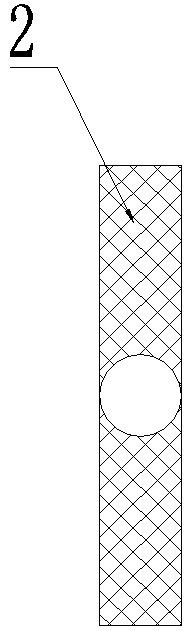

[0027] This embodiment provides an assembled grouting pipe self-stop grouting device, including a grouting pipe 1, a barrier grid 2 is provided on the grouting inlet of the grouting pipe 1, and an external thread is provided on the outer wall of the grouting inlet; It includes a sleeve 3, a sealing ring 4, a check plug 5 and a grouting connecting pipe 6; the inlet end of the sleeve 3 is provided with an annular sealing plate 7, and the inner wall of the outlet end is provided with an annular groove 3.1 that is matched with the grouting pipe 1 The annular groove 3.1 is provided with an internal thread that matches the outer thread of the outer wall of the grouting conduit 1; the sealing ring 4 is arranged between the end surface of the annular groove 3.1 and the end surface of the grouting conduit 1 to prevent the grout from the grouting conduit Flow out from the gap between 1 and the casing 3; the grouting connecting pipe 6 is fixed on the sealing plate 7; the check plug 5 is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com