Thick-oil thermal recovery device in oil fieldSelf-sealing type thermal recovery packer.

A packer and thermal recovery technology, which is applied in the directions of sealing/isolation, earthwork drilling, wellbore/well parts, etc., can solve problems such as troublesome operation, complex structure, well stuck accidents, etc., and achieve safe and reliable use and excellent operation Simple, short setting time results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

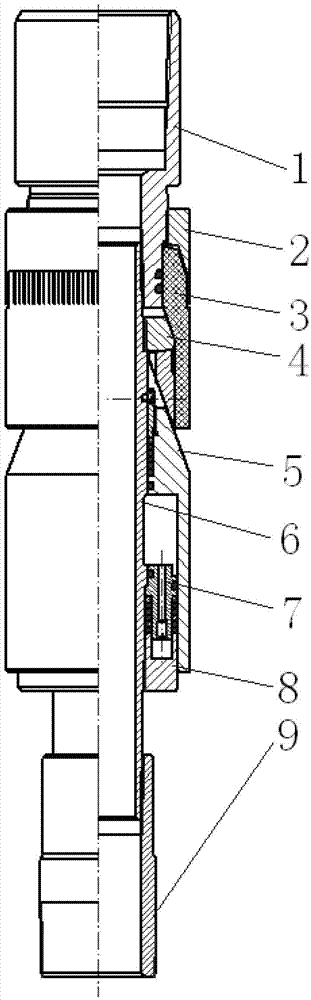

[0009] As shown in the attached figure, a self-sealing thermal recovery packer includes an upper joint 1, a central pipe 6 and a lower joint 9; the upper joint 1, the central pipe 6 and the lower joint 9 are connected sequentially from top to bottom, and the cylinder liner 5 is set on the central tube 6 and fixed by pin connection. The interior of the cylinder liner 5 is filled with expansion liquid. The lower end of the cylinder liner 5 is sealed by the sealing head 7 and the double pressure cap 8. The assembly 3 is installed on the outer side of the sliding locking device 4 and the inner side of the lower end of the support ring 2 . The outer sealing assembly 3 adopts a leather cup structure.

[0010] The present invention adopts a hydraulic power-assisted setting seal. When the temperature rises to 200°C, the expansion liquid in the cylinder liner 5 expands and gasifies, pushing the cylinder liner 5 upward to cut off the control pin, and prompting the movable slider in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com