Patents

Literature

56results about How to "Reduce production operation cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Treatment method for inferior heavy oil and residual oil

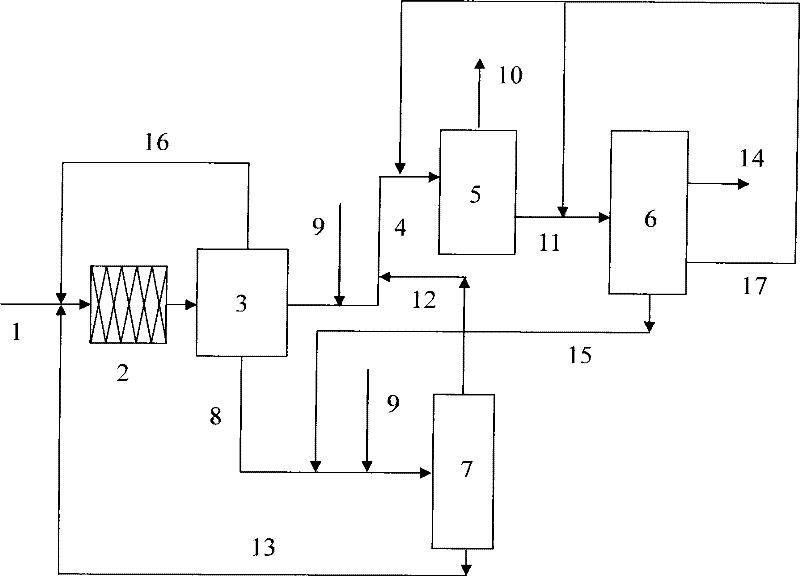

ActiveCN1766059ABroaden sources of raw materialsReduce production operating costsTreatment with hydrotreatment processesSolventChemistry

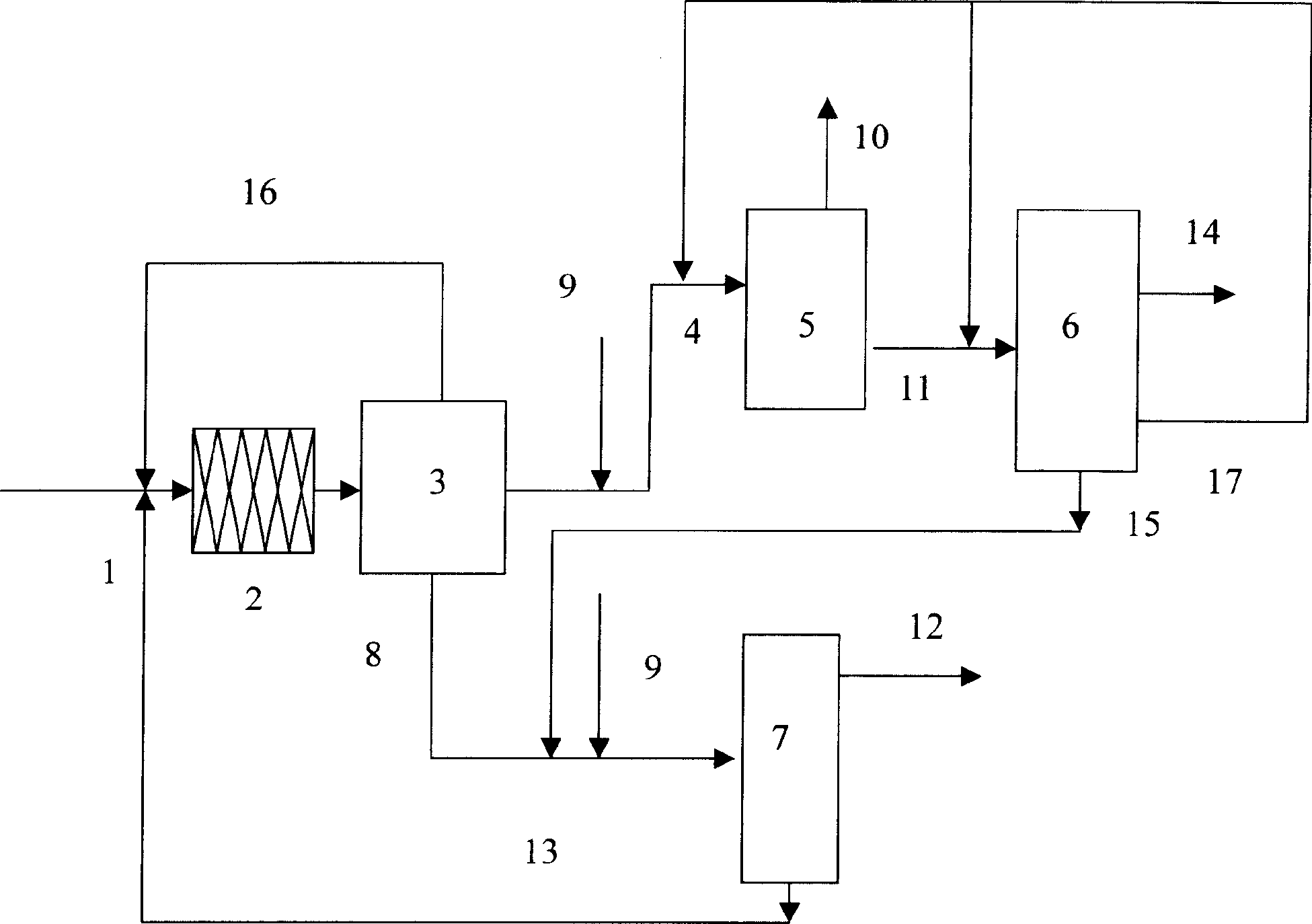

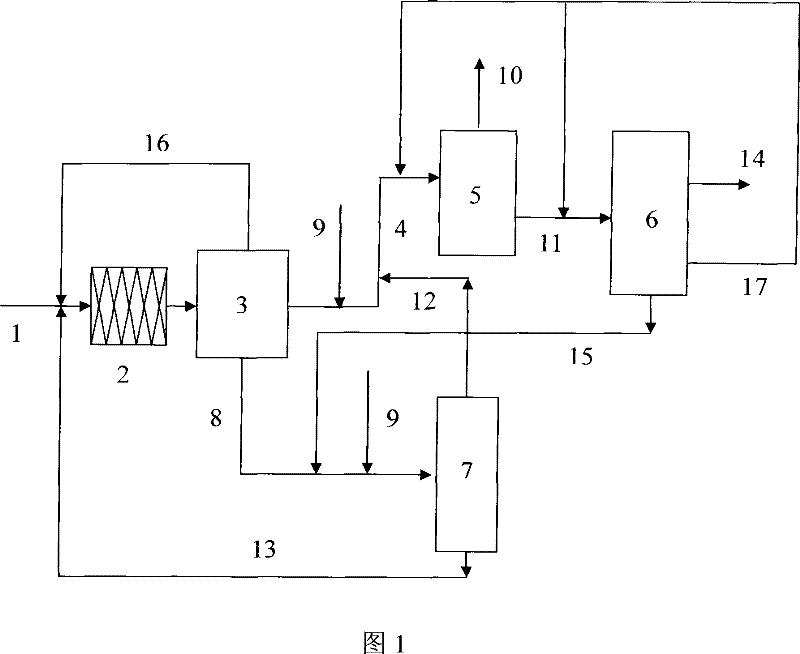

The invention discloses a process for treating inferior heavy oil and residual oil comprising the following steps: loading heavy oil and petroleum residue into a solvent extraction apparatus, charging the obtained deasphalted oil into a fixed bed for hydrotreatment, entering the obtained tail oil into a catalytic cracking device, loading part or total slurry oil and de-oiled asphalt into a floating bed hydrogenation unit, separating the outcome yield to obtain lightweight fraction and untransformed tail oil, which is circulated to the solvent extraction device.

Owner:CHINA PETROLEUM & CHEM CORP +1

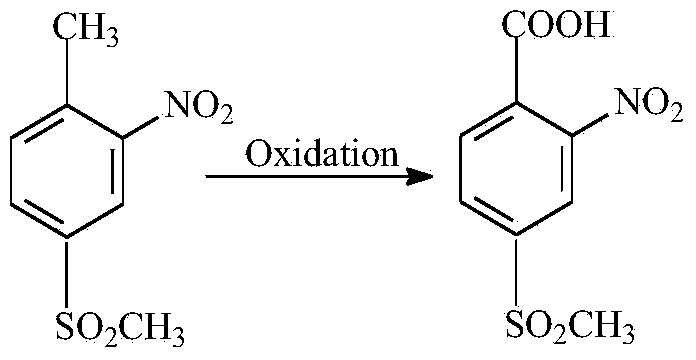

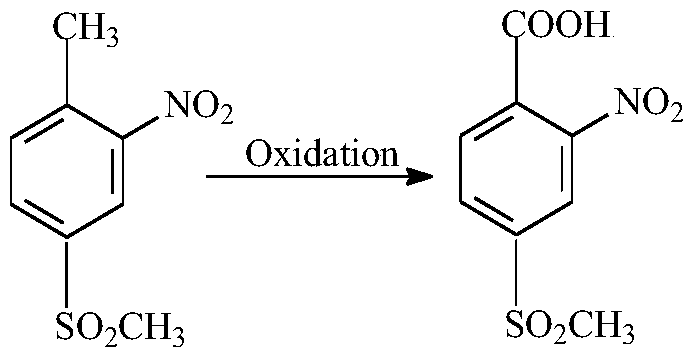

Preparation method of 2-nitro-4-methylsulphonylbenzoic acid

ActiveCN103787934AReduce pollutionEliminate pollutionOrganic chemistryOrganic compound preparationFiltrationSolvent

The invention relates to a preparation method of 2-nitro-4-methylsulphonylbenzoic acid. The preparation method comprises the steps of using 2-nitro-4-methyltolylsulfone as a raw material in a reactor under the 5-75 atmospheric pressure at the temperature of 110-450 DEG C, feeding air, oxygen-enriched air or oxygen which serves as oxidizing gas, using low-grade carboxylic acid as a solvent, adopting heteropolyacid, transition metal and halide to form a multi-element homogeneous catalysis system, producing gas-liquid reaction to convert 2-nitro-4-methyltolylsulfone in reaction liquid into the 2-nitro-4-methylsulphonylbenzoic acid; performing filtration to obtain a crystallized and sedimented 2-nitro-4-methylsulphonylbenzoic acid product after the reaction finishes; continuously recycling filtrate, namely supplementing the raw material and then performing oxidizing reaction. The defect that an existing 2-nitro-4-methylsulphonylbenzoic acid producing method causes large exhaust gas and wastewater pollution, severe corrosion, low selectivity, high production cost and the like is overcome, the selectivity is improved, the environmental pollution is reduced, and clean production of the 2-nitro-4-methylsulphonylbenzoic acid is achieved.

Owner:SINOCHEM AGRO +1

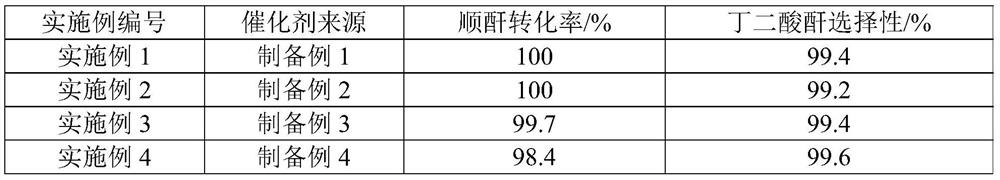

Hydrogenation catalyst, preparation method and application thereof, and method for preparing succinic anhydride through maleic anhydride hydrogenation

PendingCN114433100AHigh activityHigh selectivityOrganic chemistryHeterogenous catalyst chemical elementsPolymer sciencePtru catalyst

The invention relates to the technical field of catalysts, in particular to a hydrogenation catalyst, a preparation method and application thereof and a method for preparing succinic anhydride through maleic anhydride hydrogenation, the catalyst comprises a carrier and active components loaded on the carrier, the active components contain Ni elements, Cu elements and Ce elements, and the carrier contains SiO2; in the catalyst, on the basis of the total weight of the catalyst and in terms of oxide, the content of the Ni element is 10-40 wt%, the content of the Cu element is 1-5 wt%, the content of the Ce element is 1-8 wt%, and the content of the carrier is 47-88 wt%. The catalyst provided by the invention has excellent catalytic activity and succinic anhydride selectivity, is low in cost and simple in process, and can be applied to continuous large-scale production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrogenation catalyst, preparation method and application thereof, and method for preparing succinic acid through maleic anhydride hydrogenation

ActiveCN114433127AHigh catalytic activityImprove stabilityHeterogenous catalyst chemical elementsPreparation from carboxylic acid anhydridesPolymer sciencePtru catalyst

The invention relates to the technical field of catalysts, in particular to a hydrogenation catalyst, a preparation method and application thereof and a method for preparing succinic acid through maleic anhydride hydrogenation, the catalyst comprises a carrier and active components loaded on the carrier, the active components contain oxides of Ce, Ni and Ru, and the carrier contains SiO2; ru is distributed on the outer layer of the catalyst, and oxides of Ni and Ce are distributed in the catalyst; in the catalyst, relative to the carrier, the content of Ni is 1-15 wt%, the content of Ce oxide is 0.5-7 wt%, and the content of Ru is 0.1-2 wt%. The hydrogenation catalyst has excellent catalytic activity, stability and succinic acid selectivity, and is low in cost and simple in process. The catalyst provided by the invention can be used for preparation of succinic acid by continuous hydrogenation of maleic anhydride at a low catalytic reaction temperature (70-180 DEG C).

Owner:CHINA PETROLEUM & CHEM CORP +1

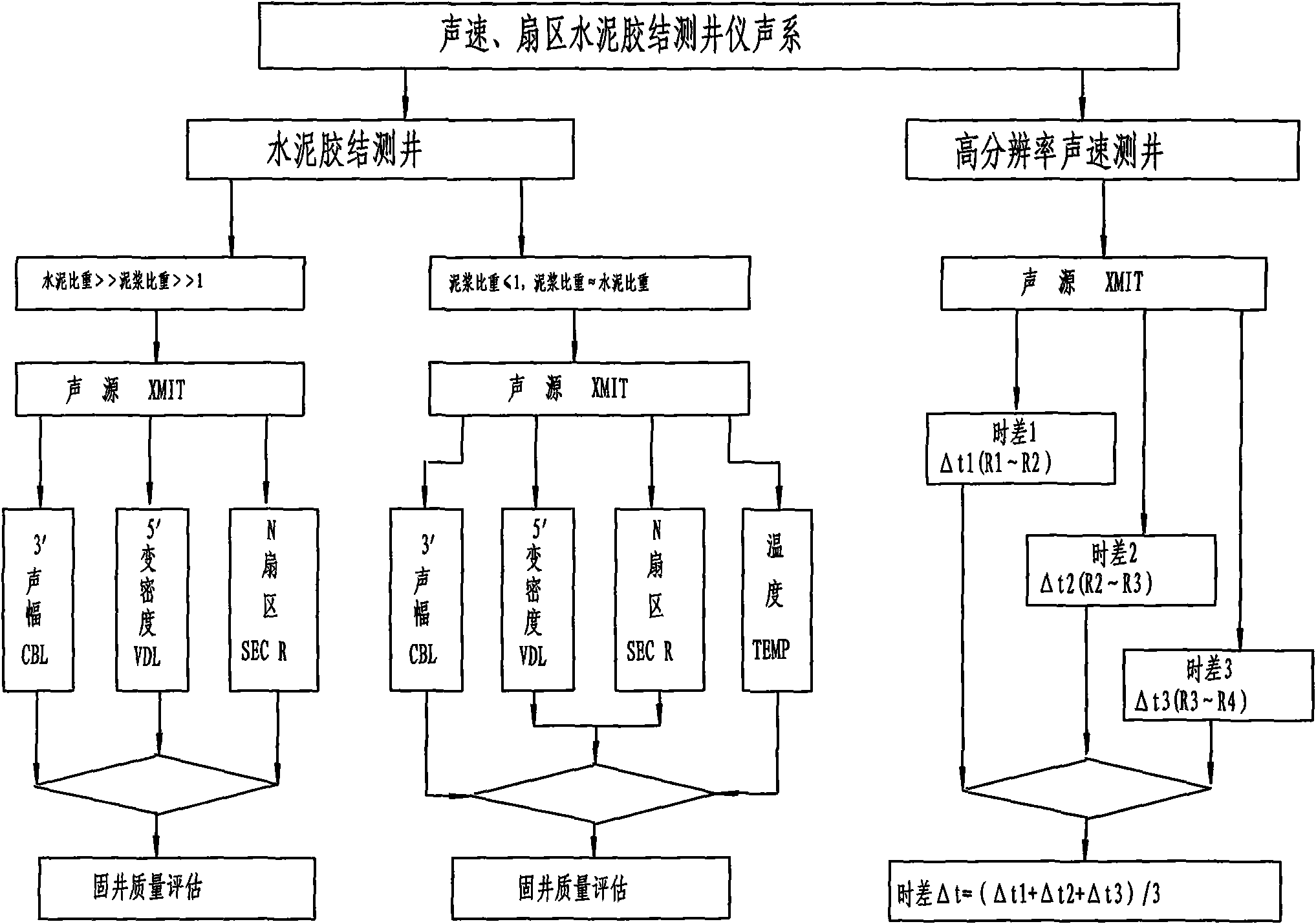

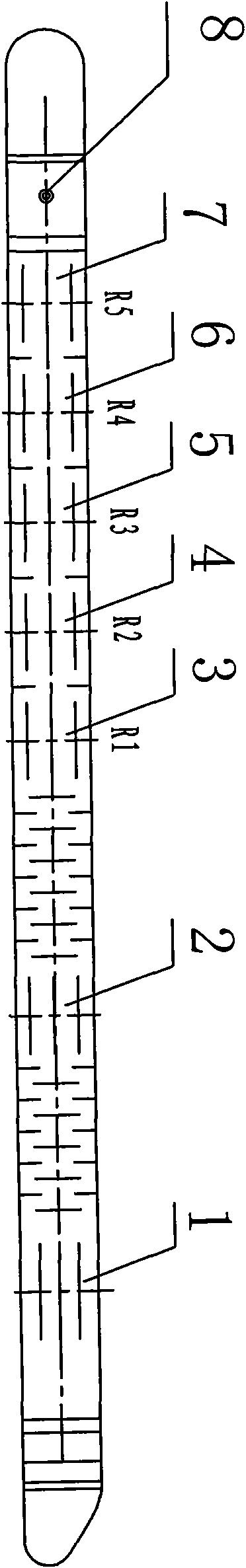

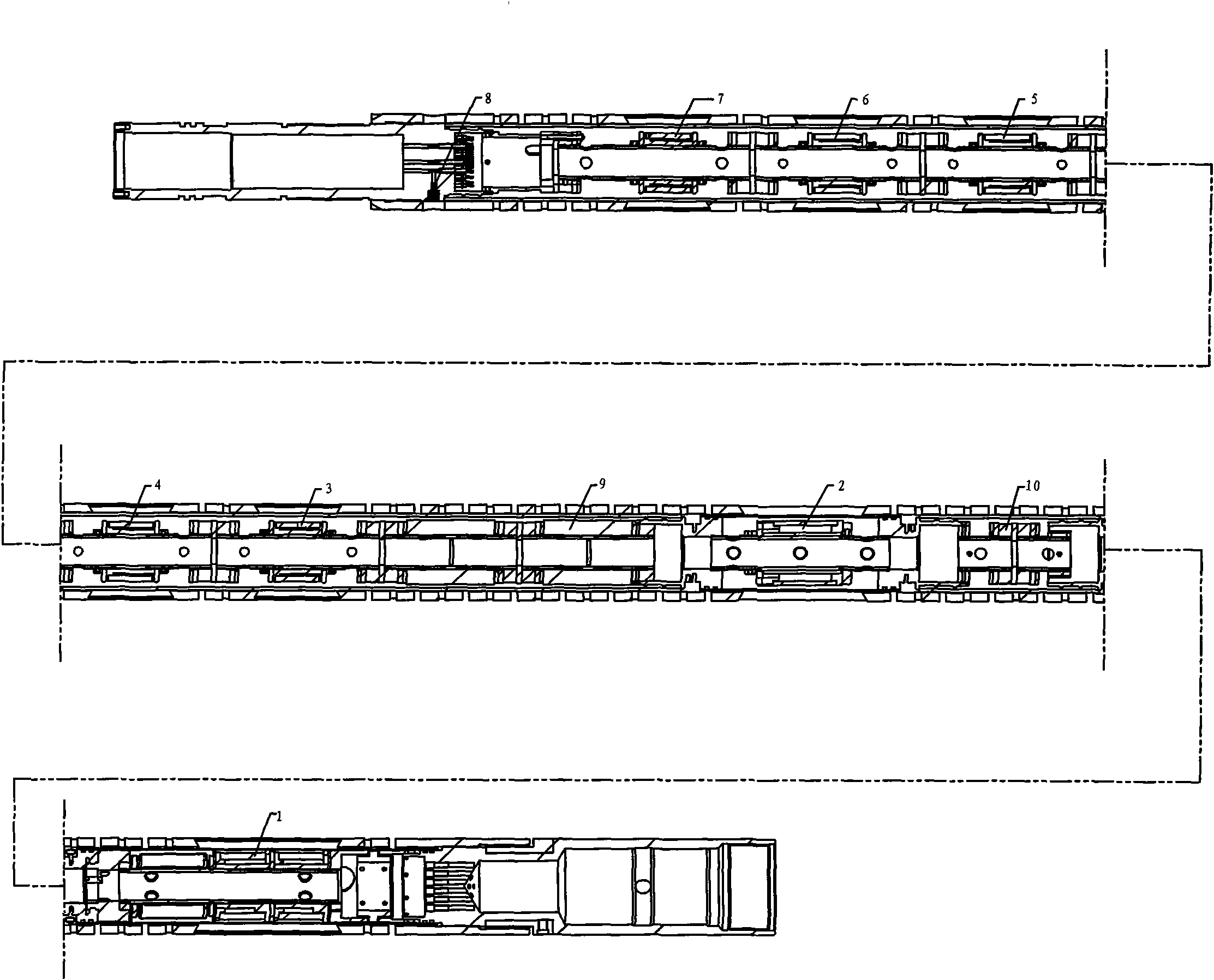

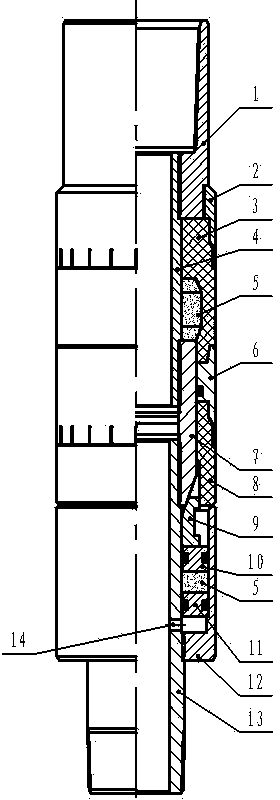

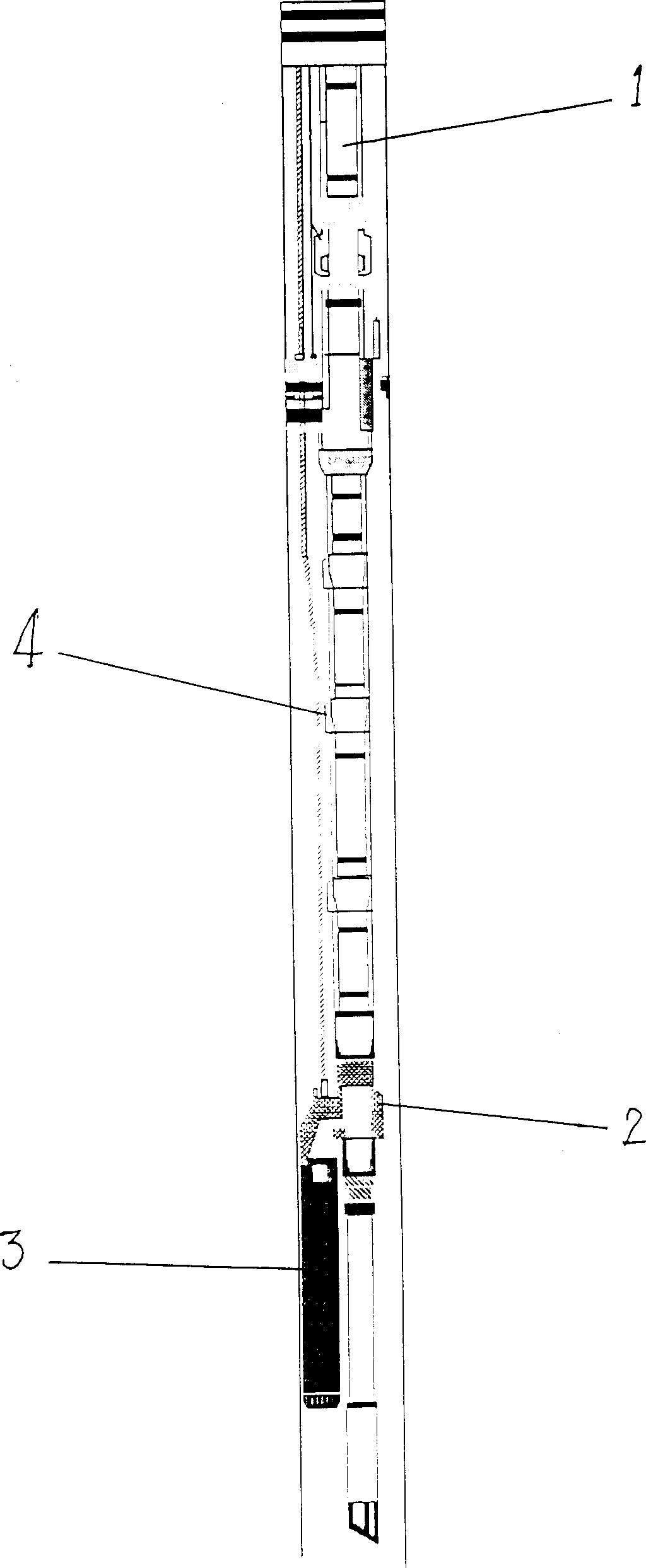

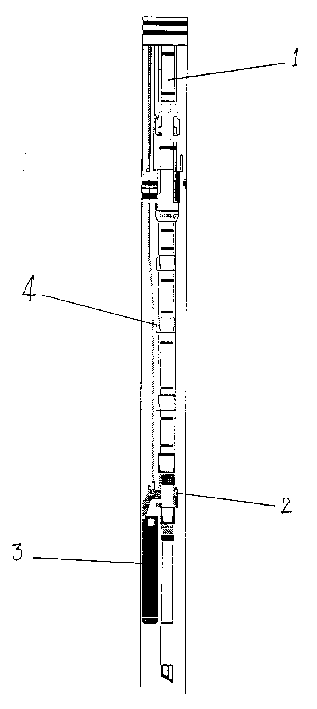

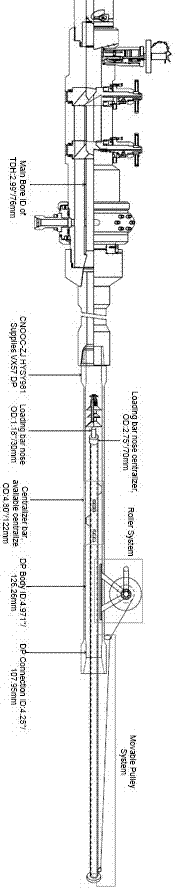

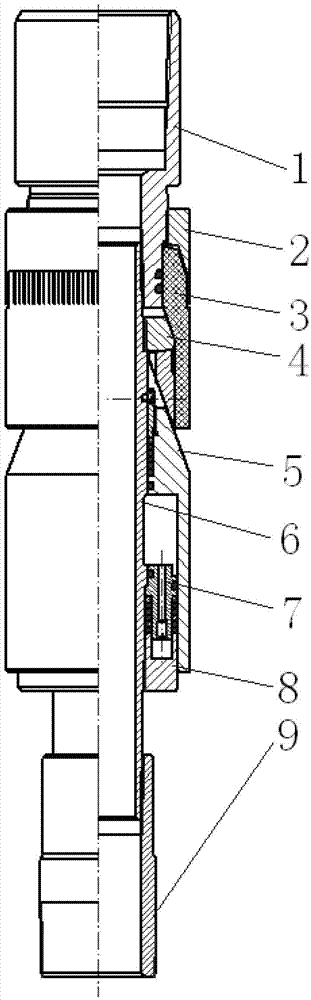

Acoustic system structure of acoustic velocity-segmented cement bond logging tool and logging method

InactiveCN102071932AImprove efficiencyReduce production operation costSurveyBond qualityTemperature curve

The invention discloses an acoustic system structure of an acoustic velocity-segmented cement bond logging tool and a logging method. The acoustic system consists of a transmitting probe, a segmented receiving probe 18 feet away from the transmitting probe, five receiving probes and a temperature probe, wherein the five receiving probes are 3 to 5 inches away from the transmitting probe respectively, and are distributed at an equal interval. In the logging method used for cement bond logging, an acoustic amplitude cement bond logging (CBL) signal and a variable density logging (VDL) signal are detected; the segmented receiving probe 18 feet away from the transmitting probe is arranged, and consists of N radial probes, and each probe covers a radial 360 / N-degree range of the circumference of a sleeve; and a real-time temperature curve in a well is detected by the temperature probe to accurately evaluate bond quality. The acoustic system structure and the logging method have the advantages that: high-resolution acoustic velocity logging and segmented cement bond logging are integrated so as to overcome the shortcomings of the conventional product, increase the utilization rate of the logging tool and reduce the production operation cost.

Owner:杭州瑞利声电技术有限公司

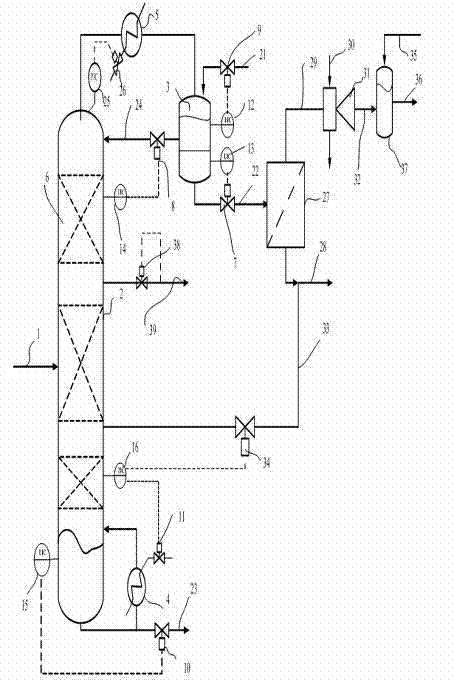

Treatment method for inferior heavy oil and residual oil

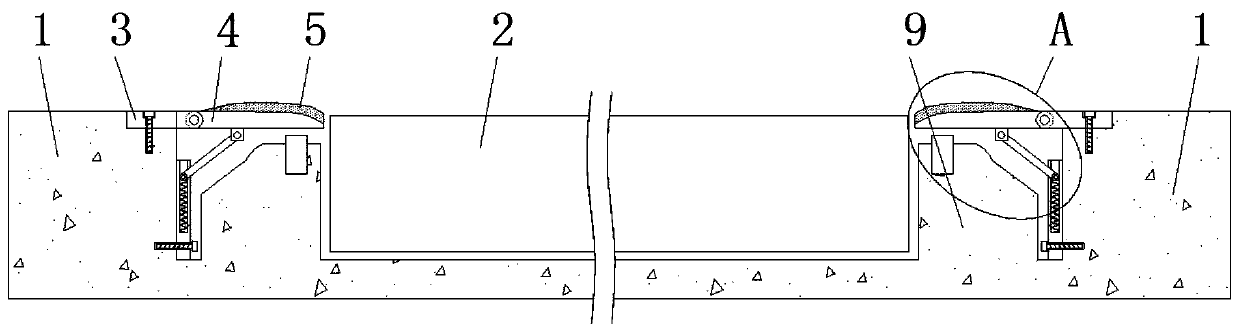

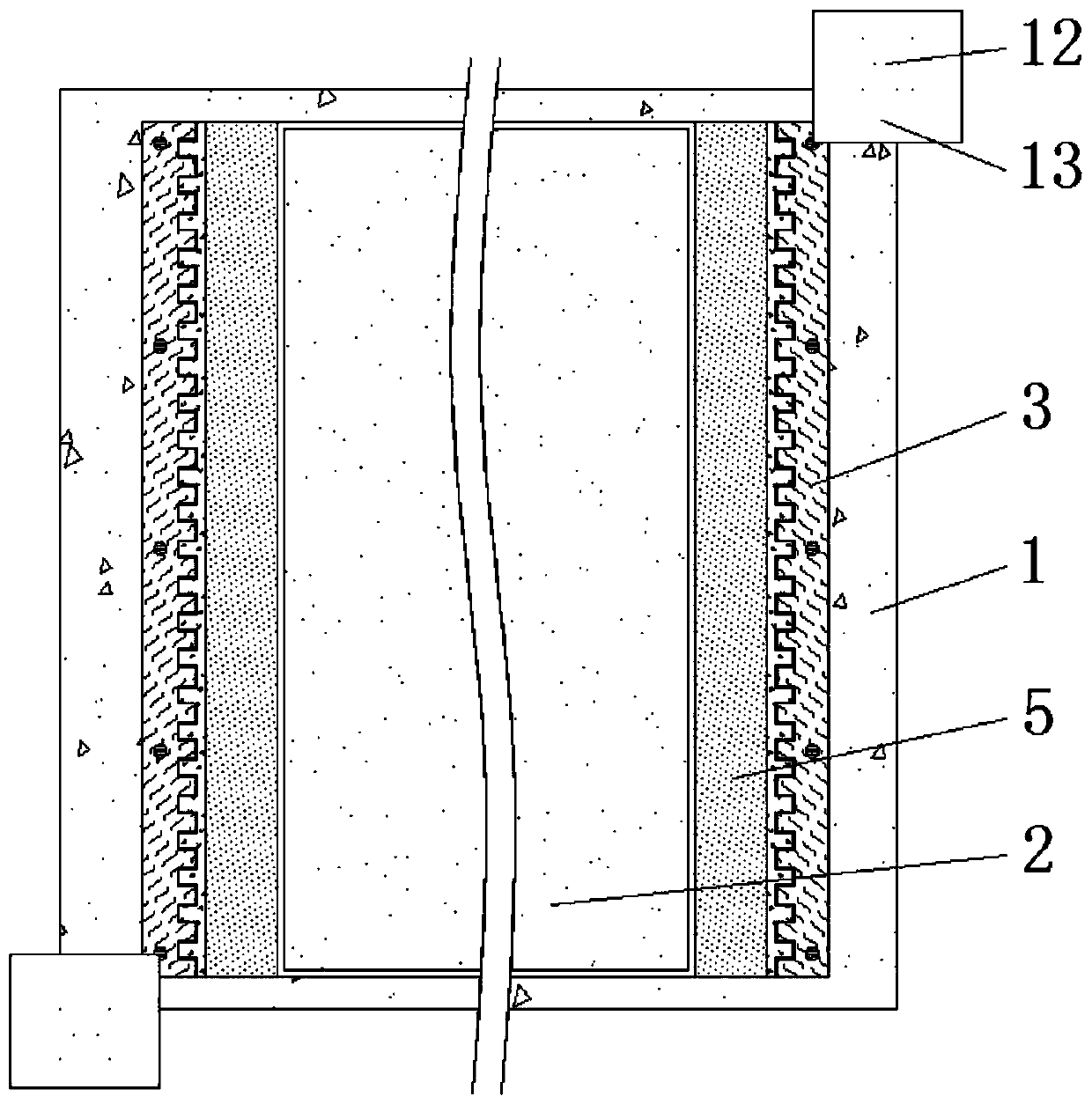

ActiveCN100340643CExpand sourceQuality improvementTreatment with hydrotreatment processesFixed bedSlurry

The invention discloses a process for treating inferior heavy oil and residual oil comprising the following steps: loading heavy oil and petroleum residue into a solvent extraction apparatus, charging the obtained deasphalted oil into a fixed bed for hydrotreatment, entering the obtained tail oil into a catalytic cracking device, loading part or total slurry oil and de-oiled asphalt into a floating bed hydrogenation unit, separating the outcome yield to obtain lightweight fraction and untransformed tail oil, which is circulated to the solvent extraction device.

Owner:CHINA PETROLEUM & CHEM CORP +1

Double-stage self-sealing thermal recovery packer

InactiveCN103696728AImprove the effect of heavy oil recoveryRealize automatic settingFluid removalSealing/packingUpper jointEngineering

The invention relates to a double-stage self-sealing thermal recovery packer which is a down-hole tool for heavy oil thermal recovery and comprises an upper joint, an upper sheath, an upper sealing sleeve, an upper central tube, expansion solid, a lower sheath, an inner cone, a lower sealing sleeve, a combined slider, an upper piston, a lower piston, a cylinder and a lower central tube. The upper joint, the upper central tube, the inner cone and the lower central tube are sequentially connected with one another in a threaded manner from top to bottom, the upper sheath is connected onto the upper joint, the upper sealing sleeve is arranged in the upper sheath, the corresponding expansion solid is filled in the upper sealing sleeve, the lower sheath is respectively connected with the upper sealing sleeve and the lower sealing sleeve in an interference manner, the lower sheath and the lower sealing sleeve are sleeved on the inner cone, the cylinder is connected with the lower central tube in a threaded manner, the combined slider, the upper piston and the lower piston are sequentially arranged inside the cylinder from top to bottom, and the corresponding expansion solid is arranged between the upper piston and the lower piston. The double-stage self-sealing thermal recovery packer is of a double-stage sealing structure, accordingly, thermodynamic automatic setting and hydraulic-assisted setting effects can be realized, and the double-stage self-sealing thermal recovery packer has the advantages of short setting time, durability in setting, good sealing performance, smooth unsetting and the like.

Owner:杨德杰

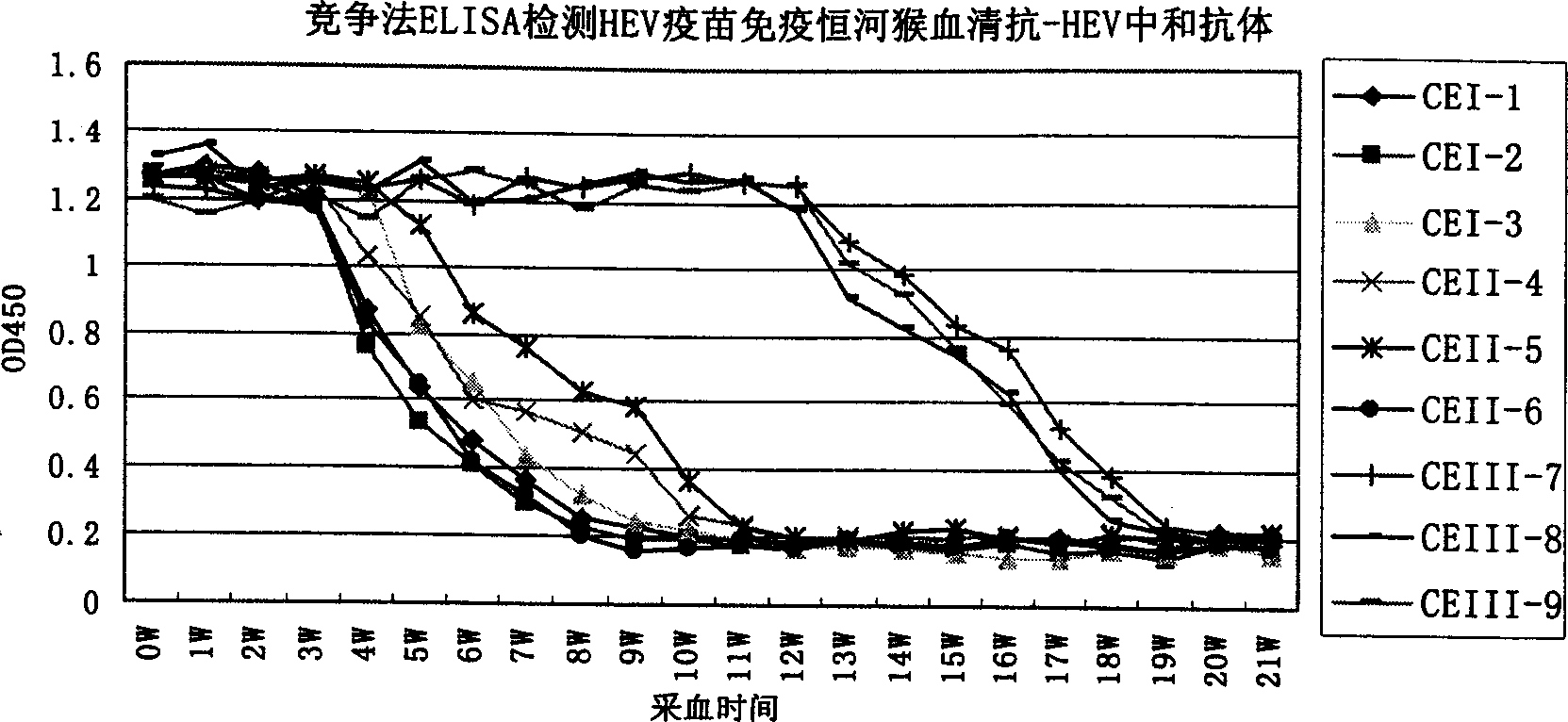

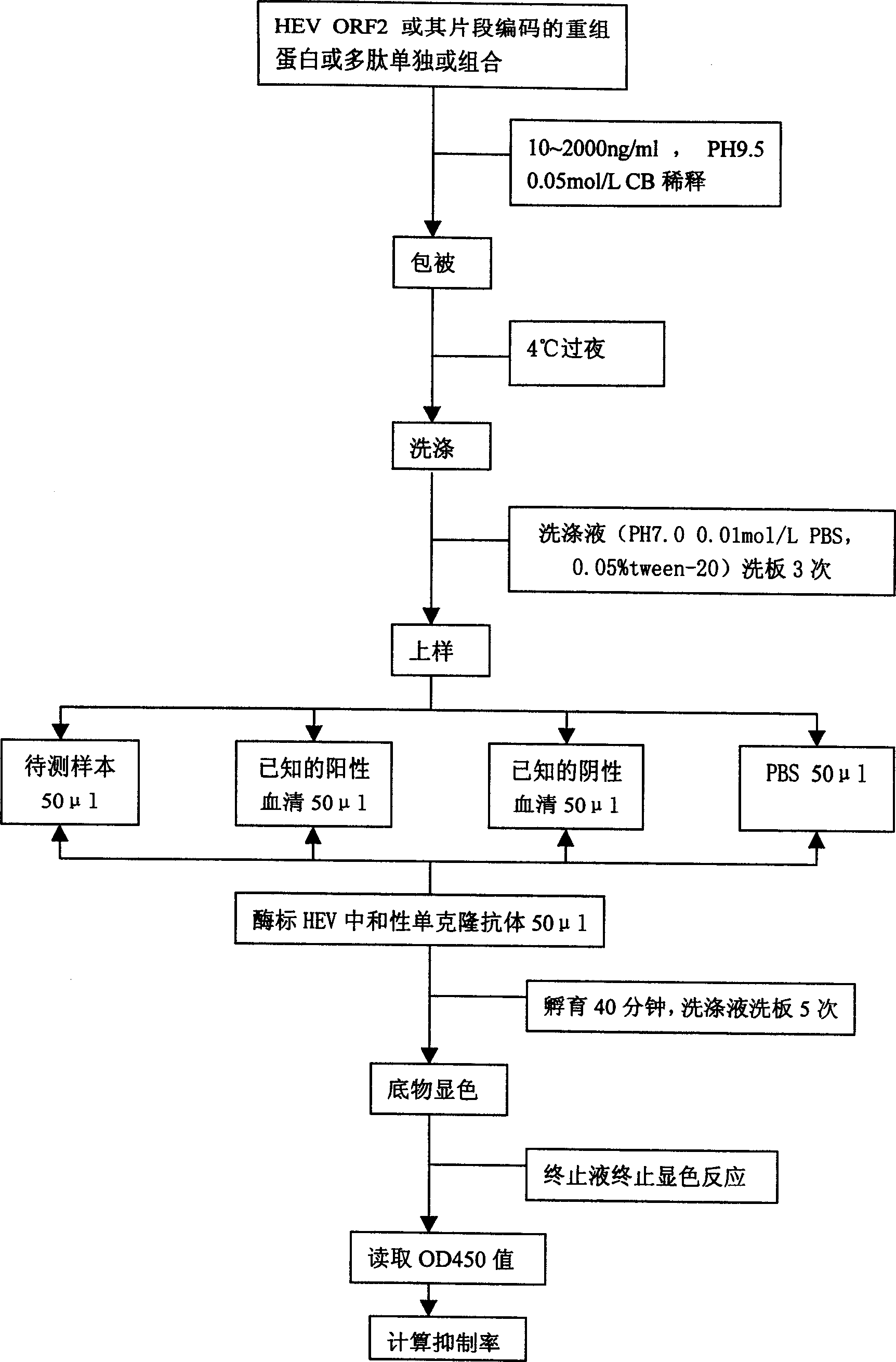

Competitive enzyme-linked immune detection method of hepatitis E virus neutralization antibody

InactiveCN1793929AStrong specificityLow costMaterial analysis by observing effect on chemical indicatorAntigenEnzyme action

A competition enzyme ¿C linked immune detection method of neutralization antibody on hepatitis virus in the fifth type includes competing and combining neutralization antibody resisting hepatitis virus in the fifth type with neutralization single clone antibody of enzyme labeled hepatitis virus in the fifth type to encapsulate neutralization antigen tabular position on antigen, realizing competition enzyme ¿C linked immune detection of neutralization antibody on the fifth type of hepatitis virus in biological sample according to color developing decrease degree of enzyme action substrate.

Owner:SOUTHEAST UNIV

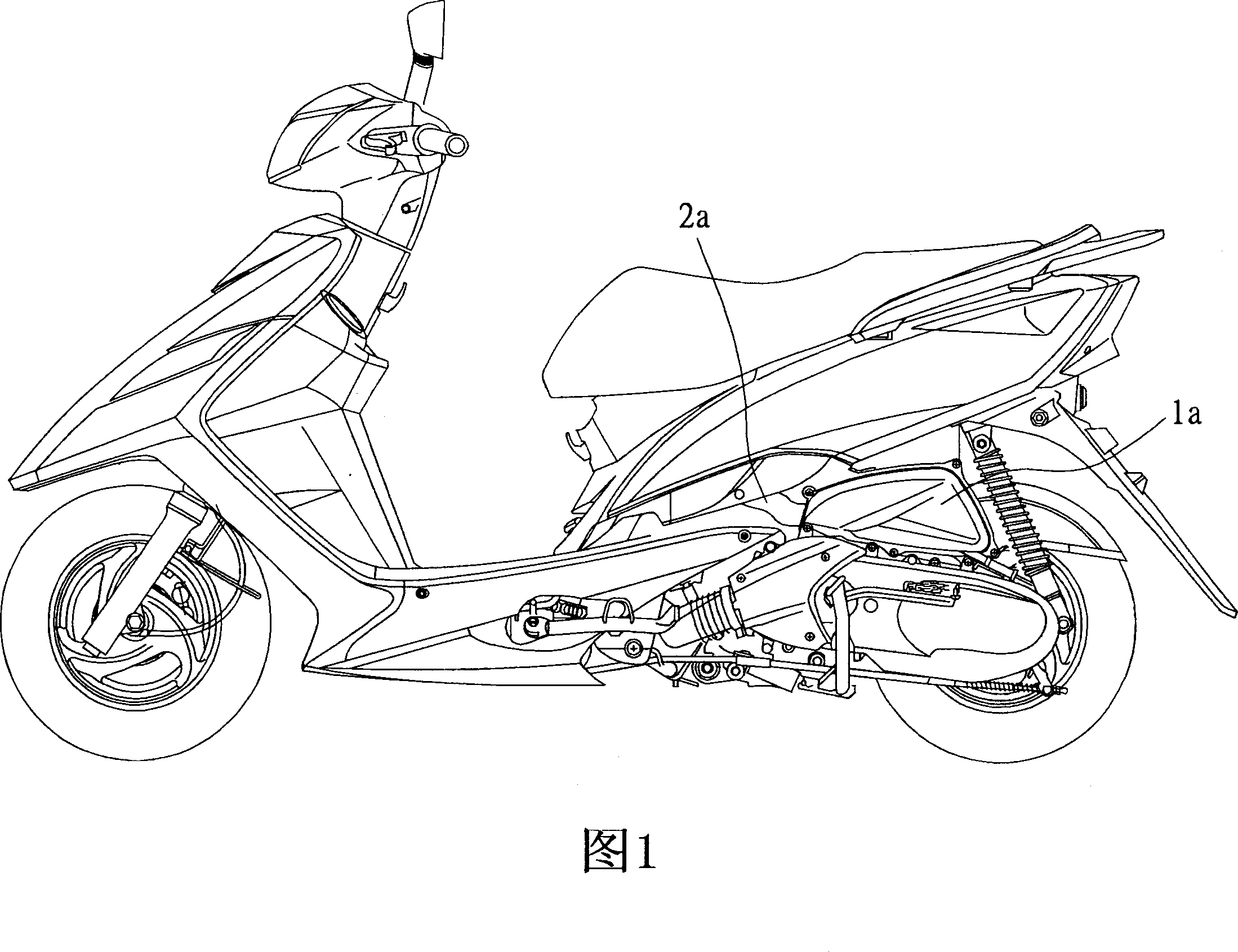

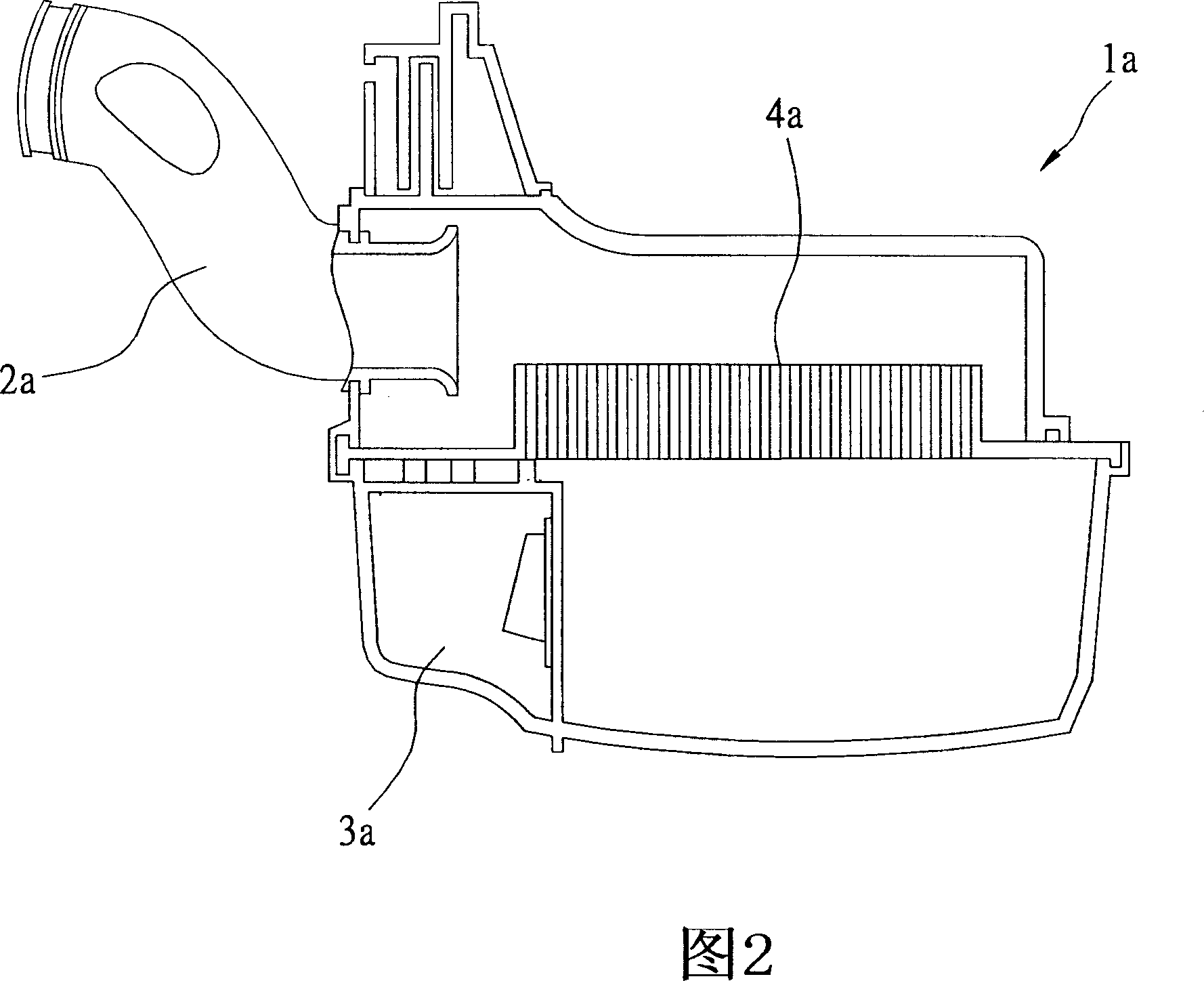

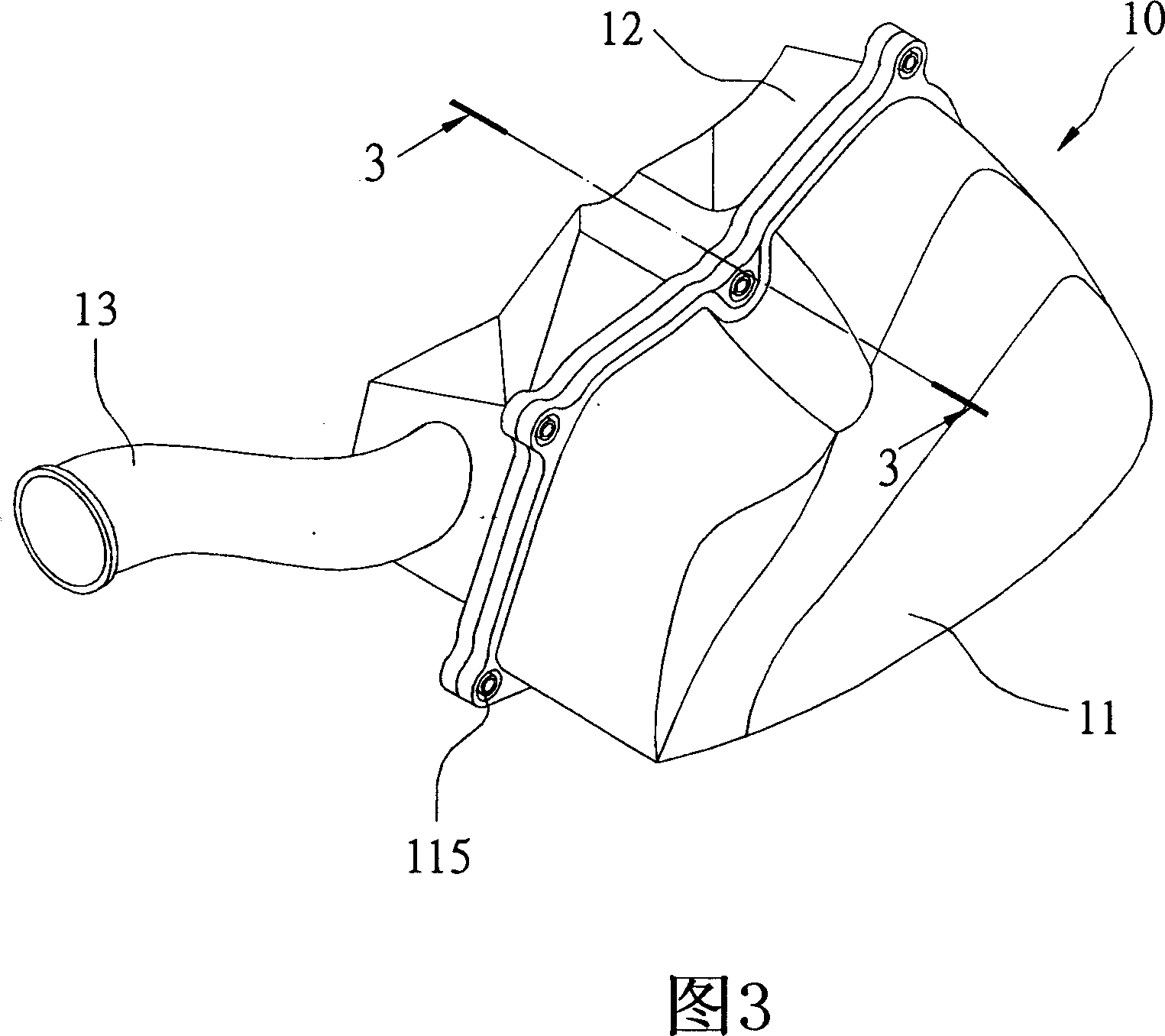

Air filter of sukeda-type locomotive

InactiveCN101070800AWeight increaseImprove combustion efficiencyMachines/enginesAir cleaner and silencer combinationCombustionAir filter

A Ke-Da-speed locomotive's air filter, which includes a main body, several ribs and a strengthening filters. The main dock has the inlet side of a shell and a outgassing side shell. These enhance rib spacing Outgassing installed at the side of the shell wall. The filter installed at the inlet side of the shell and the shell side of the Outgassing between to form a Ke-Da-speed locomotive's air filter, and the air flow rate can be accelerated to improve the efficiency of combustion engine fuel, fuel-efficient vehicles and environmental protection to achieve the purpose, and the main weight of the air filter will not be a substantial increase, and no additional silencers other devices to reduce the cost of production operations, effective reduce noise and the volume.

Owner:YAMAHA MOTOR CO LTD

Method for preparing harmless rock fragments by using well drilling waste liquid and application of rock fragments

ActiveCN103240261AReduce manufacturing costSimple processSolid waste managementSolid waste disposalWell drillingEconomic benefits

The invention discloses a method for preparing harmless rock fragments by using well drilling waste liquid and an application of the rock fragments. The method comprises four steps of separation, oil removal sedimentation, oxidation sedimentation and oxidation adsorption to ensure that the well drilling waste liquid is subjected to harmless treatment, the harmless rock fragments can be separated from the well drilling waste liquid, and the rest is water which can reach an industrial water standard. The harmless rock fragments treated by a harmless technology are used as main materials for preparing dry-mixed mortar. By adopting the method, the phenomena that the petroleum drilling enterprises in the past dig pits for landfill of harmful mixed wastes, the soil is destroyed, the environment is polluted and resources are wasted are avoided; and moreover, a precedent for carrying out harmless comprehensive treatment, recycling waste mixed resources, and promoting the development of cyclic economy for the petroleum drilling enterprises to make money is opened up for the petroleum drilling enterprises, and the method meets the requirements of the strategic planning of energy saving and emission reduction comprehensive utilization during the twelfth five-year of the country. The method has considerable economic benefits and wide market application prospects.

Owner:薛西伟

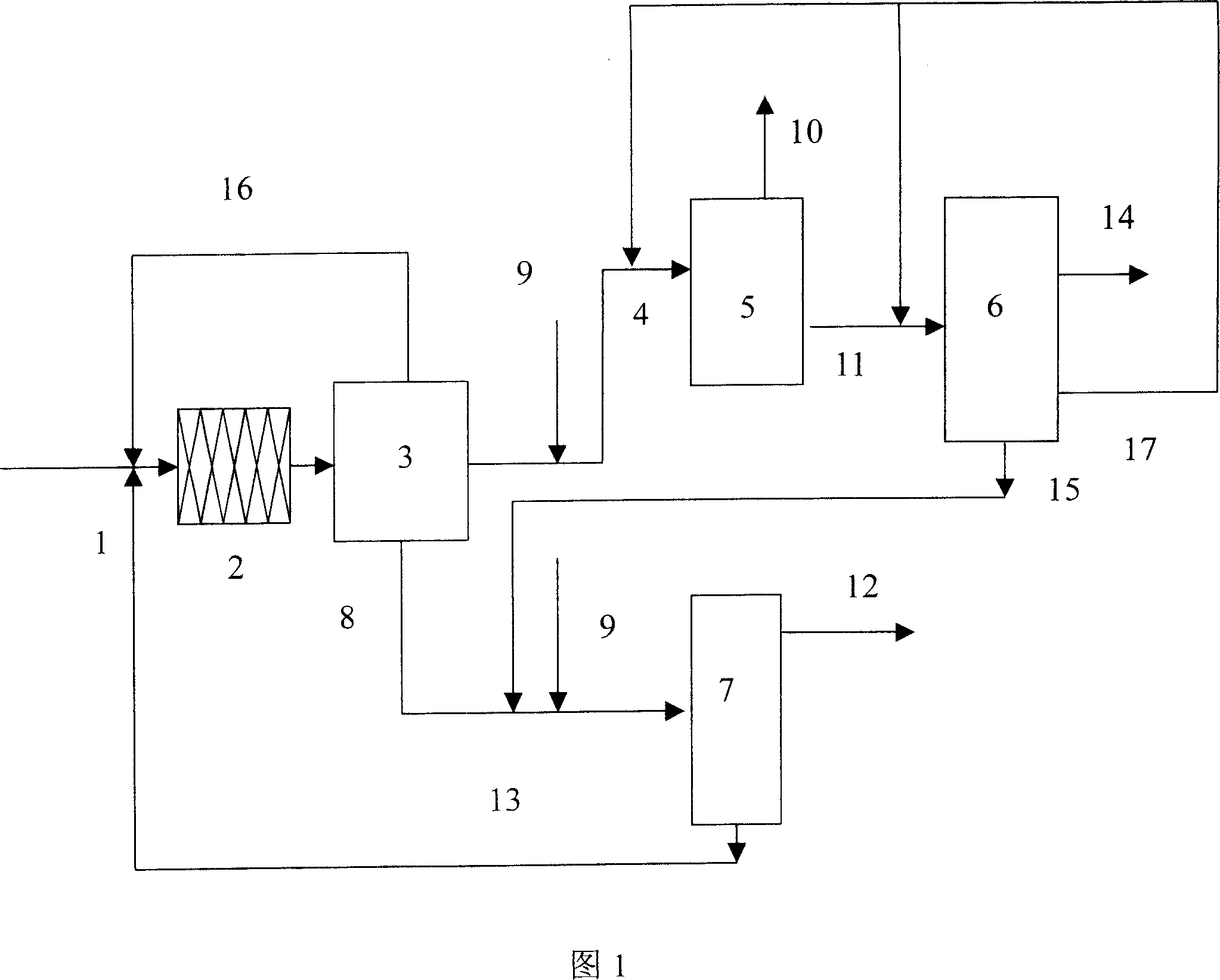

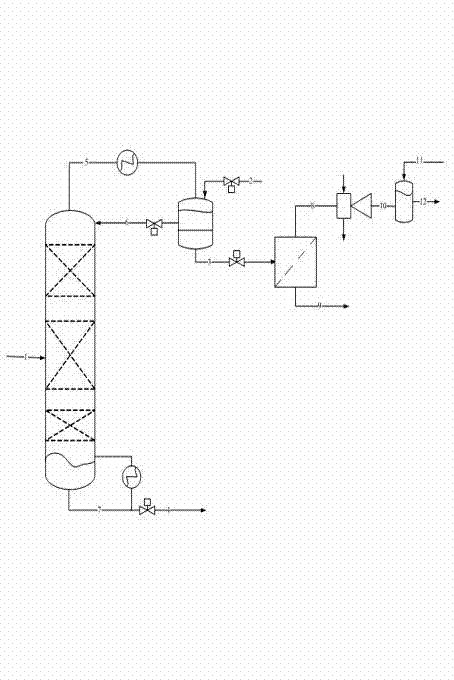

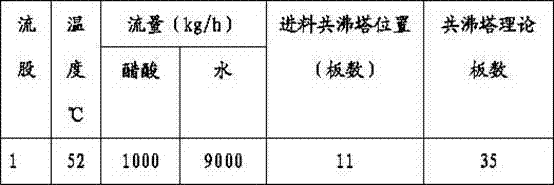

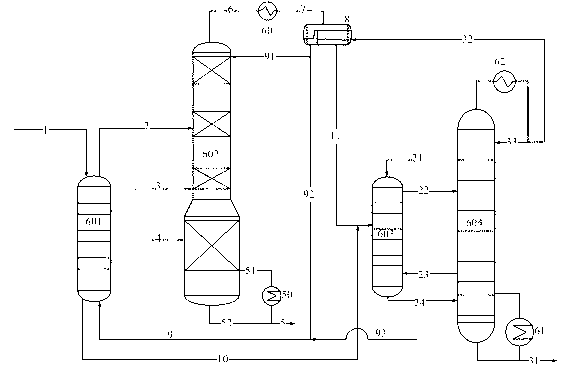

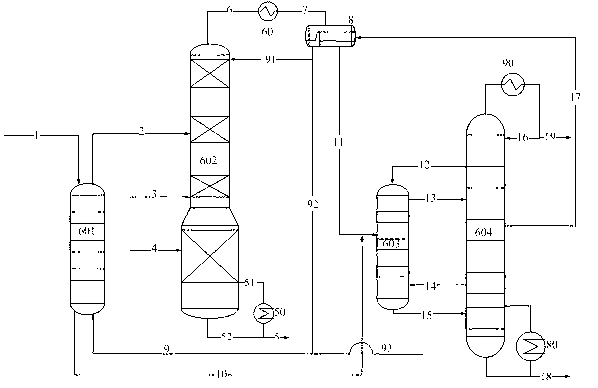

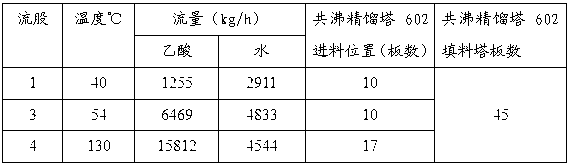

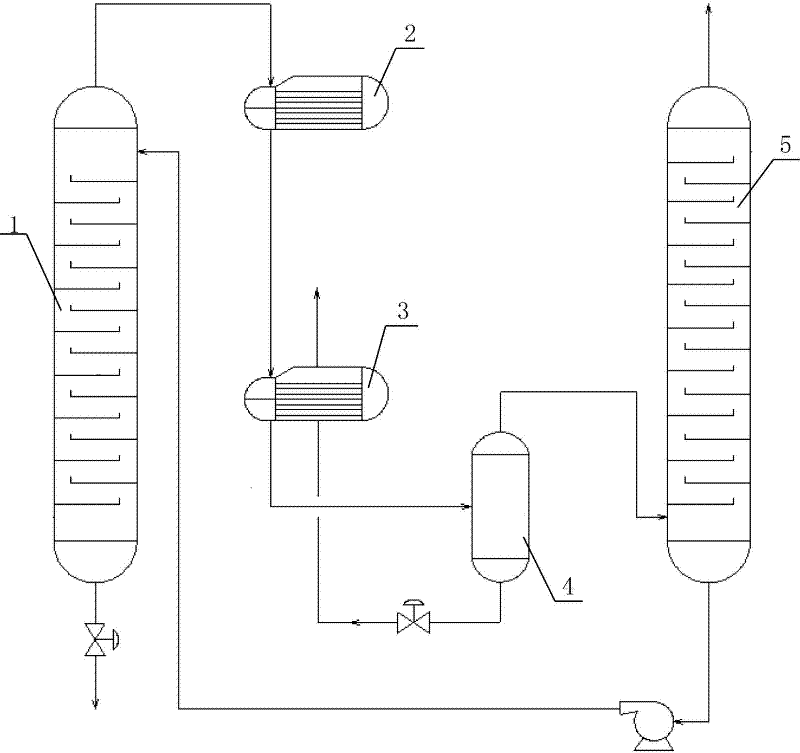

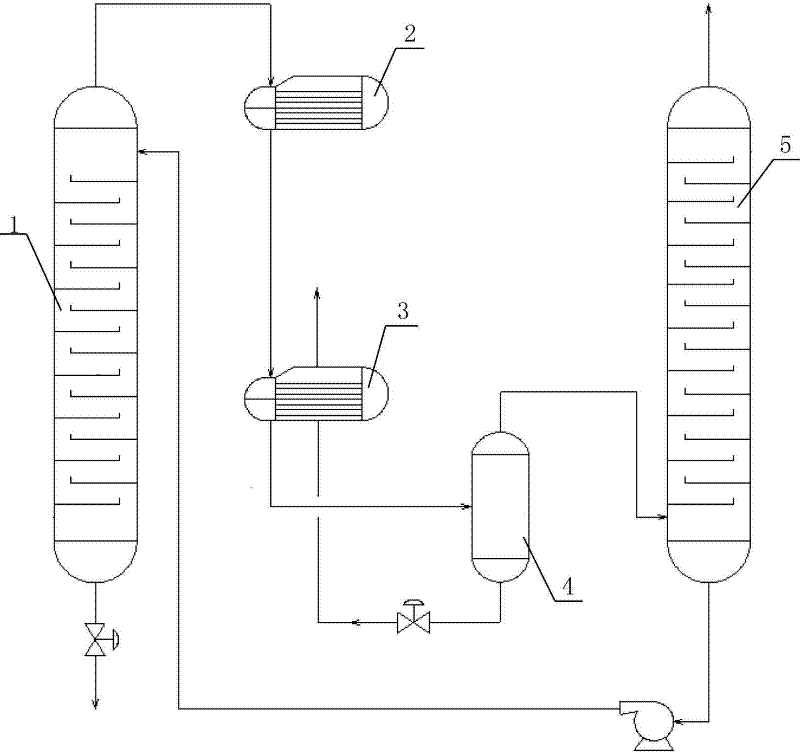

Method for recycling water from separation system for acetic acid and water

ActiveCN102766036AImprove separation efficiencyReduce production operation costOrganic compound preparationCarboxylic compound separation/purificationAcetic acidEthylic acid

The present invention relates to a method for recycling water from a separation system for acetic acid and water. Materials with high water content are added to an azeotropic rectifying column; all light component oil flows back to the azeotropic rectifying column; water phase penetrates into a penetration evaporator; water phase with organic matter content less than 100ppm is obtained at the bottom of the penetration evaporator; an acetic acid solvent basically free of an azeotropic agent can be generated at the bottom of the azeotropic rectifying column, wherein water content of the solvent is controlled at 4-10% (mass percentage); and water with total organic matter content less than 100ppm can be produced at the top of the azeotropic rectifying column. The method provided by the invention can further improve separating efficiency of the separation system for acetic acid and water.

Owner:CHINA PETROLEUM & CHEM CORP +1

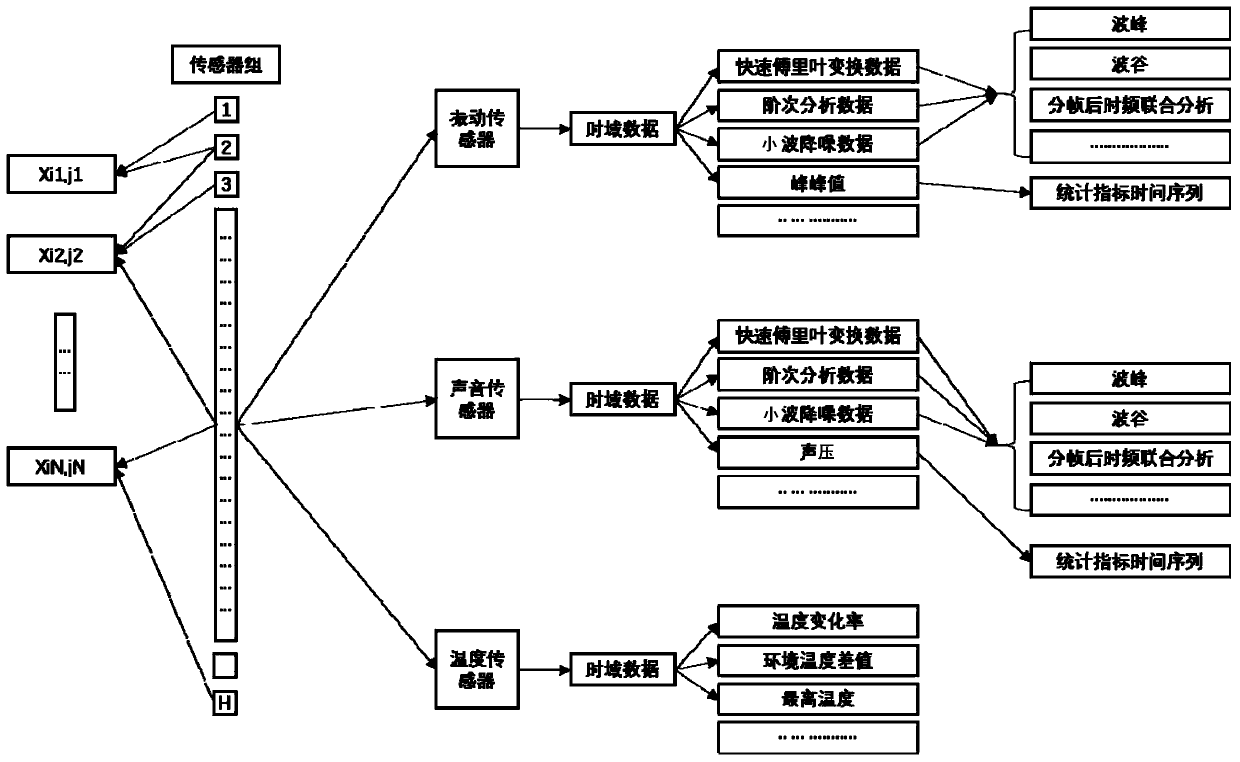

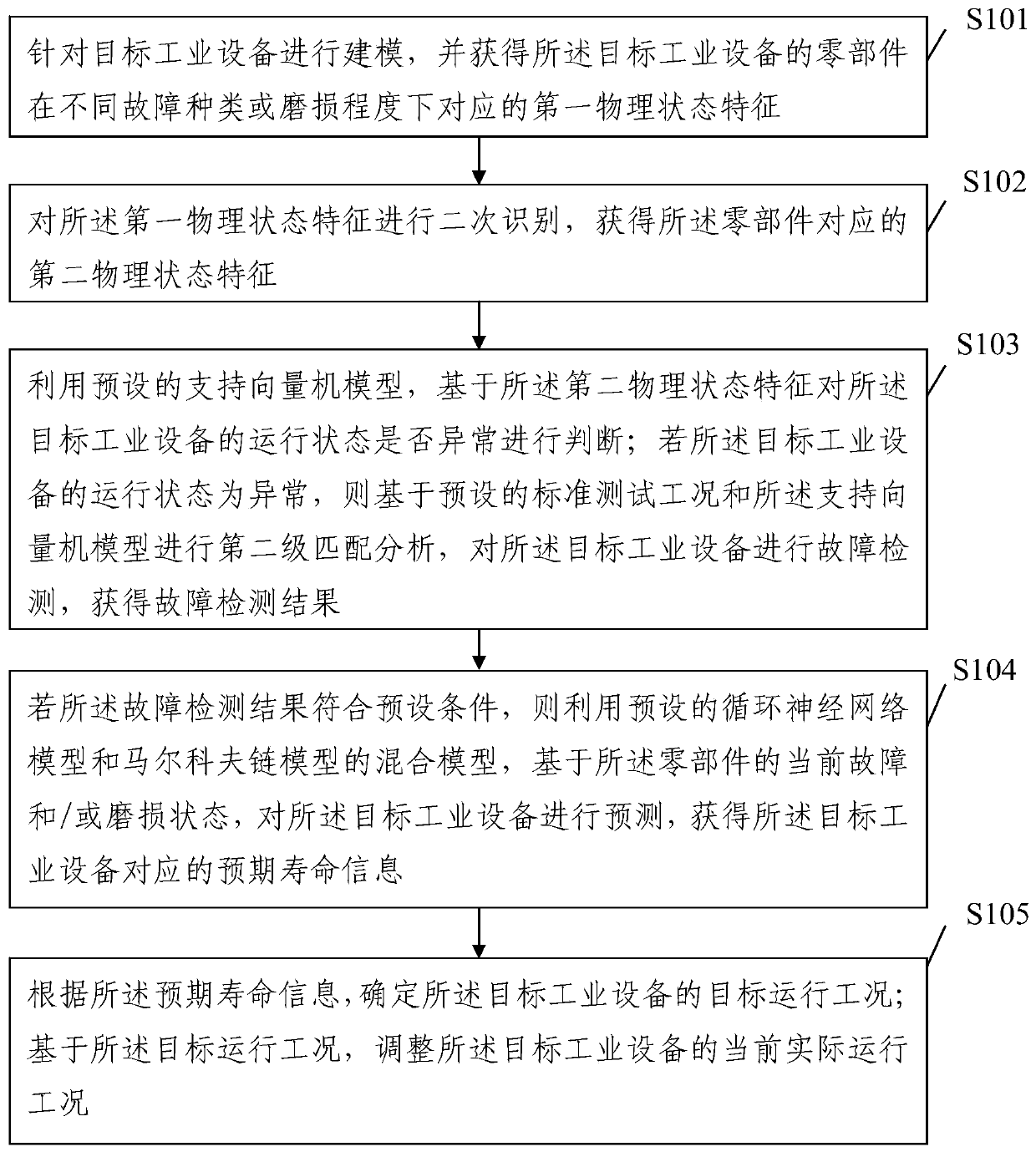

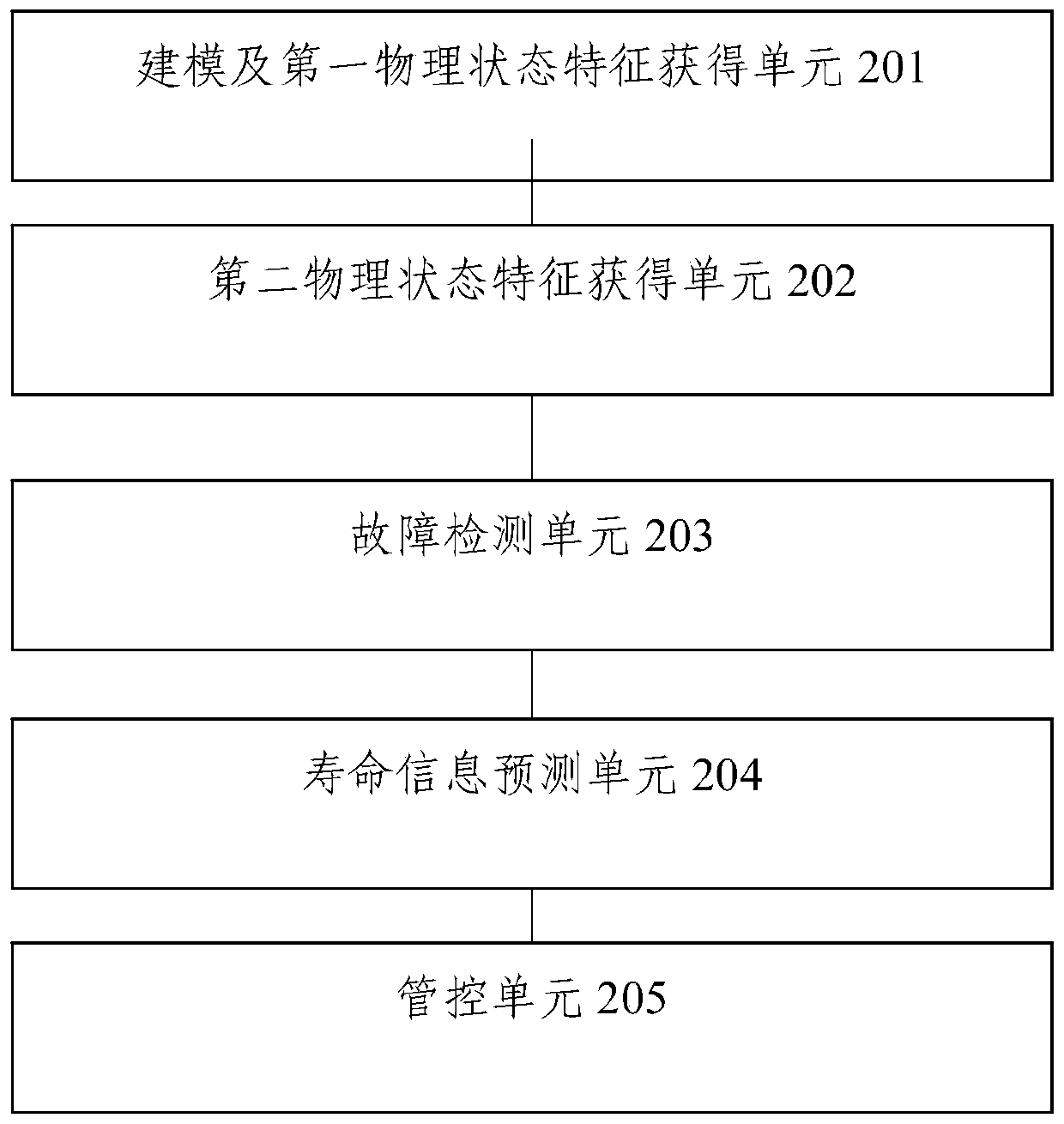

Industrial equipment state management and control method and device integrated with artificial intelligence algorithm

PendingCN111191838AImprove operational efficiencyAccurate analysis and processingMathematical modelsKernel methodsControl engineeringIndustrial equipment

The embodiment of the invention discloses an industrial equipment state management and control method and device integrated with an artificial intelligence algorithm, and the method comprises the steps: carrying out the secondary recognition after obtaining a first physical state feature corresponding to target industrial equipment, and obtaining a second physical state feature; judging the running state of the target industrial equipment based on the second physical state feature, and if the running state is abnormal, performing fault detection on the target industrial equipment based on a preset standard test working condition; if the fault detection result meets a preset condition, predicting the target industrial equipment by utilizing a preset hybrid model to obtain expected life information; determining a target operation condition of the target industrial equipment according to the expected life information; and based on the target operation condition, adjusting the actual operation condition of the equipment. By the adoption of the method, the actual working condition of the industrial equipment can be measured and calculated, then set parameters are corrected, automatic management and control are achieved, and the operation efficiency of the industrial equipment is improved.

Owner:赛腾机电科技(常州)有限公司

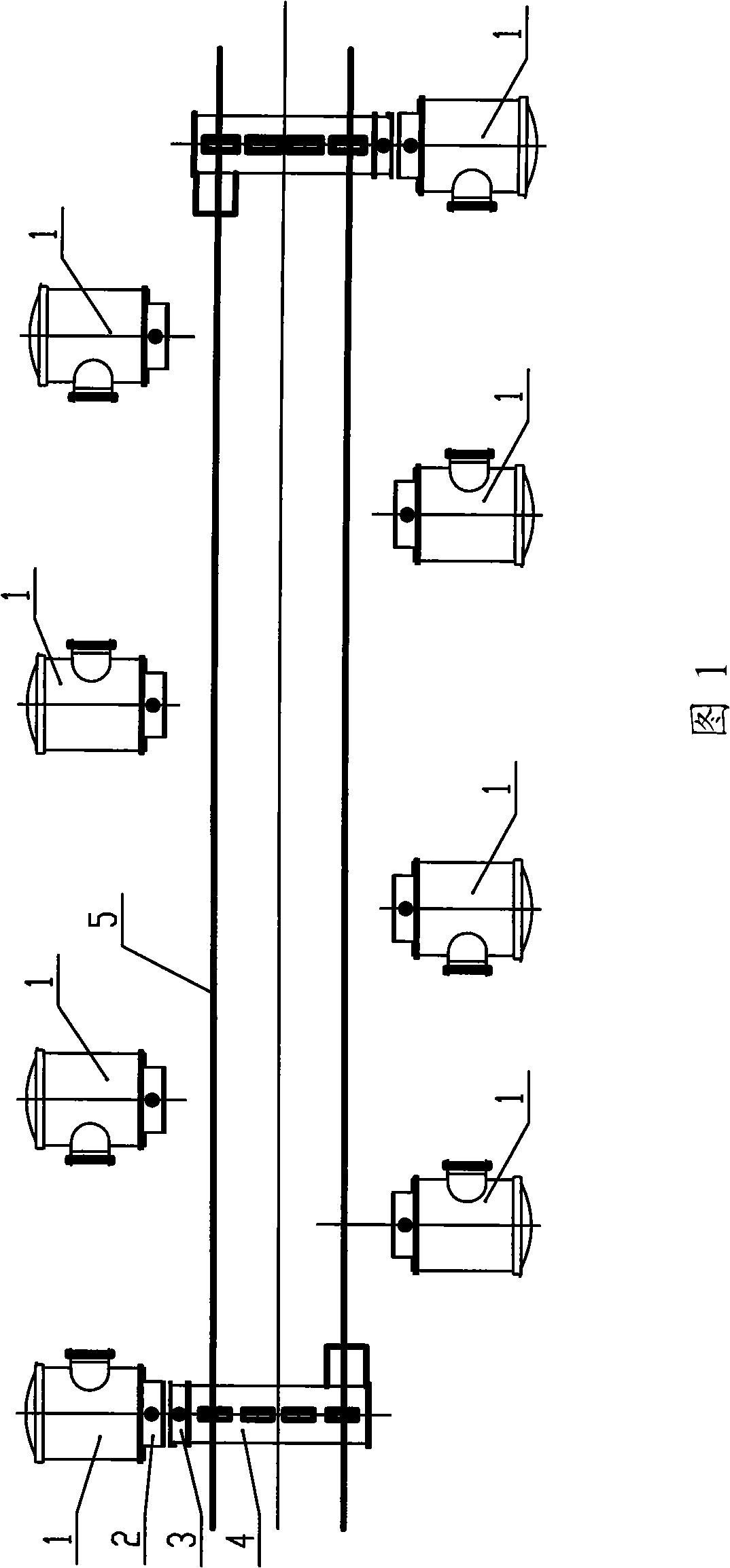

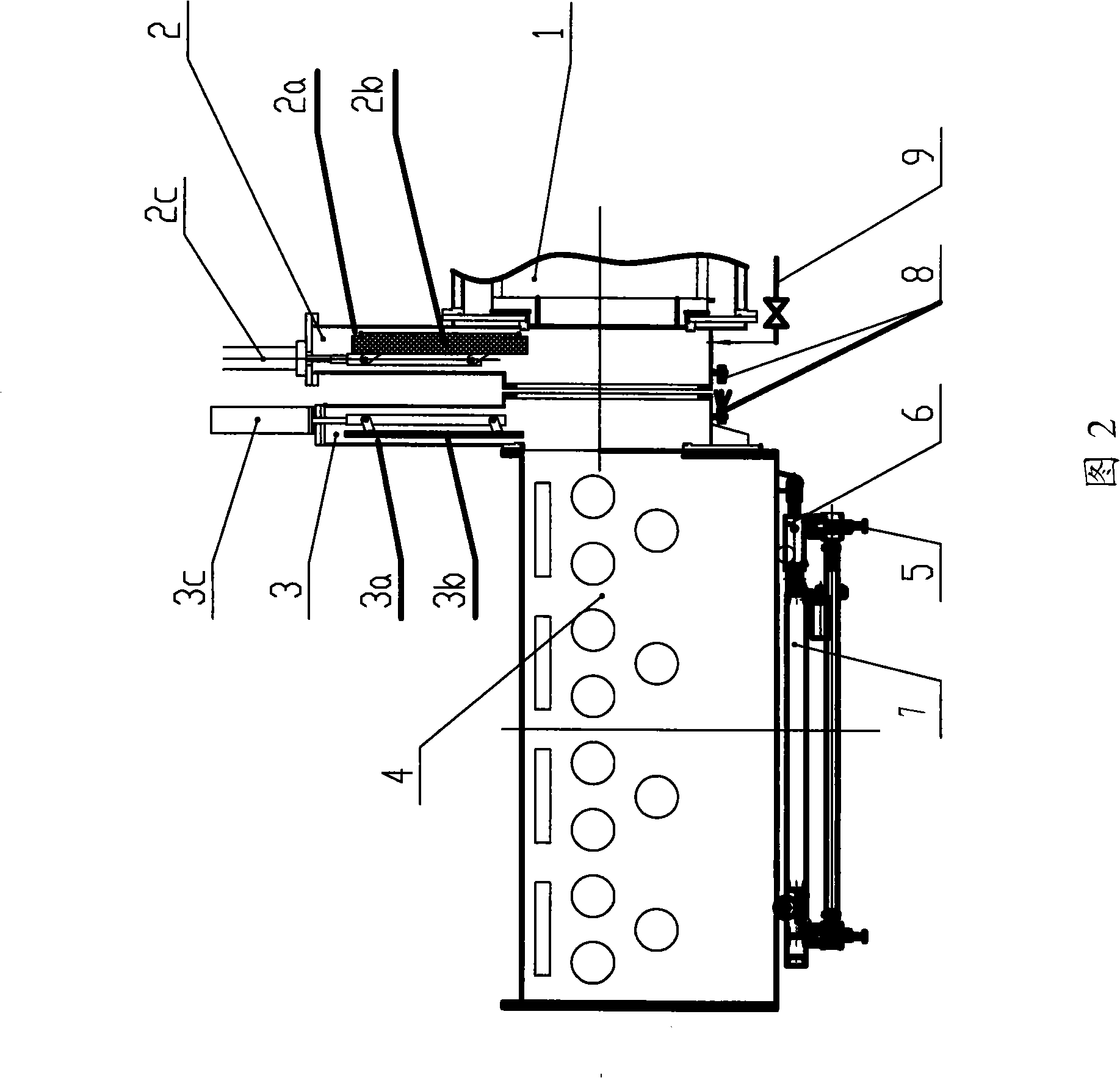

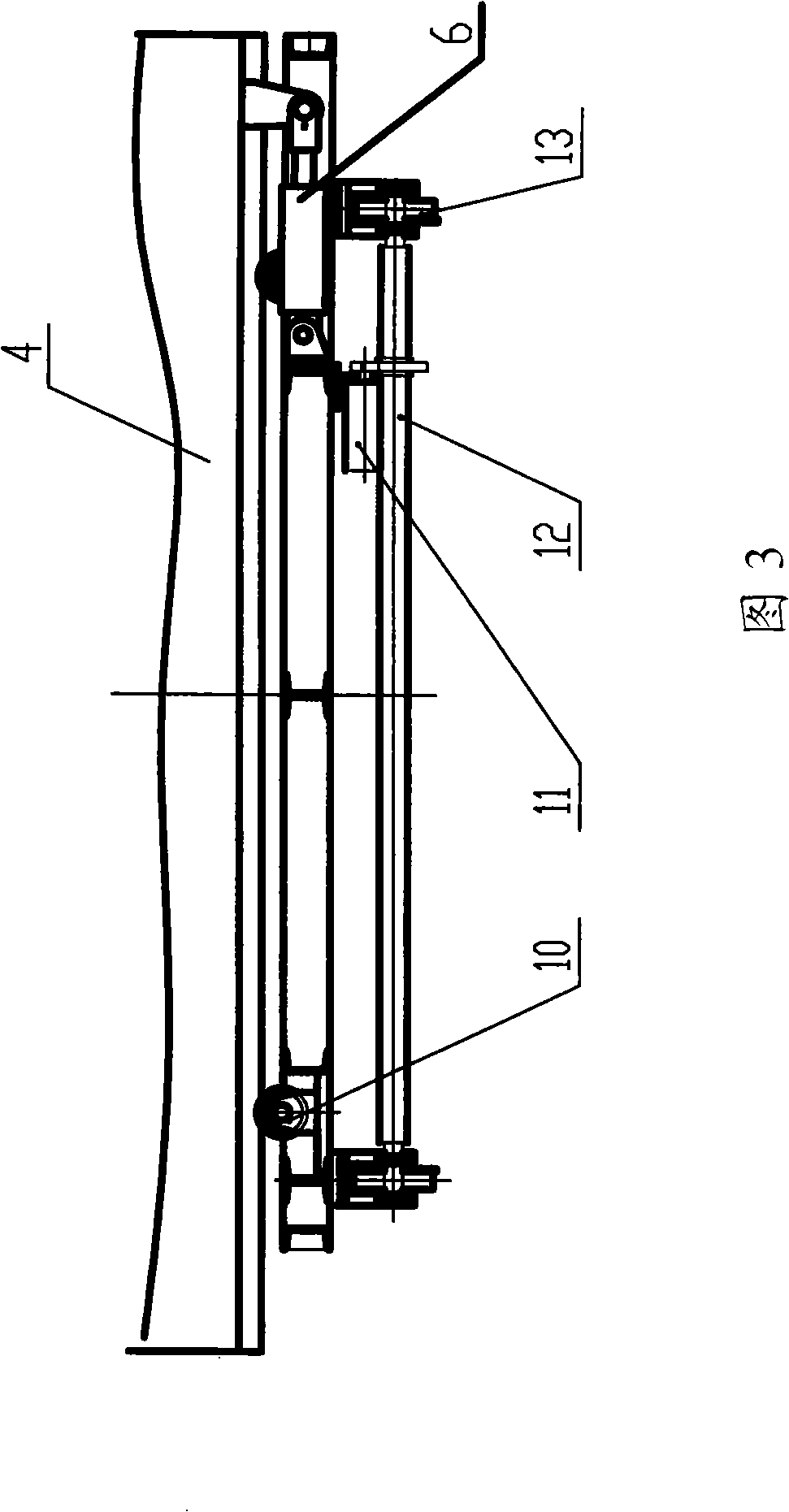

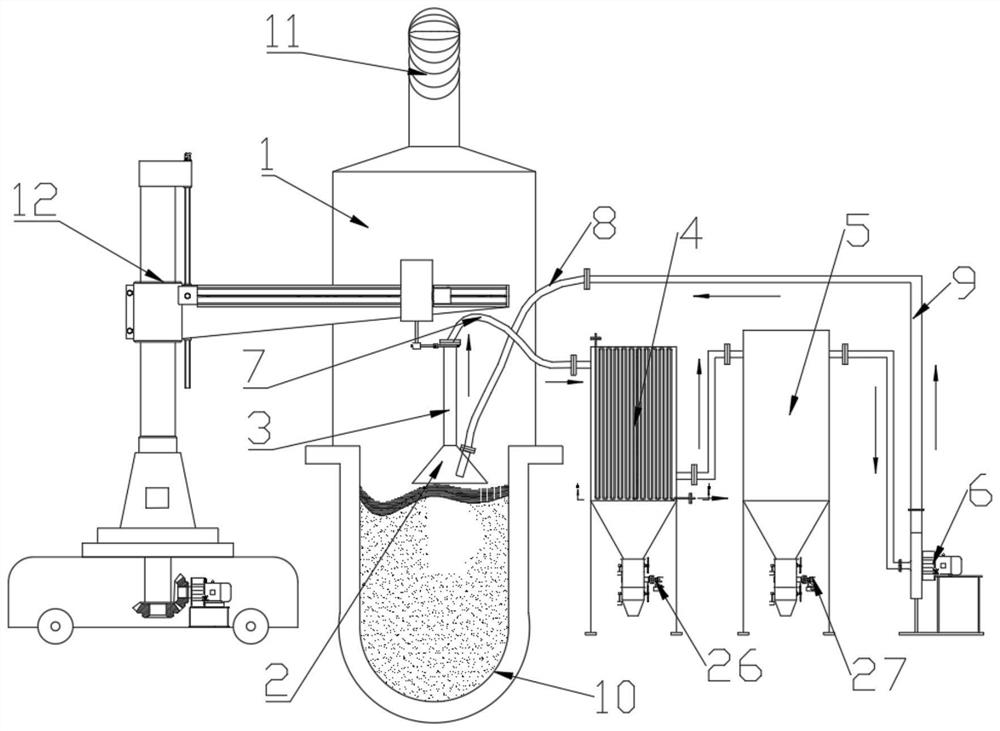

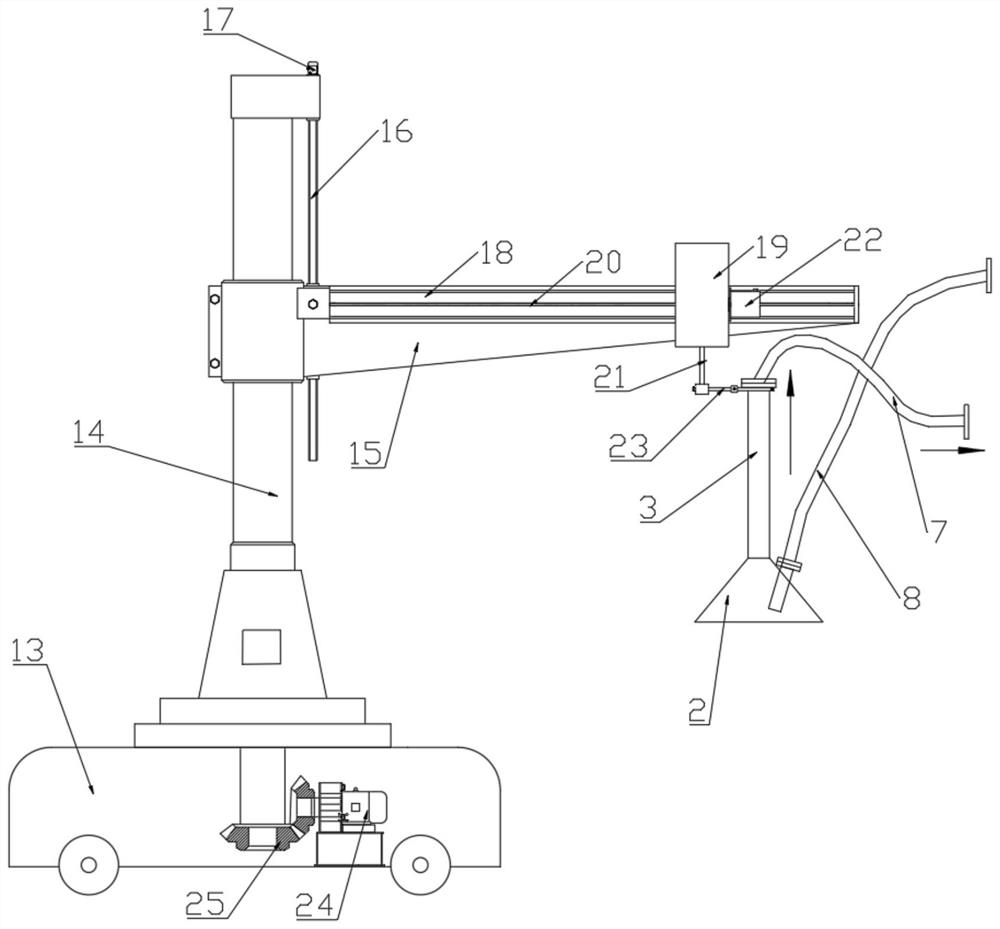

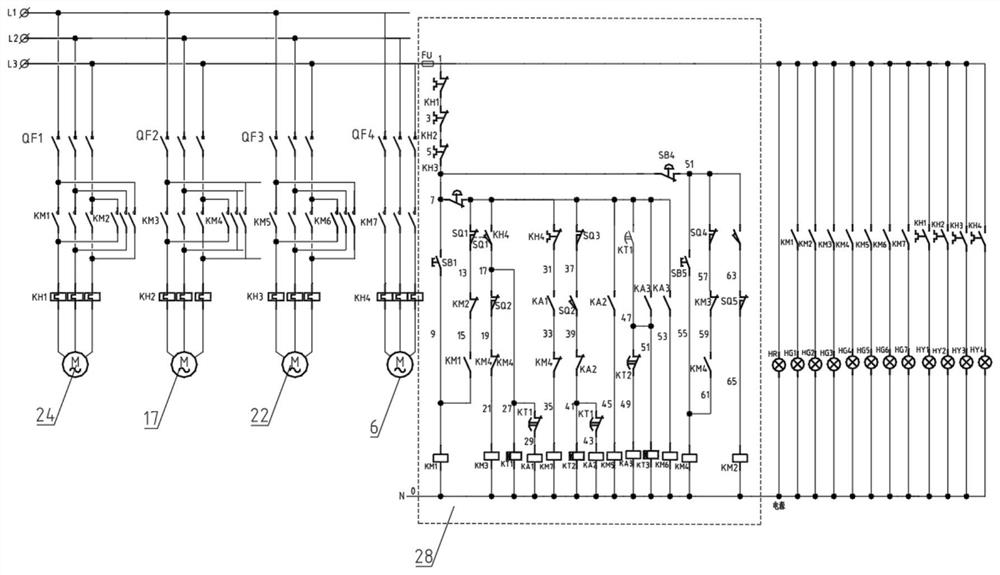

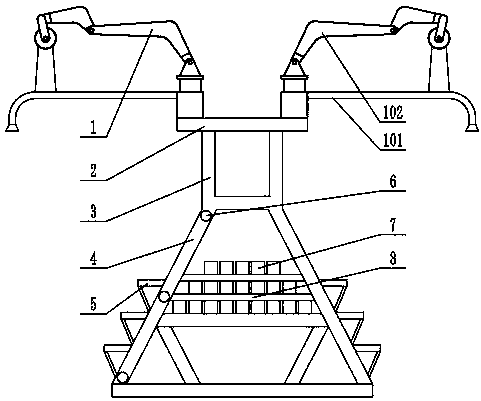

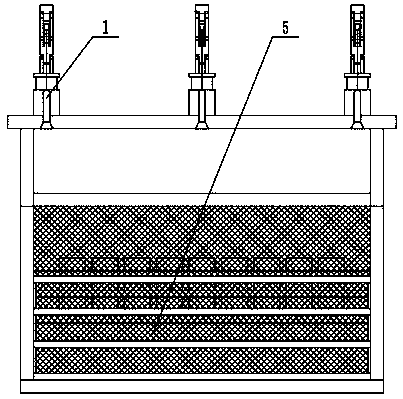

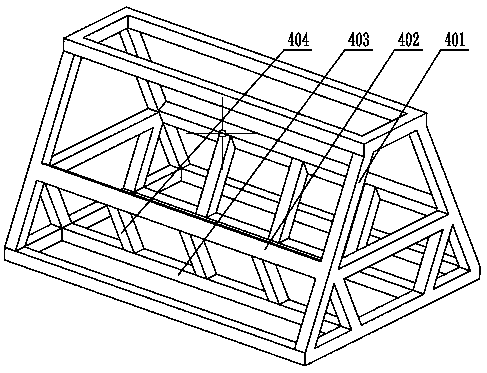

Vacuum sintering cluster system sharing glove box for protecting feed

A vacuum sintering cluster system for sharing a feeding-protective glove box includes a plurality of sintering chambers, a feeding-protective glove box and a self-control system. The vacuum sintering cluster system is characterized in that both the door of a combustion chamber and the door of the feeding-protective glove box adopt a board plug valve structure; a protection space is formed at the connecting locations of the doors of the sintering chambers and the doors of the feeding-protective glove box which are both board plug valve types; the feeding-protective glove box is arranged a vehicle chassis with a pushing mechanism; at least one feeding-protective glove box is arranged on a track; two feeding-protective glove boxes are reversely arranged on a pair of tracks; a plurality of sintering chambers are arranged at the outer side of the track to form the sintering cluster; the self-control system controls and dispatches the movable feeding-protective glove box to work, thus realizing to share one movable feeding-protective glove box by a plurality of combustion chambers by dynamic combination. The vacuum sintering cluster system can reduce the arrangement of the glove boxes by 80 percent, thus obviously saving the investment and fields, improving the operating factor of the feeding-protective glove box and greatly reducing the production and operation costs, thereby not only improving the stability of technique operation, but also being convenient for storing, transferring and managing materials; besides, the vacuum sintering cluster system is more beneficial to the technique stability and the management on the operation field.

Owner:SHENYANG HENGJIN VACUUM TECH

Oil-submersible electric pump-gas lift oil extraction method and its equipment

InactiveCN1538035AAvoid and overcome technical flawsImprove production timelinessFluid removalElectricityIt equipment

An electric submerged pump-gas lifting method for recovering oil by oil well features that a gas lifting valve is installed to the oil pipe above the electric submerged pump and the oil pipe for said electric submerged pump has the Y-shaped structure. As a result, the gas lifting method and the electric submerged pump method can be used simultaneously or individually for recovering petroleum.

Owner:上海石油天然气有限公司

Method of recovering acetic acid and water in production of aromatic carboxylic acid

ActiveCN103012102AReduce production operation costSave energy for separationCarboxylic compound separation/purificationWater dischargeSeparation technology

A method of recovering acetic acid and water in the production of aromatic carboxylic acid adopts a separation technology of combined four towers which comprise an extracting tower, an azeotropic rectifying tower, a solvent extraction pro-tower and a solvent extraction tower connected orderly. The separation technology comprises the following steps: carrying out extraction, azeotropic distillation and solvent separation on the materials to obtain the water and the acetic acid, wherein the material with high water content is extracted first, then is combined with other materials for azeotropic distillation, the extraction and the azeotropic distillation adopt the same acetic ester separating agent, and the solvent recovery tower system adopts the compositive energy conservation combined technology. By adopting the method in the invention to separate and recover the acetic acid and water in the production of aromatic carboxylic acid, the organic matter in the water is less than or equal to 100ppm, the water and the acetic acid recovered can be used in the production system of aromatic carboxylic acid, thereby reducing the acid consumption and waste water discharge in the productive process. The method has low-cost separating agent, reasonable technology, is energy-saving and efficient in the separation process, and can save energy consumption by 20-30%, and reduce operating cost by 10-20%.

Owner:CHINA PETROLEUM & CHEM CORP +1

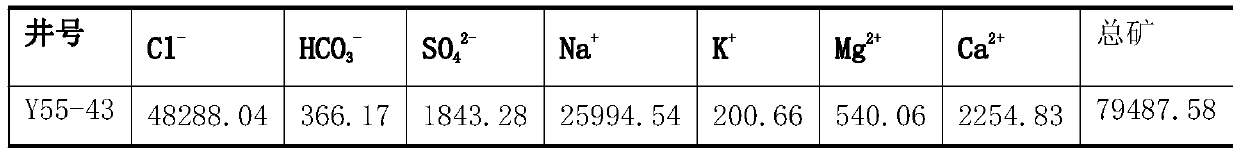

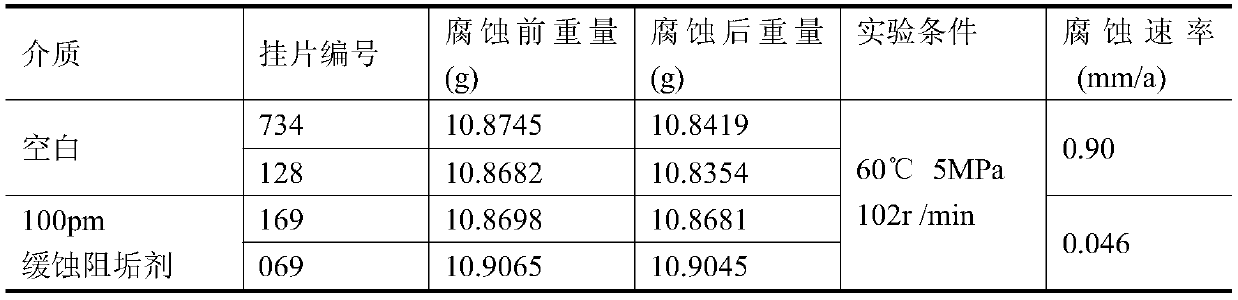

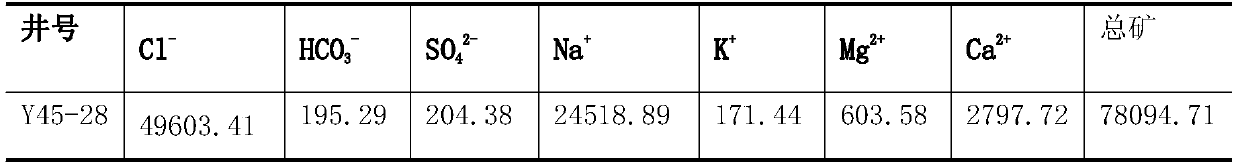

Corrosion and scale inhibitor

InactiveCN111472007AFormation effect is goodImprove anti-corrosion performanceOil fieldAqueous solubility

The invention belongs to the field of oilfield chemistry, and particularly provides a corrosion and scale inhibitor. The corrosion and scale inhibitor is prepared from, by mass percentage, 1.6-10% ofa water-phase scale inhibitor, 1-15% of an organic-phase corrosion inhibitor, 0.1-0.3% of a thickening agent, 9-15% of an emulsifier, 52-65% of oil and the balance water. The problem that common water-soluble scale inhibitors and oil-soluble corrosion inhibitors are poor in compatibility is solved. The corrosion and scale inhibitor can also achieve corrosion resistance and scale prevention of oilwells. Indoor experiments show that the corrosion inhibition rate of a system is larger than 90%, the scale prevention rate is larger than 80%, the effect is obvious, and the preparation process is simple. The corrosion and scale inhibitor has high thermodynamic and dynamic stability, is gradually released and demulsified after being injected into the wells, can be evenly dispersed in a produced aqueous medium while protecting the corrosion resistance of a shaft carbon steel pipe column, achieves effective scale prevention of a shaft, and also reduces the production and operation cost of oilfields.

Owner:PETROCHINA CO LTD

Method for phase-change wax decoloring

InactiveCN101550357ALess investmentReduce production operation costPetroleum wax refiningWaxPhase change

The present invention relates to a method for refining phase-change wax. The method includes steps as follows: melting the phase-change wax under 100-300 deg c, contacting with active clay by 2%-8% weight of the phase-change wax, adsorption reaction about 60 minutes, separating the active clay with the phase-change wax, stirring the phase-change wax with 2%-5% active clay under 100-300 deg c about 60 minutes, and removing colouring substance in the phase-change wax by repeating above steps for obtaining the phase-change wax with low colour tint; mixing the carclazyte with water under 60-95 deg c, separating and obtaining coarse phase-change wax, the obtained waste carclazyte does not contain the phase-change wax and colouring substance basically. The method has advantages of low manufacture cost, simple and easy to operation, little phase-change wax loss and less environmental pollution by the waste carclazyte.

Owner:WUHAN POLYTECHNIC UNIVERSITY

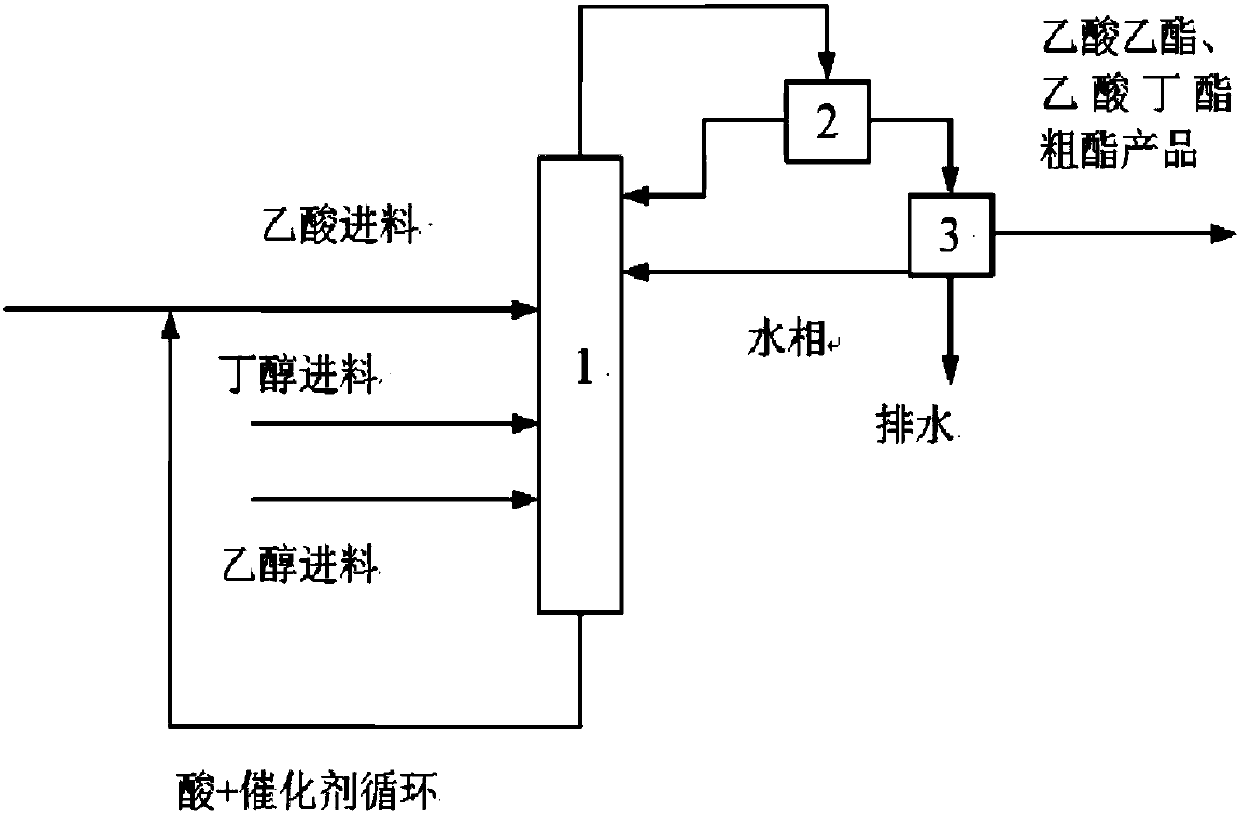

Method for synthesizing mixed ester through catalyst distillation

InactiveCN107827746AReduce difficultyIncrease acetic acid contentOrganic compound preparationChemical industryStrong acidsCatalytic distillation

The invention discloses a method for synthesizing mixed ester through catalyst distillation. The method comprises the following steps: by taking ethanol, n-butyl alcohol and acetic acid as raw materials, a strong acid cation exchange resin as a catalyst and a catalyst distillation tower as a reactor, performing a catalyst distillation backflow reaction, and finally performing phase separation, thereby obtaining mixed ester of ethyl acetate and butyl acetate. According to the method, the intense water carrying power of the butyl acetate is utilized, azeotrope is prepared from the butyl acetate,butanol and water, and water generated from reactions is completely carried out from a tower top. Therefore, the conversion rate of alcohol reactants and the content of the acetic acid in the catalyst distillation tower can be increased, and the influence of product water to the reaction process in the tower is also eliminated. A tower top product is generally an ester-water mixture and comprisesa very small amount of acetic acid, so that the later purification difficulty of the ethyl acetate and the butyl acetate is greatly reduced, the production procedures are simplified, the production efficiency is improved, and the energy consumption is reduced.

Owner:GUANGXI UNIV FOR NATITIES

The preparation method of 2-nitro-4-thiamphenicol benzoic acid

ActiveCN103787934BReduce pollutionEliminate pollutionOrganic chemistryOrganic compound preparationBenzoic acidFiltration

The present invention relates to the preparation method of 2-nitro-4-thiamphenicol benzoic acid, comprising: in the reactor, 5-75 atmospheric pressure, 110~450 ℃, with 2-nitro-4-thiamphenicol toluene as raw material , feed air, oxygen-enriched air or oxygen as oxidizing gas, low-level saturated carboxylic acid as solvent, heteropolyacid-transition metal-halide to form a multi-component homogeneous catalytic system, forming a gas-liquid reaction process, and 2 in the reaction liquid ‑Nitro‑4‑thiamphenicol toluene is oxidized to 2‑nitro‑4‑thiamphenicol benzoic acid; after the reaction is finished, filter to obtain 2‑nitro‑4‑thiamphenicol product crystal precipitation; and the filtrate continues Recycling, that is, after adding raw materials, continue the oxidation reaction. The present invention can overcome the defects of existing 2-nitro-4-thiamphenicol benzoic acid production method, such as large waste gas and waste water pollution, serious corrosion, low selectivity, high production cost, etc., improves selectivity, reduces environmental pollution, and realizes 2 Cleaner Production of ‑Nitro‑4‑Thiamphenicol Benzoic Acid.

Owner:SINOCHEM AGRO +1

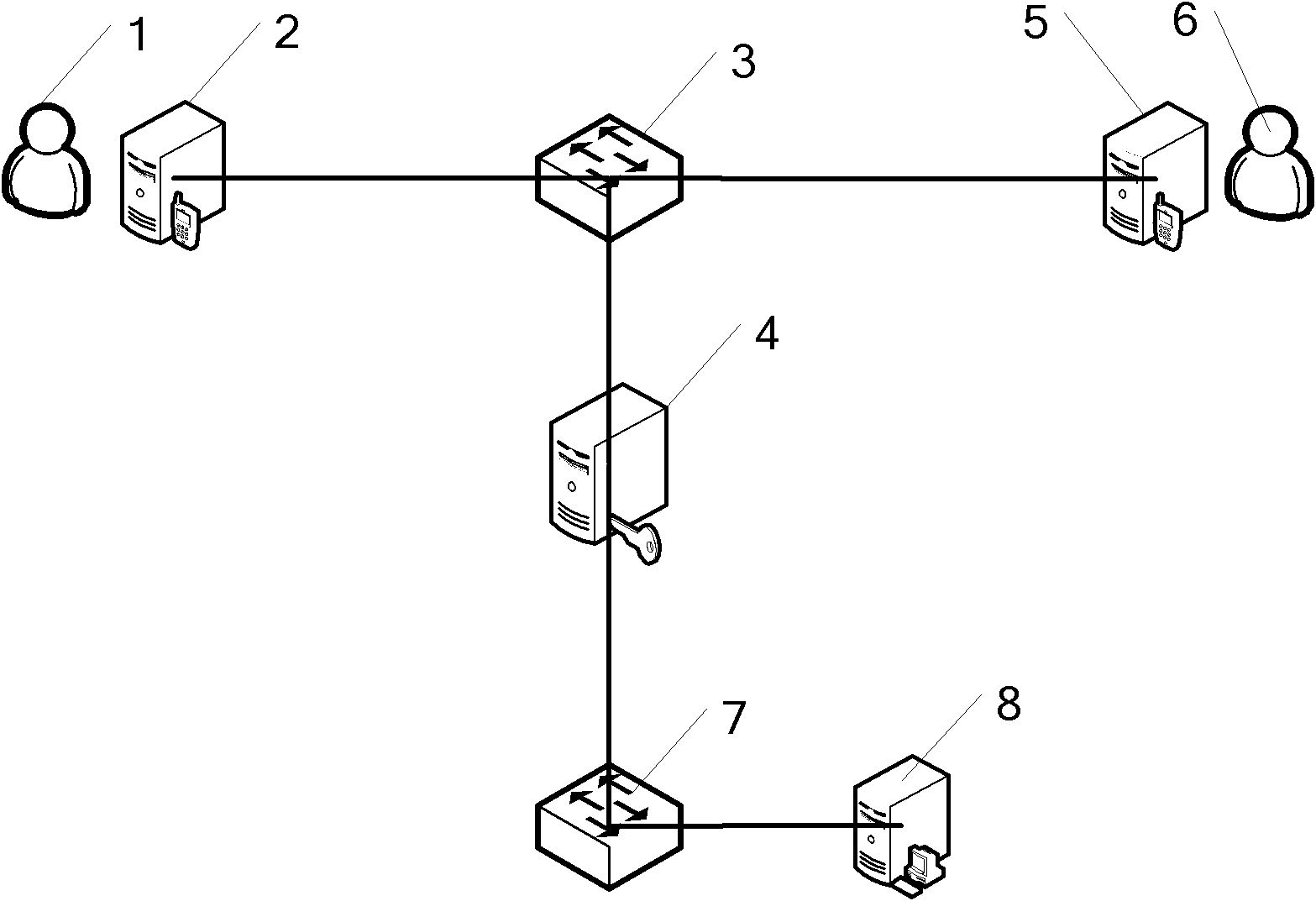

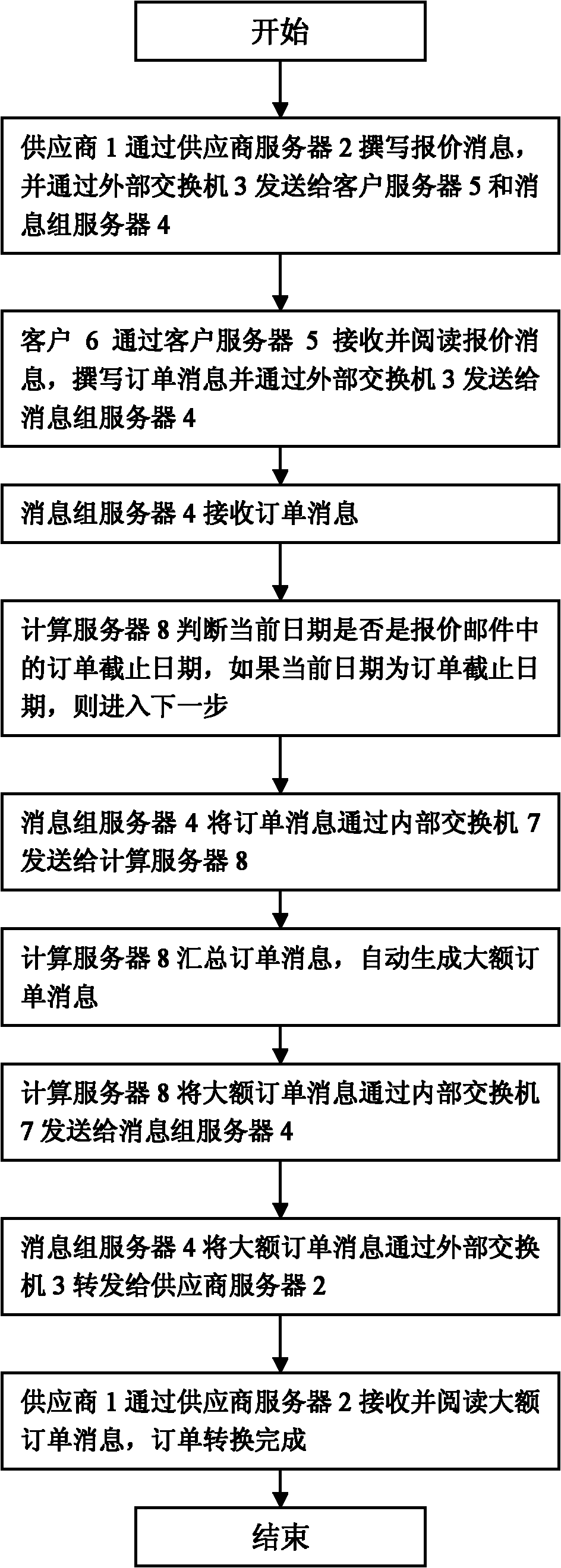

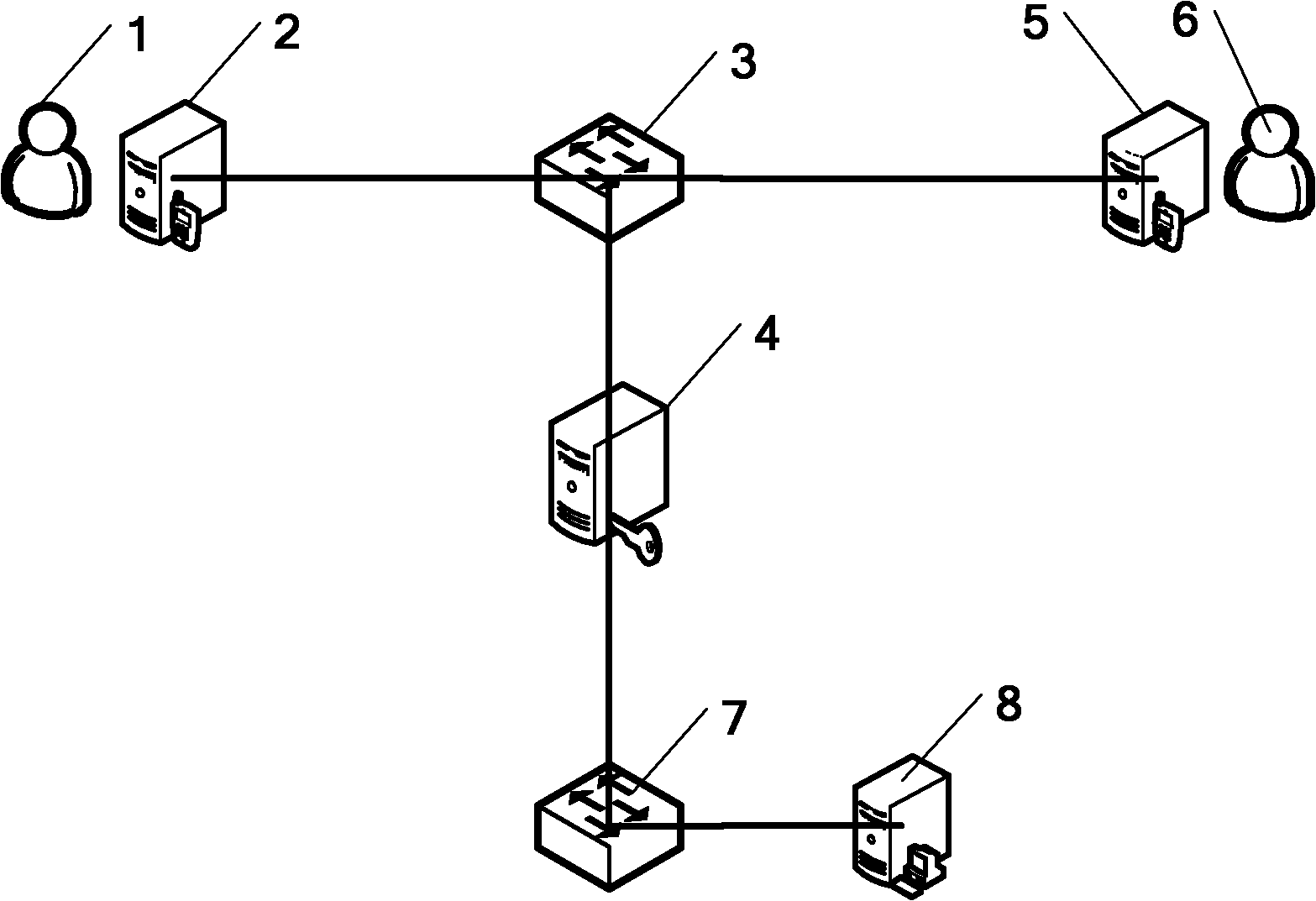

System and method for transforming small orders

InactiveCN101968870AEffective dredgingReduce service pressureTransmissionCommercePersonalizationLogistics management

The invention discloses a system and a method for transforming small orders. The structure of the system is characterized in that a client server and a supplier server are connected with an information group server through an external switch; and the information group server is connected with a calculation server for combining orders through an internal switch in a communication mode. The method comprises the following steps that the supplier server emits quotation information; the client server and the information group server receive the quotation information; the client server transmits order information according to the quotation information; and the information group server intercepts and captures the order information to be automatically generated large orders to be sent to the supplier server after being transmitting to the calculation server to be summarized. The system and the method for transforming small orders of the invention are suitable for the individual consumption field with many small orders, can be used as an automatic switching tool for the small orders in electronic commerce websites, and purchasing departments and logistics departments of enterprises and has the advantages of saving manpower operation cost g and ensuring material supply quality.

Owner:HUNAN UNIV

Cementing cement head column assembly method

ActiveCN107503710AReduce time spentReduce the number of lifting operationsSealing/packingTop driveLine tubing

The invention discloses a cementing cement head column assembly method. The cementing cement head column assembly method comprises the following steps: firstly pre-connecting a cement head and a short drill rod off line on a deck to form a cement head composition A; then installing a drill rod capsule off line on the deck through a pulley block method; hoisting three drill rods and the cement head to a well logging deck from the deck, enabling a top drive to be matched with a catwalk machine to move the two drill rods to a drill floor, connecting the two drill rods on a wellhead, tightly fastening to form a composition B, sitting a slip-weld hanger; enabling the top drive to be matched with the catwalk machine to move the cement head composition A to the drill floor from the well logging deck, combining, connecting and tightly fastening with the composition B of the wellhead, forming an integral cementing cement head column; connecting a cementing pipeline with the cement head, binding the cementing pipeline on a proper position of the cement head column, supporting a bearing of the cement head; finally enabling the well bound cement head column to stand on the drill floor, and finishing the cementing preparation work. The hold-up time of the wellhead is shortened by 60 minutes, the number of hoisting operations is reduced by twice, and the cementing cement head column assembly method has an excellent application effect.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Separation and purification method of beta-glucan

The invention discloses a separation and purification method of beta-glucan, and the method comprises the following steps: (1) extraction of a beta-glucan solution; (2) filtration; (3) defatting and enzyme deactivation; (4) refiltration; and (5) pressure filtration. When the method is used for separation and purification of the beta-glucan, the molecular structure and chemical quality of the beta-glucan cannot be destroyed, the purity and yield of the beta-glucan can be effectively improved, and the whole separation process is pollution-free, green, environment-friendly and easy to realize industrial popularization.

Owner:SICHUAN HUI TAI AGRI TECH CO LTD

A device for removing low-density scum in metal refining process

ActiveCN112143905BReduce in quantityImprove the level of mechanical automationCasting cleaning apparatusSlagFlue gas

Owner:YUNNAN TIN

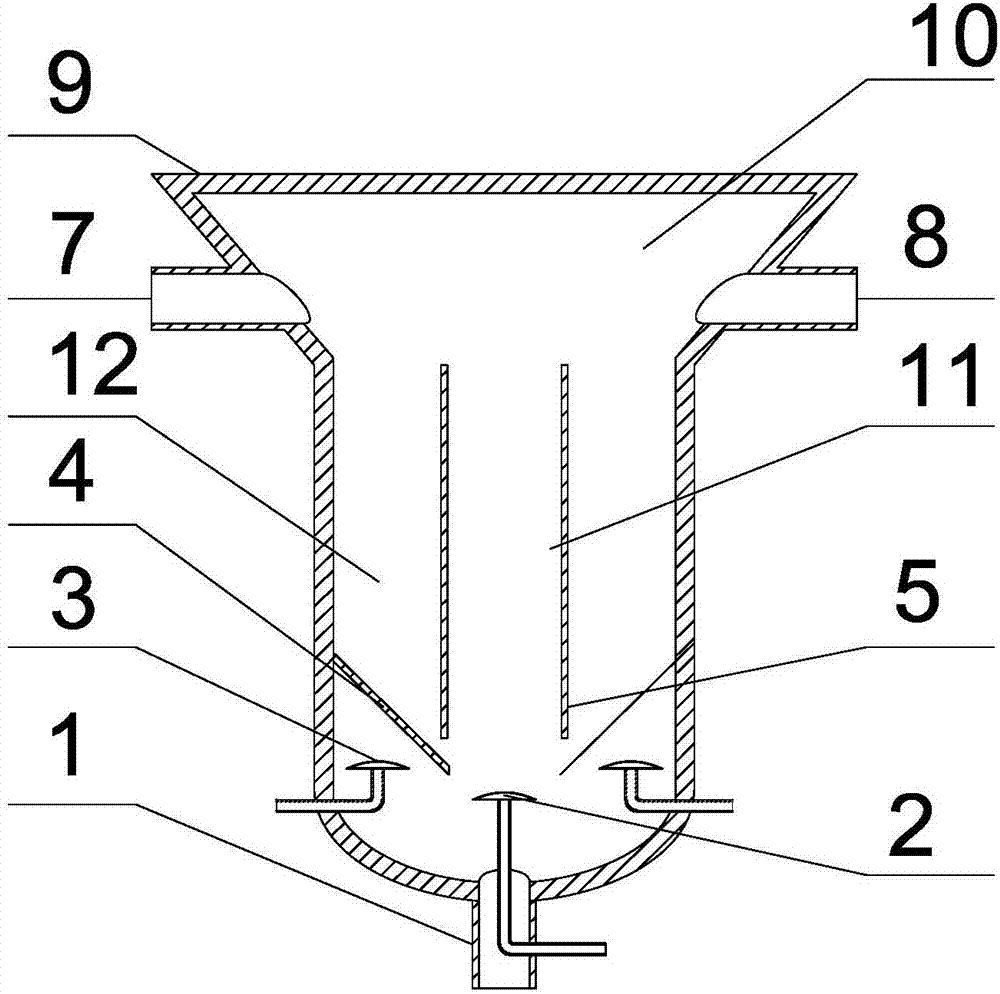

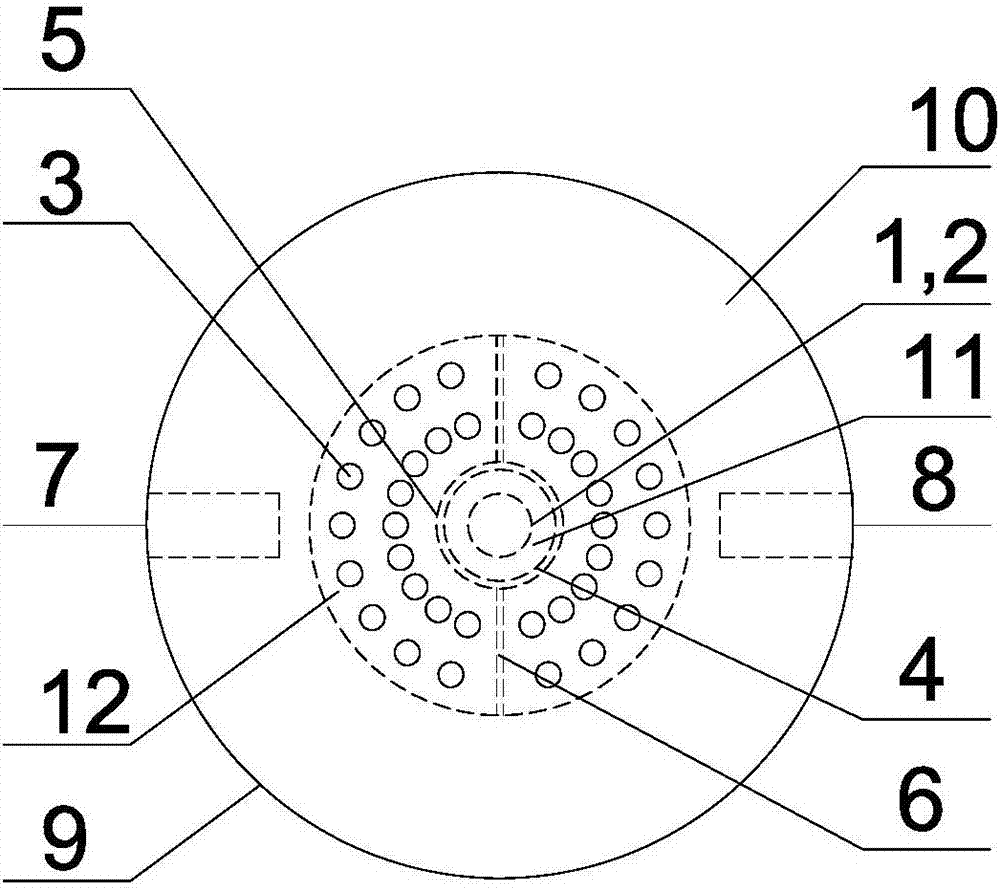

Integrated circulating fluidized bed apparatus

ActiveCN106914192ASmall process footprintSimple production equipmentFluidized bed combustionChemical/physical processesFluidized bedMaximum diameter

The invention relates to an integrated circulating fluidized bed apparatus. The upper part of an external sleeve cylinder is in a circular truncated cone structure with a thick top and a thin bottom, wherein ratio of maximum diameter to minimum diameter is 1.1-5. The lower part of the external sleeve cylinder is a cylinder in equal diameter and is connected to an internal sleeve cylinder through a screw bolt. The fluidized bed apparatus, from bottom to top, successively includes a solid collection port, a center gas distributor, an annular space gas distributor, a solid collector, and the internal sleeve cylinder. A gas outlet and a solid inlet are disposed on the upper part of the external sleeve cylinder. The center gas distributor is located right under the internal sleeve cylinder and the annular space gas distributor is located around the periphery of the center gas distributor and between the internal and the external sleeve cylinders. A gas-solid separation zone is formed in the upper part of the external sleeve cylinder. The lower part of the external sleeve cylinder is totally cylindrical in shape and is separated into a lifting zone and a circulating zone by means of the internal sleeve cylinder. The apparatus integrates a fluidized bed, a solid circulating system and a gas-solid separation system, so that the production apparatus is simplified. Gas flows in the status of plug flow, so that a gas phase and a solid phase are completely contacted and dead zone is avoided. The apparatus reduces power consumption and reduces manufacturing and producing cost.

Owner:TIANJIN UNIV

Improved low-temperature rectisol and improved low-temperature rectisol device

InactiveCN102517097ALower carbon dioxide levelsReduced Methanol RecycleCarbon compoundsGas purification by non-gaseous materials condensationCo2 absorptionNitrogen

Provided are an improved low-temperature rectisol method and an improved low-temperature rectisol device. Hydrogen sulfide and carbon dioxide in process gas are removed respectively in two absorbing towers, and the process gas is cooled between two towers so that part of carbon dioxide is liquefied and separated. The two towers absorb hydrogen sulfide and carbon dioxide respectively. Part of carbon dioxide is liquefied and separated by cooling the process gas after hydrogen sulfide is removed through the hydrogen sulfide absorbing tower so that content of carbon dioxide in the process gas is reduced, and content of carbon dioxide in the process gas entering the carbon dioxide absorbing tower is correspondingly reduced. The method can effectively reduce dimensions of a low-temperature rectisol pipeline and equipment, reduces methanol circulating quantity, equipment investment and production running costs are reduced, air-lift nitrogen dosage is reduced, and more pure-state carbon dioxide facilitating application and treatment is obtained.

Owner:李德全 +1

Source management and supervision acquisition terminal

InactiveCN110410639AGuaranteed accuracyQuick installationNon-rotating vibration suppressionClosed circuit television systemsEngineeringInformation acquisition

The invention discloses a source management and supervision acquisition terminal. The terminal comprises a concrete bottom plate and an outer connecting block, the middle part of the inner side of theconcrete bottom plate is provided with a wagon balance, and a fixed plate which is fixedly connected with the concrete bottom plate is arranged on the outer side of the wagon balance. The inner sideof the fixed plate is connected with a buffer plate, and a deceleration pad adheres to the outer side of the buffer plate. The bottom of the buffer plate is connected with a supporting rod, a spring is installed inside a limiting mechanism, the outer connecting block is installed on the outer side of the concrete bottom plate, an outer clamping plate is arranged on the outer side of an installingrod, a connecting groove is formed in the middle of an inner clamping plate, a convex block is fixed to the outer side of a locating block, a frame plate is fixed to the outer side of a lantern ring,and an outer connecting plate is arranged on the outer side of the frame plate. According to the source management and supervision acquisition terminal, the accuracy of information acquisition can beensured, rapid installation is facilitated, meanwhile, the production operation cost is reduced, and long-term effective stable working use can be guaranteed.

Owner:郑州今迈衡器有限公司

A method of using drilling waste fluid to prepare harmless cuttings and application of cuttings

ActiveCN103240261BReduce manufacturing costSimple processSolid waste managementSolid waste disposalLiquid wasteWell drilling

The invention discloses a method for preparing harmless rock fragments by using well drilling waste liquid and an application of the rock fragments. The method comprises four steps of separation, oil removal sedimentation, oxidation sedimentation and oxidation adsorption to ensure that the well drilling waste liquid is subjected to harmless treatment, the harmless rock fragments can be separated from the well drilling waste liquid, and the rest is water which can reach an industrial water standard. The harmless rock fragments treated by a harmless technology are used as main materials for preparing dry-mixed mortar. By adopting the method, the phenomena that the petroleum drilling enterprises in the past dig pits for landfill of harmful mixed wastes, the soil is destroyed, the environment is polluted and resources are wasted are avoided; and moreover, a precedent for carrying out harmless comprehensive treatment, recycling waste mixed resources, and promoting the development of cyclic economy for the petroleum drilling enterprises to make money is opened up for the petroleum drilling enterprises, and the method meets the requirements of the strategic planning of energy saving and emission reduction comprehensive utilization during the twelfth five-year of the country. The method has considerable economic benefits and wide market application prospects.

Owner:薛西伟

Composite process for treatment of inferior residual oil

ActiveCN101418222BWide adaptability of raw materialsAchieve maximum light weightTreatment with hydrotreatment processesTar working-up by solvent extractionDistillationHydrogenation process

The invention discloses a combined process method for treating inferior residual oil. The method comprises the following steps: a residual oil material enters a solvent deasphalting device to obtain DAO and deoil asphalt; the obtained DAO enters a hydrogenation device of a boiling bed and is treated to obtained a lightweight distillation fraction and hydrogenated tail oil; the hydrogenated tail oil enters a catalytic cracking device and is treated to obtain a lightweight distillation fraction and oil slurry; at least partial oil slurry and the deoil asphalt are mixed, enter a hydrogenation device of a suspension bed and are treated to obtain a lightweight distillation fraction and unconverted tail oil, wherein the unconverted tail oil circularly returns the solvent deasphalting device; and the lightweight distillation fraction and the DAO are mixed and enter the hydrogenation device of the boiling bed. The combined process course organically combines a decarbonization process and a hydrogenation process; and according to different properties of raw materials, a corresponding process and operation condition is adopted so as to maximize conversion of the residual oil material while minimizing equipment investment.

Owner:CHINA PETROLEUM & CHEM CORP +1

Multi-ecological large-scale artificial fish reef

ActiveCN111513010ARealize integrated operationLow costClimate change adaptationPisciculture and aquariaAquatic productZoology

The invention provides a multi-ecological large-scale artificial fish reef, and relates to the field of proliferation and breeding of aquatic products, in particular to an artificial facility having functions of multi-ecological proliferation and breeding of marine organisms and assisting in gathering. The multi-ecological large-scale artificial fish reef comprises a framework connected with a platform, wherein gathering devices are mounted on the platform. A stuffing material is placed in a cavity of the framework, gathering surfaces are arranged on one or more sides of the framework, and grids cover peripheries of the framework and the gathering surfaces. Breeding boxes are mounted at the upper part of the cavity of the framework. The gathering devices are fish suckers, and a fish sucking duct can lift and move when being supported by a lifting rocker arm. The gathering devices can gather and convey fish to the platform, so that integrated management of breeding and harvesting can berealized, the cost for employing divers and harvesting vessels can be saved, and massive production and operation cost can be saved. Algae can be planted on the gridded gathering surfaces, so that multi-ecological intergrowth breeding can be realized, and the reef has the positive effects of comprehensively utilizing space and being superior in ecological condition.

Owner:王波

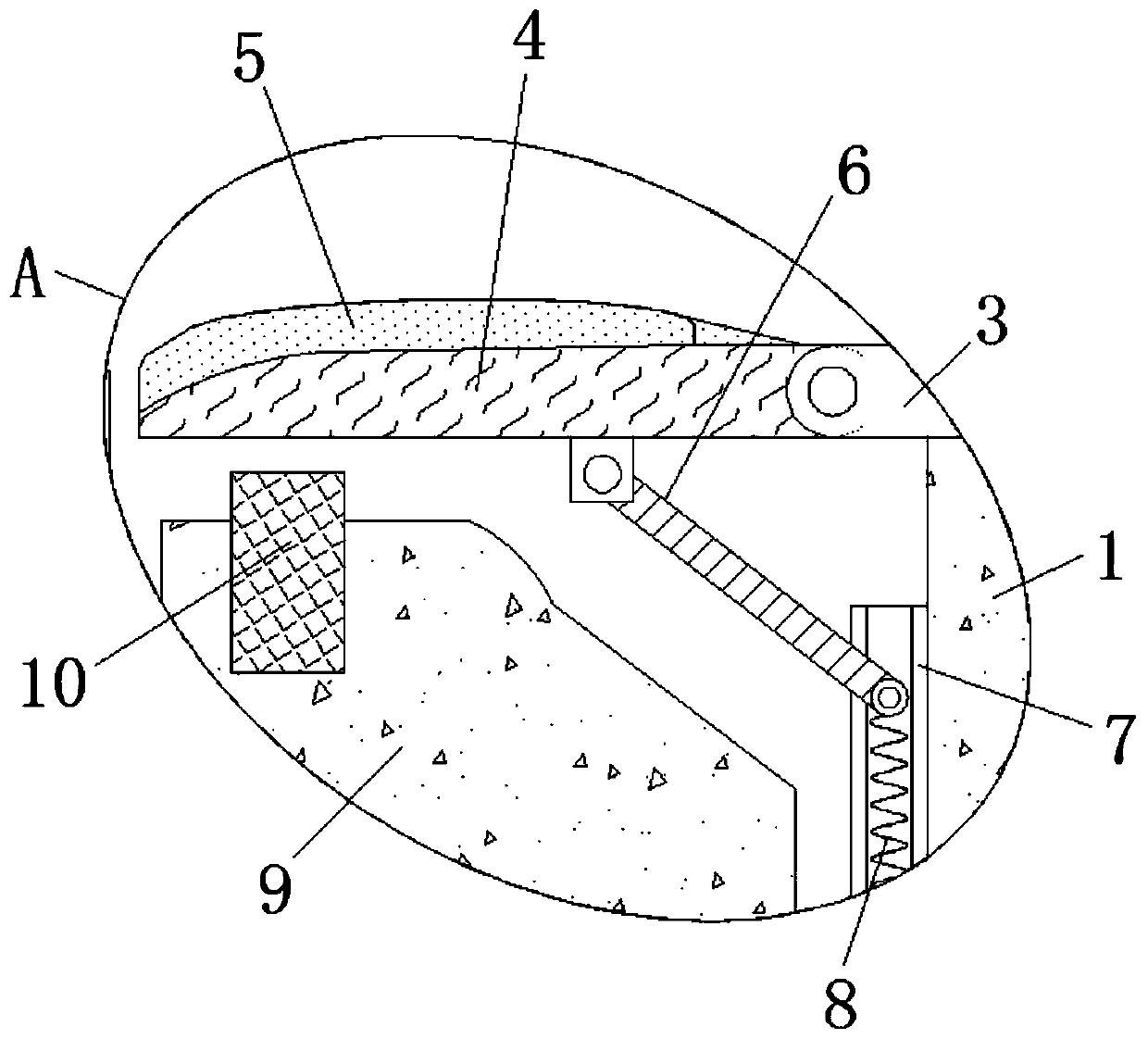

Thick-oil thermal recovery device in oil fieldSelf-sealing type thermal recovery packer.

The invention relates to a thick-oil thermal recovery device in an oil field, in particular to a self-sealing type thermal recovery packer. The thick-oil thermal recovery deviceself-sealing type thermal recovery packer. is characterized in that an upper joint, a central pipe and a lower joint are connected in sequence from top to bottom; a cylinder sleeve is sheathed on the central pipe and is fixedly connected with the central pipe by a pin; expanding liquid is filled in the cylinder sleeve; the lower end of the cylinder sleeve is sealed by a sealing head and a double-pressing cap; the upper end of the cylinder sleeve is provided with a sliding and locking device; and an outer sealing assembly is arranged at the outer side of the sliding and locking device and the inner side of the lower end of a supporting ring. The thick-oil thermal recovery deviceself-sealing type thermal recovery packer. has the advantages that automatic setting is realized, the setting time is short, the setting is durable, the structure is compact, the sealing is excellent, the unsealtting is smooth, the production and operation cost is reduced, and the defects of complex structure, longer size, troublesome operation and easy well blocking in the existing packer are overcome.

Owner:CNPC BOHAI EQUIP MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com