Method for recycling water from separation system for acetic acid and water

A separation system and reclaimed water technology, applied in the separation/purification of carboxylic acid compounds, chemical instruments and methods, preparation of carboxylate, etc., can solve the problems of limited utilization, excessive steam consumption, large energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

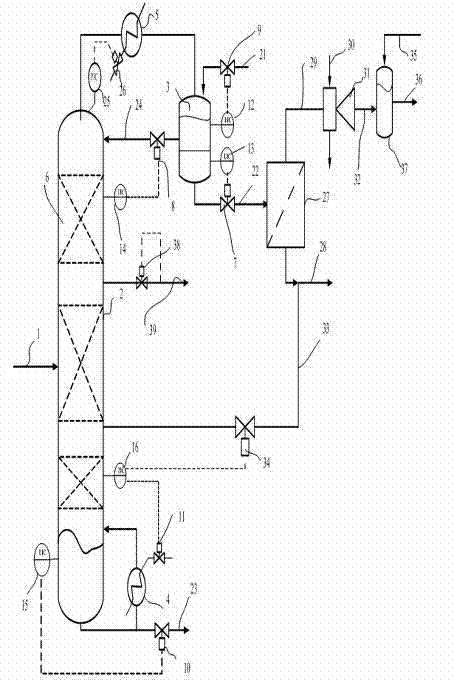

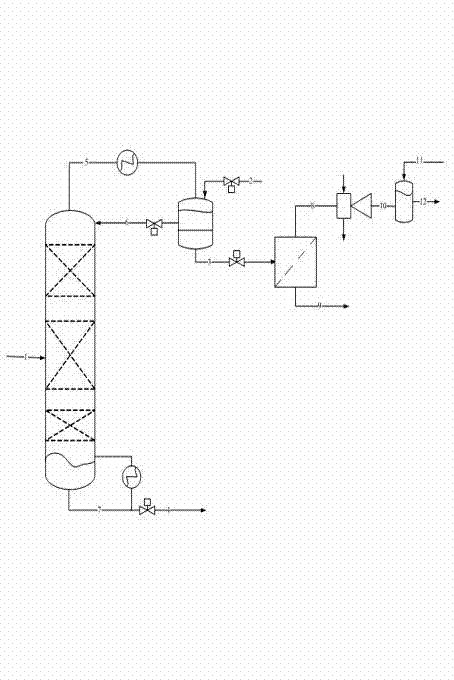

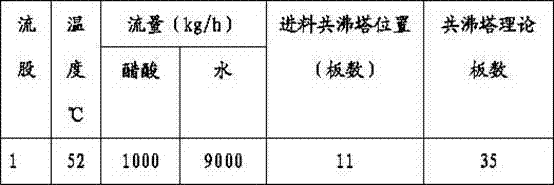

[0042] Example 1, in order to understand the effect of pervaporation on the recovery of purified water, the simulated analysis of the separation and purification of the stream containing only acetic acid and water from the oxidation reaction system of oxidative carboxylic acid production, wherein the process parameters of stream 1 are shown in Table 1 below Show. The flow chart used for the simulation is as figure 2 As shown, stream 1 enters at 11 positions of the number of trays in the azeotropic rectification column, and supplements the entrainer sec-butyl acetate through stream 2 at the top of the azeotropic rectification column, and the gas phase 5 at the top of the tower is condensed by the condenser into a liquid phase, and then carry out standing and stratification of the heterogeneous liquid in the decanter. After the stratification, the oil phase in the decanter flows back to the top of the azeotropic column through stream 64, and the water phase enters through s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com