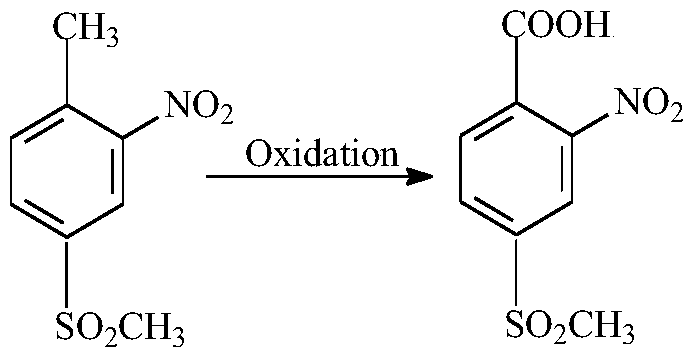

The preparation method of 2-nitro-4-thiamphenicol benzoic acid

A technology of methylsulfonyl benzoic acid and methylsulfonyl toluene is applied in the field of catalytic oxidation synthesis technology of 2-nitro-4-methylsulfonyl benzoic acid, and can solve the problem that the degree of oxidation reaction is difficult to control and the methyl oxidation is difficult. , limited oxidation capacity and other problems, to achieve the effect of reducing waste water pollution, eliminating waste gas pollution, high conversion rate and selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The experiment was carried out in a stirred reactor with a volume of 1000ml, glacial acetic acid 800ml, water 50g, 2-nitro-4-thiamphenicol toluene 80g, phosphomolybdovanadate 6g, manganese sulfate 9.5g, potassium iodide 0.6g were added, and the reaction The temperature is 180°C, the pressure is 40atm, and the air flow rate is 500ml / min. After the reaction starts, liquid samples are taken every 0.5h and analyzed by liquid chromatography. After 4h of reaction, the conversion rate of 2-nitro-4-thiamphenicol toluene reaches 95%. , The yield of 2-nitro-4-thiamphenicol benzoic acid reached 91%.

[0055] The reaction solution was cooled to 5°C, and the precipitate was separated from the reaction solution by filtration.

[0056] Gained solid precipitation is fully dissolved with the sodium hydroxide solution of 200ml 15% (mass), filters insoluble solid impurity, and the filtrate of filtering gained is adjusted to pH1.0 with sulfuric acid again, and crystallization precipitates ...

Embodiment 2

[0059] The experiment was carried out in a reactor with a volume of 1000ml. The gas-liquid two-phase flowed through the reactor continuously from bottom to top. The flow rate of the liquid was 5ml / min, and the flow rate of the air was 500ml / min. In the liquid feed, 2-nitro- 10% (mass) of 4-thiamphenicol toluene, 10% (mass) of water, 0.70% (mass) of phosphomolybdovanadic acid, 0.30% (mass) of manganese, 0.05% (mass) of iodine, the rest are acetic acid, and the reaction temperature is 210 ℃, pressure 30atm, the outlet liquid of the reactor was analyzed by liquid chromatography, the conversion rate of 2-nitro-4-thiamphenicol toluene reached 96%, and the yield of 2-nitro-4-thiamphenicol benzoic acid reached 91%.

Embodiment 3

[0061] The experiment was carried out in a stirred reactor with a volume of 1000ml, adding 800ml of glacial acetic acid, 80g of water, 80g of 2-nitro-4-thiamphenicol toluene, 4g of phosphotungstic acid, 2g of cobalt acetate, 4g of manganese acetate, tetrabromoethyl Alkane 0.5g, reaction temperature 210 ℃, pressure 30atm, air flow rate is 500ml / min, after the reaction begins, take liquid sample every 0.5h and use liquid chromatography analysis, after reaction 4h, 2-nitro-4-thiamphenicol toluene The conversion rate reaches 98%, and the yield of 2-nitro-4-thiamphenicol benzoic acid reaches 91%.

[0062] The reaction solution was cooled to 5°C, and the precipitate was separated from the reaction solution by filtration.

[0063] The resulting solid precipitate was purified by the method described in Example 1 to obtain 80.3 g of pale yellow 2-nitro-4-thiamphenicol benzoic acid.

[0064] Add 50ml of glacial acetic acid to the resulting filtrate, then add 80g of 2-nitro-4-thiampheni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com