Cementing cement head column assembly method

A technology of cementing cement and assembly method, which is applied in earth-moving drilling, wellbore/well components, sealing/packaging, etc., can solve problems such as the health and safety risks of cargo and ground commanders, achieve good application effects, reduce The effect of wellhead occupancy time and the reduction of the number of hoisting operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] A method for assembling cement head columns of the present invention comprises the following steps:

[0010] S1: The cement head and short drill pipe are pre-connected offline on the deck to form the combination of cement head A, and the selected short drill pipe must meet the matching length requirements; this step does not take up wellhead time.

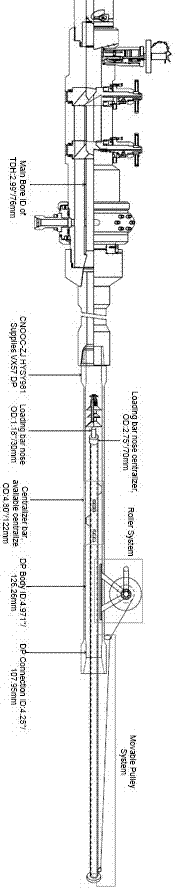

[0011] S2: Utilize the pulley block method to install the drill pipe rubber plug offline at the deck; as figure 1 shown. By adopting the pulley block installation method, it is labor-saving and quick, only one person is needed, and the wellhead time is not occupied.

[0012] S3: Hoist the 3 drill pipes and the cement head from the deck to the logging deck, the top drive cooperates with the catwalk machine to move the two drill pipes to the drill floor, connect the two drill pipes at the wellhead, and fasten them to form a combination B, then sit on the jam Tile, wait for the next step to connect with the cement head A comb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com