Method for adhering blades of megawatt wind turbine in die assembly

A technology of wind power blades and bonding methods, which is applied in the direction of sustainable manufacturing/processing, climate sustainability, household components, etc., can solve the problem of missing or excessive amount of bonding glue, inability to effectively control the thickness of the web bonding glue, and influence Blade quality and other issues, to achieve the effect of reducing consumption, shortening occupation time, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

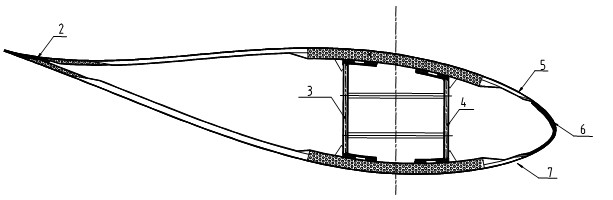

[0027] A method for clamping and bonding megawatt wind power blades, the construction steps are as follows:

[0028] 1. Connect the LE web and TE web into a whole according to the correct relative position.

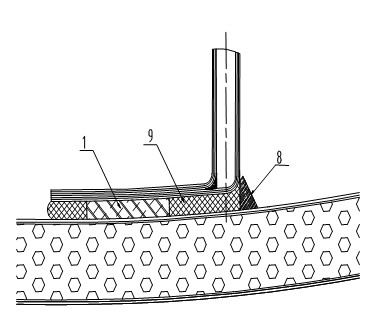

[0029] 2. Bond a positioning control block every 2m at the bonding position of the blade SS shell web.

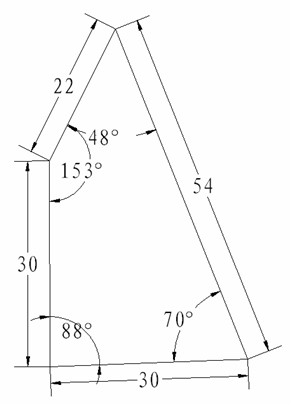

[0030] 3. The material of the positioning control block is cork, and the cross-sectional shape is attached image 3 , the length is 50mm.

[0031] 4. Bond positioning control blocks every 2m at the bonding position of the blade PS shell web.

[0032] 5. The material of the positioning control block is cork, and the cross-sectional shape is attached image 3 , with a length of 50mm.

[0033] 6. Apply glue to the bonding position of the blade SS shell web, and place gap control blocks every 1.5m.

[0034] 7. The material of the blade SS shell web gap control block is cured adhesive, the shape is a cuboid, the length is 50mm and the width is 20mm, and the thickness i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com