Integral equipment bay

An integrated technology for equipment cabins, applied in the direction of railway car body, railway car body parts, transportation and packaging, etc., can solve problems such as excessive local installation stress, non-uniform skirt board curvature, structural cracks, etc., and improve assembly efficiency And, the effect of shortening the occupation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

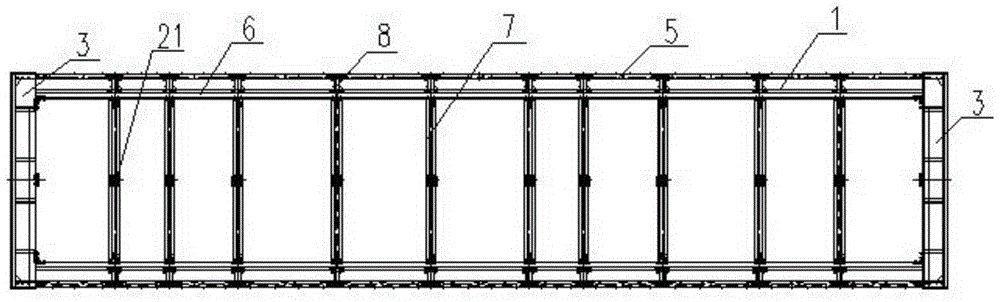

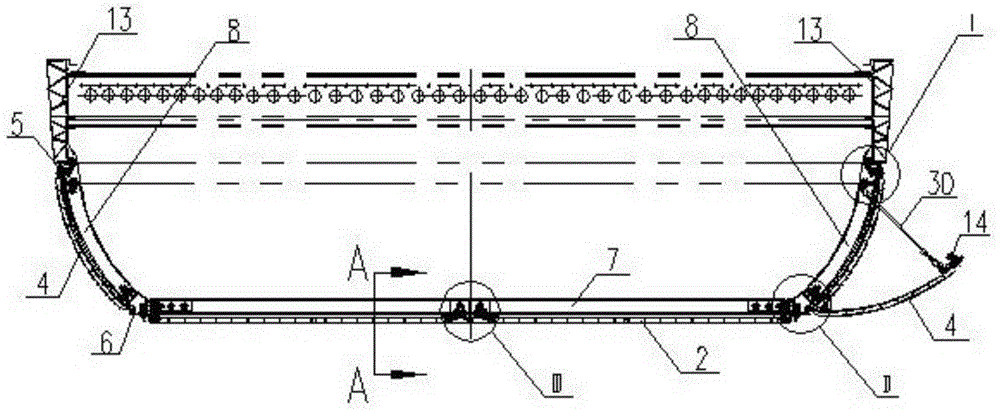

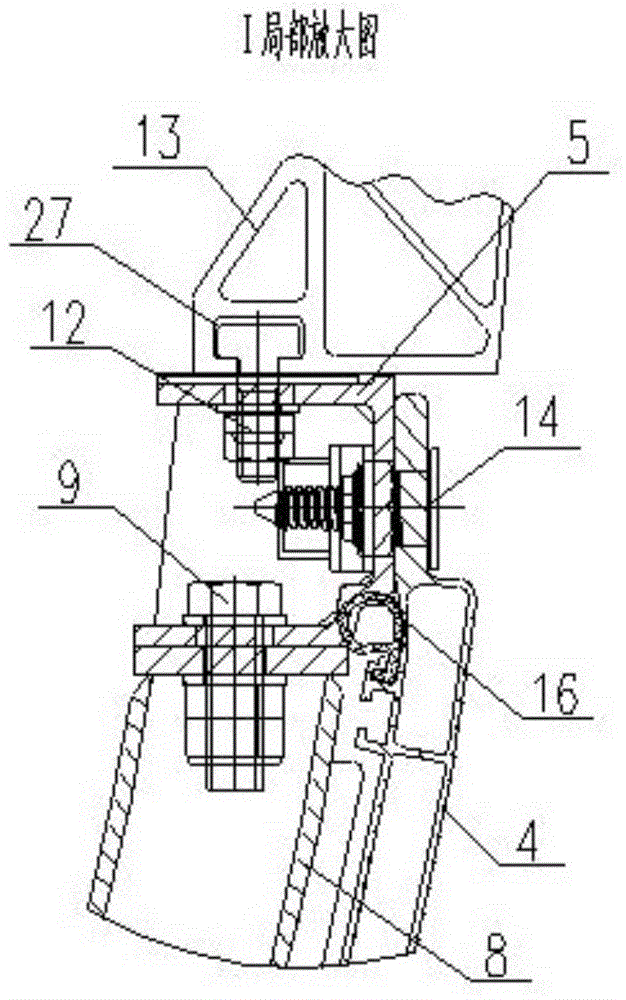

[0024] Such as figure 1 As shown, the present invention provides an integral equipment cabin, comprising a skeleton 1, a bottom plate 2, end plates at both ends (not shown in the figure) and skirt plates 4 located on both sides of the car body, a bottom plate 2, an end plate 3 and The skirt boards 4 are all fixed on the frame 1 to form an integral equipment compartment. The equipment under the vehicle is hung on the underframe of the vehicle body through the suspension bolts, and all the equipment under the vehicle is enclosed in the sealed equipment compartment. Good protection, the rain, snow, sundries, etc. in the environment will not enter the equipment and affect the normal operation of the equipment. Among them, the main body of the bottom plate 2 is made of aluminum alloy profile, and the structure is smooth, which ensures the smoothness...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com