Method for quickly preparing precious metal parts at low temperature

A technology for precious metals and parts, which is applied in the field of rapid preparation of precious metal parts by electric field-assisted sintering at low temperature, can solve problems such as difficulty in forming, and achieve the effects of achieving uniform reliability, improving preparation speed, and refining grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

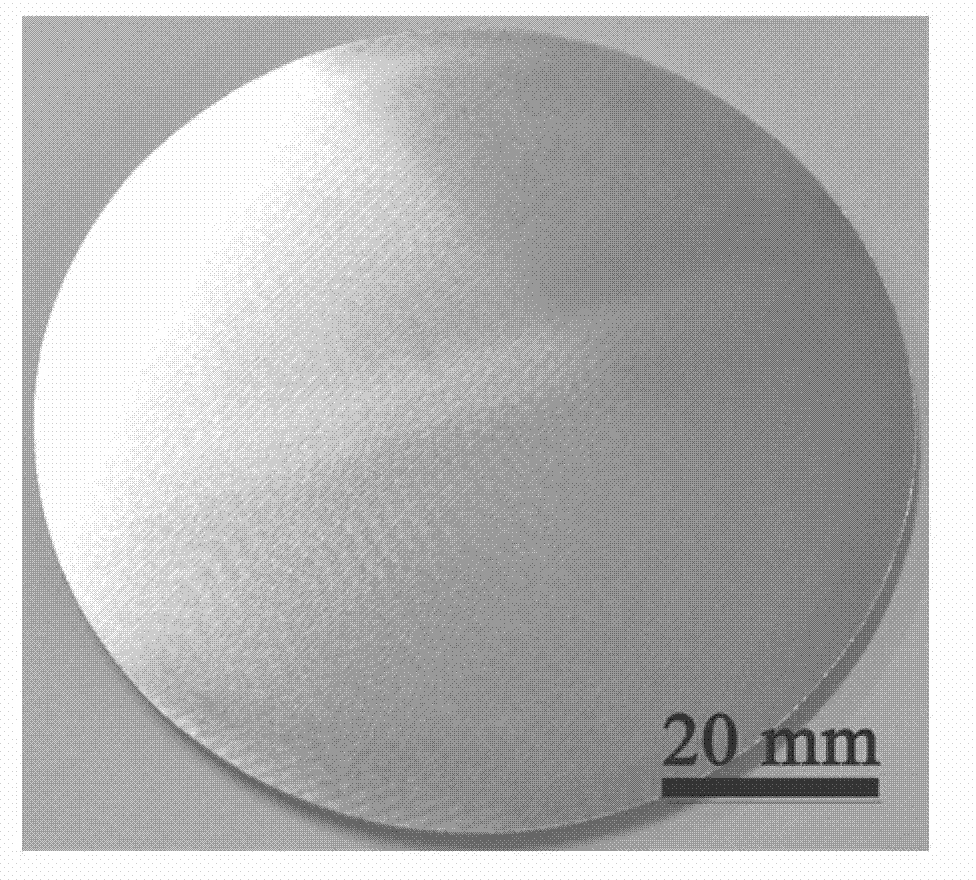

[0031] In this embodiment, the precious metal part is a cylindrical ruthenium target, and its appearance is as follows figure 1 As shown, the cross-sectional diameter is 80mm, and the thickness is 4mm. The following is the specific preparation method of the ruthenium target:

[0032] First, the shape and size of the graphite mold are precisely designed according to the actual shape and size of the preformed ruthenium target; then, the precious metal ruthenium powder with a particle size of 600 mesh and a purity of 99.99% is accurately weighed and put into the graphite mold for cold pressing. The applied pressure is 10 MPa; finally, put the cold-pressed graphite mold into an electric field-assisted electric spark ion sintering furnace for sintering, and keep it warm after sintering to the sintering temperature. After sintering to the sintering temperature, keep it warm for 10 minutes, apply a pressure of 40MPa, and the entire sintering process is carried out in a vacuum with a ...

Embodiment 2

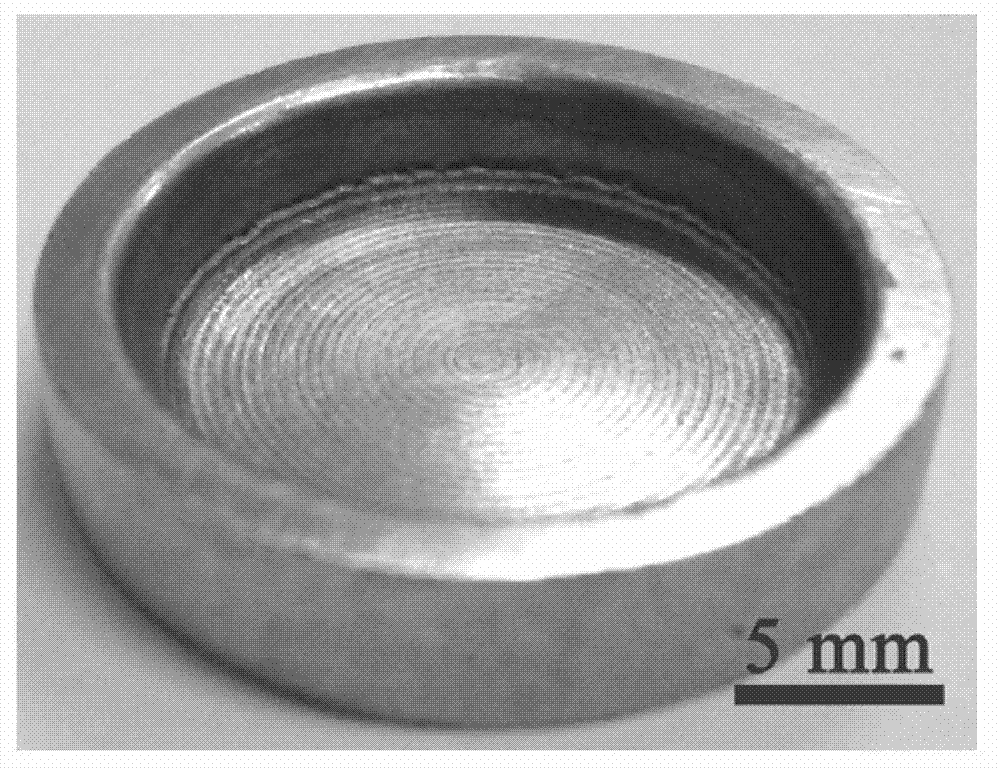

[0036] In this embodiment, the precious metal product is a ruthenium crucible, and its appearance is as follows figure 2 As shown, the cross-sectional diameter is 20mm, the height is 4mm, and the uniform thickness is 2mm. The following is the specific preparation method of the ruthenium crucible:

[0037] First, the shape and size of the graphite mold are precisely designed according to the actual shape and size of the preformed ruthenium crucible; then, the precious metal ruthenium powder with a particle size of 300 mesh and a purity of 99.99% is accurately weighed and put into the graphite mold for cold pressing. The applied pressure is 30MPa; finally, put the cold-pressed graphite mold into an electric field-assisted electric spark ion sintering furnace for sintering, and keep it warm after sintering to the sintering temperature. The heating rate is 50°C / min, and the sintering temperature is 1300°C The time is 30 minutes, the applied pressure is 30MPa, and the whole sinterin...

Embodiment 3

[0040] In this embodiment, the precious metal part is a ruthenium-gold mixed target, wherein the mass percentage of ruthenium and gold is 1:1, and the appearance of the ruthenium-gold mixed target is similar to figure 1 As shown, the cross-sectional diameter is 50 mm, and the thickness is 5 mm. The following is the specific preparation method of the ruthenium-gold hybrid target:

[0041] First, accurately design the shape and size of the graphite mold according to the actual shape and size of the preformed ruthenium-gold mixed target; then, weigh 50% by mass of the precious metal ruthenium powder and gold powder with a particle size of 200 mesh and a purity of 99.99%. Put it into a resin tank and use resin balls as the medium to dry mix for 10 hours. After sieving, put the mixed powder into a graphite mold for cold pressing, and apply a pressure of 10 MPa; finally, put the cold-pressed graphite mold into an electric field assisted Sinter in an electric spark ion sintering furn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com