Hydrogenation catalyst, preparation method and application thereof, and method for preparing succinic anhydride through maleic anhydride hydrogenation

A hydrogenation catalyst and catalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc. Advanced problems, to achieve the effect of simplifying the production operation process, saving energy consumption and reducing production operation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

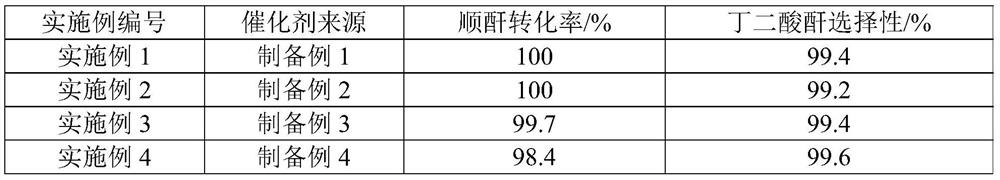

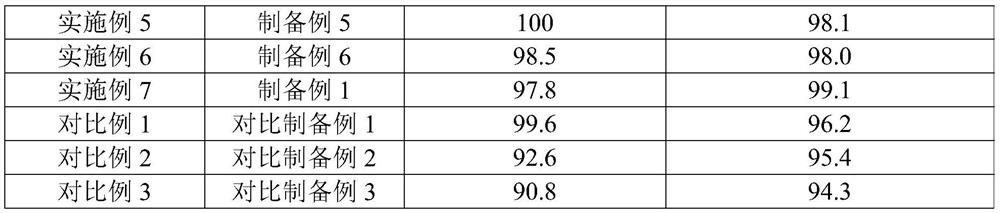

Examples

Embodiment approach

[0073] According to a preferred embodiment of the present invention, the method includes synthesizing the copper ammonium complex and the nickel ammonium complex in the next step: in the presence of the third solvent and ammonia, nickel salt, copper salt and the third The complexing agent is mixed together, and the pH value of the system is adjusted by feeding ammonia gas, and stirred at 40-90° C. until all solids are dissolved; The ratio is 1:0.5-2.

[0074] According to the present invention, there is no limitation on the conditions of the first mixing in step (1), as long as the mixing is uniform, for example, it can be mixed at room temperature (20±5° C.).

[0075] The present invention is not limited to the conditions of the aging, as long as it is beneficial to improve the activity of the catalyst and the selectivity of succinic anhydride; preferably, in step (2), the conditions of the aging include: the temperature is 40-90 ° C, the time for 12-36h.

[0076]According ...

preparation example 1

[0115] (1) Take by weighing 50.00g basic nickel carbonate (wherein the nickel content in terms of elements is 45% by weight), 9.16g of Cu (NO 3 ) 2 ·3H 2 O, 49.91g ethylenediaminetetraacetic acid, 500g deionized water and 100g of 25% by weight ammonia water are mixed, and feed ammonia gas to adjust the pH value of the solution to 10.5, and stir at 45°C until all solids are dissolved to obtain nickel-copper The solution of ammonia complex (that is, the solution of copper ammonia complex and nickel ammonia complex);

[0116] (2) Weigh 458.31g of silica sol (where SiO 2 content of 25% by weight) is mixed with the nickel-copper ammonia complex solution obtained in step (1) to obtain a mixed solution;

[0117] (3) aging the mixed solution at a temperature of 60° C. for 14 hours under stirring, and then drying at 120° C. for 12 hours to obtain a catalyst precursor;

[0118] (4) will contain 11.41g of Ce(NO 3 ) 3 ·6H 2 O in cerium nitrate solution (where Ce(NO 3 ) 3 ·6H 2 O...

preparation example 2

[0122] (1) get basic nickel carbonate (nickel content is the same as preparation example 1), Cu(NO 3 ) 2 ·3H 2 O, 49.91g ethylenediaminetetraacetic acid, 500g deionized water and 100g of 25% by weight ammonia water are mixed, and feed ammonia gas to adjust the pH value of the solution to 12, and stir at 70°C until all solids are dissolved to obtain nickel-copper The solution of ammonia complex (that is, the solution of copper ammonia complex and nickel ammonia complex);

[0123] (2) Get silica sol (same as preparation example 1) and the nickel-copper ammonia complex solution that step (1) obtains and mix, obtain mixed liquor;

[0124] (3) aging the mixed solution at a temperature of 90° C. for 12 hours under stirring, and then drying at 110° C. for 15 hours to obtain a catalyst precursor;

[0125] (4) will contain 11.41g of Ce(NO 3 ) 3 ·6H 2The cerium nitrate solution of O (same as Preparation Example 1) is saturated impregnated described catalyst precursor, obtains matr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com