Vacuum sintering cluster system sharing glove box for protecting feed

A technology of vacuum sintering and cluster system, which is applied in the field of anaerobic material sintering equipment in metallurgical processing, can solve the problems of high production cost accounting, large user input, and large floor space, and is conducive to management, saving investment and reducing production. The effect of job cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

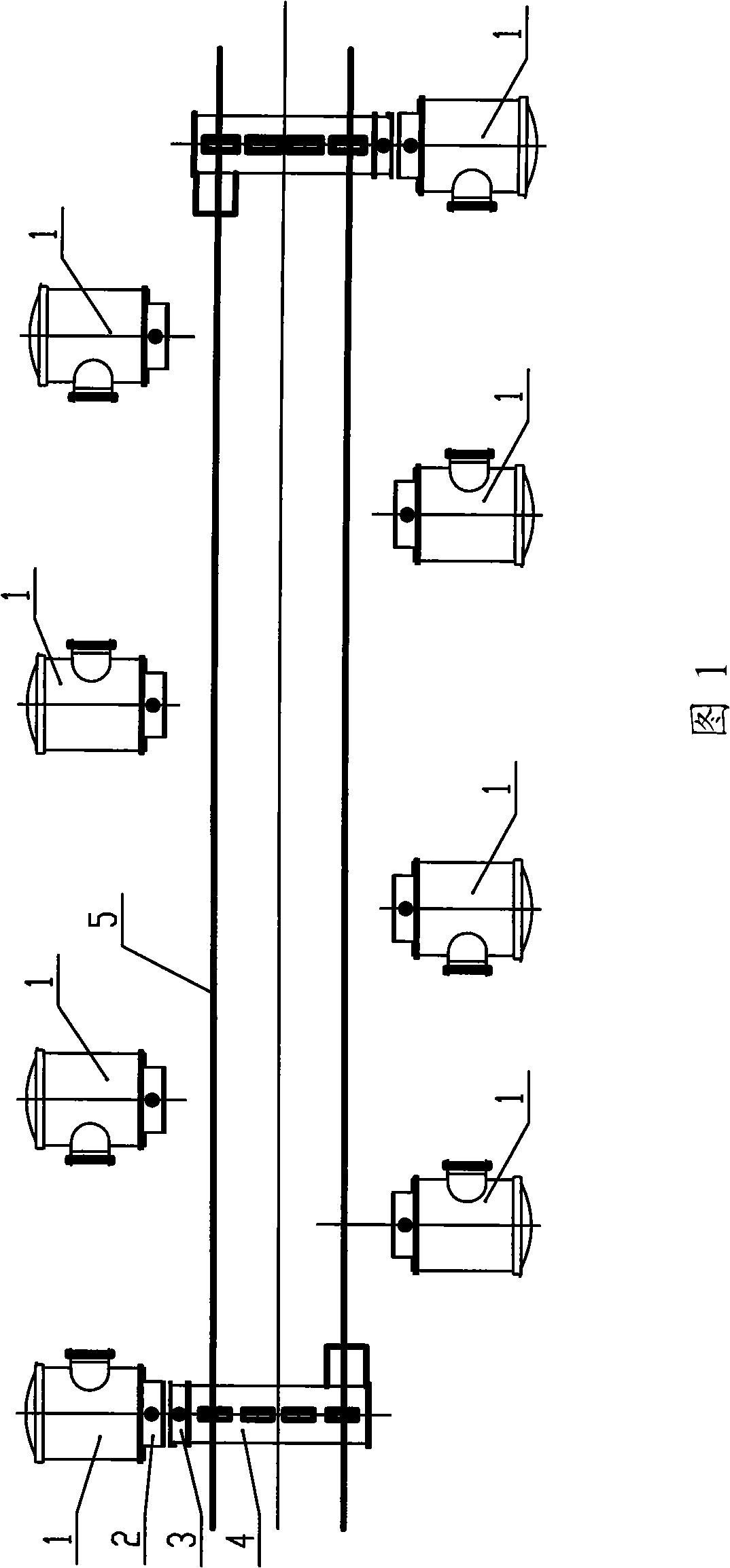

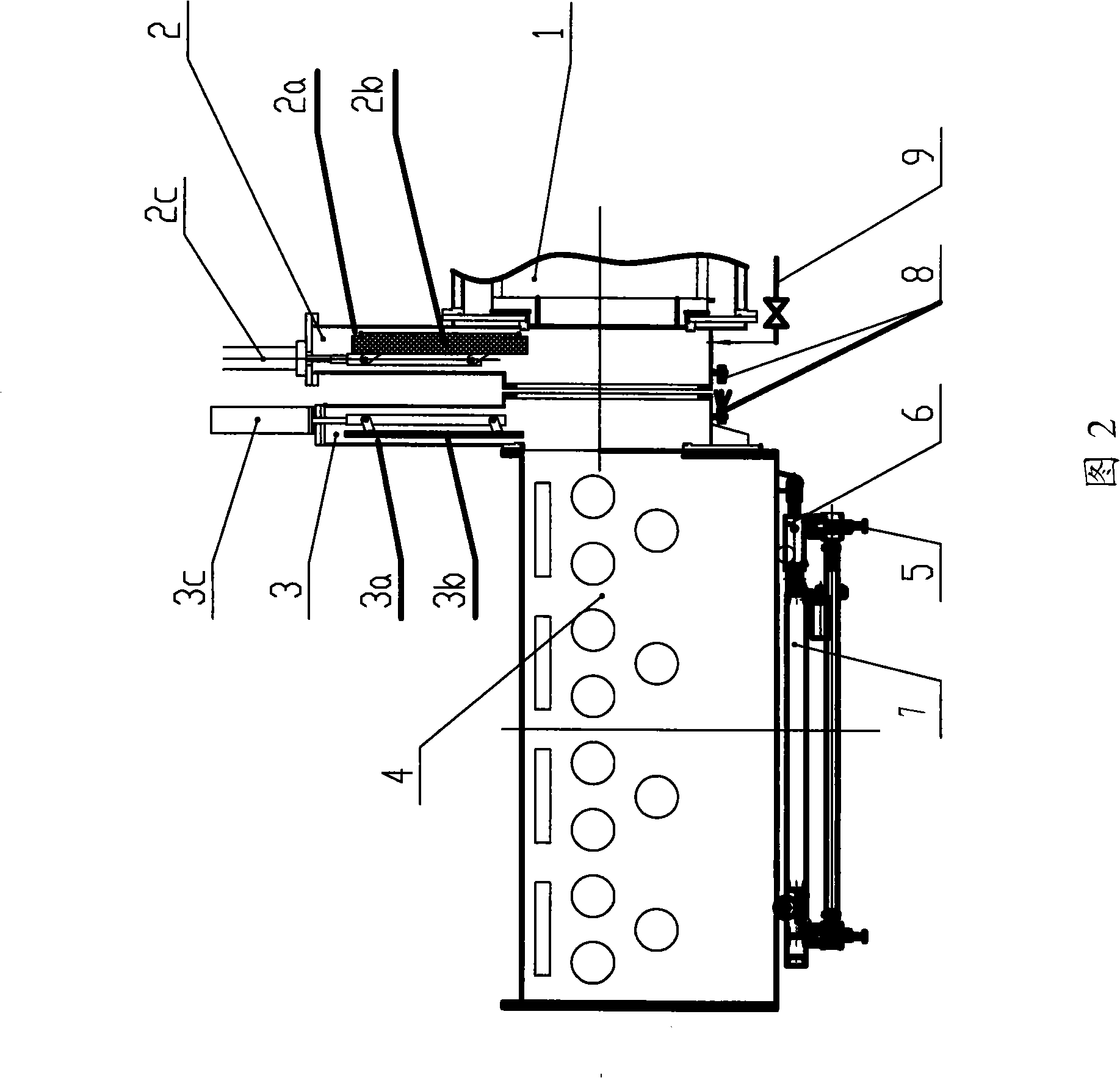

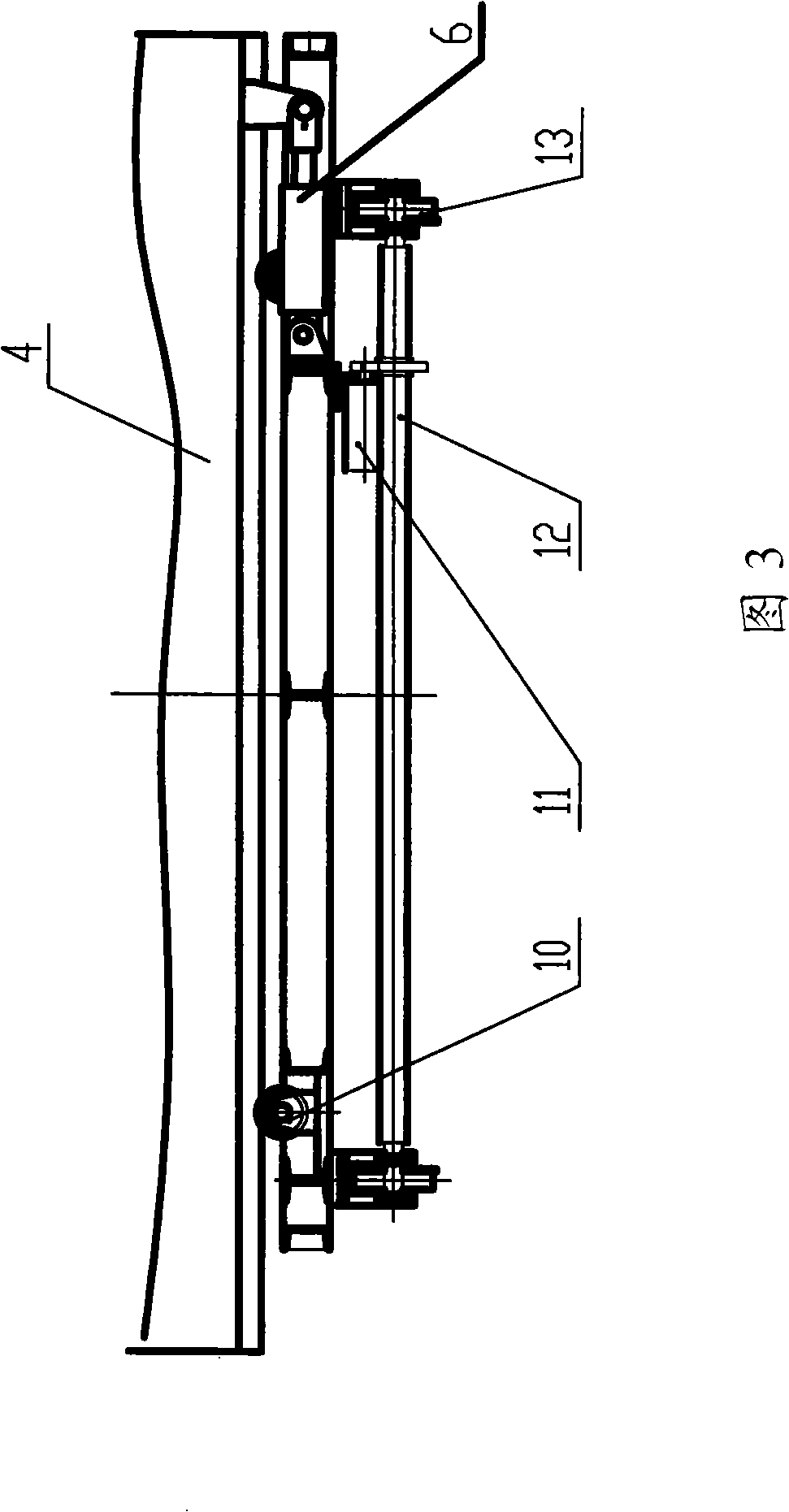

[0011] The vacuum sintering cluster system of the present invention, which shares a protective feeding glove box, includes a plurality of sintering chambers, a protective charging glove box, and an automatic control system, and is characterized in that the sintering chamber door 2 and the protective charging glove box door 3 both adopt plug-in Plate valve structure, the connection between the gate 2 of the gate valve type sintering chamber and the glove box door 3 forms a protective space, and the protective charging glove box 4 is placed on the frame 7 with a propulsion mechanism, and the two carts are on the track 5. The sintering chamber 1 is arranged on one side of the track 5 . Figure 1 shows the optimized combination: two protective charging glove boxes 1 are reversely installed on a pair of rails 5, and more sintering chambers 1 are distributed on the outside of the rails 5 to form a sintering cluster; the control and deployment of the automatic control system can Mobil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com