Method of recovering acetic acid and water in production of aromatic carboxylic acid

An aromatic hydrocarbon carboxylic acid and acetic acid technology, which is applied in the separation/purification of carboxylic acid compounds, organic chemistry and other directions, can solve the problems of inability to meet water recycling, increase separation operation costs, low yield of aromatic hydrocarbon carboxylic acid, etc., and save energy for separation , low cost, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

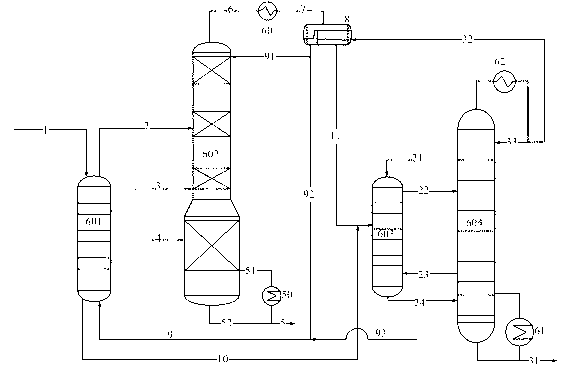

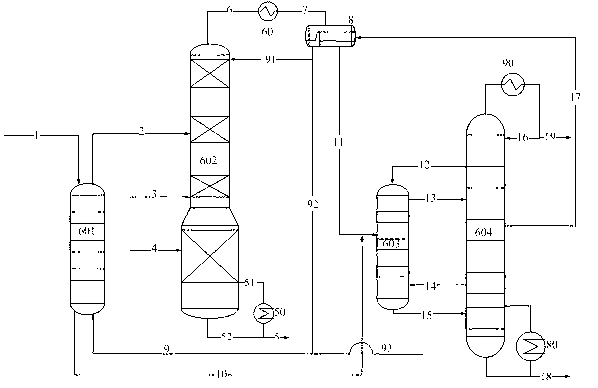

Image

Examples

Embodiment 1

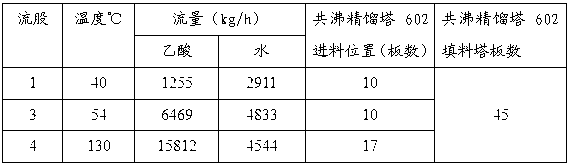

[0072] use figure 2 In the shown flow process, stream 1 in embodiment 1 is first entered into a pre-extraction tower 601 for pre-separation, and the extractant and entrainer all adopt sec-butyl acetate. When the phase extraction component is carried out solvent recovery, adopt technology of the present invention, promptly the tower top and tower bottom product of plate type solvent recovery front tower 603 enter the 10th and the 20th plate of solvent recovery tower 604 respectively, simultaneously, in solvent recovery A side outlet is added to the 14th tray of the tower 604 to extract stream 17 for extracting high-concentration entrainer. The data related to the separation of the whole system are shown in Table 3.

[0073]

[0074] Carry out simulation calculation to different process systems in the above example, compare the superiority of the process of the present invention according to the calculation results under different processes. The specific comparison content a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com