Patents

Literature

32results about How to "Small process footprint" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

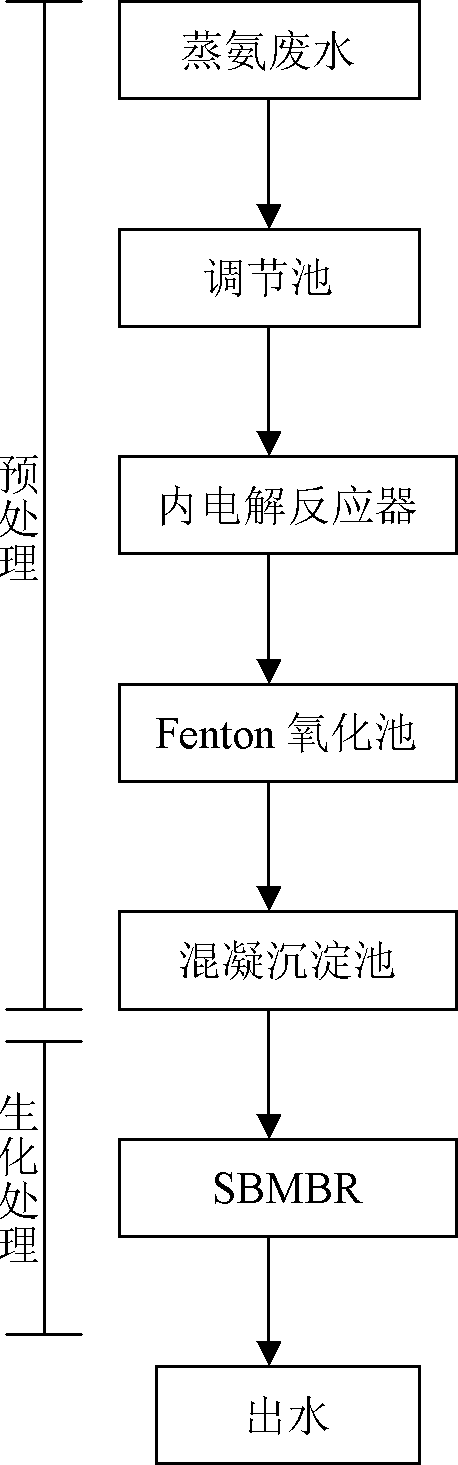

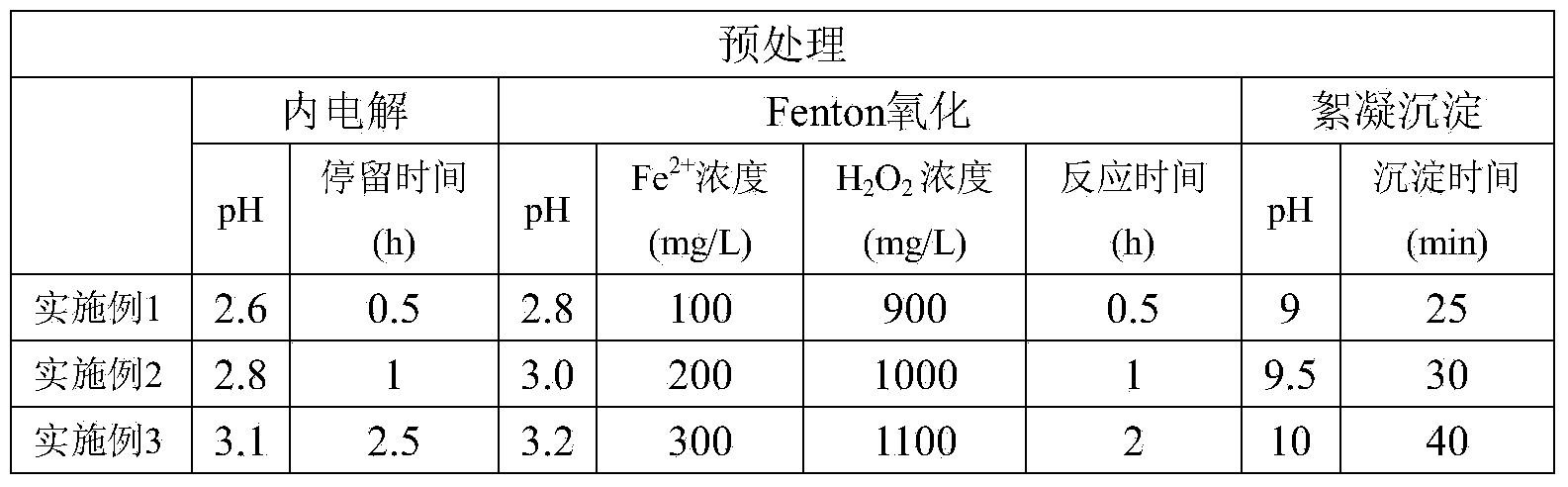

Processing method of coking steaming ammonia wastewater

ActiveCN103130379AEasy to useEasy to recycleMultistage water/sewage treatmentElectrolysisPersistent organic pollutant

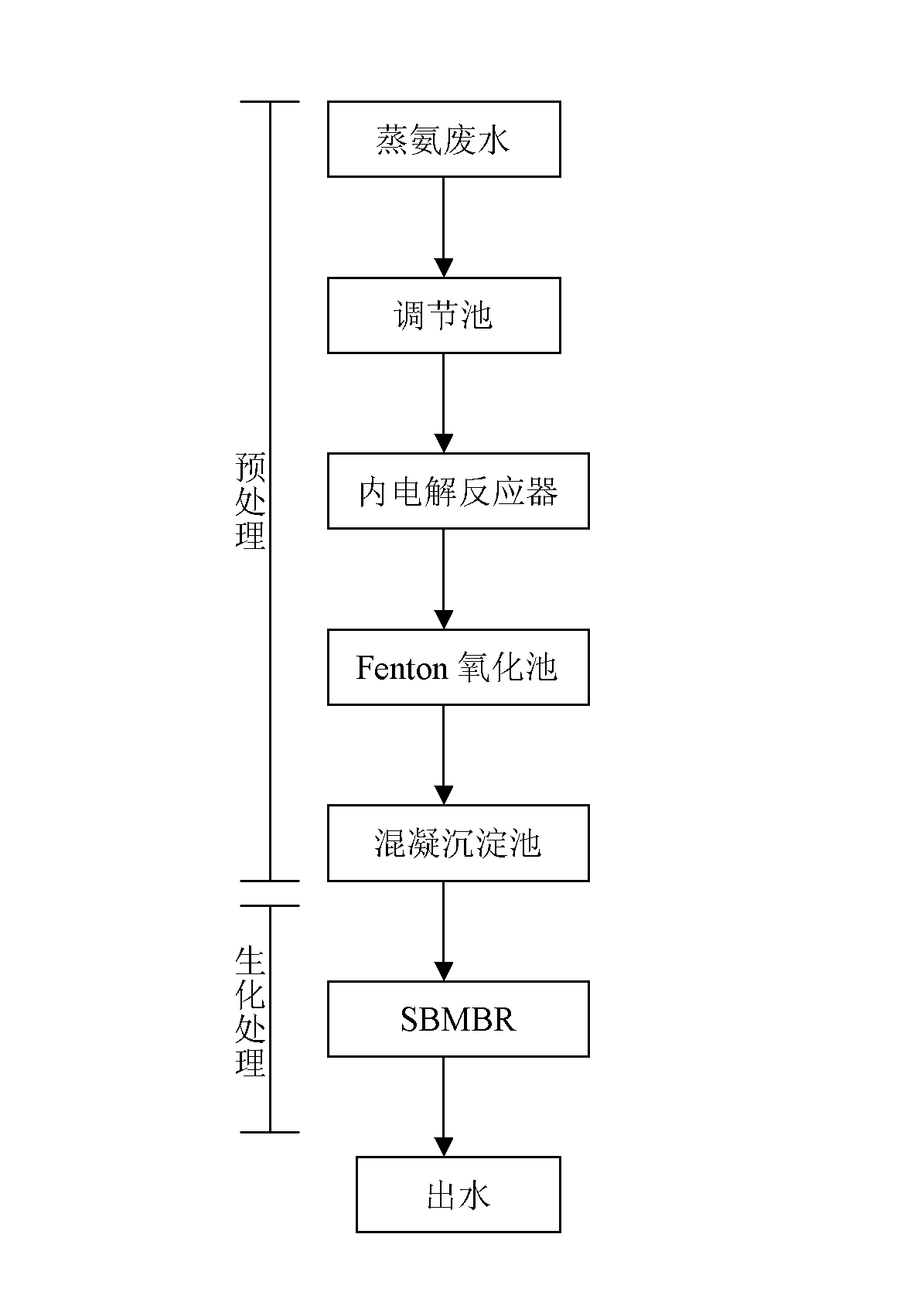

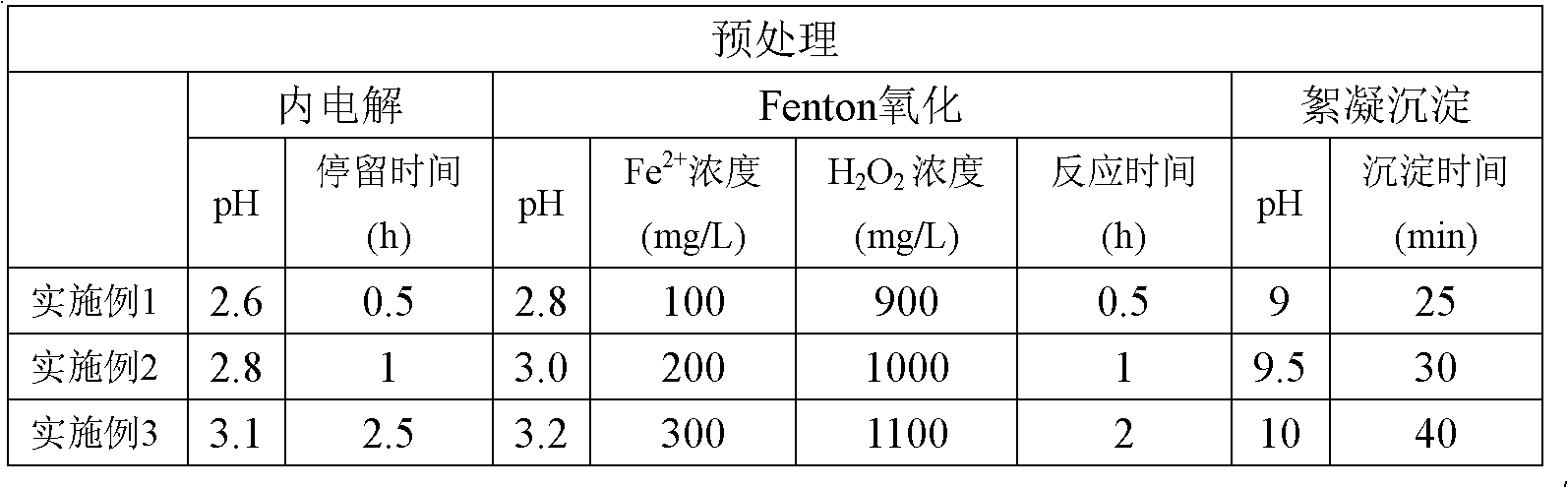

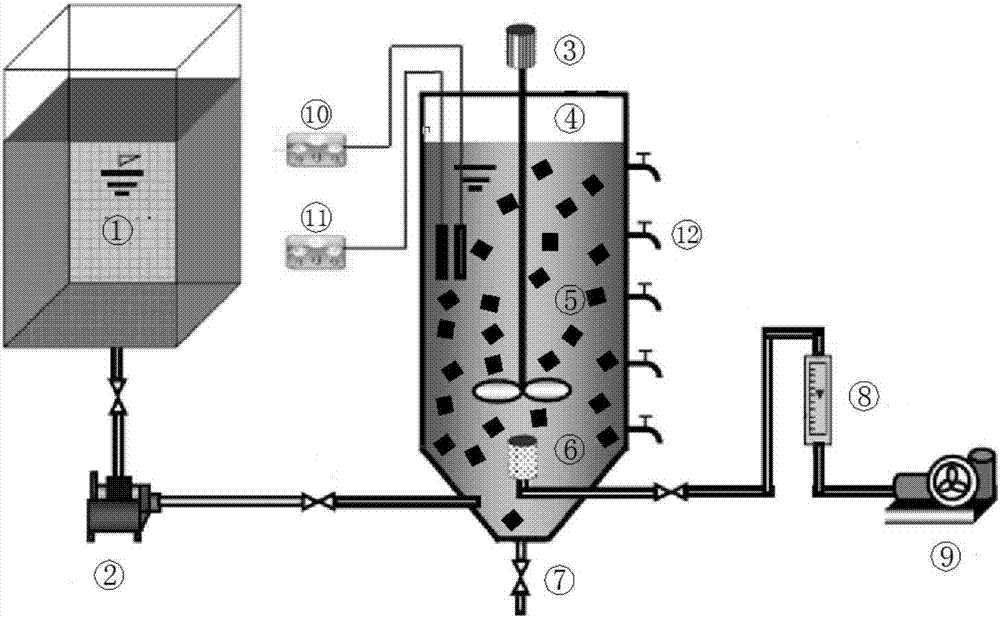

The invention discloses a processing method of coking steaming ammonia wastewater. The processing method of the coking steaming ammonia wastewater comprises pretreatment of coking steaming ammonia wastewater and biochemical treatment of the coking ammonia wastewater. The pretreatment of the coking steaming ammonia wastewater uses an adjusting pool, an internal electrolysis reactor, a Fenton oxidation pond and a coagulative precipitation tank. A sequencing batch membrane bioreactor technology is adopted by the biochemical treatment, and working procedures of inflow, unused-leaving, reacting and discharging are sequentially performed according to a time period. The processing method of the coking steaming ammonia wastewater can effectively remove persistent organic pollutants and ammonia nitrogen, strengthen effluent quality, and reduce operational and investing costs of equipment.

Owner:ANGANG STEEL CO LTD

Whole process low-oxygen aeration SBMBBR synchronous denitrification and dephosphorization method

ActiveCN107010727AGood denitrification and phosphorus removalHigh organic loadWater contaminantsTreatment with aerobic and anaerobic processesSequencing batch reactorMoving bed biofilm reactor

Owner:GUANGZHOU UNIVERSITY

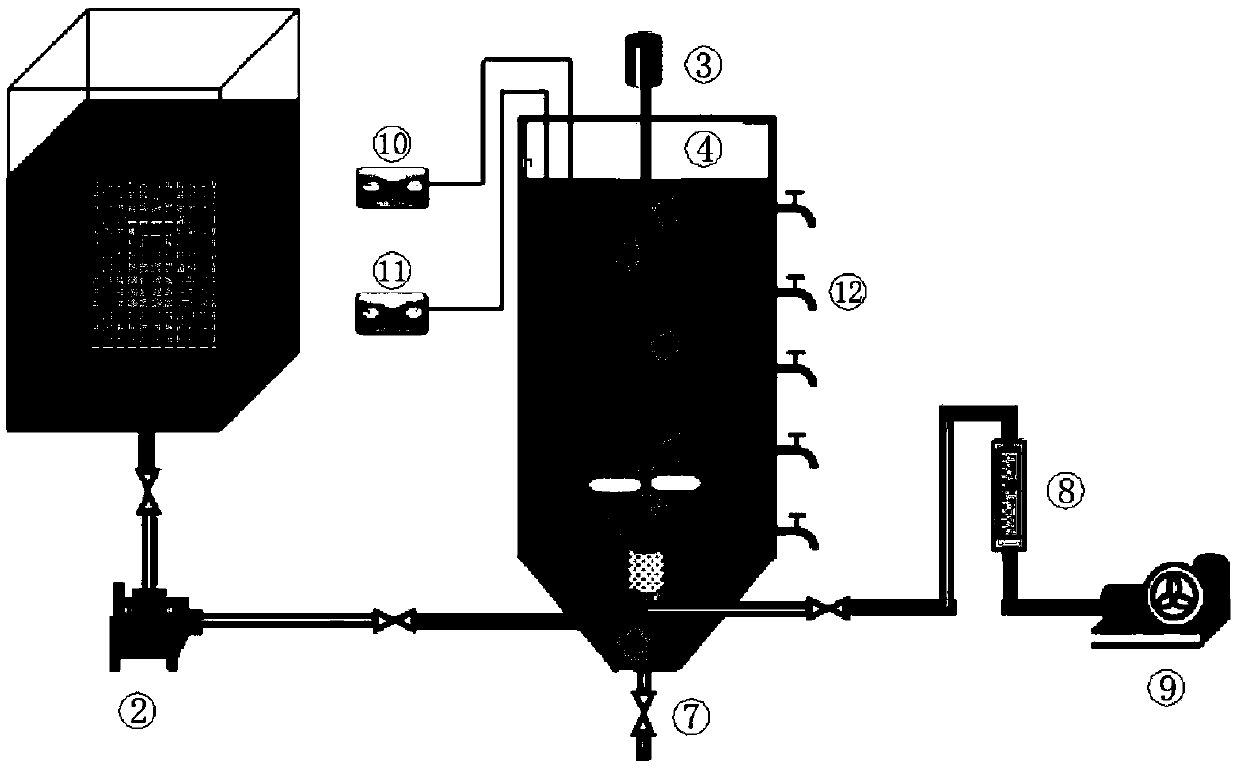

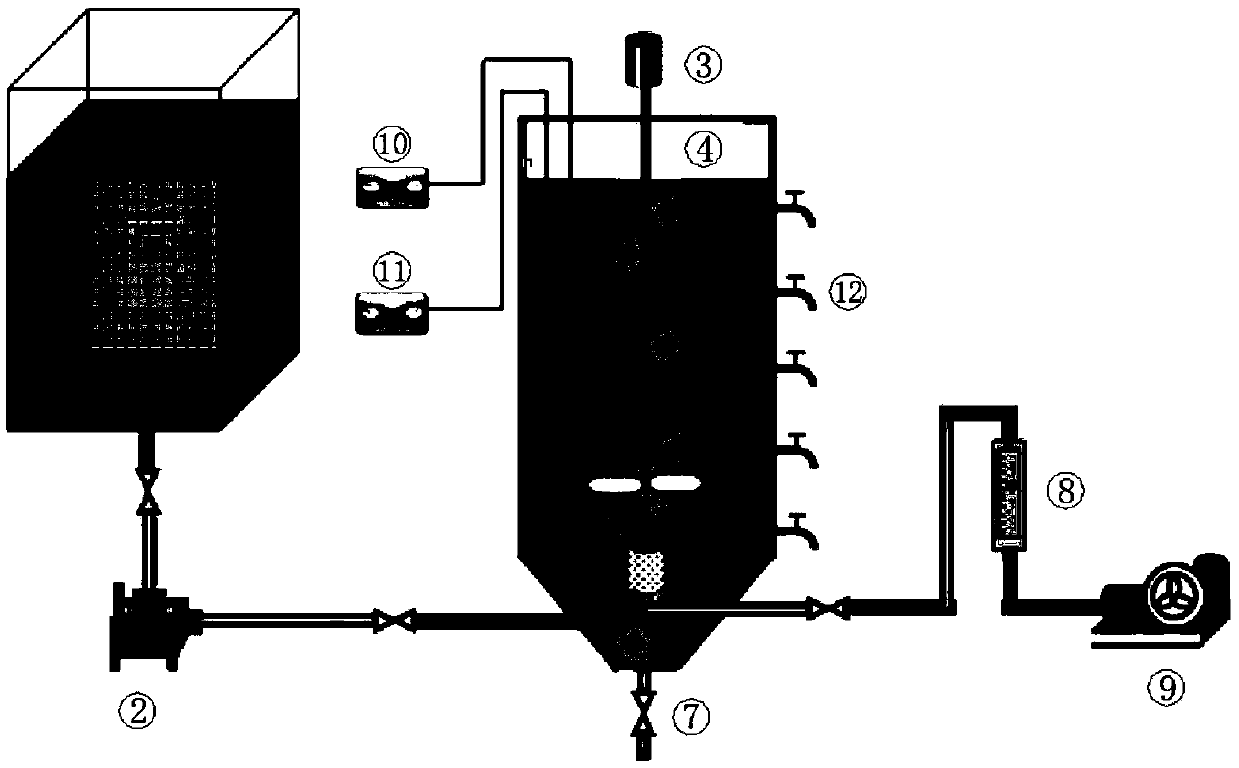

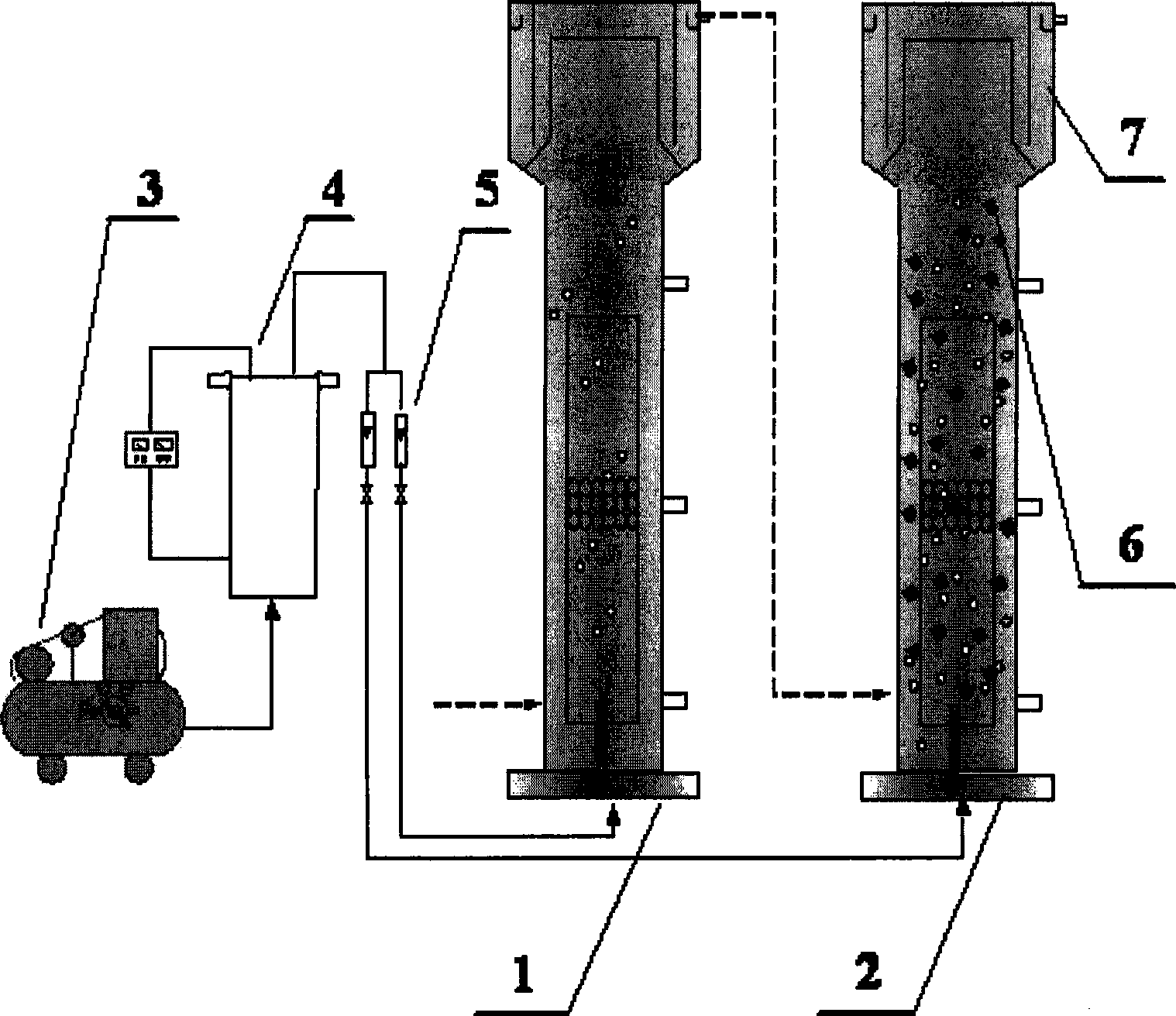

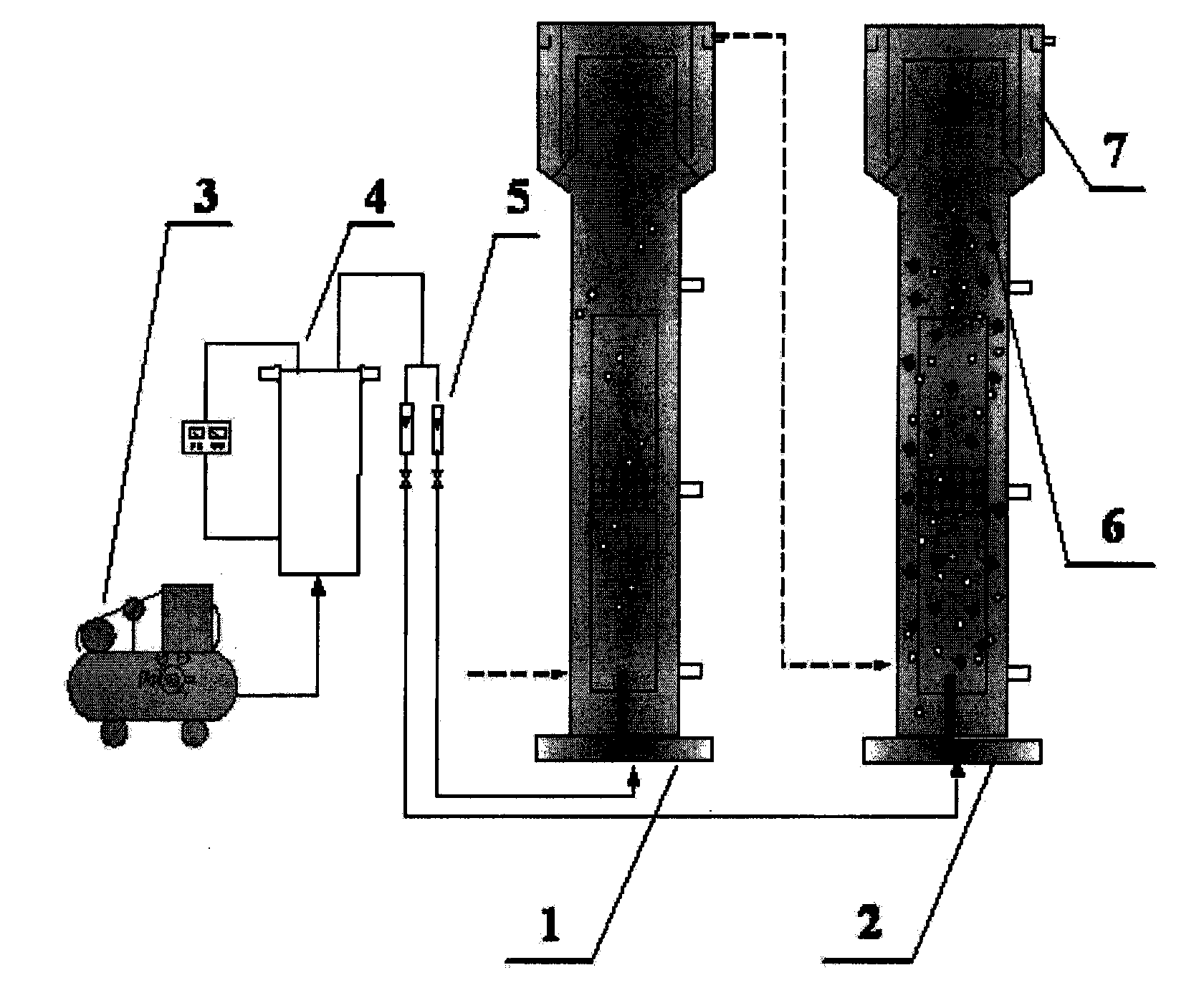

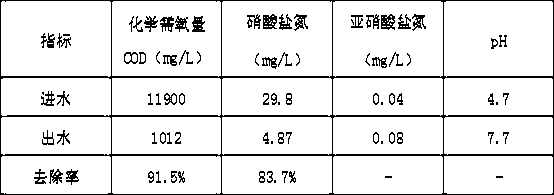

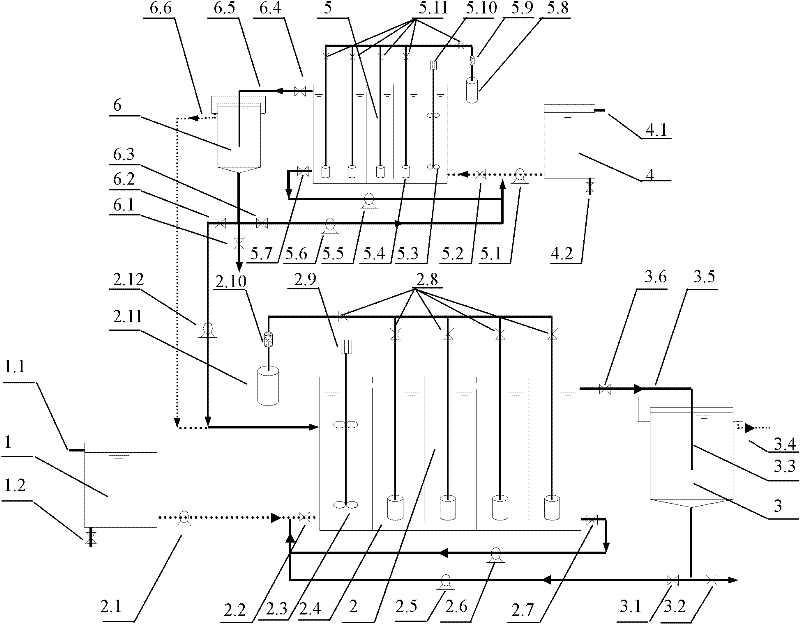

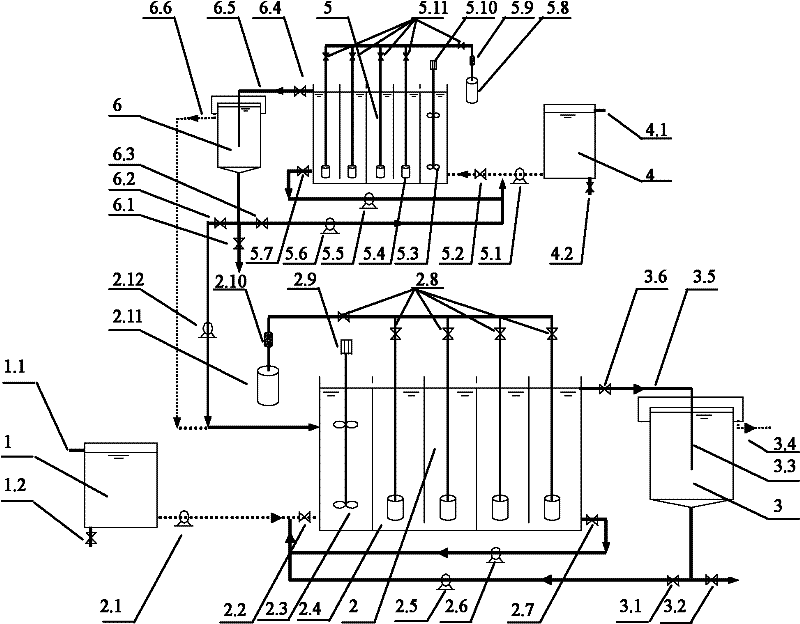

Biochemical degradation system coupling hydrolytic acidification-anaerobic and aerobic

ActiveCN101381163AIncrease dissolved oxygen levelsImprove mass transfer efficiencyTreatment with aerobic and anaerobic processesIndustrial waste waterContinuous flow

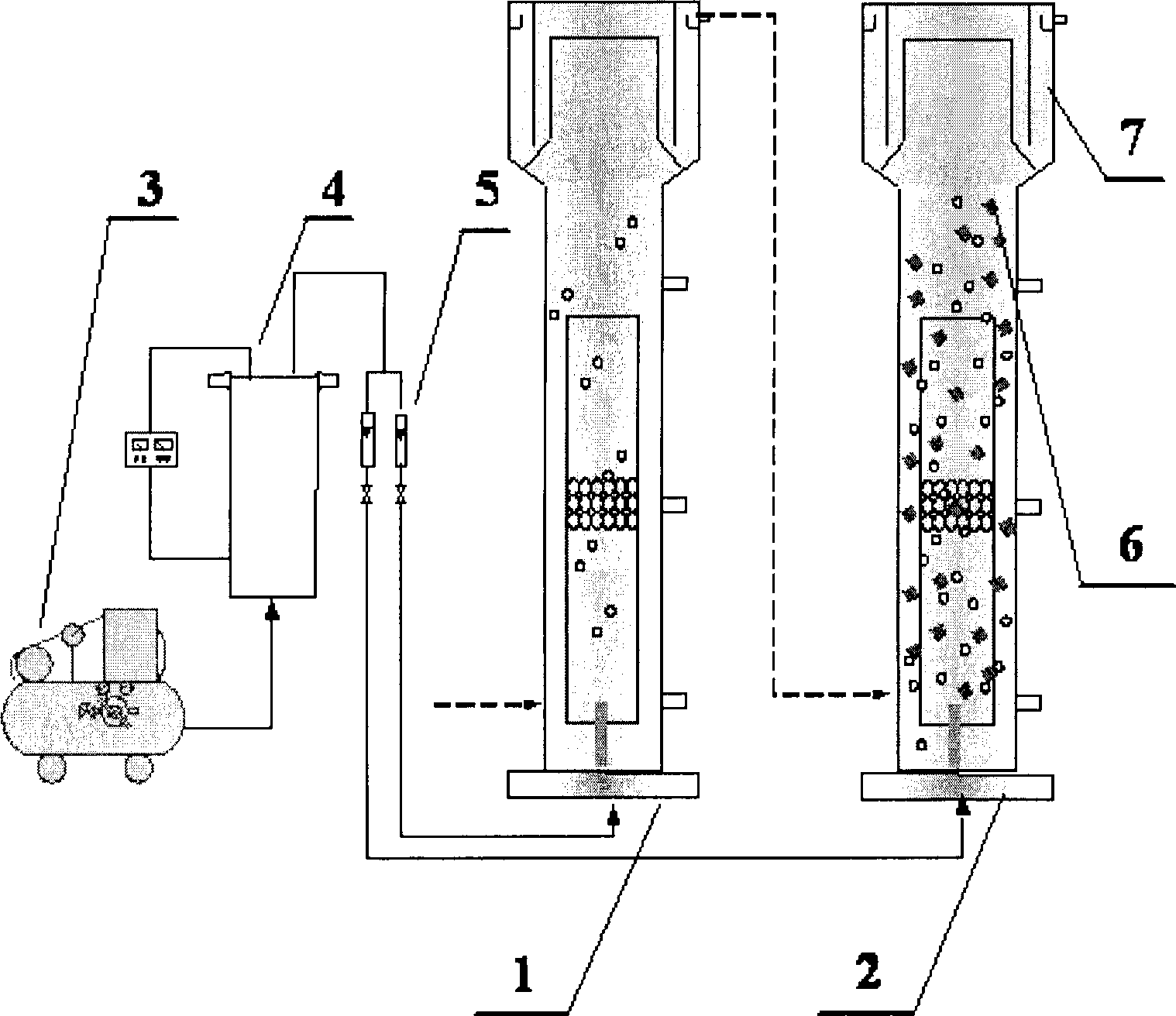

The present invention discloses a hydrolization and acidification - anaerobism and aerobism coupling biochemical degradation system, which belongs to the technical field of environment engineering and industrial waste water disposal. The system is used for disposing organic waste that is difficult to be degraded. The biochemical degradation system consists of two serially connected airlift internally circulating biological fluidized beds. The front airlift internally circulating biological fluidized bed is an anaerobe fluid bed which adopts micro-aeration operation and carries out hydrolization and acidification processing; and the rear airlft internally circulating biological fluidized bed is an anaerobism and aerobism coupling biological fluid bed which is constructed by filling macropore carriers and carries out the complete degradation of organisms. The organic waste water which is difficult to be degraded enters the anaerobic fluid bed first, and enters the anaerobism-aerobism coupled biological fluid bed after the hydrolization and acidification processing so as to be completely degraded. The system achieves high efficiency and quick coupling of the anaerobe degradation and the aerobe, and has the characteristics of high disposing efficiency, short residence time, small floor space, low investment, low running cost and so on. The method can be applied to the sequencing batch type disposal process, and can be applied to the continuous flow type disposal process as well.

Owner:TSINGHUA UNIV

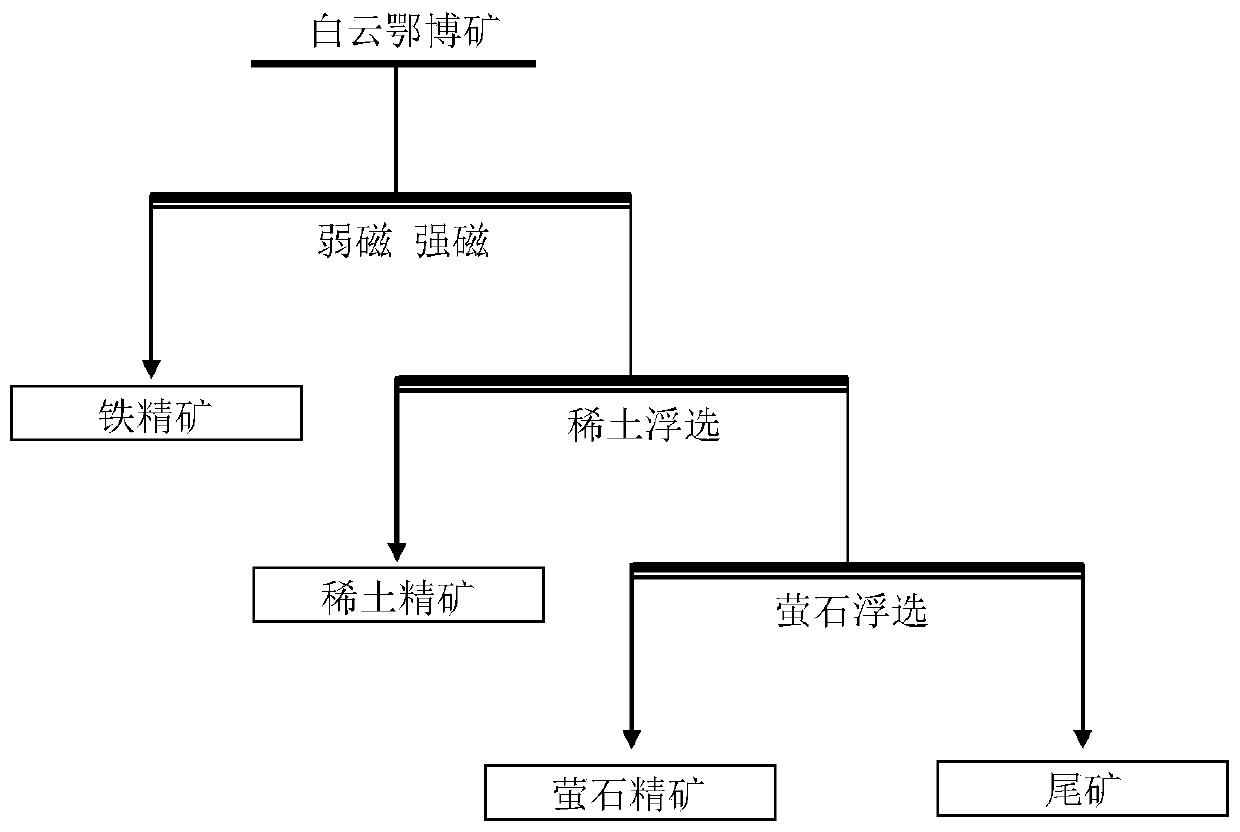

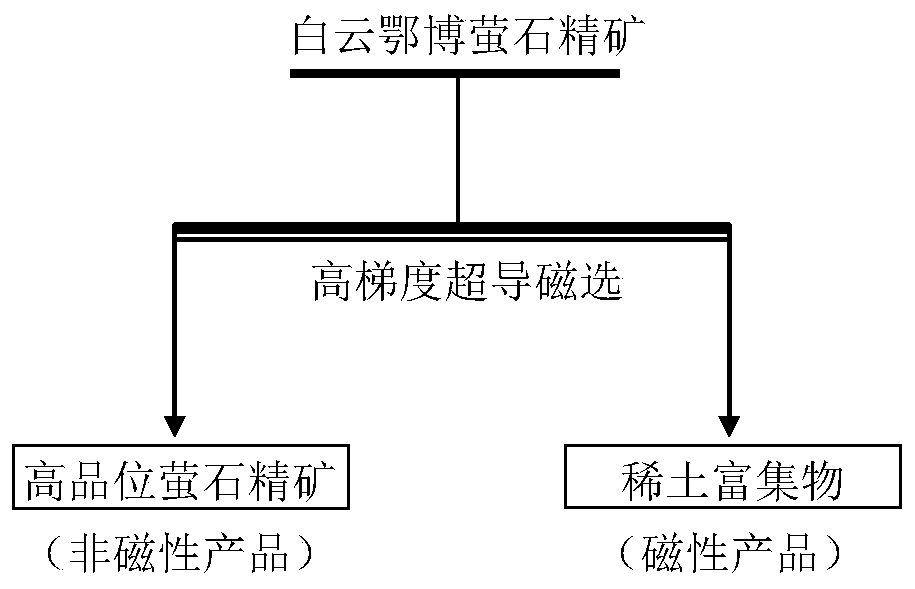

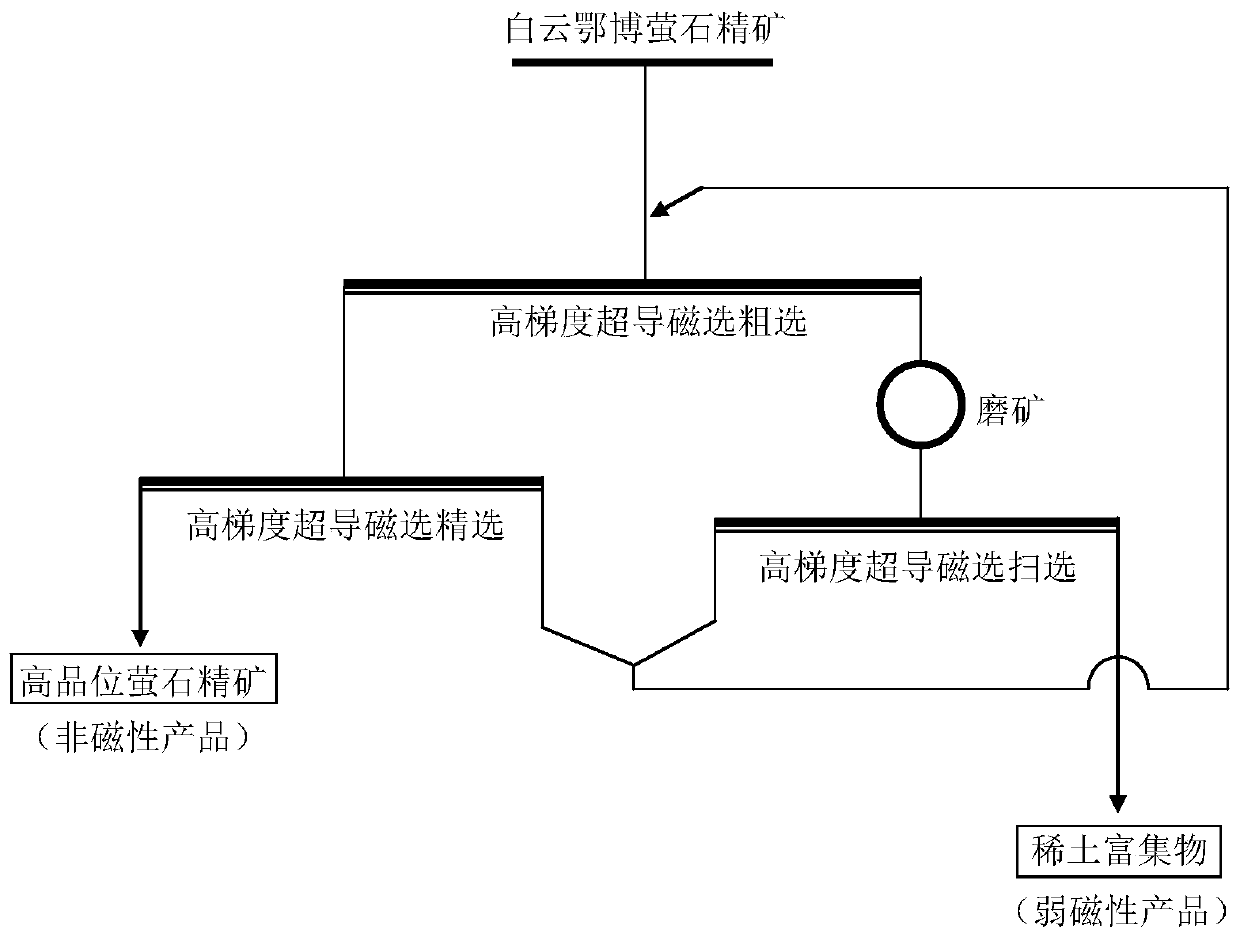

Method for improving grades of fluorite ore concentrate and rare earth ore concentrate of baiyuneboite through high-gradient superconducting magnetic separation

The invention relates to a method for improving grades of fluorite ore concentrate and rare earth ore concentrate of baiyuneboite through high-gradient superconducting magnetic separation. Fluorite ore concentrate graded from baiyuneboite is subjected to magnetic separation through a high-gradient superconducting magnetic separator by a high-gradient superconducting magnetic separation technology,so that the grade of CaF2 in the fluorite ore concentrate is improved to 90-99%, a mineral separating index of fluorite of the baiyuneboite is improved, and rare earth enrichment is obtained at the same time. The superconducting magnetic separation method is similarly suitable for rare earth ore concentrate products in the baiyuneboite, the grade of REO in the rare earth ore concentrate is improved to be more than 60%. According to the high-gradient superconducting magnetic separation technology, the simpleness and the high efficiency are realized, the occupied area is small, the power consumption is small, the cost is low, no chemical agent is used, water is directly recycled, and the environmental friendliness is achieved; and according to the method for improving the grades of the fluorite ore concentrate and the rare earth ore concentrate of the baiyuneboite through the high-gradient superconducting magnetic separation, the concentrate grades of the fluorite ore concentrate and the rare earth ore concentrate of the baiyuneboite are greatly improved, and the technical problems that the grade of the fluorite ore concentrate sorted from the baiyuneboite is low and the inclusion content of weak magnetic mineral rare earth is high are effectively solved.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

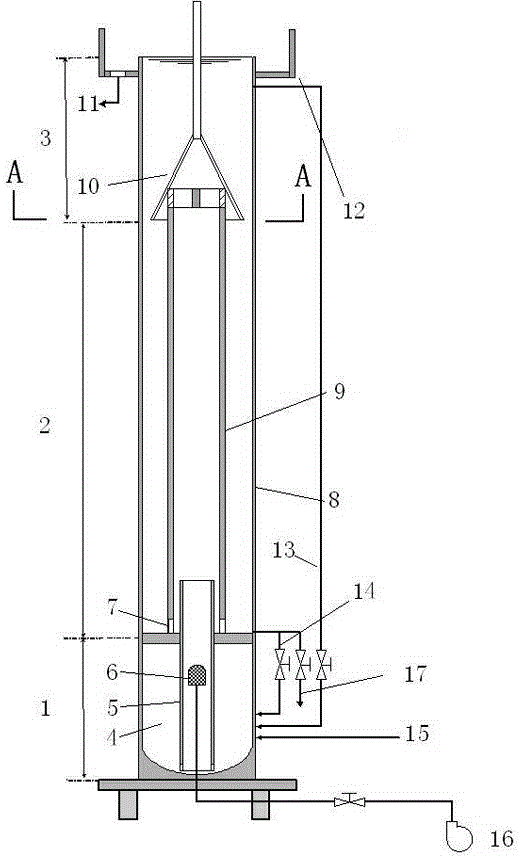

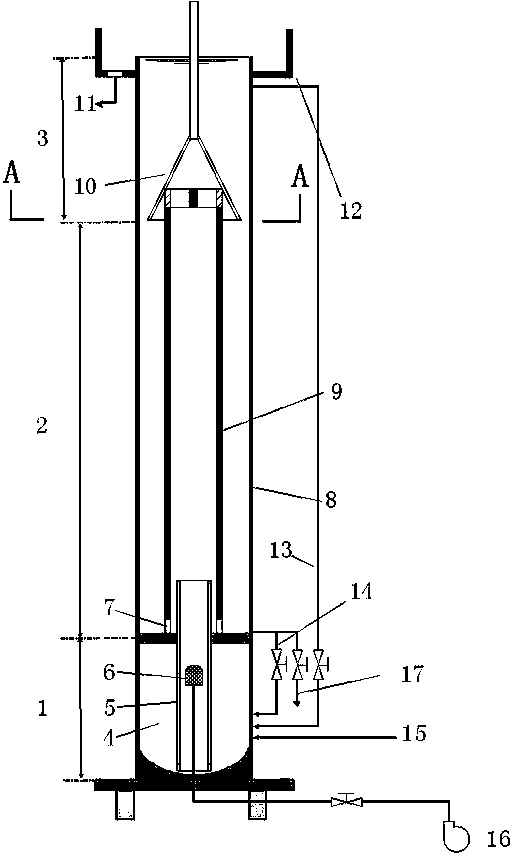

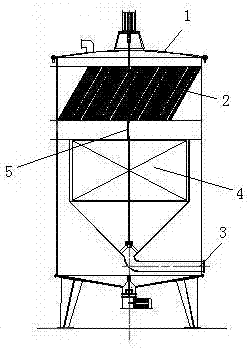

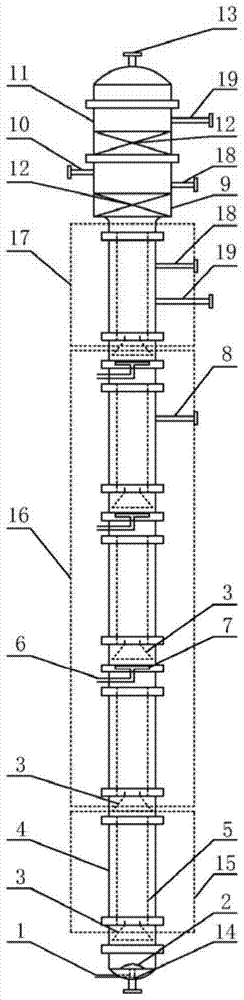

Aerobic granular sludge sewage processing method having nitrogen removal effect and special-purpose equipment thereof

InactiveCN105819568AAccelerated settlementMicrobial biomass is large and harmfulTreatment with aerobic and anaerobic processesActivated sludgeNitrogen removal

The invention relates to an aerobic granular sludge sewage treatment method with denitrification effect and special equipment. The method comprises the steps of cultivating and acclimating activated sludge, treating target sewage, and sludge disposal. The special equipment includes a tower body, which is divided into a reaction zone at the bottom of the tower, an aerobic nitrification zone in the middle, and a three-phase separation zone at the top. The beneficial effect of the invention is that the sewage treatment effect is good, the tower design occupies a small area, the sludge particle formation effect is good, and the denitrification effect is good, and the nitrification liquid circulation and the sludge circulation do not need external power, which saves costs.

Owner:JILIN NORMAL UNIV

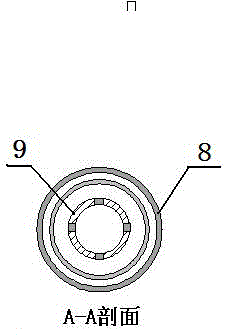

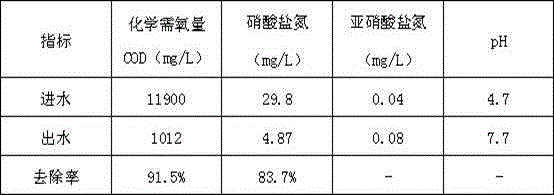

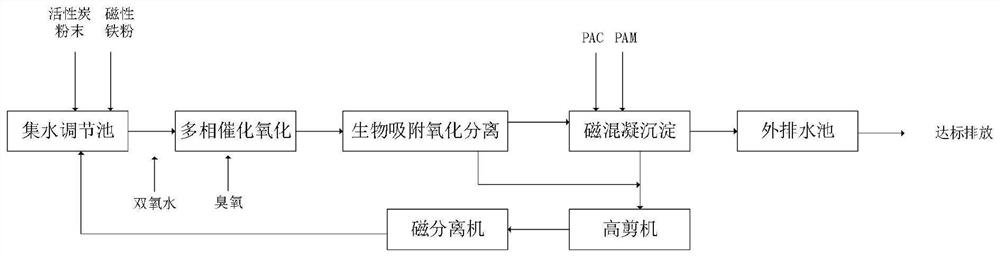

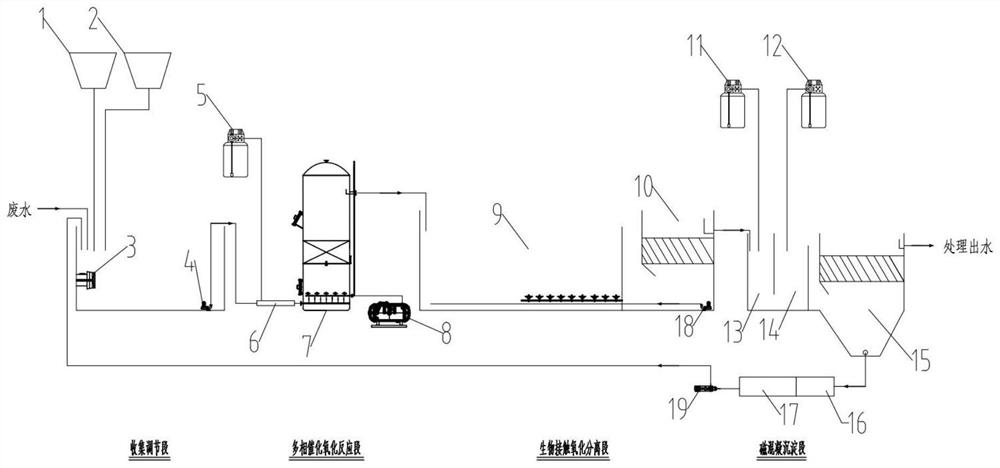

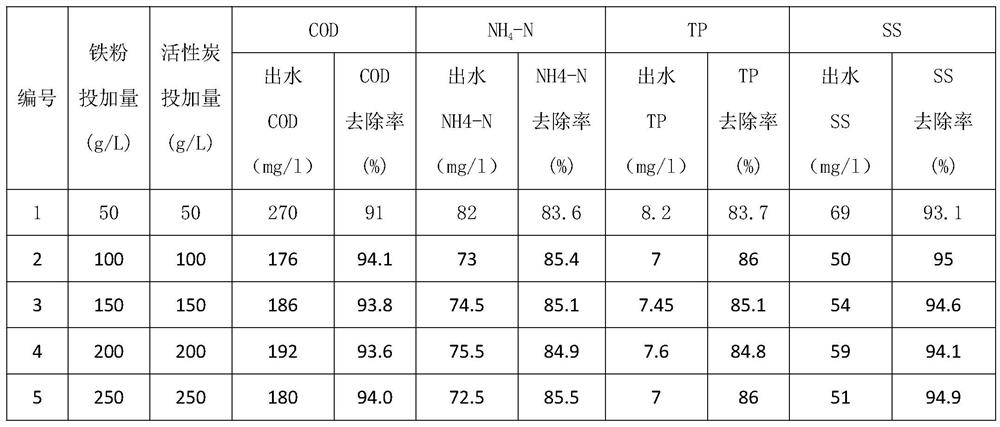

Low-concentration refractory chemical wastewater treatment method and system

PendingCN111762969AEasy to handleImprove catalytic performanceWater treatment compoundsWater contaminantsActivated charcoal powderActivated carbon

The invention relates to the field of wastewater treatment systems, and especially relates to a low-concentration refractory chemical wastewater treatment method and system. The method comprises the following steps: collecting and adjusting wastewater, and adding activated carbon powder and magnetic iron powder into a pool; carrying out heterogeneous catalytic oxidation: carrying out heterogeneouscoupling catalytic oxidation through ozone, hydrogen peroxide, activated carbon powder and magnetic iron powder; carrying out biological adsorption oxidation; and carrying out magnetic coagulative precipitation. According to the low-concentration refractory chemical wastewater treatment method, physicochemical and biochemical combined treatment is adopted, the activated carbon / magnetic iron powder penetrates through the whole system process, the whole-process adsorption micro-electrolysis environment is achieved, the treatment effect is enhanced, pollutants are enriched in a limited mode by adding the activated carbon / magnetic iron powder into the water collection adjusting tank, and subsequent stage treatment is facilitated.

Owner:北京新林环境科技有限公司

Method for treating sludge digestion liquid by coupling short-cut nitrification/anaerobic ammonia oxidation-fermentation short-cut denitrification/anaerobic ammonia oxidation and device thereof

PendingCN113800636ASmall process footprintAvoid cumbersome stepsWater treatment parameter controlSpecific water treatment objectivesChemistryHeterotrophic bacteria

The invention discloses a method for treating sludge digestion liquid by coupling short-cut nitrification / anaerobic ammonia oxidation-fermentation with short-cut denitrification / anaerobic ammonia oxidation and a device thereof, and belongs to the field of biochemical treatment of sludge digestion liquid. The method comprises the following steps: after sludge digestion liquid enters an SBR, removing organic matters in raw water and residual nitrate nitrogen in the last period through heterotrophic bacteria and denitrifying bacteria by adopting a pre-anoxic / aerobic / anoxic operation mode, removing part of total nitrogen in the raw water through ammonia oxidizing bacteria and anaerobic ammonium oxidizing bacteria on a biological membrane, and enabling an effluent to enter a UASB reactor, and further reducing the total nitrogen in the effluent through the combined action of hydrolytic acidification bacteria, denitrifying bacteria and anaerobic ammonium oxidation bacteria in the granular sludge. According to the invention, an additional carbon source is not needed, the aeration energy consumption is saved, the emission of greenhouse gases can be reduced, the problem of unstable denitrification effect of the system caused by easy loss of anaerobic ammonia oxidation sludge is solved by utilizing the biological membrane and the granular sludge, the denitrification load and stability of the system are improved, and the deep denitrification of the sludge digestion liquid and the reduction and recycling of the sludge are realized.

Owner:BEIJING UNIV OF TECH

Seawater desalination system for removing boron by using electrodeionization

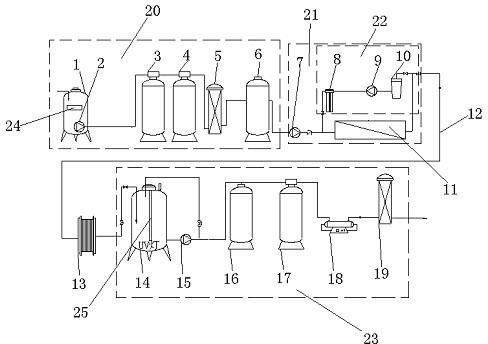

InactiveCN102690009AEfficient removalSmall process footprintWater/sewage treatment by irradiationGeneral water supply conservationWater desalinationSeawater reverse osmosis

The invention relates to a seawater desalination system for removing boron by using electrodeionization, comprising a water pipe, a seawater pretreatment system, a seawater reverse osmosis desalting and boron-removing desalination system, an electrodeionization boron-removing desalination system and a seawater deep treatment system, wherein the seawater pretreatment system, the seawater reverse osmosis desalting and boron-removing desalination system, the electrodeionization boron-removing desalination system and the seawater deep treatment system are sequentially connected in series to the water pipe. The seawater desalination system is characterized in that a reverse osmosis technology and an electrodeionization technology are jointly used to remove boron in seawater with high efficiency and low consumption; with the adoption of the technologies, more than 99% of salt and more than 92% of boron in the seawater can be removed, so that produced water reaches Sanitary Standard for Drinking Water (GB5749-2006). The seawater desalination system for removing boron by using the electrodeionization has the advantages of small space occupation, low energy and agent consumption, low operation cost, safety and reliability for equipment operation and simplicity in maintenance.

Owner:NANCHANG UNIV

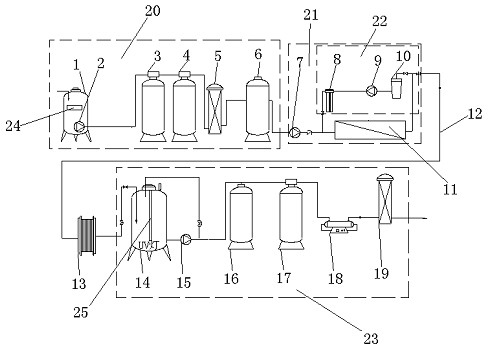

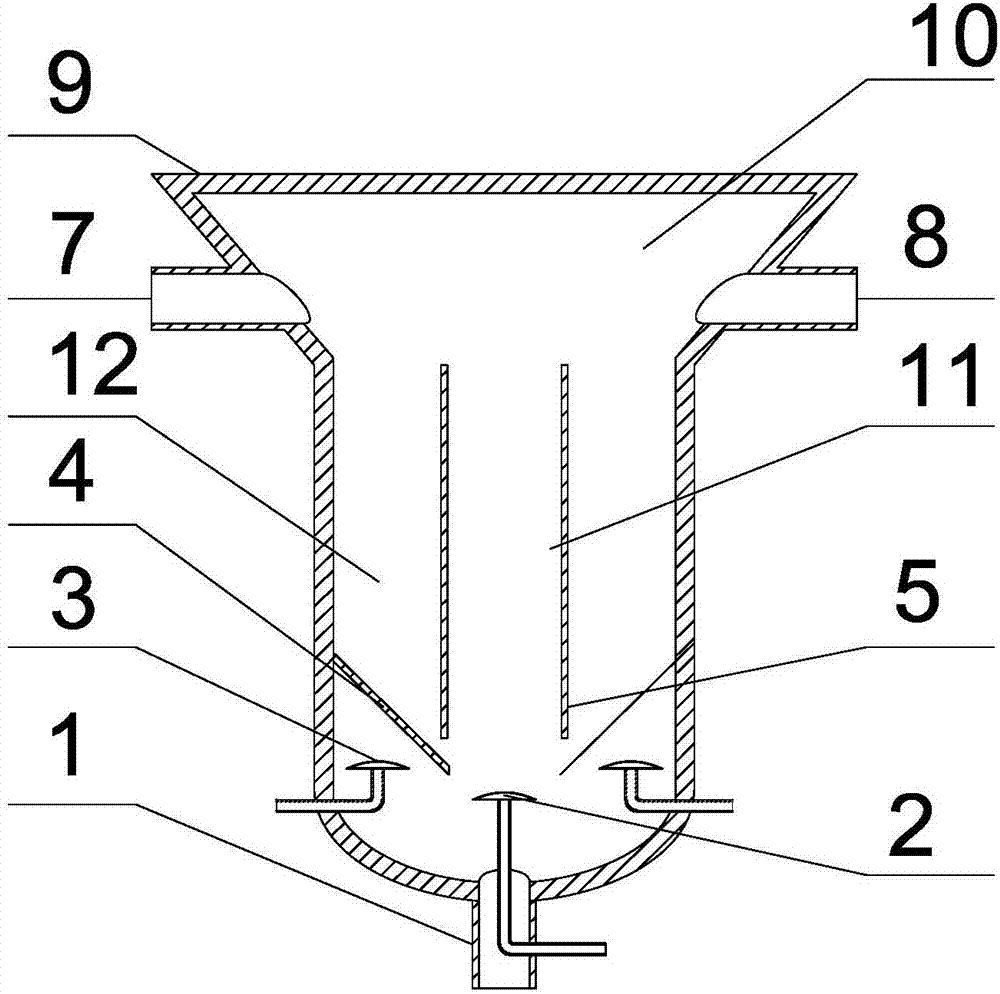

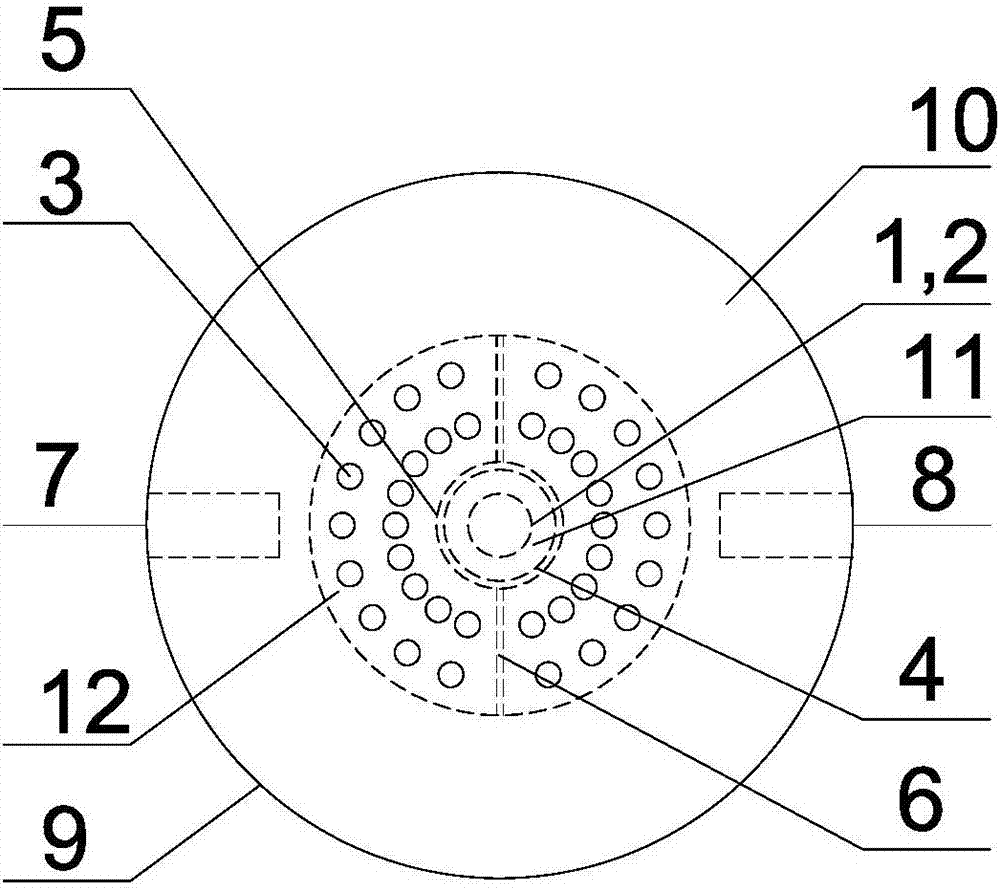

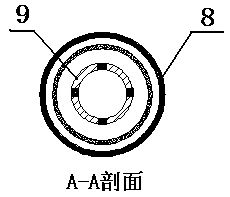

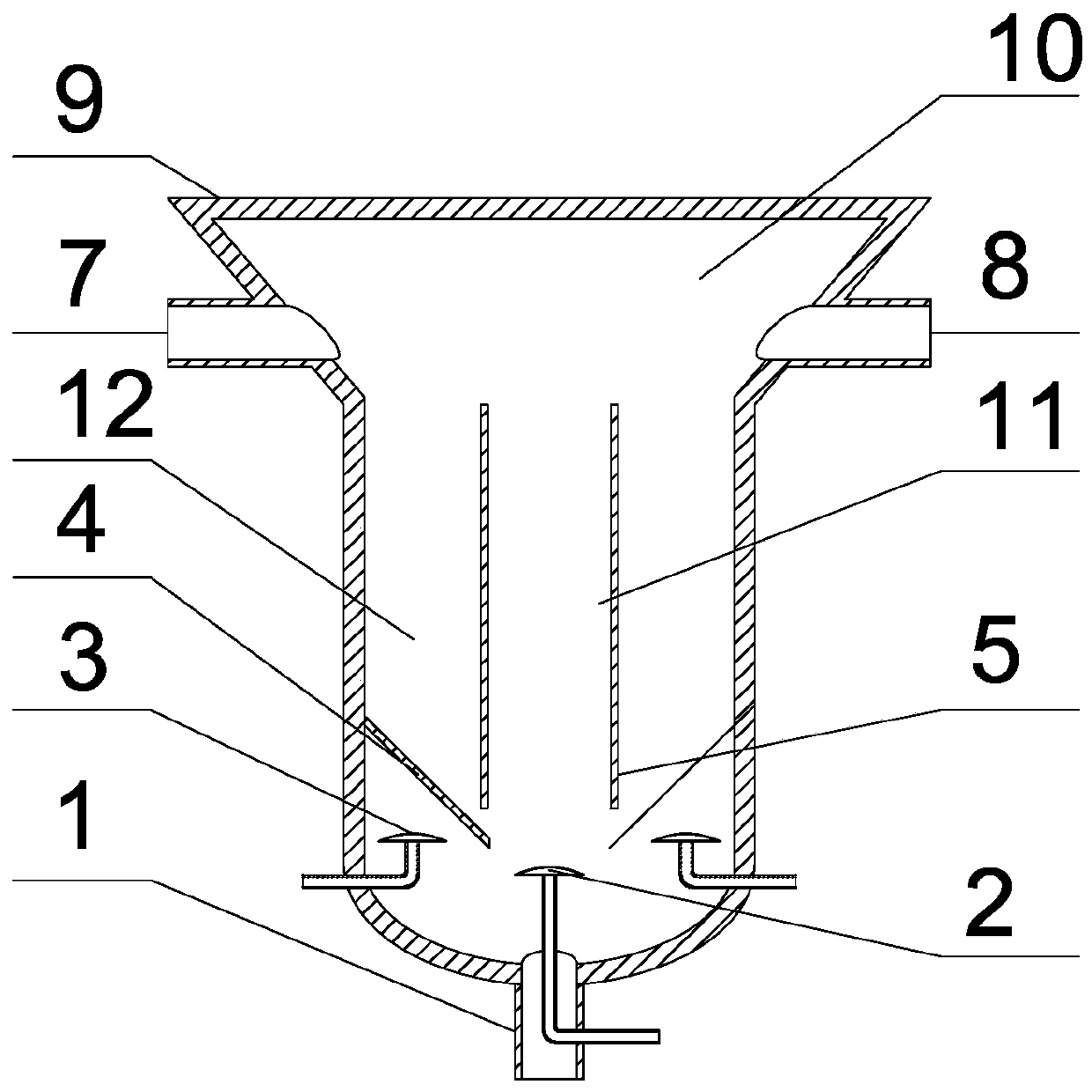

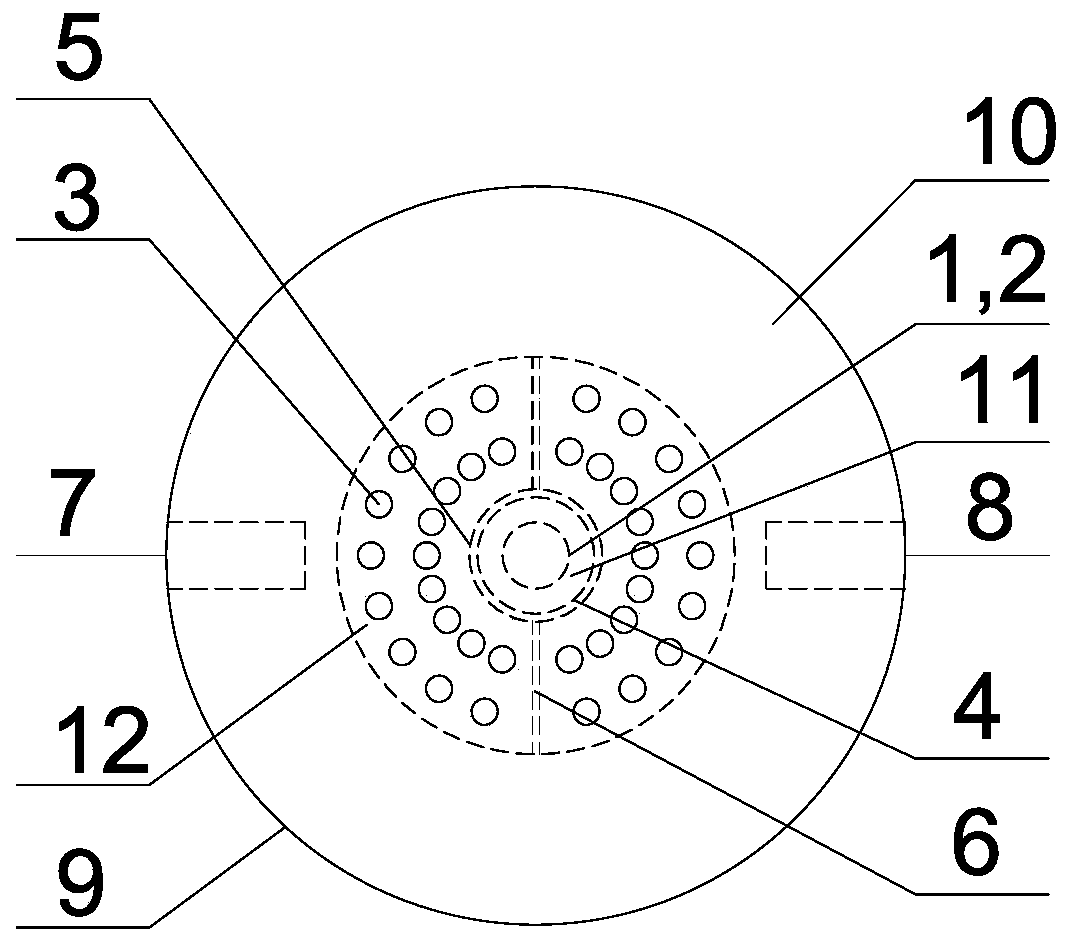

Integrated circulating fluidized bed apparatus

ActiveCN106914192ASmall process footprintSimple production equipmentFluidized bed combustionChemical/physical processesFluidized bedMaximum diameter

The invention relates to an integrated circulating fluidized bed apparatus. The upper part of an external sleeve cylinder is in a circular truncated cone structure with a thick top and a thin bottom, wherein ratio of maximum diameter to minimum diameter is 1.1-5. The lower part of the external sleeve cylinder is a cylinder in equal diameter and is connected to an internal sleeve cylinder through a screw bolt. The fluidized bed apparatus, from bottom to top, successively includes a solid collection port, a center gas distributor, an annular space gas distributor, a solid collector, and the internal sleeve cylinder. A gas outlet and a solid inlet are disposed on the upper part of the external sleeve cylinder. The center gas distributor is located right under the internal sleeve cylinder and the annular space gas distributor is located around the periphery of the center gas distributor and between the internal and the external sleeve cylinders. A gas-solid separation zone is formed in the upper part of the external sleeve cylinder. The lower part of the external sleeve cylinder is totally cylindrical in shape and is separated into a lifting zone and a circulating zone by means of the internal sleeve cylinder. The apparatus integrates a fluidized bed, a solid circulating system and a gas-solid separation system, so that the production apparatus is simplified. Gas flows in the status of plug flow, so that a gas phase and a solid phase are completely contacted and dead zone is avoided. The apparatus reduces power consumption and reduces manufacturing and producing cost.

Owner:TIANJIN UNIV

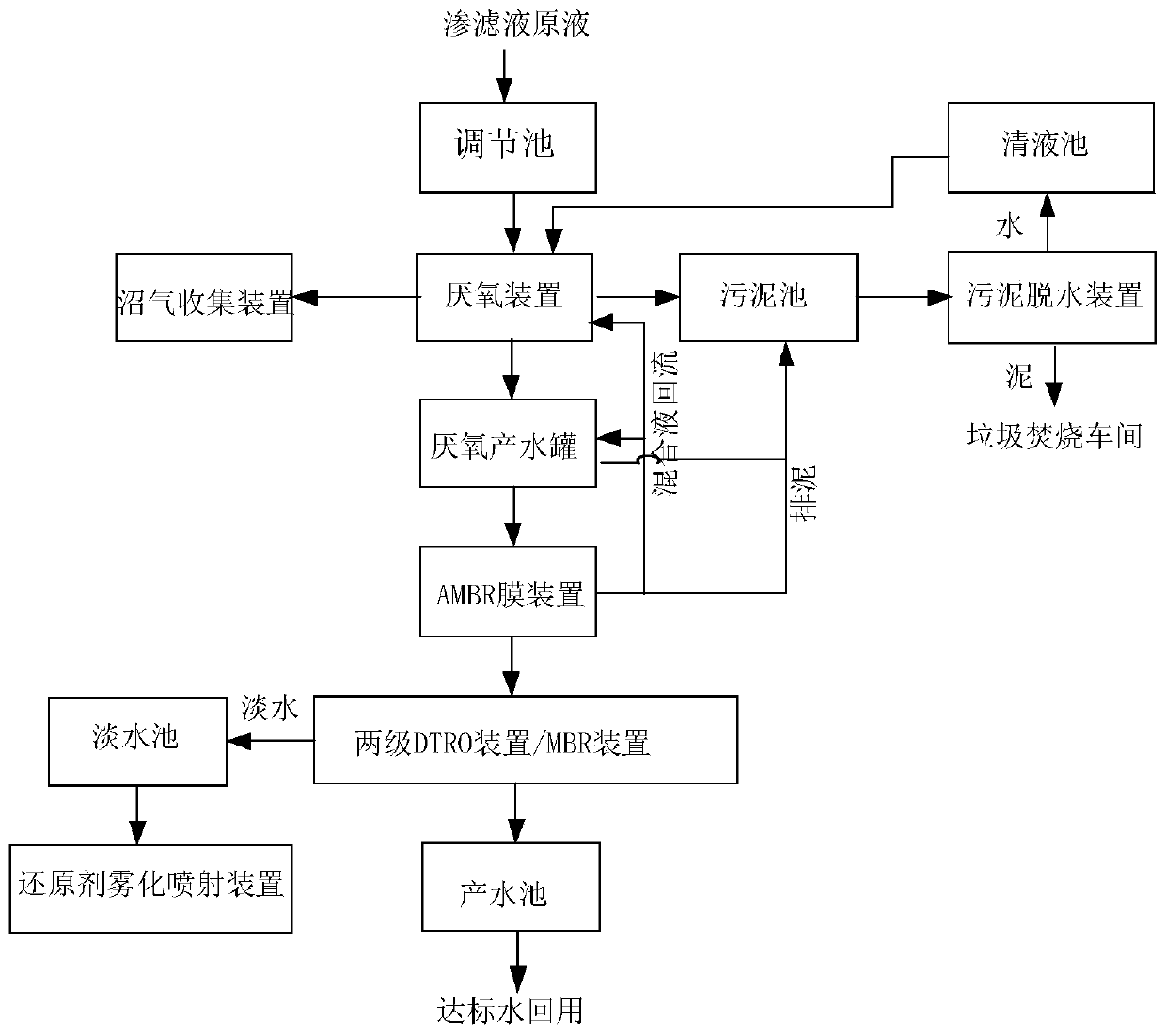

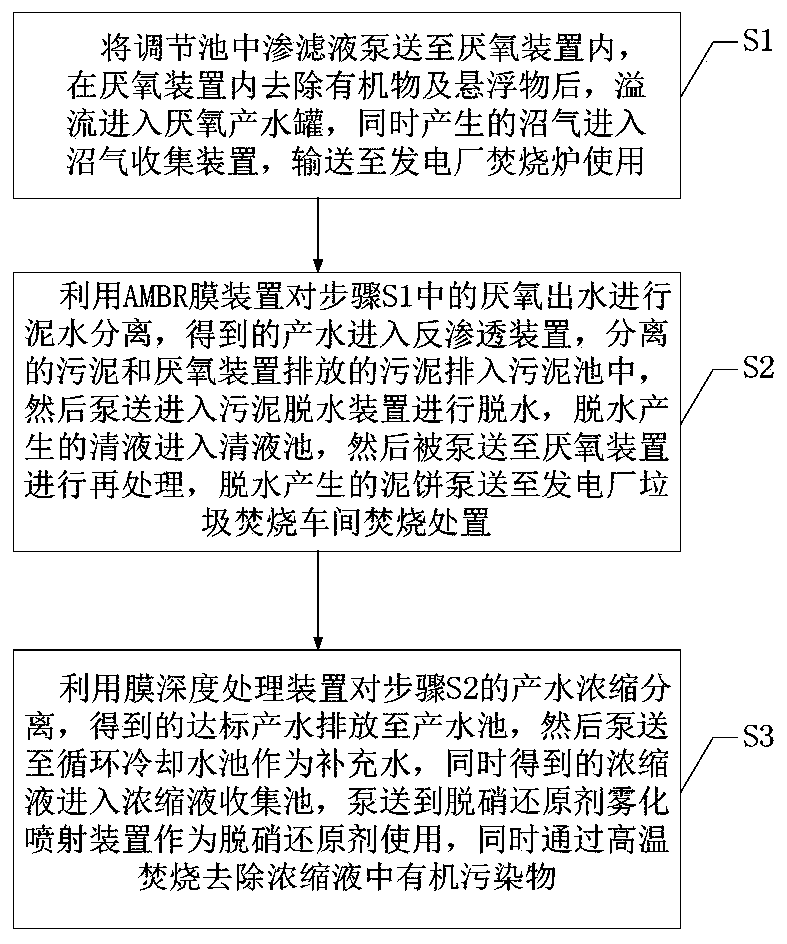

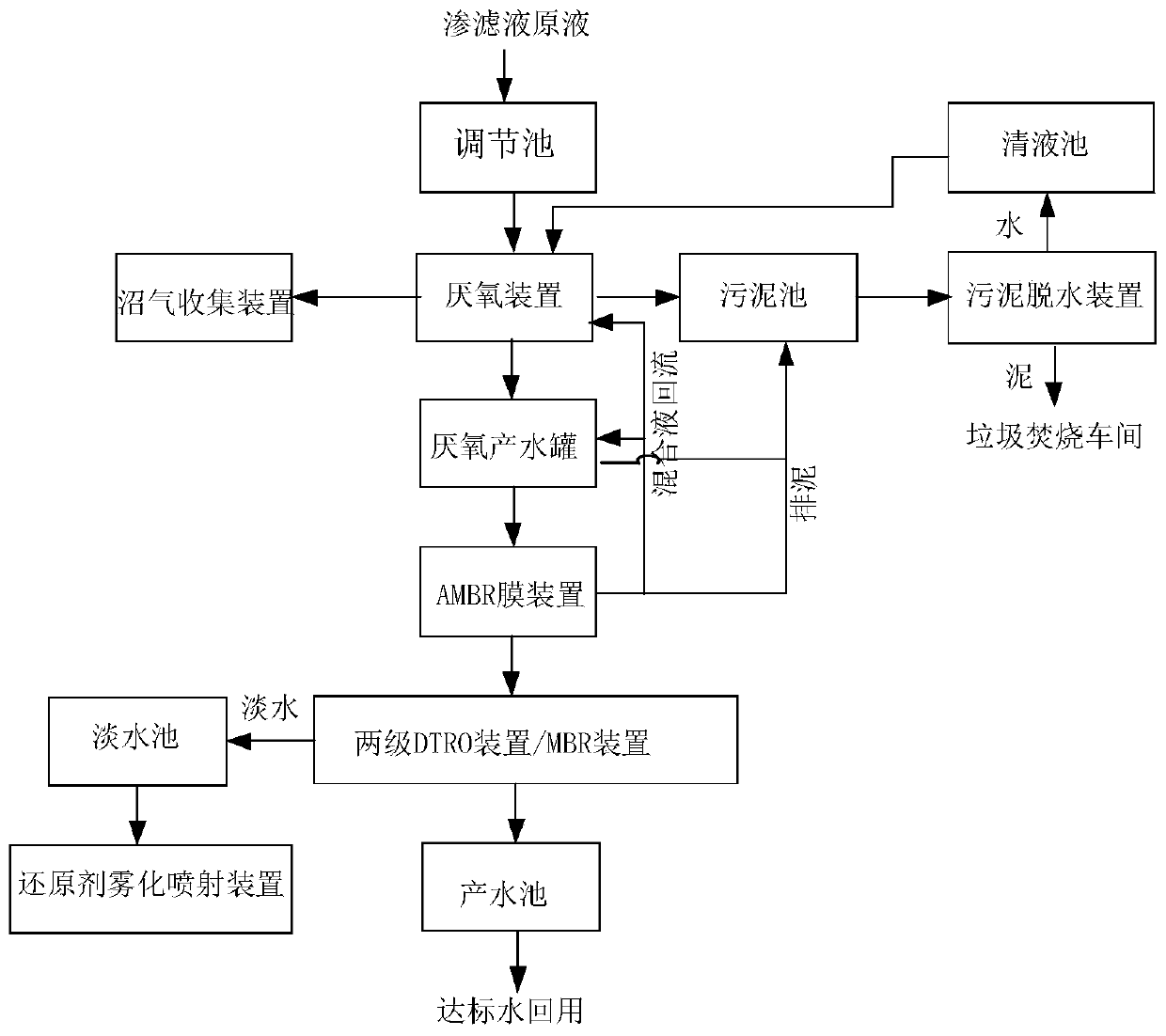

Waste incineration power plant leachate treatment system and treatment method

PendingCN111115978AShort processReduce the difficulty of operation and managementSpecific water treatment objectivesTreatment with anaerobic digestion processesAmmoniacal nitrogenSludge

The invention discloses a waste incineration power plant leachate treatment system and treatment method. The system comprises an adjusting tank, an anaerobic device, an anaerobic water production tank, an AMBR membrane device, a membrane advanced treatment device and a water producing tank, and further comprises a sludge tank and a concentrated solution collecting tank; the anaerobic device and the AMBR membrane device are connected with the sludge tank through pipelines respectively, and the membrane advanced treatment device is connected with the concentrated solution collecting tank througha pipeline. The system and method have the advantages that the yield of the concentrated solution is low, the technological process is short, ammonia nitrogen in leachate is recycled as a denitrationreducing agent after being concentrated and enriched, the pollutant treatment cost is reduced, resource recovery is achieved, and material consumption in the flue gas denitration stage is reduced.

Owner:北京首创环境科技有限公司

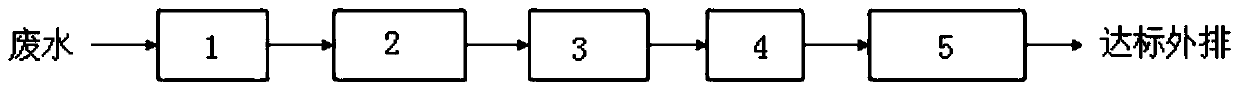

System for wastewater advanced treatment

PendingCN110015805AAvoids the need to adjust pH to acidic conditions for reactionsNo secondary pollutionWater contaminantsMultistage water/sewage treatmentFiltrationEngineering

The invention belongs to the technical field of wastewater treatment, and particularly relates to a system for wastewater advanced treatment. The system comprises a regulating tank, a flocculation sedimentation tank, a biochemical reaction tank, a sedimentation tank and an advanced treatment reactor which are connected in sequence, wherein the upper part of the sedimentation tank is connected witha liquid inlet pipeline of the advanced treatment reactor, the interior of a cylinder of the advanced treatment reactor is divided into a heterogeneous Fenton synergistic ozone reaction zone and a biological aeration filtration tank zone, the liquid inlet pipeline is arranged at the lower part of the cylinder and communicates with the heterogeneous Fenton synergistic ozone reaction zone, a heterogeneous Fenton catalyst is introduced to make hydrogen peroxide can be reacted under the neutral condition to generate hydroxyl radicals to degrade organic matters in the wastewater, and the requirement of the pH adjustment to the acidic condition required by a Fenton oxidation system is avoided. At the same time, no iron mud is generated in the whole reaction, no secondary pollution is generated,the air source after the ozone oxidation is fully utilized, the aeration electricity consumption cost is reduced while ensuring the effect of the biological filtration tank, and the outlet water reaches the standard and is directly discharged.

Owner:杰瑞环境工程技术有限公司

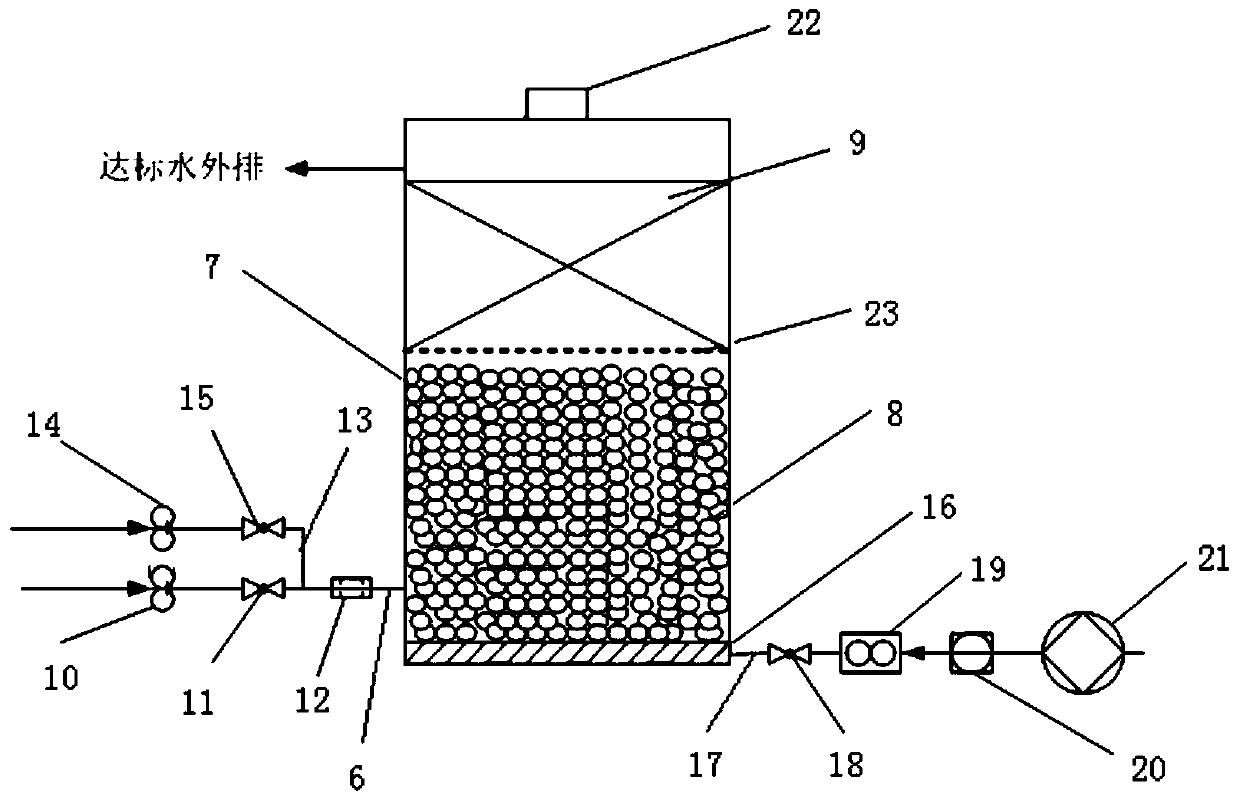

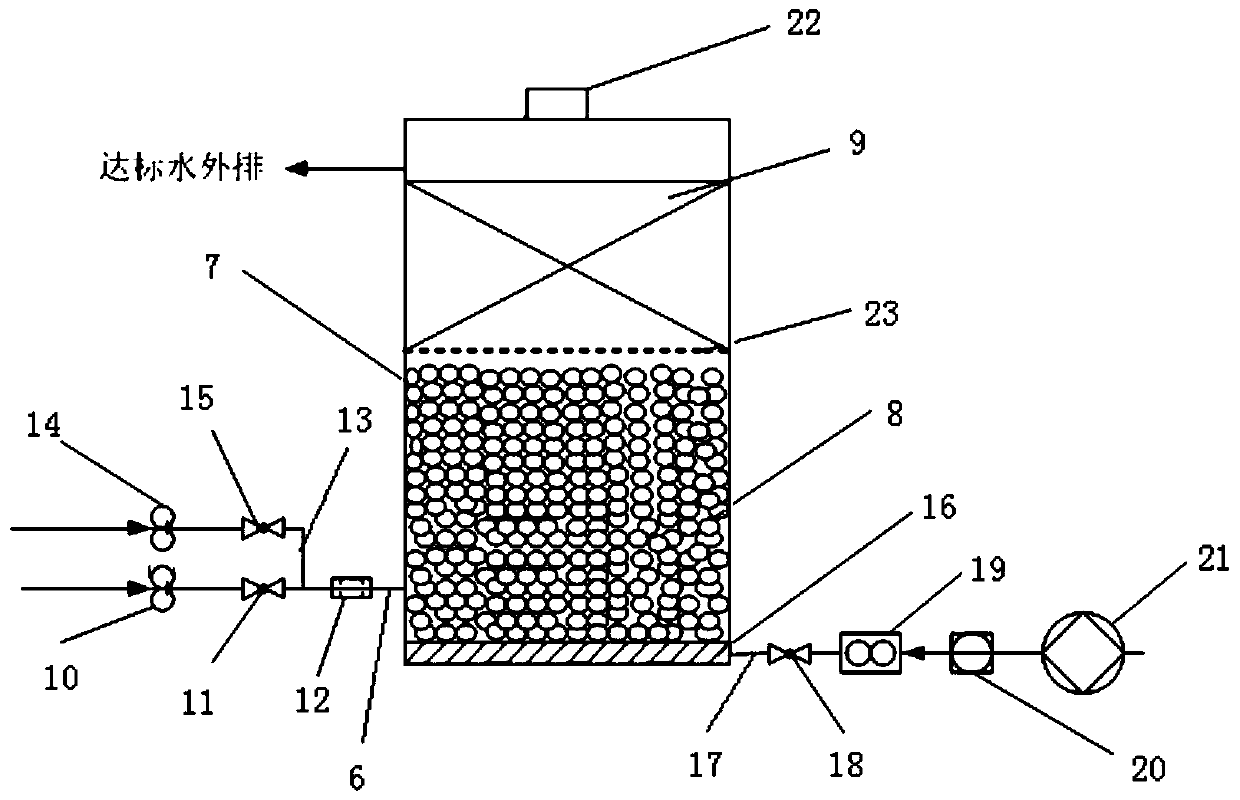

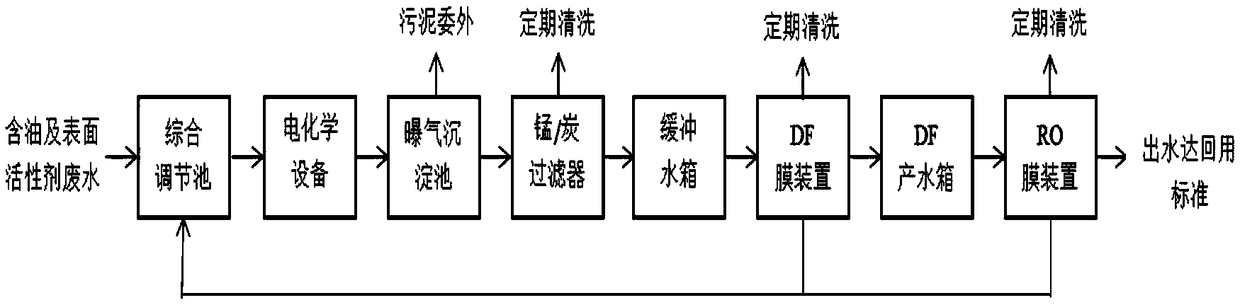

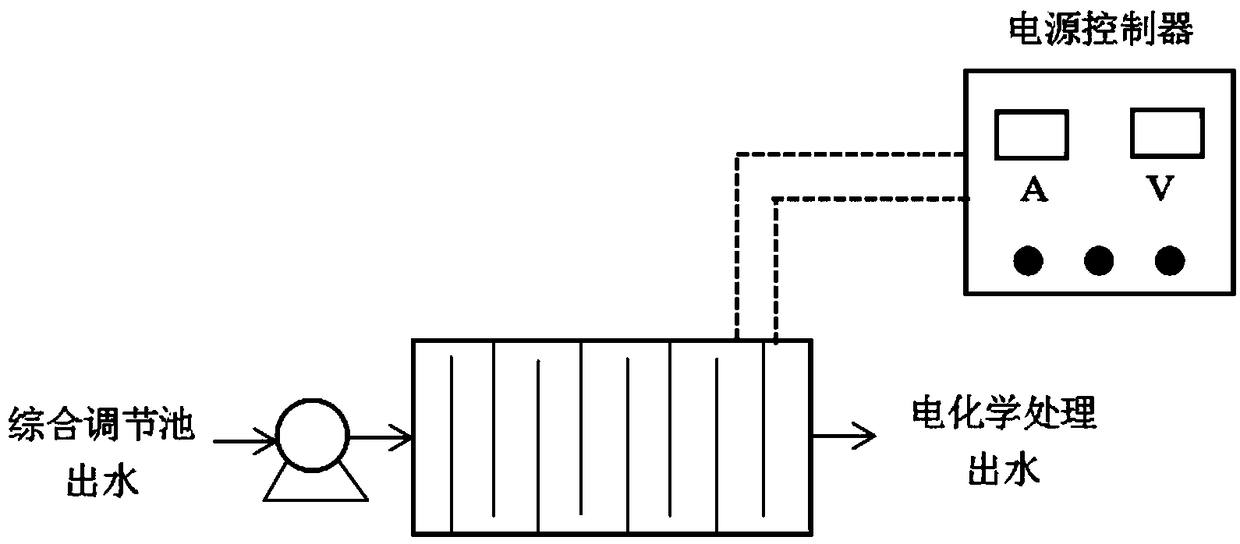

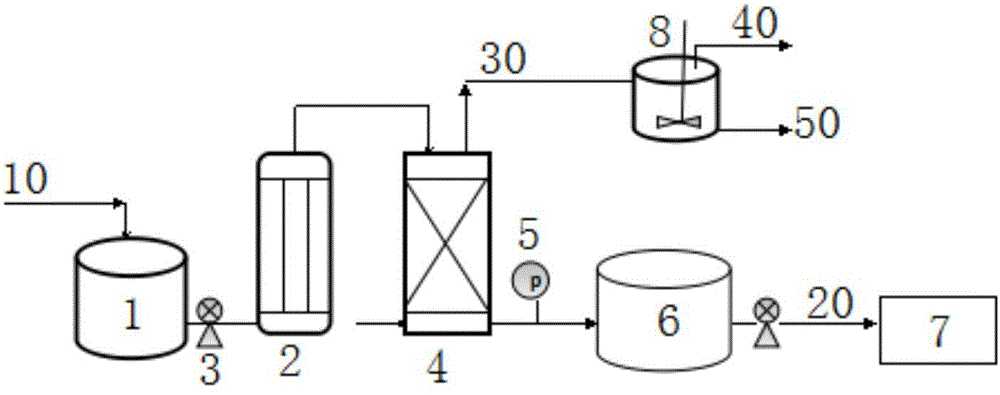

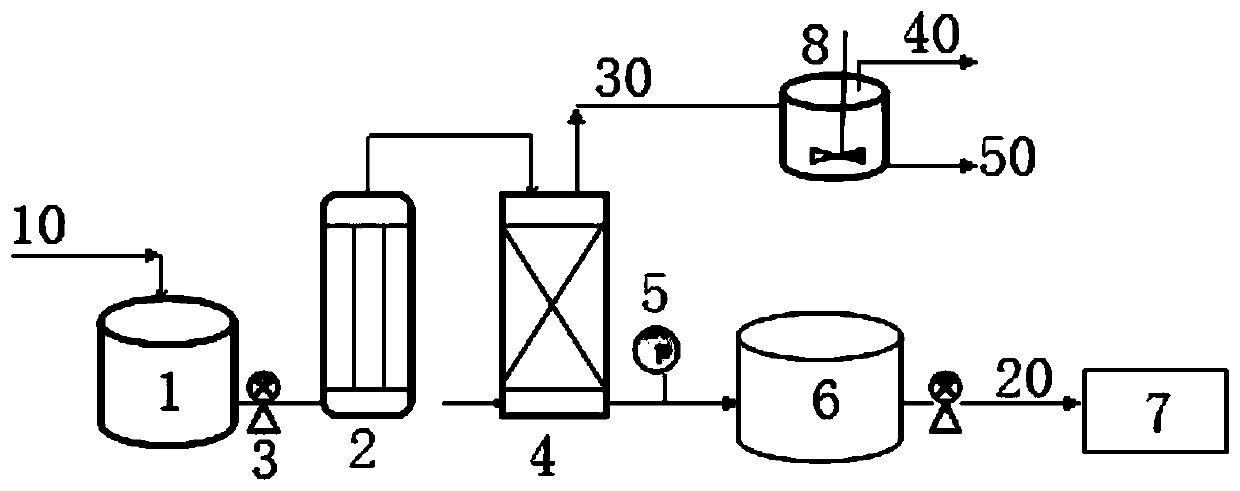

Equipment and technology for recycling wastewater containing oil and surfactants

InactiveCN109437451AImprove processing efficiencyReduce volumeTreatment involving filtrationMultistage water/sewage treatmentMembrane foulingTherapeutic effect

The invention belongs to the technical field of industrial wastewater treatment and discloses equipment and technology for recycling wastewater containing oil and surfactants. According to the technology, substances such as oil substances, the surfactants and the like resulting in membrane fouling blockage in the wastewater are removed by electrochemical equipment, and the purpose of wastewater recycling is achieved by coupling with membrane devices. The technology has the characteristics of occupying a small area, being good in treatment effect, short in time, free of secondary pollution andsimple and convenient to operate and the like, and therefore, the broad application prospect is provided for recycling of the wastewater containing oil and the surfactants.

Owner:GUANGDONG ENG TECH INST

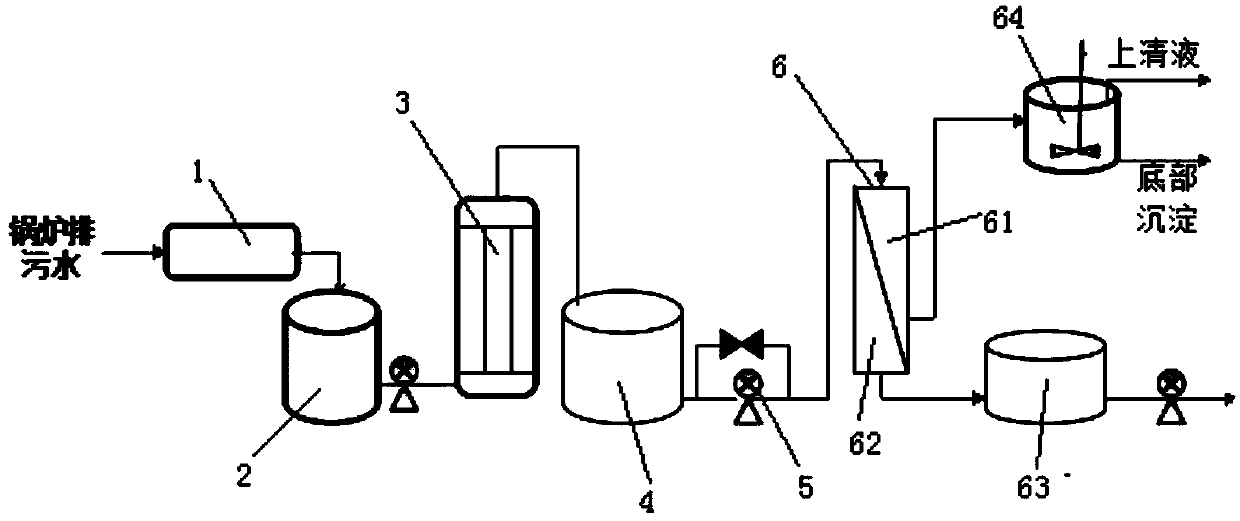

Boiler blowdown water recycling treatment technology based on ion exchange and chemical precipitation

ActiveCN106082501AImprove exchange capacityStable water qualityWater contaminantsMultistage water/sewage treatmentIonIon exchange

The invention relates to a boiler blowdown water recycling treatment technology based on ion exchange and chemical precipitation. The technology comprises the following steps that boiler blowdown water is filtered by an efficient fiber filter, so that the turbidity of the filtered and purified blowdown water is decreased to be smaller than 1 NTU, and an SDI value of the filtered and purified blowdown water is smaller than 3; the filtered and purified blowdown water is delivered to an ion exchanger, effluent water exchanged by anion exchange resin enters a boiler raw water tank, and after the anion exchange resin is saturated, regenerating is conducted by adopting a regenerating agent, so that an exchange function of the anion exchange resin is recovered; coagulation treatment and flocculent precipitation treatment are conducted on regenerated waste liquid and backwashing waste liquid of the ion exchanger by adopting a coagulant and a flocculant. Compared with the prior art, the high-concentration waste liquid or regenerated liquid achieves solid-liquid separation by adding a small quantity of the coagulant and a coagulant aid through the coagulation effect and the flocculent precipitation effect while high-quality recycling on the boiler blowdown water is achieved through ion exchange, removal of phosphate in the boiler blowdown water is completed, and zero discharge of the boiler blowdown water is achieved.

Owner:SHANGHAI EMPEROR OF CLEANING HI TECH

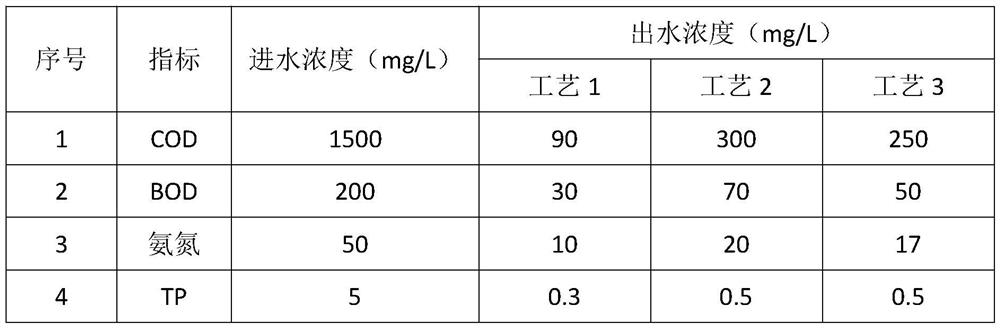

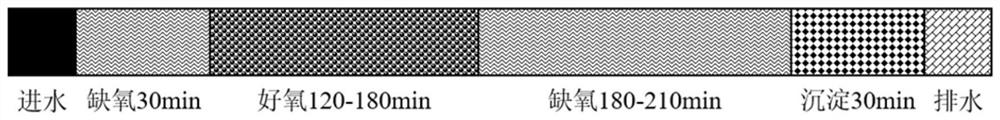

A method for synchronous denitrification and dephosphorization of whole process hypoxic aeration sbmbbr

ActiveCN107010727BGood denitrification and phosphorus removalHigh organic loadWater contaminantsTreatment with aerobic and anaerobic processesSequencing batch reactorMoving bed biofilm reactor

The invention discloses a whole process low-oxygen aeration SBMBBR (sequencing batch moving bed biofilm reactor) synchronous denitrification and dephosphorization method and belongs to the technical field of sewage treatment. The method achieves synchronous denitrification and dephosphorization by adding suspension filling into the traditional SBR (sequencing batch reactor) to form an SBMBBR, controlling an organic load, a nitrogen and phosphorus load and a DO (dissolved oxygen) value in the reactor, performing staged culture and acclimation on an inoculum, and performing synchronous nitrification-denitrification and denitrification-dephosphorization on enriched denitrification polyphosphate accumulating bacteria and aerobic polyphosphate accumulating bacteria and by other approaches. The method achieves the synchronous denitrification and dephosphorization for low C / N (carbon / nitrogen) ratio sewage in the same reactor under a whole process low-oxygen aeration condition, has the advantages of a simple technology, simple operational control, a high sludge load, small floor area, low energy consumption, no need of an additional carbon source, stable denitrification and dephosphorization effects and the like. The method has very practical significance in simplifying the traditional denitrification and dephosphorization sewage treatment technology, improving the denitrification and dephosphorization effects and reducing the floor area and energy consumption, and is a sewage treatment technology with good application prospects.

Owner:GUANGZHOU UNIVERSITY

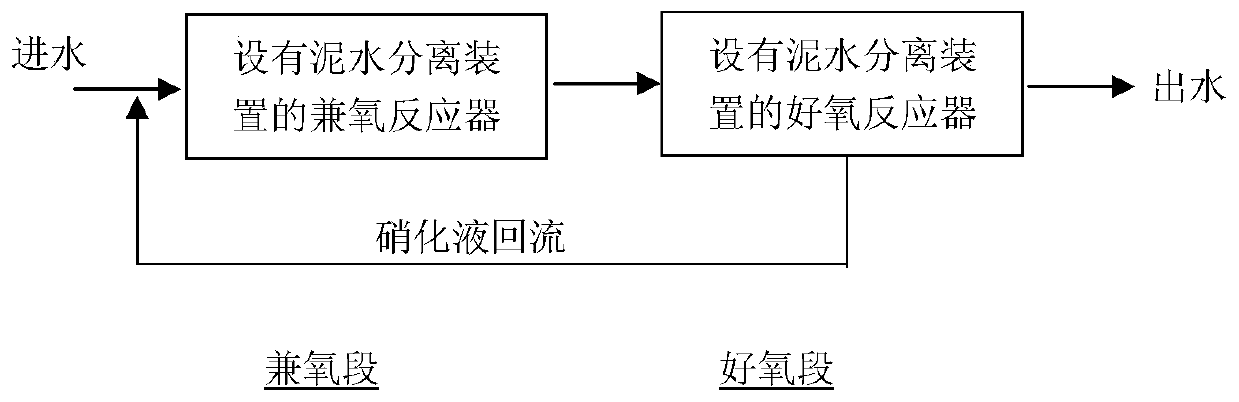

Low-energy-consumption rapid biochemical sewage denitrification process

InactiveCN110577329AEasy to handleImprove nitrogen removal efficiencyWater contaminantsTreatment with aerobic and anaerobic processesNitrationPhysical separation

The invention discloses a low-energy-consumption rapid biochemical sewage denitrification process. The method comprises the steps: step 1, sewage enters an aerobic section, the sewage and aerobic microorganisms are subjected to a denitrification reaction and a short-cut nitrification and denitrification reaction in the aerobic section, a sludge-water separator is further arranged in the aerobic section, sludge obtained after sludge-water separation continues to remain in the aerobic section, and separated supernatant enters the next step; and step 2, the supernatant separated from the aerobicsection enters an aerobiotic section, nitration reaction is carried out on the supernatant and aerobiotic microorganisms in the aerobiotic section, clear water physically separated from one part of anitration liquid after the nitration reaction is used as system effluent, and the other part of the nitration liquid flows back to the aerobic section. According to the process, the sewage treatment efficiency is improved, and the energy consumption is low because the hydraulic retention time of the aerobiotic section is short.

Owner:SHENZHEN QINGYAN ENVIRONMENTAL TECH CO LTD

Biochemical degradation system coupling hydrolytic acidification-anaerobic and aerobic

ActiveCN101381163BImprove processing efficiencyImprove biodegradabilityTreatment with aerobic and anaerobic processesIndustrial waste waterContinuous flow

The present invention discloses a hydrolization and acidification - anaerobism and aerobism coupling biochemical degradation system, which belongs to the technical field of environment engineering and industrial waste water disposal. The system is used for disposing organic waste that is difficult to be degraded. The biochemical degradation system consists of two serially connected airlift internally circulating biological fluidized beds. The front airlift internally circulating biological fluidized bed is an anaerobe fluid bed which adopts micro-aeration operation and carries out hydrolization and acidification processing; and the rear airlft internally circulating biological fluidized bed is an anaerobism and aerobism coupling biological fluid bed which is constructed by filling macropore carriers and carries out the complete degradation of organisms. The organic waste water which is difficult to be degraded enters the anaerobic fluid bed first, and enters the anaerobism-aerobism coupled biological fluid bed after the hydrolization and acidification processing so as to be completely degraded. The system achieves high efficiency and quick coupling of the anaerobe degradation and the aerobe, and has the characteristics of high disposing efficiency, short residence time, small floor space, low investment, low running cost and so on. The method can be applied to the sequencing batch type disposal process, and can be applied to the continuous flow type disposal process as well.

Owner:TSINGHUA UNIV

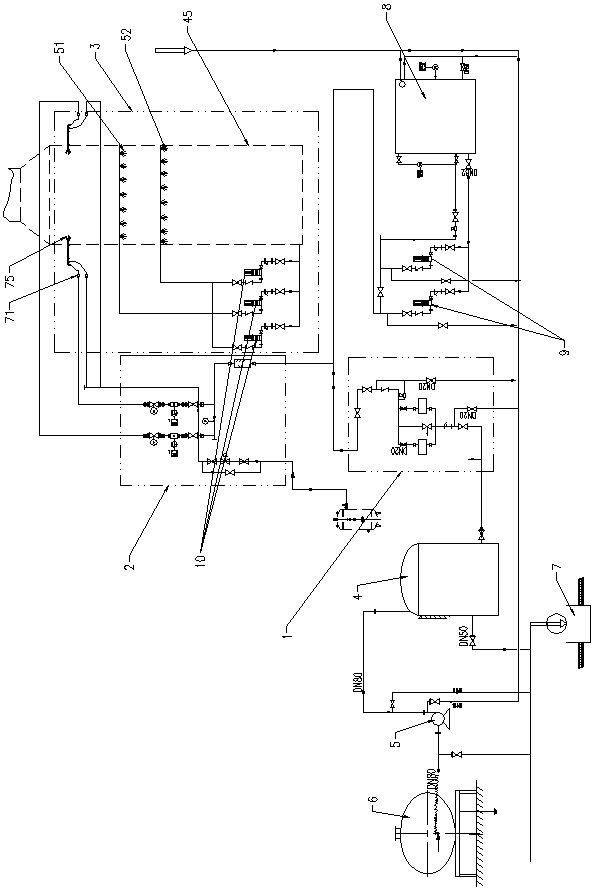

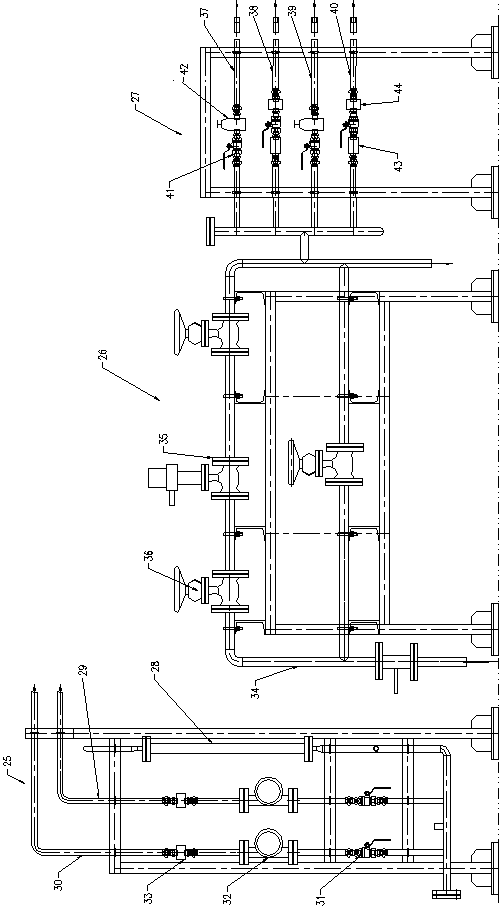

Efficient integrated desulfurization and denitrification device for coal-fired boiler fuel gas and implementation method of device

InactiveCN109331631ALess investmentReduce maintenance costsGas treatmentDispersed particle separationSlurryFuel gas

The invention relates to an efficient integrated desulfurization and denitrification device for coal-fired boiler fuel gas and an implementation method of the device. The efficient integrated desulfurization and denitrification device for the coal-fired boiler fuel gas comprises a desulfurization and denitrification agent conveying module, a desulfurization and denitrification agent metering and spraying module and a circulating spraying system, wherein the desulfurization and denitrification agent conveying module is connected with the desulfurization and denitrification agent metering and spraying module, and the desulfurization and denitrification agent metering and spraying module is connected with the circulating spraying system. The device and the method provided by the invention have the advantages that defects of the conventional desulfurization and denitrification process and equipment such as large investments, complicated operation procedures, a high failure rate and the like are overcome, strength and acid and alkali resistance are guaranteed, the contact between fuel gas and circulating slurry is enlarged, and the desulfurization and denitrification efficiency is improved.

Owner:山东海蓝阳光环境服务有限公司

A kind of aerobic granular sludge sewage treatment method with denitrification effect and special equipment

InactiveCN105819568BAccelerated settlementMicrobial biomass is large and harmfulTreatment with aerobic and anaerobic processesActivated sludgeNitrogen removal

The invention relates to an aerobic granular sludge sewage processing method having nitrogen removal effect and special-purpose equipment thereof. The method comprises the steps of culture and domestication of activated sludge, treatment of target sewage, and treatment of the sludge. The special-purpose equipment comprises a tower body, wherein the tower body is divided into three-phase separation zones of a tower bottom reaction zone, a central aerobic nitrification zone, and a top. The method has the beneficial effects that the sewage processing effect is good, the land occupation area of the tower is small, the granular sludge forming effect is good, nitrogen removal effect is good, external power is not required for circulation of a nitrogen solution and circulation of the sludge, and the cost is saved.

Owner:JILIN NORMAL UNIV

Aquaculture water purifying agent

InactiveCN108569773AEfficient purificationImprove processing efficiencyWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionBacillus licheniformisFiber

The invention discloses an aquaculture water purifying agent, and relates to the technical field of aquaculture. The aquaculture water purifying agent is prepared from the following raw materials in percentage by mass : 20% to 30% of allophane, 10% to 20% of light shale powder, 8% to 10% of brucite fiber, 8% to 10% of diatomaceous earth, 8% to 10% of bentonite, 15% to 20% of coal-based activated carbon,10% to 20% of light calcium carbonate, 10% to 20% of polyaluminum chloride, 5% to 8% of thiobacillus denitrificans, 5% to 8% of bacillus licheniformis, 3% to 5% of bio-bacteria remover, 3% to 8%of corn flour, 10% to 15% of radix rehmanniae recen, 3% to 5% of flocculant, and 3% to 8% of coconut shell powder. According to the aquaculture water purifying agent provided by the invention, the allophane as a main component has the small particle size, strong adsorption capacity and is low in cost, and the prepared purifying agent is fast and effective in purification effect, high in treatmentefficiency, and small in process occupying area.

Owner:YANGZHOU POLYTECHNIC INST

Efficient integrated self-granulating loading flocculating device

InactiveCN107129067AReduce porosityIncrease sinking speedSpecific water treatment objectivesTreatment involving filtrationPorosityHigh density

Disclosed is an efficient integrated self-granulating loading flocculating device. A water inlet and a power device are arranged on a top cover, a treatment device is arranged below the top cover, a water outlet is connected below the treatment device, the treatment device is composed of separation equipment and filtering equipment which are mutually connected to form a complete filtering device, and a connecting passage is arranged between the separation equipment and the filtering equipment. The separation equipment and the filtering equipment are arranged in the efficient integrated self-granulating loading flocculating device, so that floc porosity can be lowered effectively, and floc density can be improved; due to improving of floc sphericity, growing particle size of floc is increased, floc settling speed is increased, and surface load is increased; in a high-density floc suspension layer, large-particle floc has high adsorption potential, so that contact flocculating effect of initial particles and microfloc is effectively enhanced, and outgoing water quality is guaranteed; water content is low.

Owner:JIANGSU TIANHONG ENVIRONMENTAL ENG

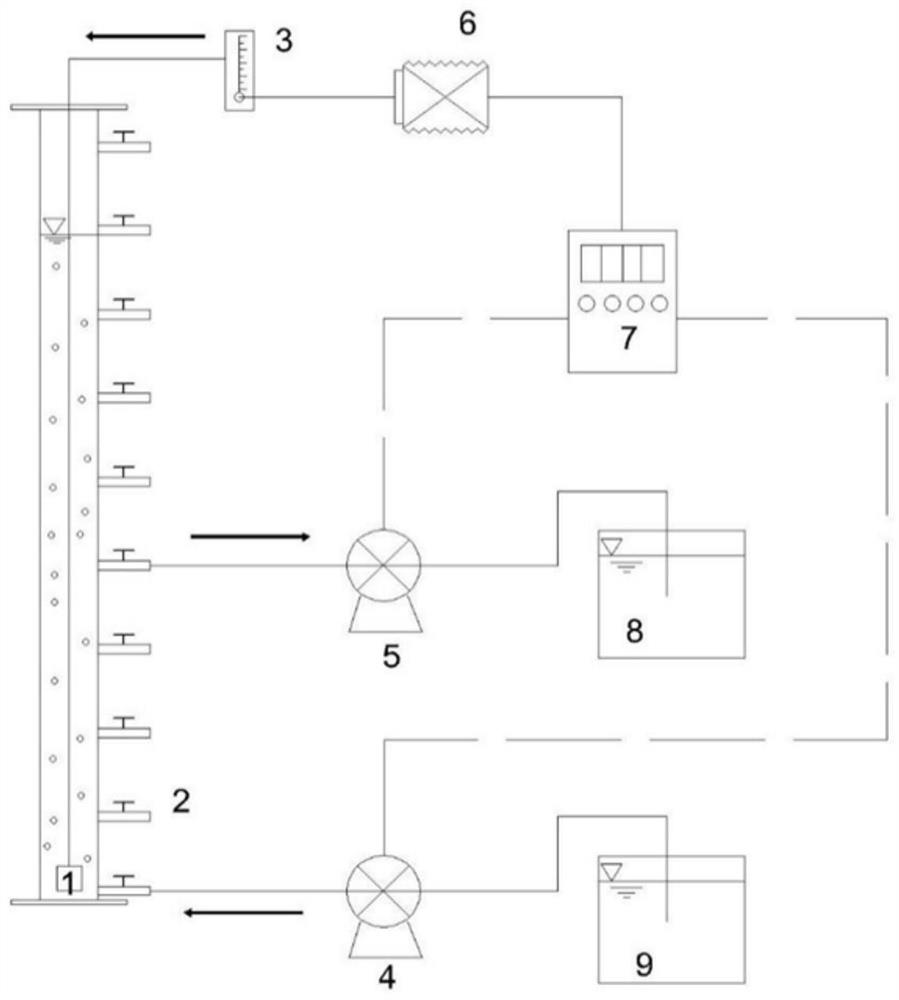

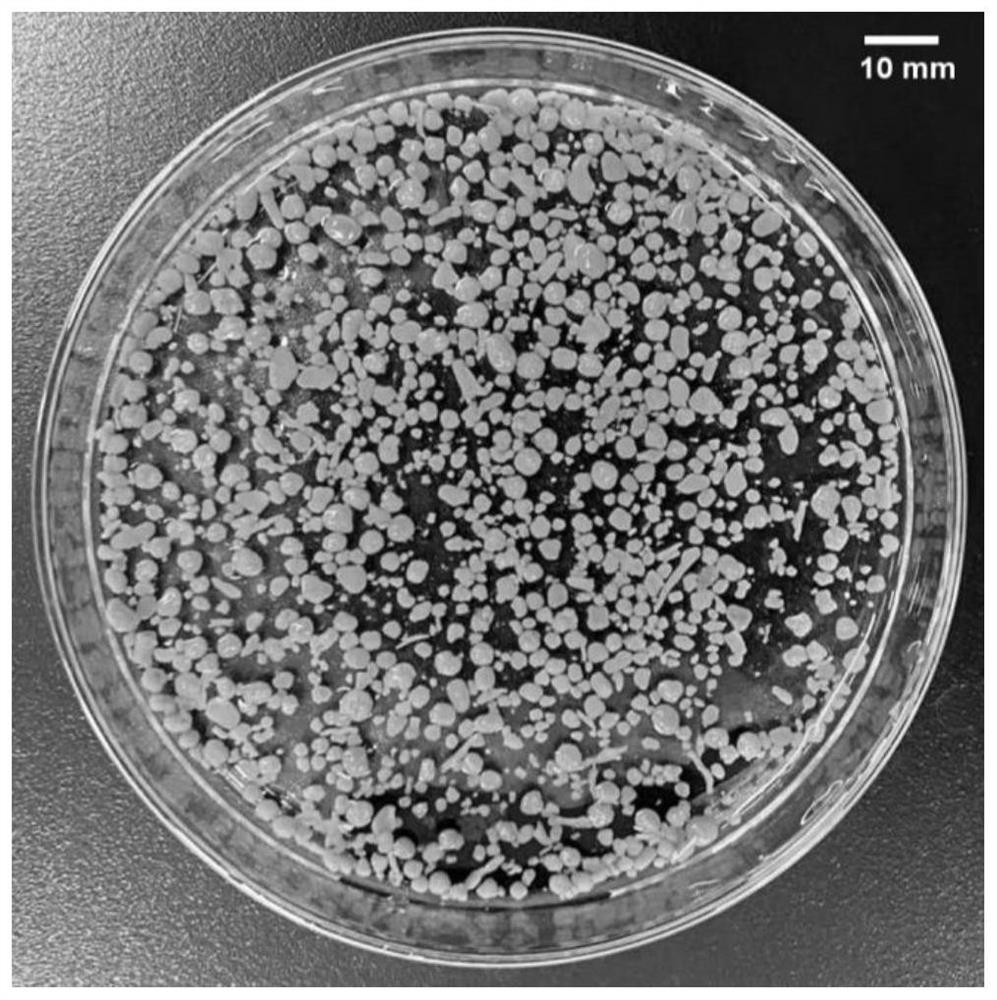

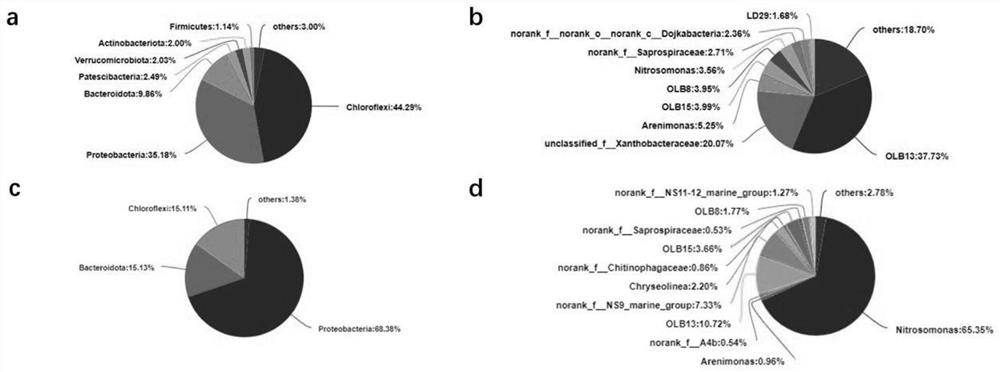

Short-cut nitrification granular sludge applied to high-salt and high-ammonia-nitrogen wastewater treatment and culture method

PendingCN114804338AGood short-range nitrification effectHigh ammonia oxidation rateWater treatment compoundsWater contaminantsActivated sludgeWater treatment

The invention belongs to the field of sewage treatment, and particularly relates to granular activated sludge for efficiently realizing short-cut nitrification of high-salt and high-ammonia-nitrogen wastewater, which is characterized in that common activated sludge of a municipal sewage treatment plant is used as seed sludge, culture is performed in a sequencing batch manner, and the short-cut nitrification of high-salt and high-ammonia-nitrogen wastewater is realized by adjusting matrix concentration and settling time. The granular activated sludge for efficiently realizing short-cut nitrification of the high-salt and high-ammonia-nitrogen wastewater is obtained. The cultured sludge can quickly start a short-cut nitrification process for high-salt and high-ammonia-nitrogen wastewater and stably operate for a long time, due to the characteristics of high biomass and good settling performance of the granular sludge, the volume of a reactor can be reduced, the efficiency of a biological process can be improved, meanwhile, the residual sludge is less, and the sludge treatment cost is reduced. Aeration required by short-range nitrification is lower than that required by traditional whole-range nitrification, the subsequent combined denitrification process and anaerobic ammonia oxidation process can greatly reduce the carbon source dosage, and the operation cost is reduced. According to the invention, the maximum nitrite accumulation rate and ammoxidation rate can reach 98% and 1.162-1.164 kgN * m <-3 > * d <-1 >.

Owner:BEIJING NORMAL UNIVERSITY

Processing method of coking steaming ammonia wastewater

ActiveCN103130379BEasy to useEasy to recycleMultistage water/sewage treatmentElectrolysisPersistent organic pollutant

The invention discloses a processing method of coking steaming ammonia wastewater. The processing method of the coking steaming ammonia wastewater comprises pretreatment of coking steaming ammonia wastewater and biochemical treatment of the coking ammonia wastewater. The pretreatment of the coking steaming ammonia wastewater uses an adjusting pool, an internal electrolysis reactor, a Fenton oxidation pond and a coagulative precipitation tank. A sequencing batch membrane bioreactor technology is adopted by the biochemical treatment, and working procedures of inflow, unused-leaving, reacting and discharging are sequentially performed according to a time period. The processing method of the coking steaming ammonia wastewater can effectively remove persistent organic pollutants and ammonia nitrogen, strengthen effluent quality, and reduce operational and investing costs of equipment.

Owner:ANGANG STEEL CO LTD

Recovery and treatment process of boiler wastewater based on ion exchange and chemical precipitation

ActiveCN106082501BEfficient removalIncrease profitWater contaminantsMultistage water/sewage treatmentFiberHigh concentration

The invention relates to a boiler blowdown water recycling treatment technology based on ion exchange and chemical precipitation. The technology comprises the following steps that boiler blowdown water is filtered by an efficient fiber filter, so that the turbidity of the filtered and purified blowdown water is decreased to be smaller than 1 NTU, and an SDI value of the filtered and purified blowdown water is smaller than 3; the filtered and purified blowdown water is delivered to an ion exchanger, effluent water exchanged by anion exchange resin enters a boiler raw water tank, and after the anion exchange resin is saturated, regenerating is conducted by adopting a regenerating agent, so that an exchange function of the anion exchange resin is recovered; coagulation treatment and flocculent precipitation treatment are conducted on regenerated waste liquid and backwashing waste liquid of the ion exchanger by adopting a coagulant and a flocculant. Compared with the prior art, the high-concentration waste liquid or regenerated liquid achieves solid-liquid separation by adding a small quantity of the coagulant and a coagulant aid through the coagulation effect and the flocculent precipitation effect while high-quality recycling on the boiler blowdown water is achieved through ion exchange, removal of phosphate in the boiler blowdown water is completed, and zero discharge of the boiler blowdown water is achieved.

Owner:SHANGHAI EMPEROR OF CLEANING HI TECH

Boiler sewage recovery and treatment process combined with reverse osmosis and chemical precipitation technology

ActiveCN106082503BEfficient removalImprove qualityWater contaminantsTreatment involving filtrationBoiler blowdownWater circulation

The invention relates to a boiler blow-down water recovery treatment process combined with reverse osmosis and chemical precipitation technologies. The boiler blow-down water recovery treatment process comprises the following steps of: regulating the temperature, pH value and suspended matter concentration of boiler blow-down water to meet inlet water requirements of a reverse osmosis system; then introducing the boiler blow-down water into the reverse osmosis system, and performing reverse osmosis treatment so as to obtain a dialysate and concentrated liquor, wherein the dialysate is used as a boiler primary demineralized water; and performing chemical precipitation treatment on the concentrated liquor by use of a coagulant and a flocculant, thereby obtaining a supernate, wherein the supernate is used as boiler raw water or make-up water for a water circulation system, so that the recovery treatment of boiler blow-down water is realized. Compared with the prior art, the boiler blow-down water recovery treatment process is capable of realizing complete zero-emission treatment of the boiler blow-down water, recovering high-quality water resources and saving the operation cost, and has the characteristics of general applicability to boiler blowdown systems, stable technical process, low cost and the like.

Owner:SHANGHAI EMPEROR OF CLEANING HI TECH

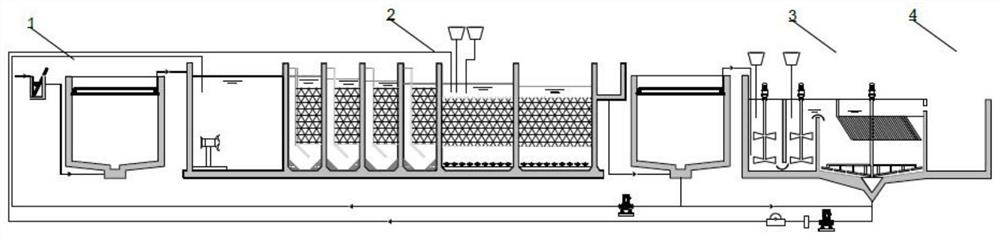

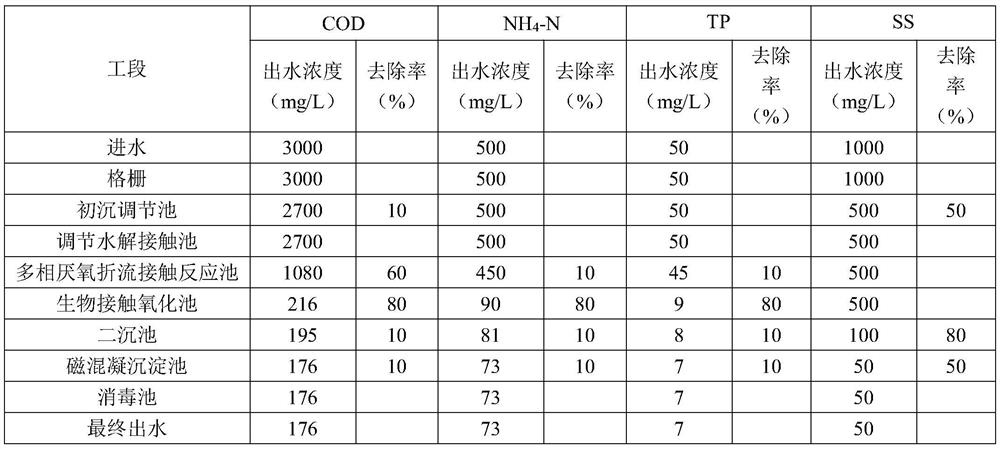

Easily-degradable high-concentration industrial wastewater treatment method and system

PendingCN111762971AIncrease the sedimentation rateReduce churnWater treatment parameter controlWater contaminantsIndustrial waste waterChemical reaction

The invention relates to the field of industrial wastewater treatment, and particularly relates to an easily-degradable high-concentration industrial wastewater treatment method and system. The systemcomprises a pretreatment section, a high-concentration wastewater biochemical treatment device, a magnetic coagulation sedimentation tank and a disinfection tank, wherein magnetic iron powder and activated carbon powder are added into a biological contact oxidation tank of the high-concentration wastewater biochemical treatment device, an aerobic filler and an aeration system are installed, and the concentration of dissolved oxygen in the tank is controlled to be 2-4mg / L. The action of the magnetic iron powder and the activated carbon powder runs through a biological and chemical reaction system, an adsorption micro-electrolysis environment can be formed, a huge specific surface area can be provided for microorganism growth, the sedimentation rate of flocculent sludge is increased, sludgeloss and the occupied area of the process are reduced, and the biochemical treatment effect is guaranteed.

Owner:北京新林环境科技有限公司

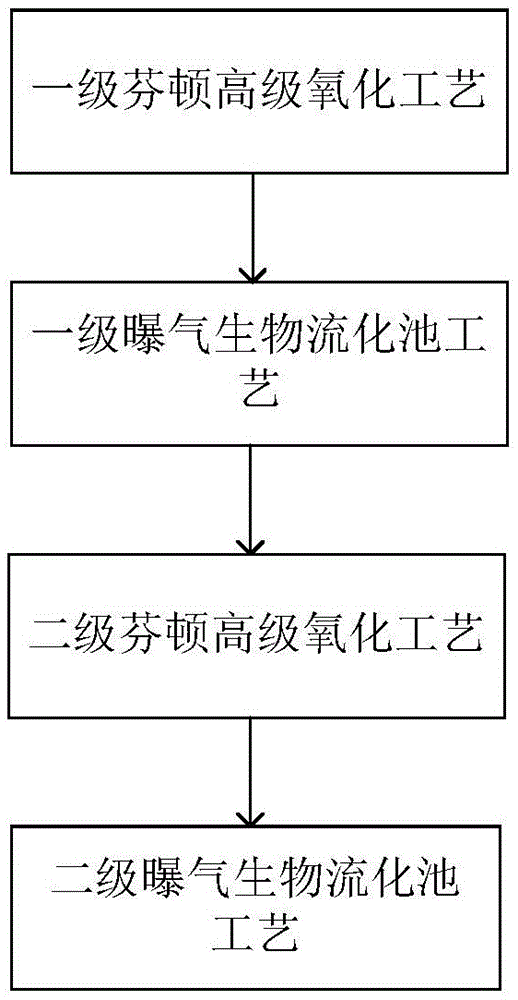

A kind of landfill leachate treatment method

ActiveCN104276733BEasy to operateProduced noWater treatment compoundsMultistage water/sewage treatmentAdvanced oxidation processEnvironmental engineering

The invention discloses a landfill leachate treatment method. The landfill leachate treatment method comprises (1) a primary Fenton advanced oxidation process, (2) a primary aerated biological fluidized tank process, (3) a secondary Fenton advanced oxidation process, and (4) a secondary aerated biological fluidized tank process. The landfill leachate treatment method is simple to operate without complex system control; due to the adoption of a degradation method, no concentrated water is generated to cause secondary pollution; meanwhile, a membrane system does not need to be replaced so that the treatment cost can be greatly reduced.

Owner:WUHAN AILV ENVIRONMENTAL PROTECTION TECH CO LTD

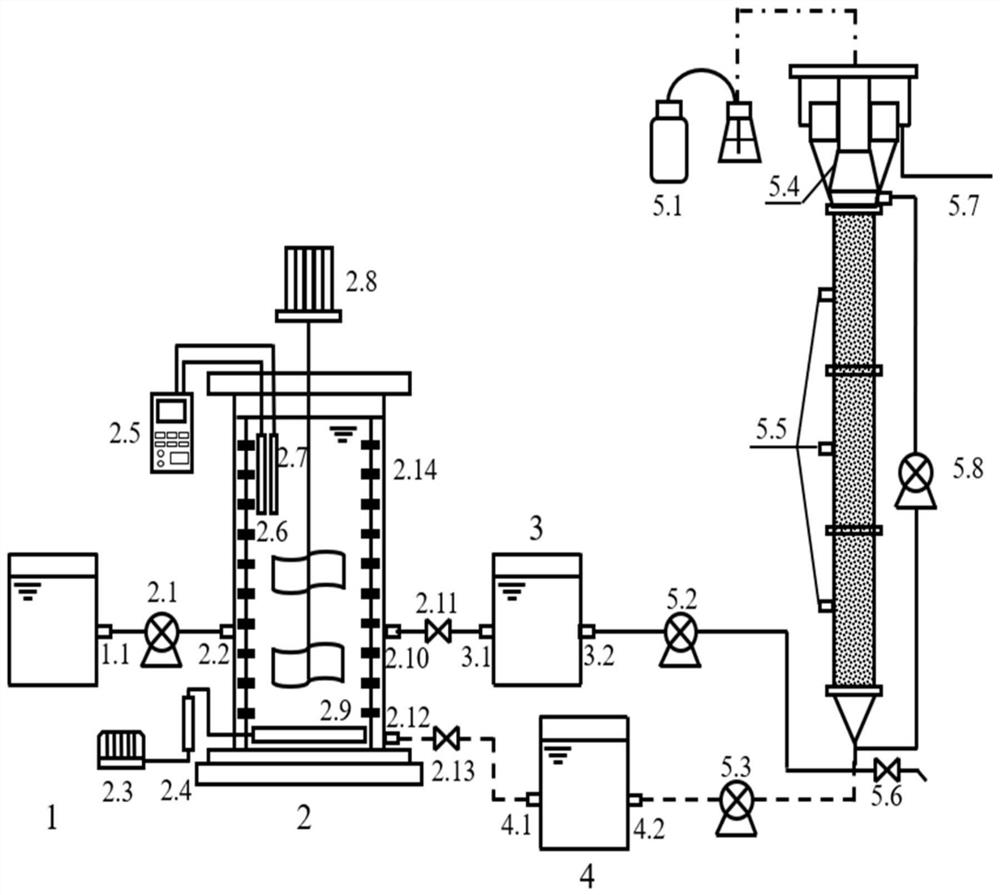

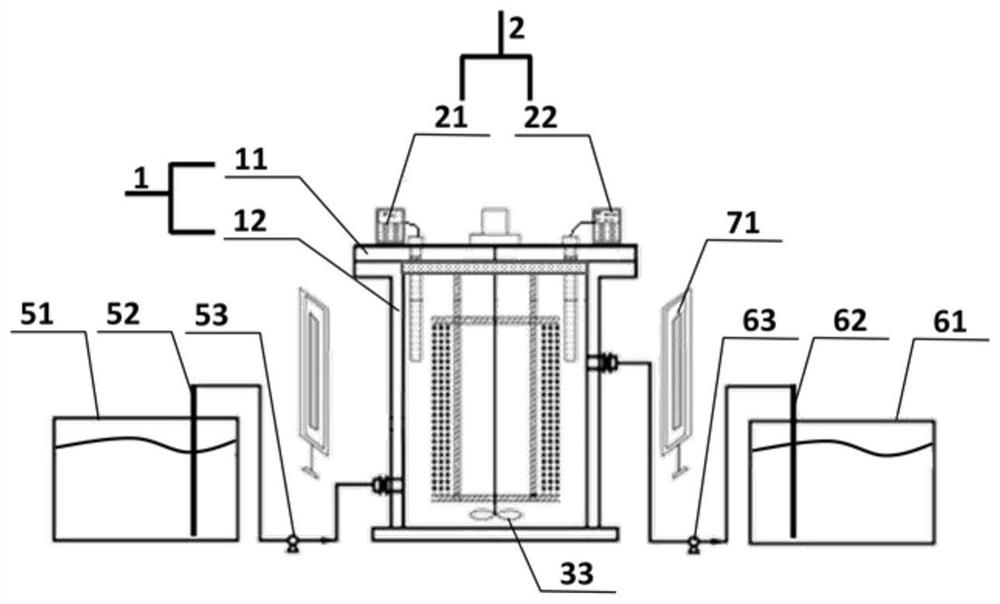

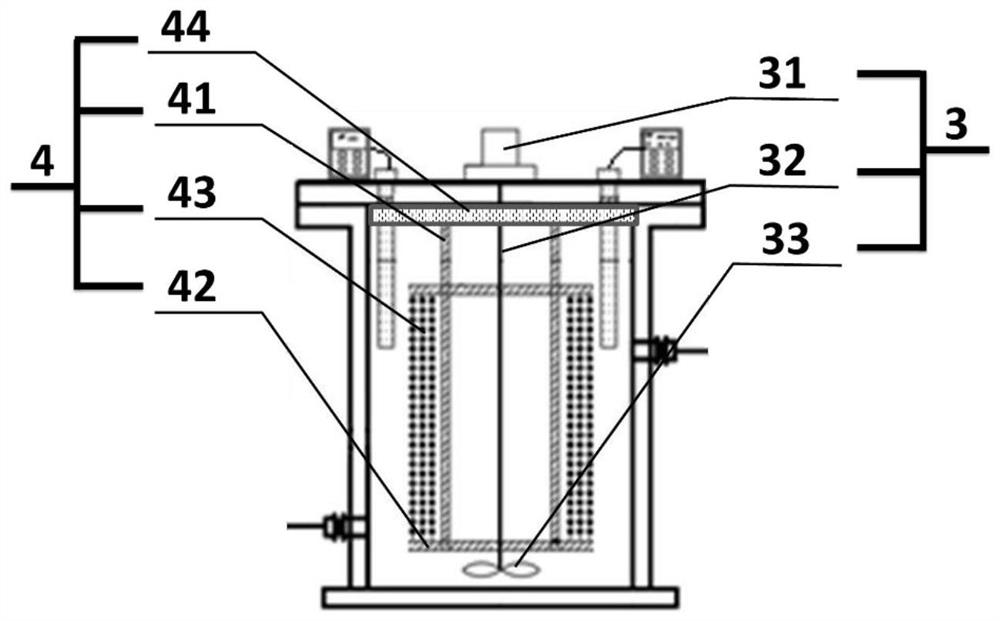

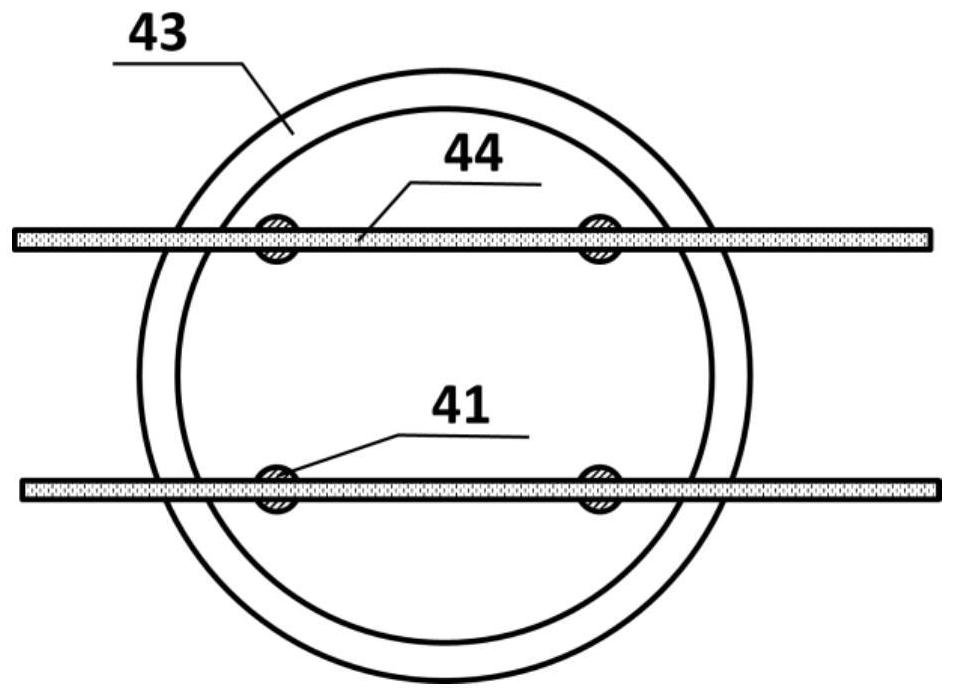

A kind of method and device for microalgae coupled anammox autotrophic biological denitrification

ActiveCN112919630BSmall process footprintEfficient denitrificationWater treatment parameter controlWater contaminantsNitrationSewage treatment

The invention discloses a method and a device for microalgae coupled anammox autotrophic denitrification, comprising a reactor, a water inlet device and a water outlet device; the water inlet device and the water outlet device are communicated with the reactor; the reactor comprises a reaction barrel , monitor, stirring device and packing frame; the cover and body of the reaction barrel can be detachably connected; the top surface of the packing frame is fixedly installed on the top of the inner wall of the barrel, and the short-range nitrification and anammox reaction are simultaneously realized in the reactor , which can reduce the area of the process, realize high-efficiency denitrification, and replace the traditional aeration method with microalgae to produce oxygen, which can reduce the energy consumption of aeration and significantly reduce the cost of sewage treatment.

Owner:HUAZHONG UNIV OF SCI & TECH +1

Device and method for biological intensified shortcut biological nitrogen removal of municipal sewage

ActiveCN102101743BStable short-cut nitrificationLow temperature resistanceMultistage water/sewage treatmentEngineeringShock resistance

The invention provides a device and method for biological intensified shortcut biological nitrogen removal of municipal sewage. The device comprises a municipal sewage raw water tank, a municipal sewage anaerobic-oxic (AO) reactor, a municipal sewage secondary sedimentation tank, a sludge digestion liquid raw water tank, a sludge digestion liquid AO reactor and a sludge digestion liquid secondarysedimentation tank, wherein the municipal sewage secondary sedimentation tank is a radial flow sedimentation tank; and the sludge digestion liquid secondary sedimentation tank is a vertical flow sedimentation tank. The method is as follows: carrying out shortcut nitrification on sludge digestion liquid through inhibition of low dissolved oxygen (DO is 0.5-1mg / L) and free ammonia (FA); and adding the excess sludge in a sludge digestion liquid shortcut nitrification system to a municipal sewage shortcut nitrification system, and simultaneously maintaining the low dissolved oxygen of the system (DO is 0.3-0.8mg / L), thereby stably achieving the efficient shortcut nitrification of the municipal sewage. By using the method, the shortcut nitrification and denitrification can be achieved, aeration energy consumption is saved, carbon source requirement for denitrification is reduced, sludge yield is reduced, and simultaneously, the volume load of the municipal sewage shortcut nitrification system is improved and the shock resistance capability of the system is enhanced.

Owner:彭永臻 +1

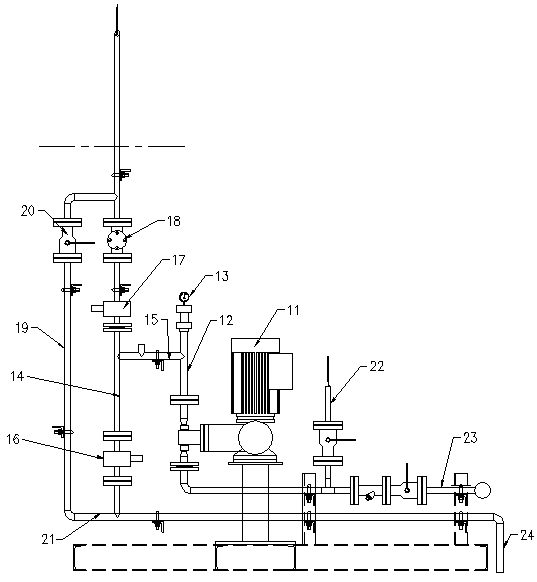

Integrated equipment for treating waste acid to produce ammonium sulfate and its operation method

ActiveCN104689769BSimple processSmall process footprintLiquid-gas reaction processesAmmonia compoundsAmmonium sulfateOperating cost

The present invention is an integrated equipment for treating waste acid to produce ammonium sulfate and its operation method. The integrated equipment is a tower reactor; a tower reactor buffer section, a reaction section, an oil-water separation section, and an oil production section are sequentially arranged from the bottom of the tower to the top of the tower. and defoaming section; there is an exhaust outlet (13) at the top of the tower, and an extraction outlet (14) is arranged at the bottom of the tower. A coaxial inner sleeve is arranged in the buffer section, the reaction section and the oil-water separation section of the tower kettle. Ammonia enters from the ammonia pipeline (1) in the tower kettle, and reacts with the water inlet of the water delivery pipeline (8) and the waste sulfuric acid pipeline (6). Extraction outlet (10) is extracted. Integrating the functions of waste acid dilution, reaction and oil-water separation into one, solves the shortcomings of the traditional preparation process such as large area and complicated operation, further reduces production and operation costs, and prepares ammonium sulfate with high purity and good appearance solution to obtain ammonium sulfate crystals that meet national standards.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com