Method for improving grades of fluorite ore concentrate and rare earth ore concentrate of baiyuneboite through high-gradient superconducting magnetic separation

A rare earth concentrate and superconducting magnetic technology, which is applied in chemical instruments and methods, wet separation, solid separation, etc., can solve problems affecting the grade of fluorite concentrate, achieve small footprint, realize comprehensive recovery, reduce The effect of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

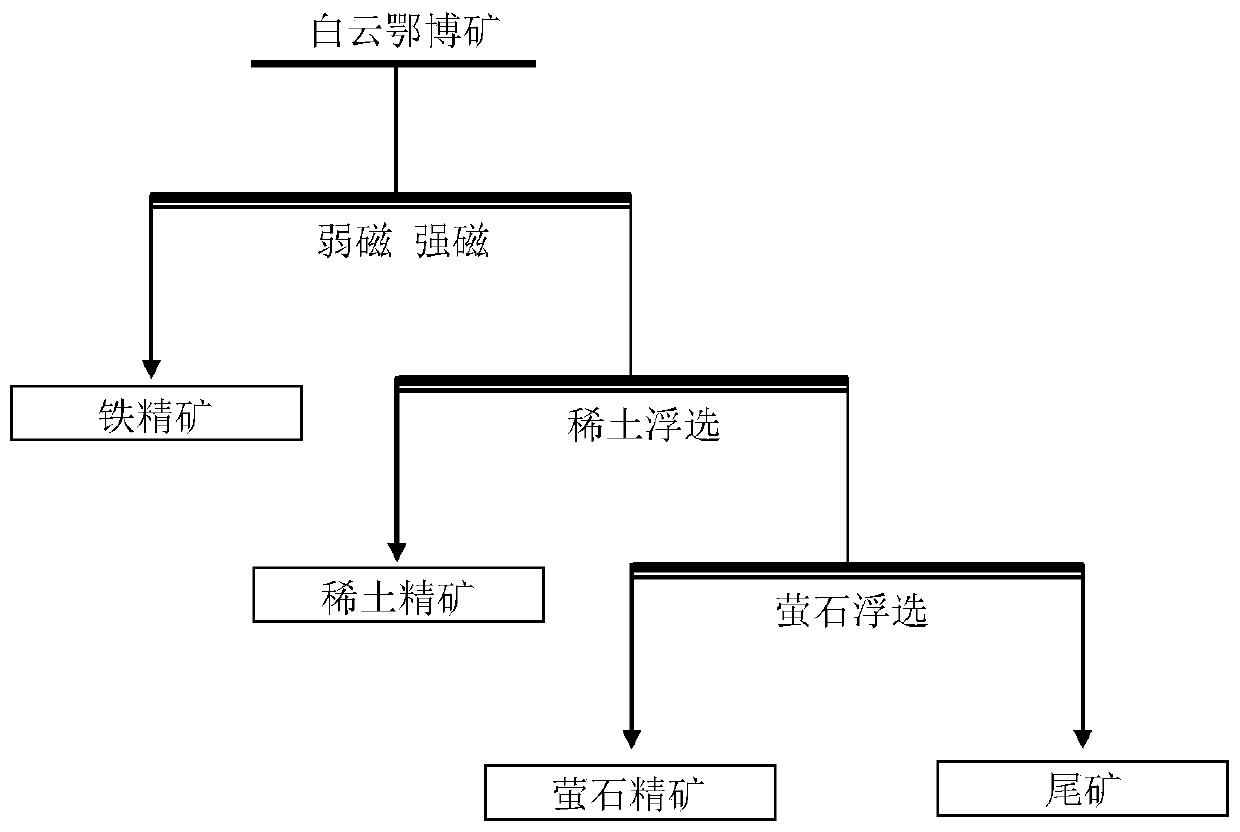

[0034] Example 1 A method for improving the grade of fluorite concentrate in Baiyan Obo Mine by high-gradient superconducting magnetic separation

[0035] The raw materials used are flotation fluorite concentrate from Baiyun Obo mine, fluorite concentrate CaF 2 The grade is 88.6%, and the mass content of REO is 3.4%.

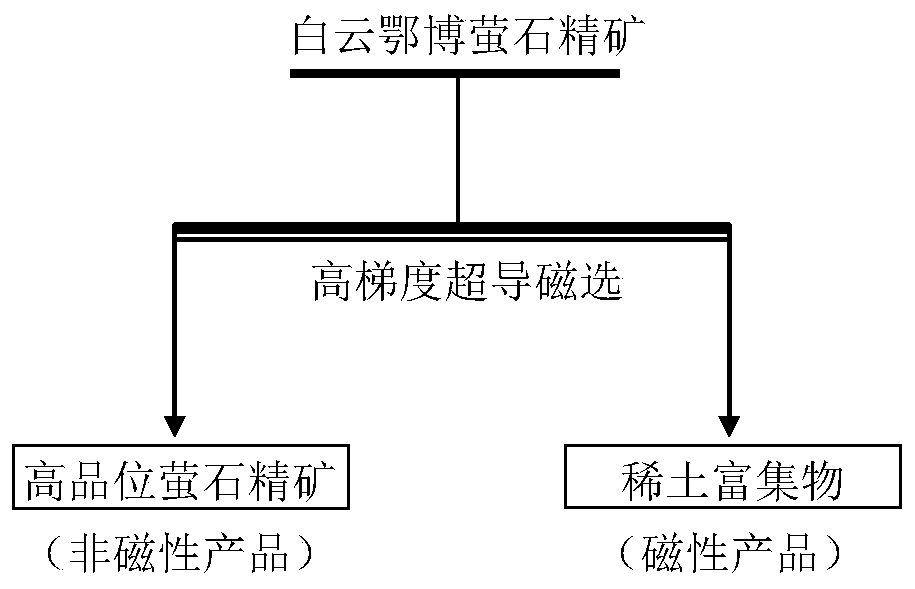

[0036]Using high gradient superconducting magnetic separator for high gradient superconducting magnetic separation, the process is as follows figure 2 shown. During the test, a high-gradient superconducting magnetic separator was used, and steel wool with a diameter of 0.12mm was used to gather magnetic media, and the magnetic field strength was 4.0T. First grind the fluorite concentrate, add water, and adjust the pulp until the pulp concentration is 12%, and the pulp flow rate is 10cm / s. After high-gradient superconducting magnetic separation, the non-magnetic product obtained is high-grade fluorite concentrate. The magnetic product is a rare earth enrichme...

Embodiment 2

[0040] Example 2 A method for improving the grade of fluorite concentrate in Baiyan Obo Mine by high-gradient superconducting magnetic separation

[0041] The raw material used is the flotation fluorite concentrate of Baiyun Obo Mine, and the fluorite concentrate CaF 2 The grade is 75.41%, and the REO content is 8.05%.

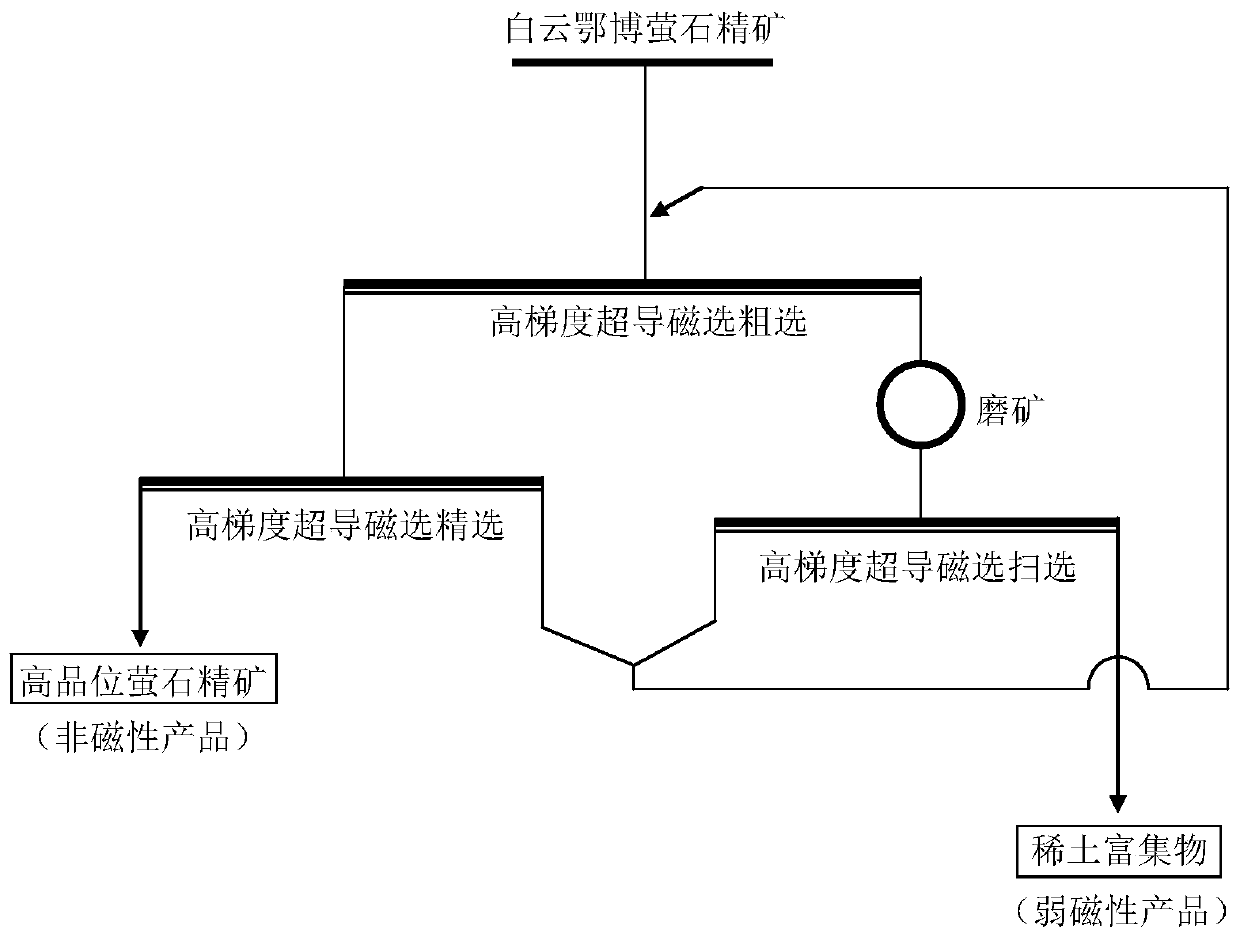

[0042] High-gradient superconducting magnetic separator is used for high-gradient superconducting magnetic separation, through the high-gradient superconducting magnetic separation process of "one rough, one fine, one sweep", roughing tailings regrinding, medium ore returning to roughing, such as image 3 shown. The magnetic gathering medium used in the magnetic separator adopts steel wool with a diameter of 0.15mm and a diamond-shaped steel mesh of 2mm×4mm, and is used in 1:1 combination.

[0043] After roughing, the roughing concentrate and roughing tailings are obtained, and the roughing concentrate is further refined to obtain a non-magnetic product, tha...

Embodiment 3

[0050] Example 3 A method of high gradient superconducting magnetic separation to improve the grade of rare earth concentrate in Baiyan Obo Mine

[0051] The raw material is the flotation rare earth concentrate of Baiyun Obo Mine, and the REO grade of the rare earth concentrate is 50.5%. The high-gradient superconducting magnetic separation closed-circuit process of "one rough and one fine" by using high-gradient superconducting magnetic separator, and the selected tailings return to roughing, the process is as follows Figure 4 shown. The magnetic gathering medium in the superconducting magnetic separator adopts a combination of steel wool with a diameter of 0.12mm and steel wool with a diameter of 0.15mm.

[0052] The roughing conditions are: magnetic field strength 4.5T, pulp concentration 10%, test pulp flow rate 12cm / s;

[0053] The selection conditions are: magnetic field strength 4.0T, pulp concentration 8%, test pulp flow rate 9cm / s;

[0054] Ultimately, the weak ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com