A kind of aerobic granular sludge sewage treatment method with denitrification effect and special equipment

A technology of aerobic granular sludge and sewage treatment method, which is applied in the directions of aerobic and anaerobic process treatment, etc., can solve the problem of long cultivation time of aerobic granular sludge, high equipment investment and operating cost, and no denitrification effect. problems, to achieve the effect of good sewage treatment effect, excellent sedimentation, and increase the effect of oxygen dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

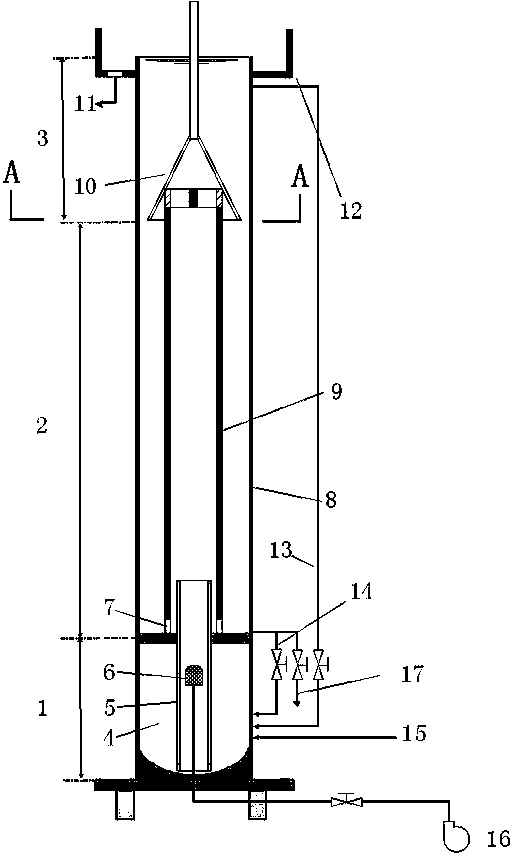

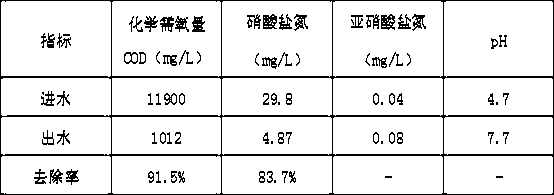

[0048] Example 1. Treatment of cornstarch factory wastewater (taken from the effluent of the regulating tank)

[0049] Reaction target solution volume: 2.8L

[0050] Reaction target solution: wastewater from a corn starch factory (taken from the effluent of the regulating tank), the water quality is:

[0051] Chemical oxygen demand (COD): 10000-12000mg / L

[0052] Nitrate nitrogen: 25-40 mg / L

[0053] Nitrite nitrogen: 0.04-0.06 mg / L

[0054] pH: 4.5-5.5

[0055] The reaction conditions are:

[0056] Aspect ratio: 1:15

[0057] Reactor height: 1.2m

[0058] The rising gas velocity in the inner tower 9 of the central aerobic nitrification zone 2 is maintained at 10m / h

[0059] Sewage hydraulic retention time 6 hours

[0060] The treatment effect is shown in Table 1, and the index parameters such as sewage and sludge in the reactor are shown in Table 2.

[0061] Table 1 Example 1 Treatment effect of sewage from a corn starch factory (taking the effluent from the regulati...

Embodiment 2

[0066] Example. 2 Treatment of urban sewage (taken from the fine screen effluent of an urban sewage plant)

[0067] The reaction target solution volume is: 2.8L

[0068] Reaction target solution: an urban sewage (taken from the fine screen effluent of an urban sewage plant), the water quality is:

[0069] Chemical oxygen demand (COD): 250-350mg / L

[0070] Total nitrogen: 25-40 mg / L

[0071] pH: 6.5-8.5

[0072] The reaction conditions are:

[0073] Aspect ratio: 1:15

[0074] Reactor height: 1.2m

[0075] The rising gas velocity in the inner tower 9 of the central aerobic nitrification zone 2 is maintained at 5m / h

[0076] Sewage hydraulic retention time 3 hours

[0077] The treatment effect is shown in Table 3, and the index parameters such as sewage and sludge in the reactor are shown in Table 4.

[0078] Table 3 Example 2 Treatment effect of fine screen effluent of urban sewage plant

[0079]

[0080] Table 2 Example 1 Treatment of sewage and sludge in the react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com