Boiler blowdown water recycling treatment technology based on ion exchange and chemical precipitation

A chemical precipitation and ion exchange technology, applied in the field of water pollution control, can solve the problems of large consumption of chemical agents, difficult to control effluent quality, and weakened inhibitory effect, so as to save high-quality water resources, save sludge disposal costs, and reduce treatment cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

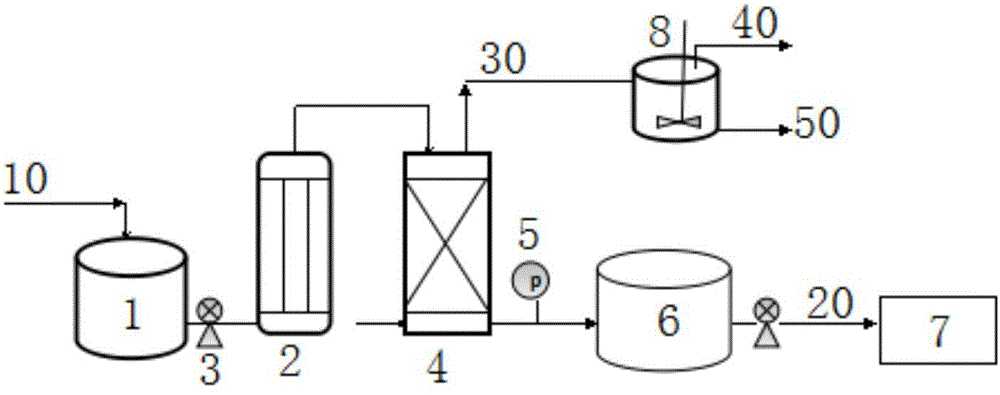

Method used

Image

Examples

Embodiment 1

[0049] Taking the treatment of sewage from the boiler blowdown cooling tank of a natural gas purification plant in Sichuan as an example, the implementation steps are further explained.

[0050] (1): The total sewage discharge volume is about 30m 3 The / h boiler sewage is transported from the sewage cooling pool to the high-efficiency fiber filter for filtration. The diameter of the filter is Φ1200mm, and the height of the filter layer is 300mm. Filter output 25m 3 / h, the turbidity of the effluent water is less than 1NTU, and the SDI is less than 3.0.

[0051] (2): Send the filtered water in step (1) into the chlorine-type ion exchanger through the clean water pump, its diameter is Φ1000mm, the resin layer height is 800mm, and the design output of a single unit is 30m 3 / h, flow rate 15m / h. Control effluent PO through online phosphorus meter 4 3- 4 3- 8.81mg / l; effluent: turbidity 0.13NTU, pH7.13, conductivity 130us / cm, PO 4 3- 0.01mg / l.

[0052] (3): The high-qualit...

Embodiment 2

[0055] Take the mixed wastewater treatment of RB boiler in a large paper mill in Hainan as an example. The specific implementation steps are as follows:

[0056] (1): about 140m 3 / h Sewage and cooling pool mixed sewage and waste water conveyed to precision filter for filtration, the flow rate of a single filter is designed to output 60m 3 / h, the turbidity of the filter water is less than 1.0NTU, and the SDI is less than 5.0.

[0057] (2): Filter the water from step (1), and send it into the chlorine-type anion exchange resin through the clean water pump, its diameter is Φ2500mm, the resin layer height is 2200mm, and the design output of a single unit is 75m 3 / h, flow rate 25m / h. Control effluent PO through online phosphorus meter 4 3- 4 3- 12.72mg / l; effluent: turbidity 0.03NTU, pH6.96, conductivity 121us / cm, PO 4 3- 0.02mg / l.

[0058] (3): Send the high-quality effluent obtained in step (2) into the raw water tank of the boiler for use in the desalinated water syst...

Embodiment 3

[0061] Taking the treatment of power boiler sewage of a petrochemical enterprise in Zhejiang as an example, the implementation steps are as follows:

[0062] (1): will be about 66m 3 / h Boiler sewage is sent to a high-efficiency fiber filter for filtration, and the flow rate of a single filter is designed to output 45m 3 / h, the turbidity of the filter water is less than 1.0NTU, and the SDI is less than 3.0.

[0063] (2): Filter the water from step (1), and send it to the chlorine-type anion exchanger through the water pump. The diameter is Φ1500mm, the height of the resin layer is 1000mm, and the design output of a single unit is 65m 3 / h, flow rate design 20m / h. Control effluent PO through online phosphorus meter 4 3- 4 3- 10.5mg / l; effluent: turbidity 0.02NTU, pH7.81, conductivity 119us / cm, PO 4 3- 0.07mg / l.

[0064] (3): Send the effluent from the ion exchanger obtained in step (2) into the raw water tank of the boiler and enter the desalinated water system. When th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com