Efficient integrated desulfurization and denitrification device for coal-fired boiler fuel gas and implementation method of device

A technology for desulfurization, denitrification, and coal-fired boilers, which is applied to chemical instruments and methods, gas treatment, and separation methods. It can solve the problems of large equipment investment, high failure rate, and cumbersome operating procedures, and achieve low one-time investment and maintenance costs. Low, simple equipment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

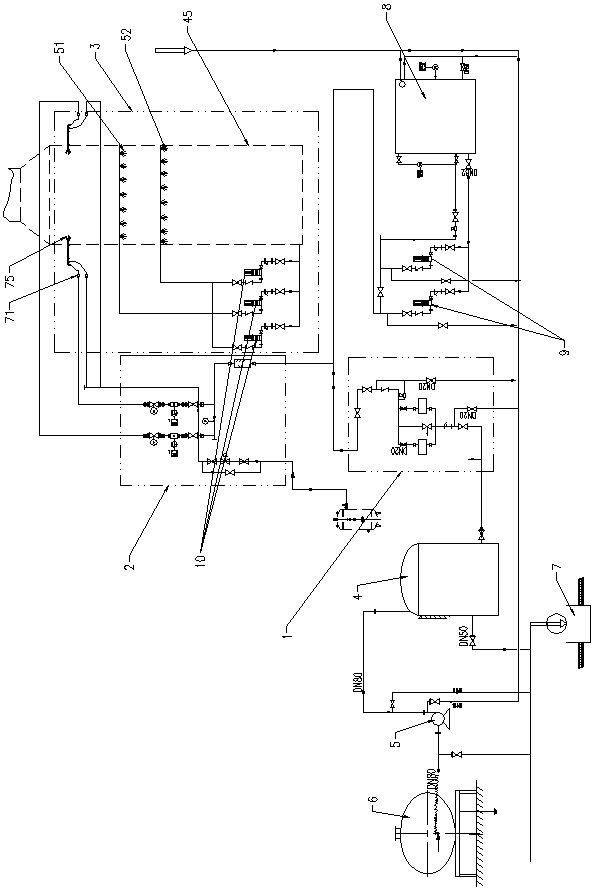

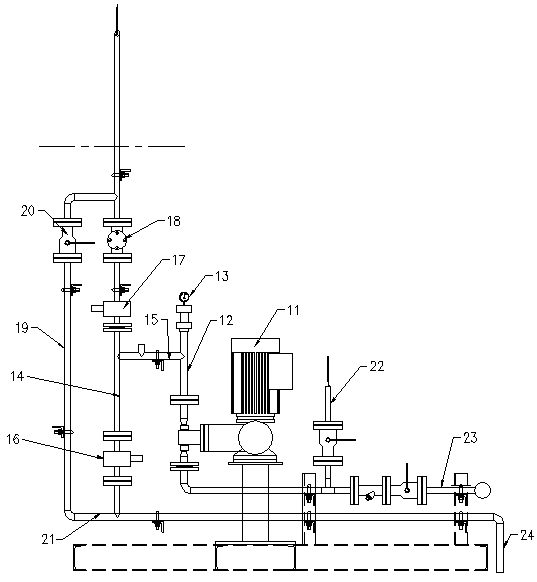

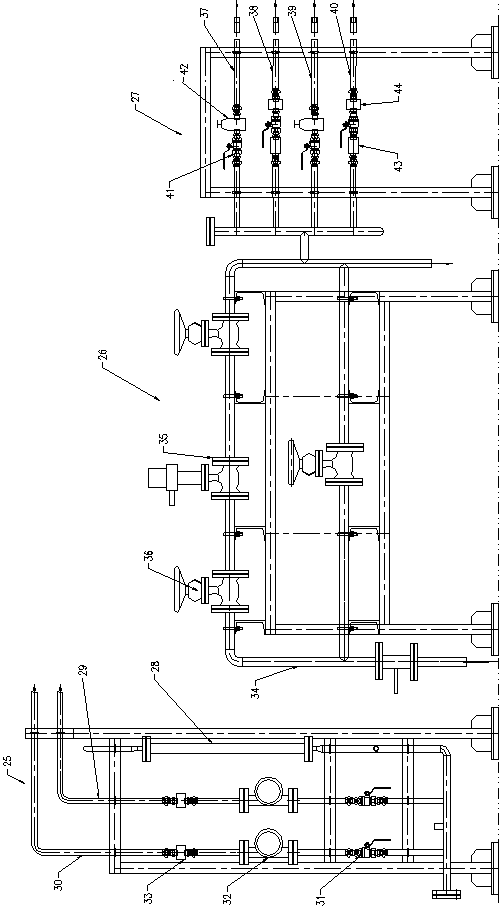

[0042] Example, as attached Figure 1-12As shown, an integrated device for high-efficiency desulfurization and denitrification of flue gas from a coal-fired boiler includes a desulfurization and denitrification agent delivery module 1, a desulfurization and denitration agent metering injection module 2, and a circulating spray system 3. One end of the desulfurization and denitrification agent delivery module 1 is connected with a sub- The sodium chlorate storage tank 4, the sodium chlorite storage tank 4 are connected with an unloading pump 5, the unloading pump 5 is connected with a transport tanker 6, and the transport tanker 6 is connected with a waste water pool 7;

[0043] The desulfurization and denitration agent delivery module 1 is respectively connected with a desulfurization and denitration agent metering injection module 2 and two sets of dilution pumps 9, the desulfurization and denitration agent metering injection module 2 is connected with a circulating spray syst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com