System for wastewater advanced treatment

A technology for advanced treatment and waste water, applied in multi-stage water treatment, water/sewage treatment, biological water/sewage treatment, etc., can solve the problems of high operating cost and complicated operating procedures, and achieve simple operation, stable effect and low operating cost cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

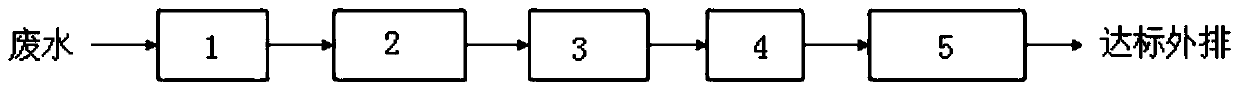

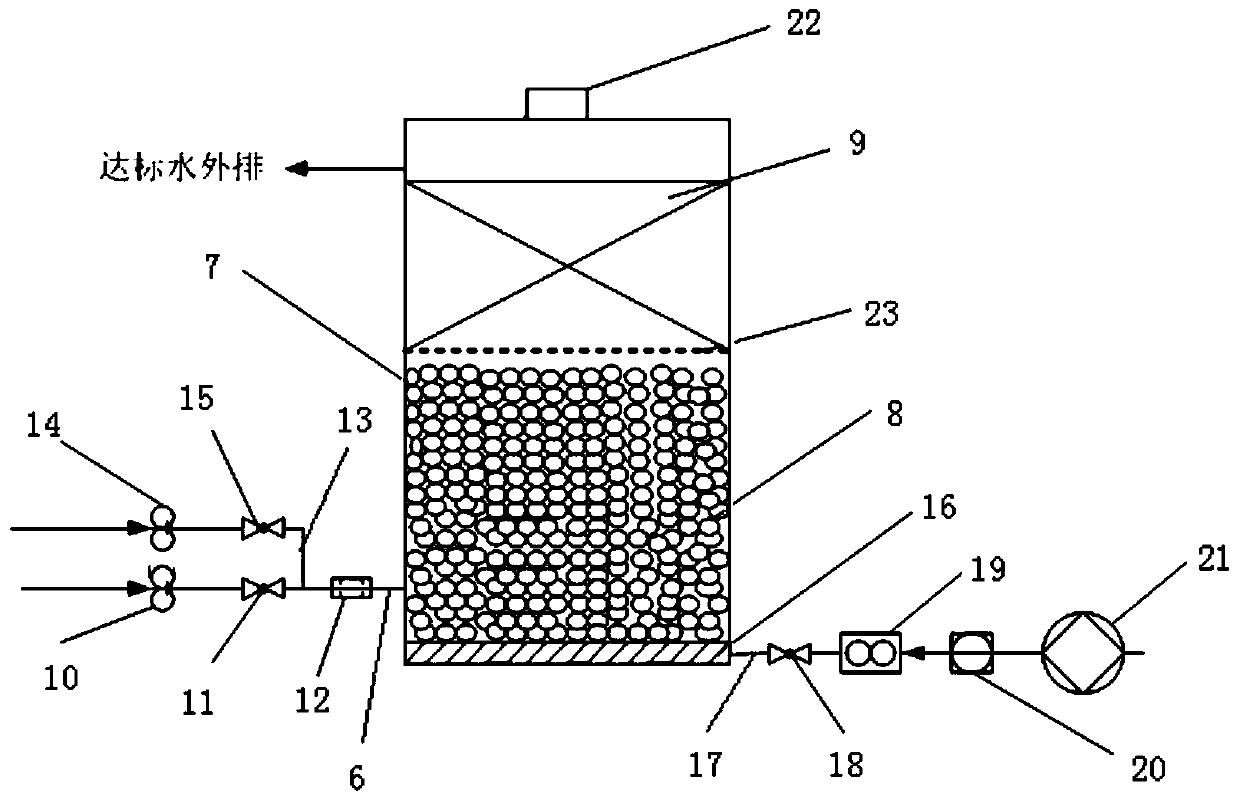

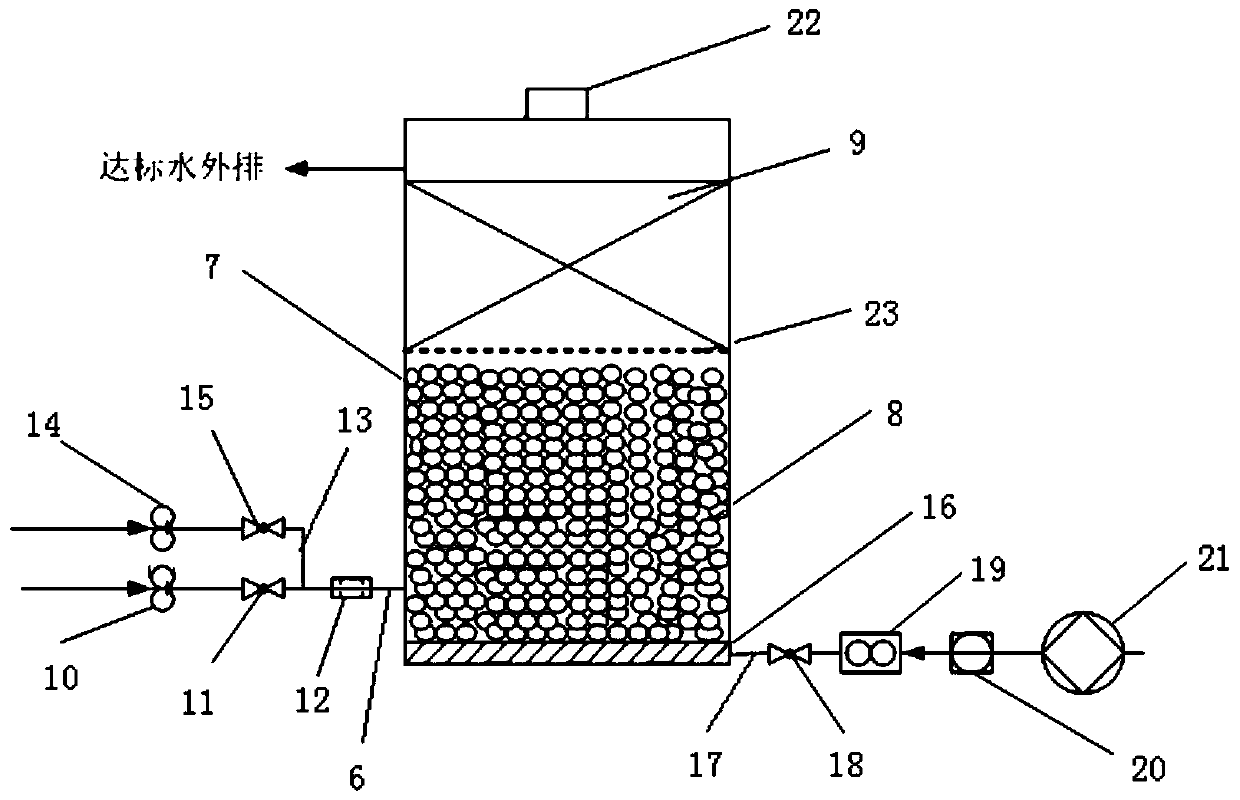

[0034] A system for the advanced treatment of wastewater, comprising a regulating tank 1, a flocculation sedimentation tank 2, a biochemical reaction tank 3, a sedimentation tank 4 and an advanced treatment reactor 5 connected in sequence, the upper part of the sedimentation tank 4 is connected with the advanced treatment reactor 5 The liquid inlet pipeline 6 is connected, and the barrel 7 of the advanced treatment reactor 5 is divided into a heterogeneous Fenton synergistic ozone reaction zone 8 and a biological aeration filter zone 9, and the biological aeration filter zone 9 is located in The upper part of the heterogeneous Fenton synergistic ozone reaction zone 8, the biological aeration filter zone 9 is filled with aeration filter filler, and the heterogeneous Fenton synergistic ozone reaction zone 8 is filled with heterogeneous Fenton catalyst, the liquid inlet pipeline 6 is arranged at the lower part of the cylinder body 7, and communicates with the heterogeneous Fenton ...

Embodiment 2

[0038] The difference from Example 1 is that the barrel 7 of the advanced treatment reactor 5 is a cylindrical structure, and the material is glass fiber reinforced plastic. The cylinder body 7 of the advanced treatment reactor 5 has an aspect ratio of 10. The height ratio of the heterogeneous Fenton synergistic ozone reaction zone 8 to the biological aeration filter zone 9 is 3:1. The gas source of the ozone generator 21 is an oxygen source.

Embodiment 3

[0040]The difference from Example 1 is that the cylinder body 7 of the advanced treatment reactor 5 is a cylindrical structure, and the material is polypropylene resin PP. The cylinder body 7 of the advanced treatment reactor 5 has an aspect ratio of 7. The height ratio of the heterogeneous Fenton synergistic ozone reaction zone 8 to the biological aeration filter zone 9 is 2.5:1. The gas source of the ozone generator 21 is an air source.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com