Method for treating sludge digestion liquid by coupling short-cut nitrification/anaerobic ammonia oxidation-fermentation short-cut denitrification/anaerobic ammonia oxidation and device thereof

An anammox and short-range denitrification technology is applied in the field of short-range nitrification/anammox-fermentation coupled with short-range denitrification/anammox to treat sludge digested liquid and devices, which can solve the problem of easy loss and systematic denitrification. The problem of unstable effect, etc., can improve the retention rate, enhance the stability and the ability to resist the impact of nitrogen load, and avoid the tedious steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

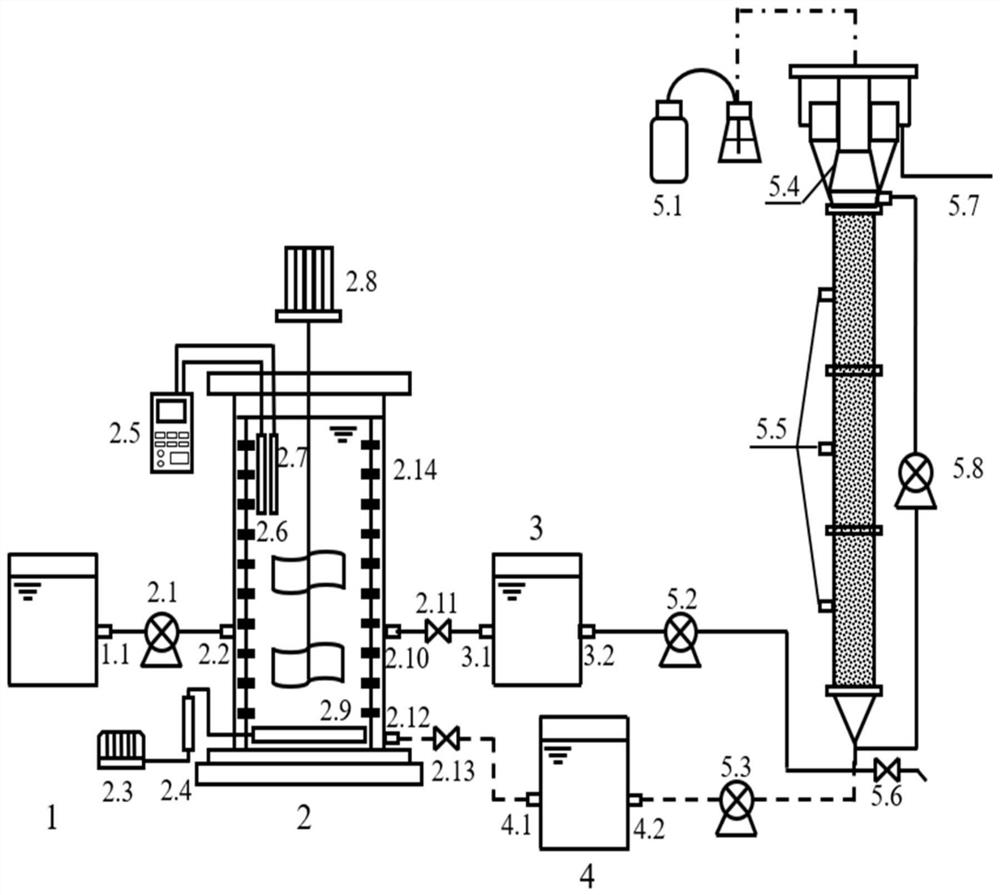

[0027] Such as figure 1 As shown, the method and device for short-range nitrification / anammox-fermentation coupled short-range denitrification / anammox treatment of sludge digestate is characterized in that it includes: raw water tank (1), short-range nitrification / anammox SBR reactor (2), intermediate water tank (3), mud storage tank (4), fermentation coupled short-range denitrification / anammox UASB reactor (5);

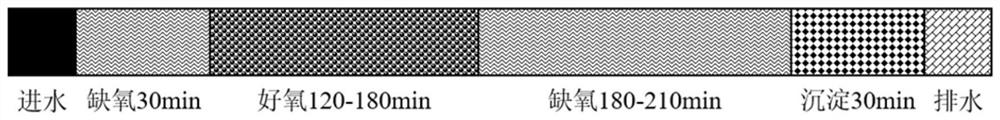

[0028] The raw water tank (1) is provided with a water outlet (1.1); the short-course nitrification / ANAMMOX SBR reactor (2) is provided with a first water inlet pump (2.1), a water inlet (2.2), an aeration pump (2.3), gas Flow meter (2.4), pH / DO real-time monitoring device (2.5), pH probe (2.6), DO probe (2.7), agitator (2.8), aeration disc (2.9), water outlet (2.10), drain valve ( 2.11), mud discharge port (2.12), mud dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com