A kind of landfill leachate treatment method

A technology for landfill leachate and a treatment method, which is applied in the field of landfill leachate treatment, can solve problems such as the replacement cost of secondary pollution membranes, and achieve the effects of good denitrification effect, high treatment load, and stable effluent quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

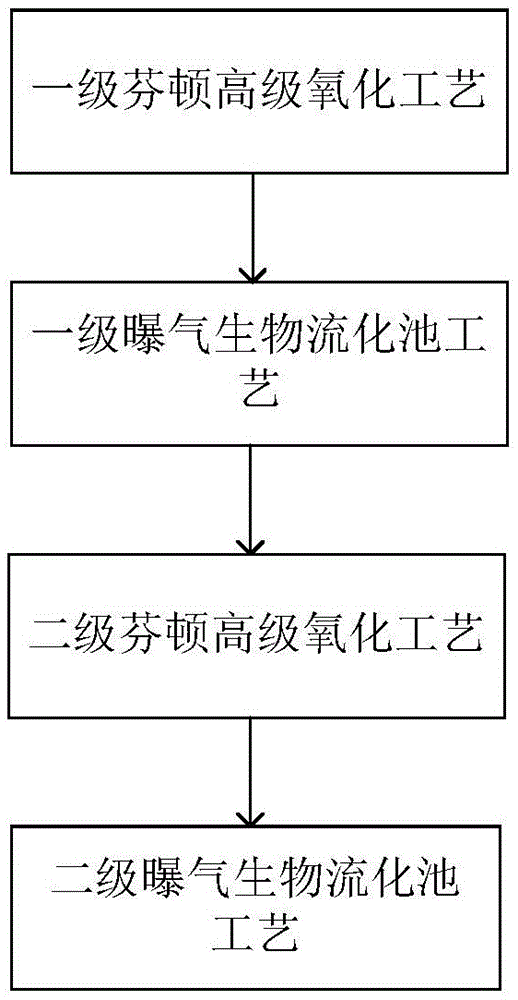

[0048] A method for treating landfill leachate, comprising the following steps:

[0049] (1) One-stage Fenton Advanced Oxidation Process:

[0050] The biochemically treated landfill leachate was adjusted to a pH value of 4, connected to a primary Fenton reaction tank, added with a primary Fenton reagent, and reacted for 18 hours to obtain effluent from a primary Fenton advanced oxidation process.

[0051] The specific steps of the biochemical treatment of landfill leachate are: the leachate is pretreated to remove part of the suspended solids and COD, and then the anaerobic reactor and the anaerobic / aerobic process are used for biochemical treatment to remove most of the COD and ammonia nitrogen. , to meet the adaptation conditions of the subsequent process.

[0052] Add the primary Fenton's reagent so that 2.75kg H is added per ton of water 2 o 2 and 5.00kg FeSO 4 .

[0053] The effluent standard of the first-stage Fenton advanced oxidation process is: the chemical oxyge...

Embodiment 2

[0069] A method for treating landfill leachate, comprising the following steps:

[0070] (1) One-stage Fenton Advanced Oxidation Process:

[0071] The biochemically treated landfill leachate was adjusted to a pH value of 3.5, connected to a primary Fenton reaction tank, added with a primary Fenton reagent, and reacted for 20 hours to obtain effluent from a primary Fenton advanced oxidation process.

[0072] The specific steps of the biochemical treatment of landfill leachate are: the leachate is pretreated to remove part of the suspended solids and COD, and then the anaerobic reactor and the anaerobic / aerobic process are used for biochemical treatment to remove most of the COD and ammonia nitrogen. , to meet the adaptation conditions of the subsequent process.

[0073] Add the primary Fenton's reagent so that 3.00kg H is added to each ton of water 2 o 2 and 5.60kg FeSO 4 .

[0074] The effluent standard of the first-stage Fenton advanced oxidation process is: the chemical...

Embodiment 3

[0090] A method for treating landfill leachate, comprising the following steps:

[0091] (1) One-stage Fenton Advanced Oxidation Process:

[0092]The biochemically treated landfill leachate was adjusted to a pH value of 3, connected to a primary Fenton reaction tank, added with a primary Fenton reagent, and reacted for 22 hours to obtain effluent from a primary Fenton advanced oxidation process.

[0093] The specific steps of the biochemical treatment of landfill leachate are: the leachate is pretreated to remove part of the suspended solids and COD, and then the anaerobic reactor and the anaerobic / aerobic process are used for biochemical treatment to remove most of the COD and ammonia nitrogen. , to meet the adaptation conditions of the subsequent process.

[0094] Add the primary Fenton's reagent so that 3.30kg H is added to each ton of water 2 o 2 and 6.25kg FeSO 4 .

[0095] The effluent standard of the first-stage Fenton advanced oxidation process is: the chemical ox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com