Integrated equipment for treating waste acid to produce ammonium sulfate and its operation method

A technology for waste acid treatment and integrated equipment, which is applied in chemical methods, chemical instruments and methods, and chemical/physical processes for reacting liquids and gaseous media. To achieve the effect of uniform reaction and heat release, increase reaction time, and strengthen the degree of mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

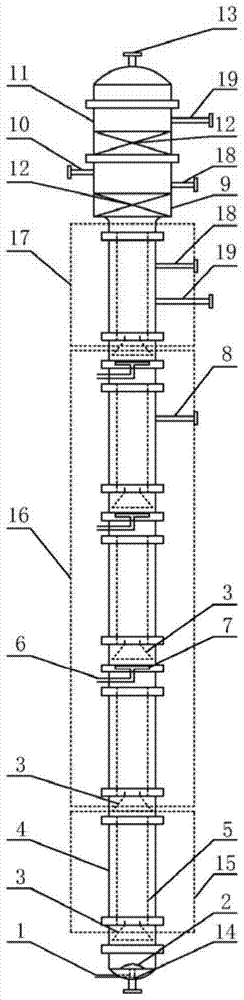

[0028] The following is a detailed description in conjunction with the description of the drawings and the specific operation process:

[0029] The integrated tower equipment involved in the present invention is a tower reactor based on an air-lift multi-stage interleaved circulation flow tower and a circulation flow structure (CN102716699A). In addition to the inlet and discharge parts of the tower kettle, the main structure of the whole tower is divided into five parts: from the bottom of the tower to the top of the tower, there are buffer section of the tower kettle, reaction section, oil-water separation section, oil production section and foam removal section. Such as figure 1 As shown, it is expressed as follows:

[0030] The ammonia gas pipeline (1) is connected to the gas phase distribution device (2) at the bottom of the tower; the buffer section of the tower kettle, the reaction section, and the oil-water separation section are all in the form of an inner sleeve, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com