Patents

Literature

34results about How to "Improve the level of mechanical automation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

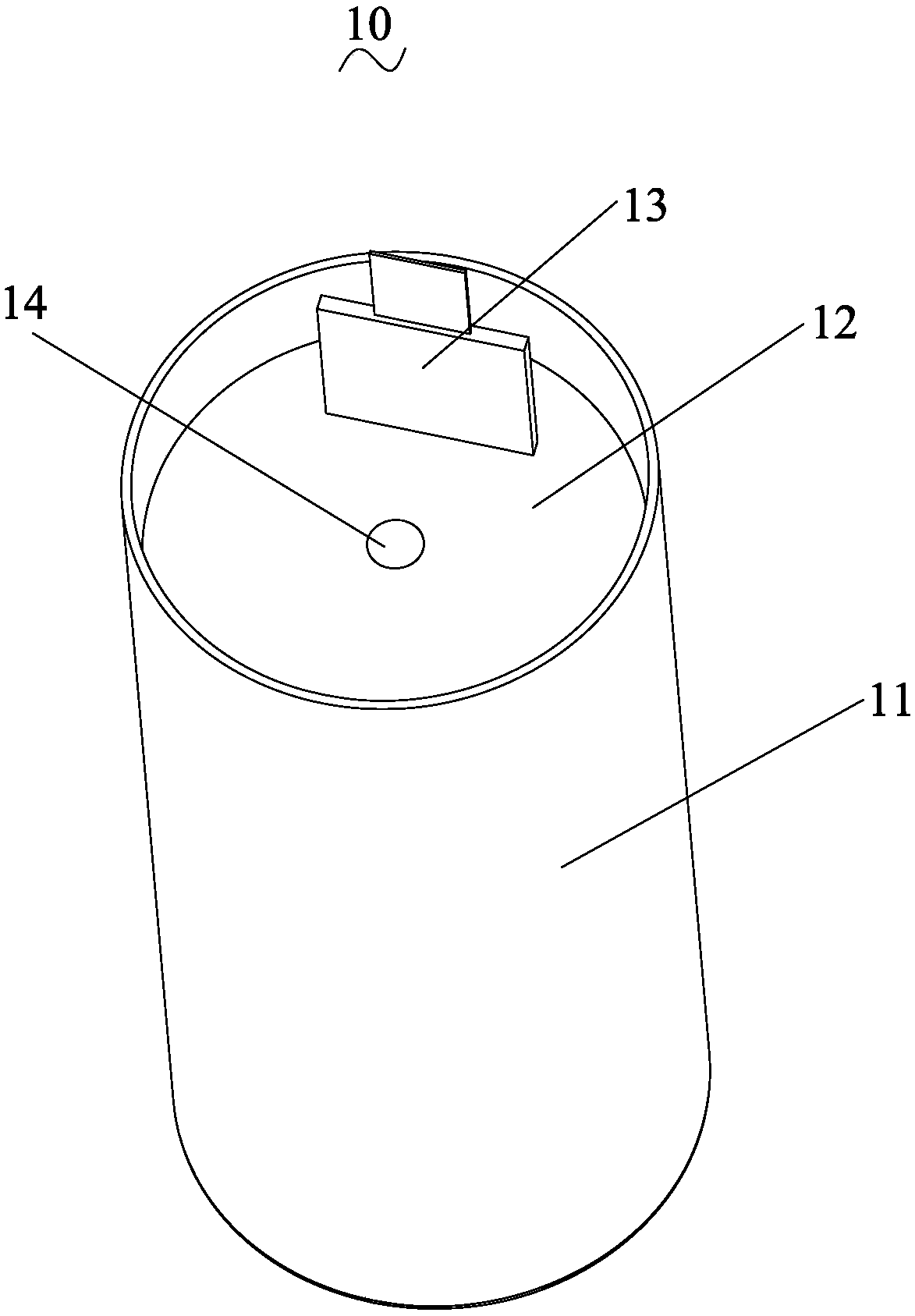

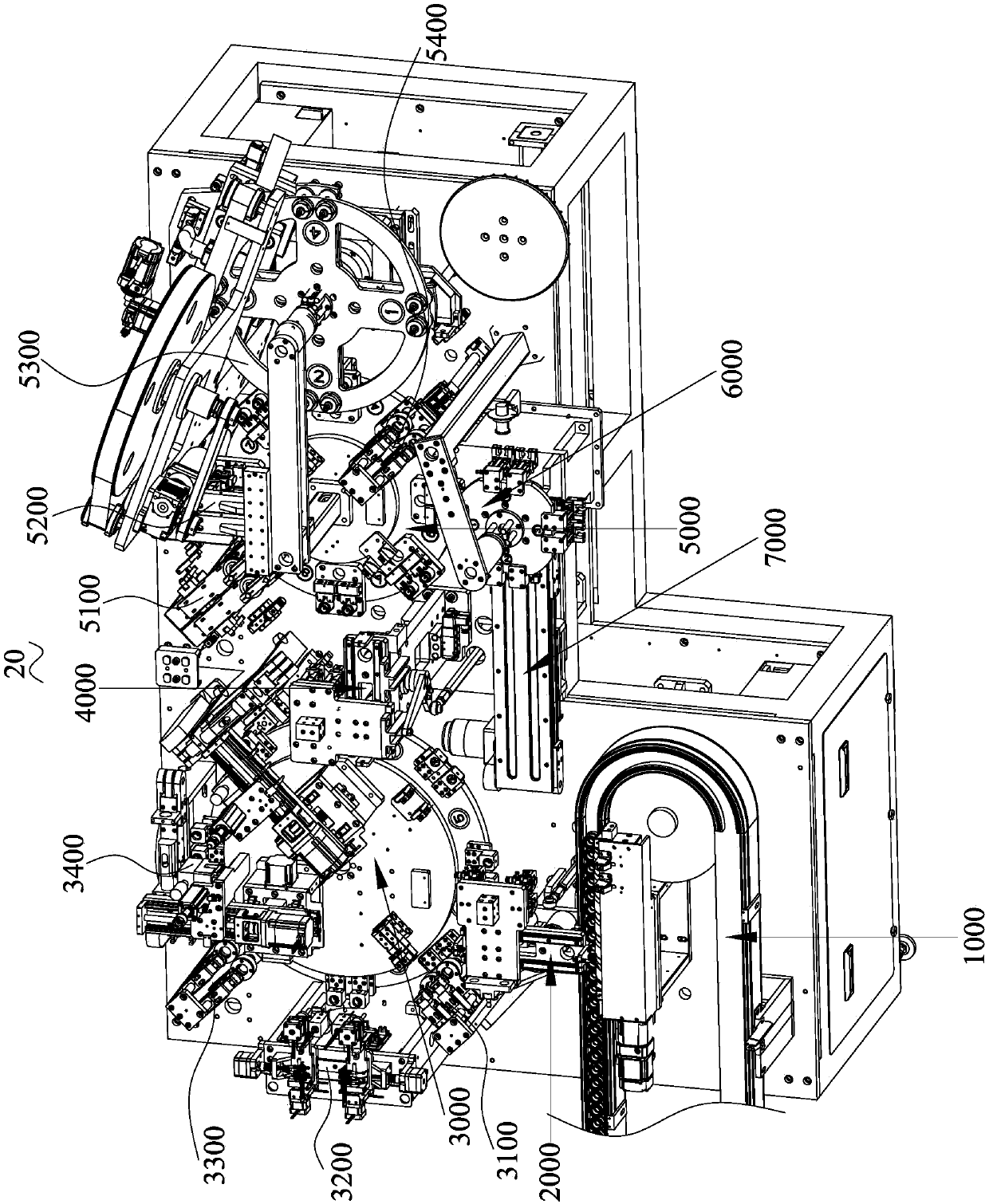

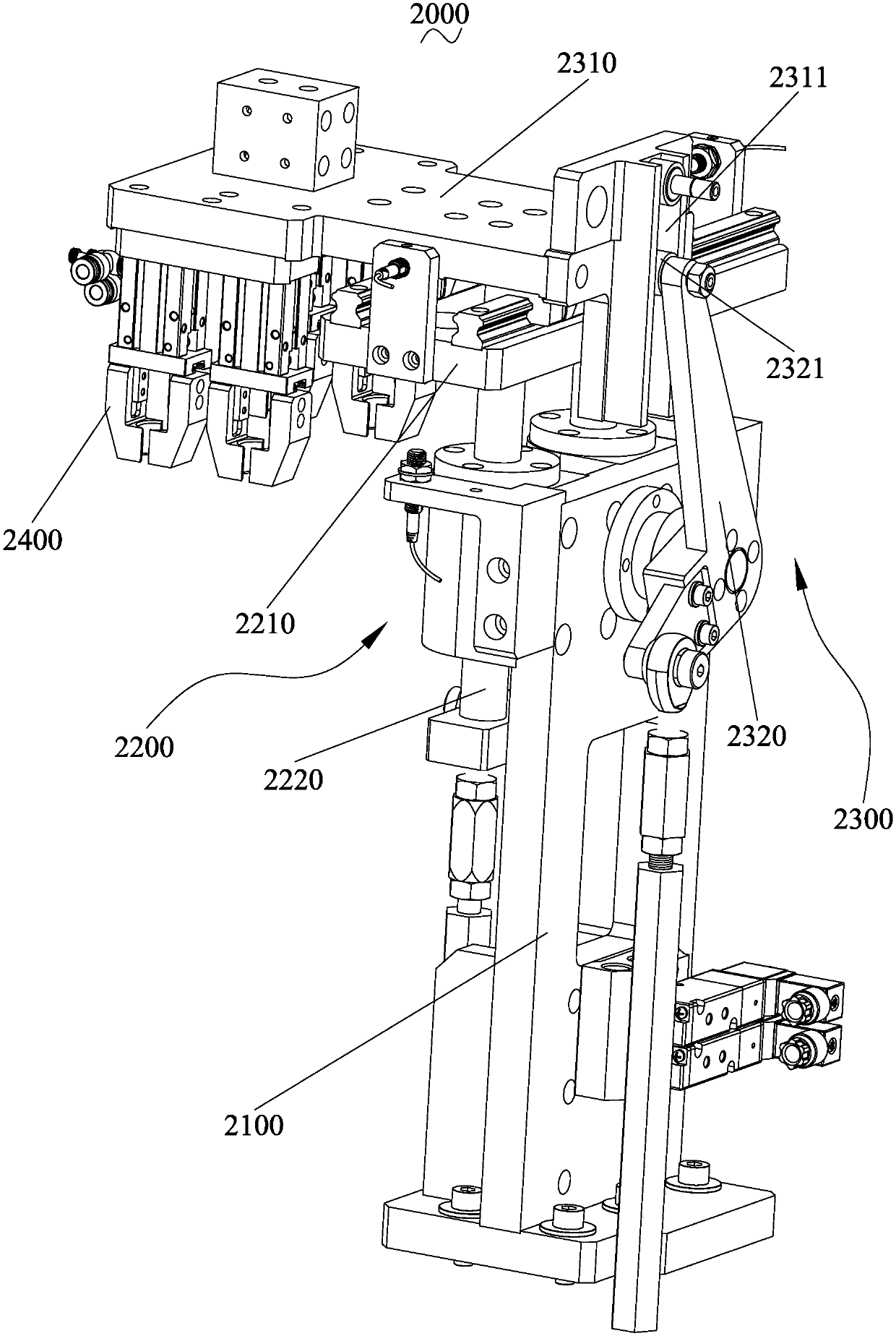

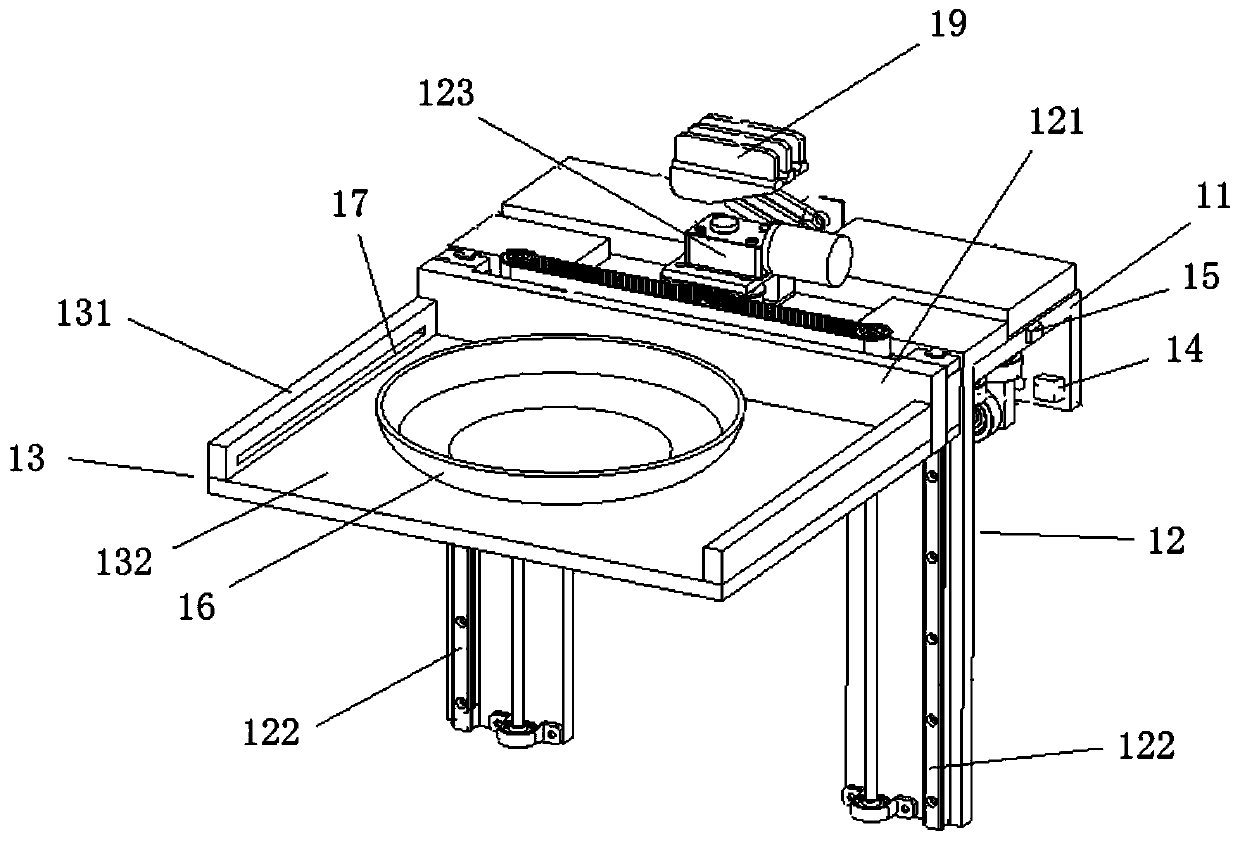

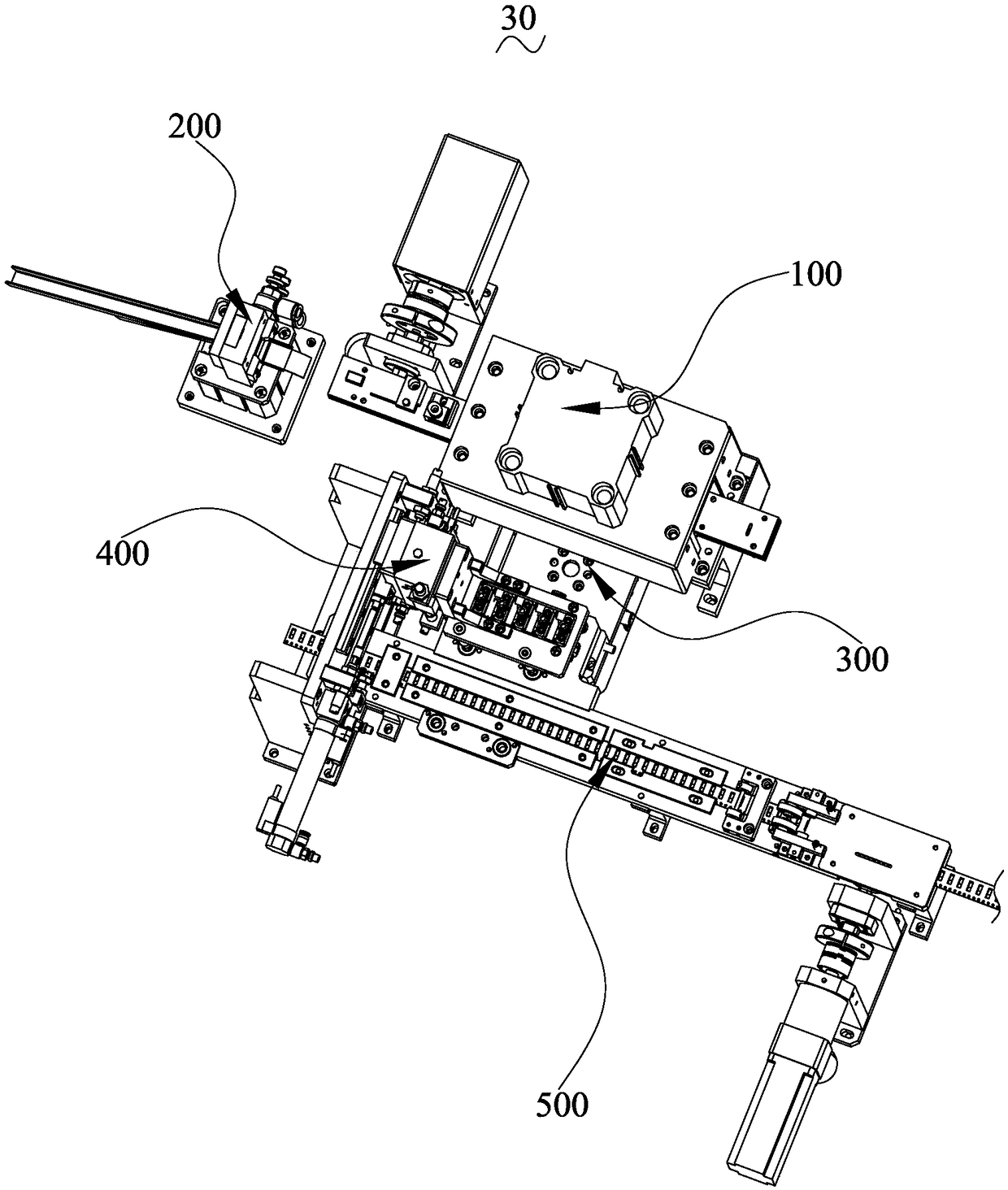

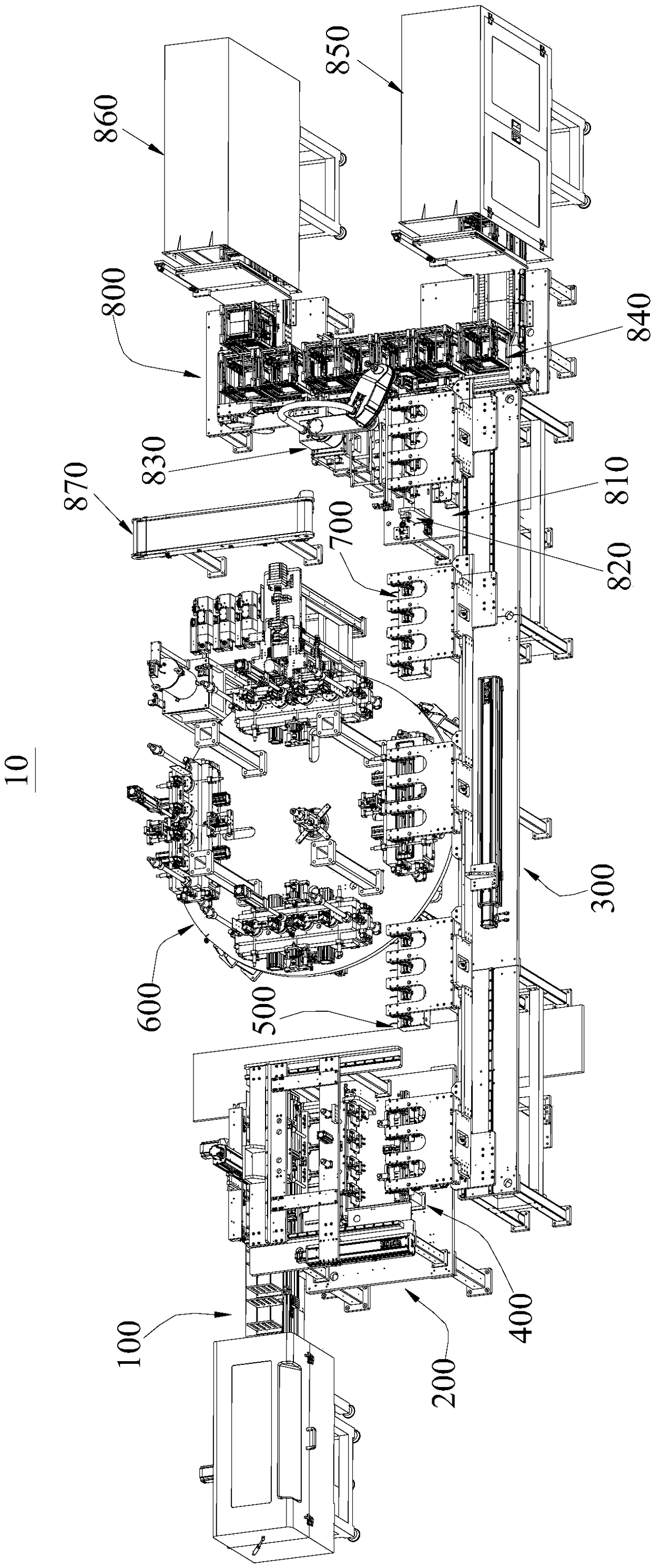

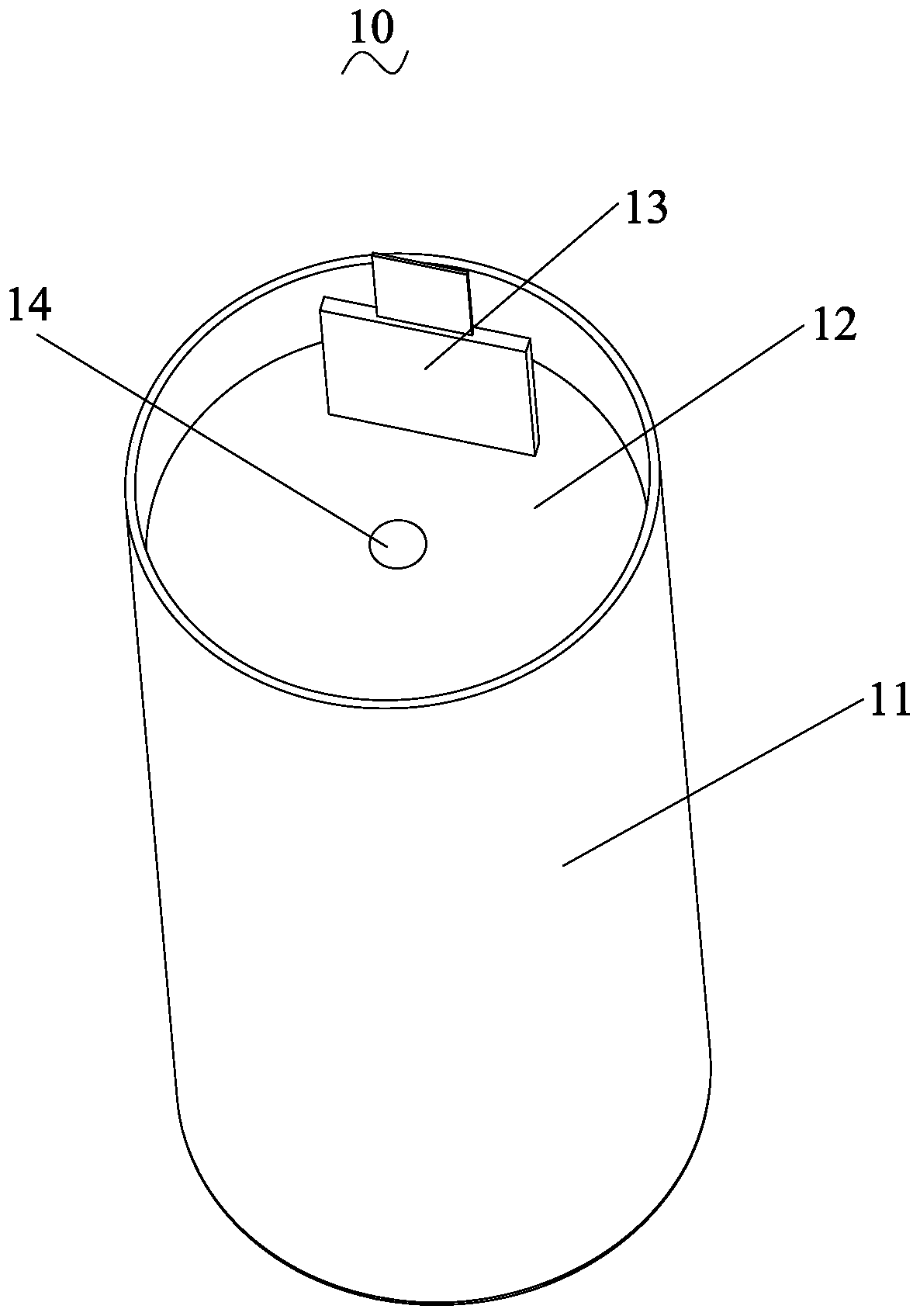

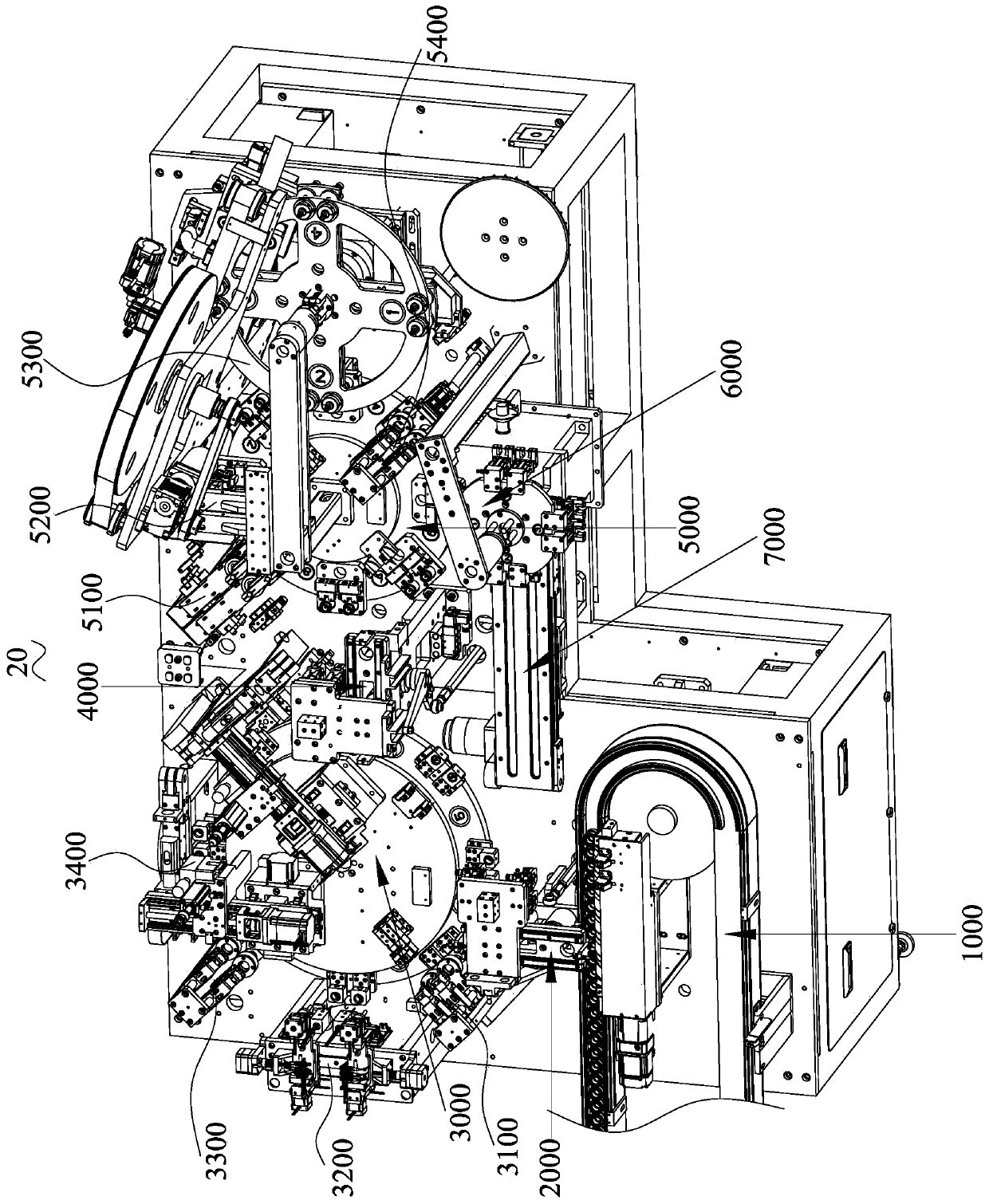

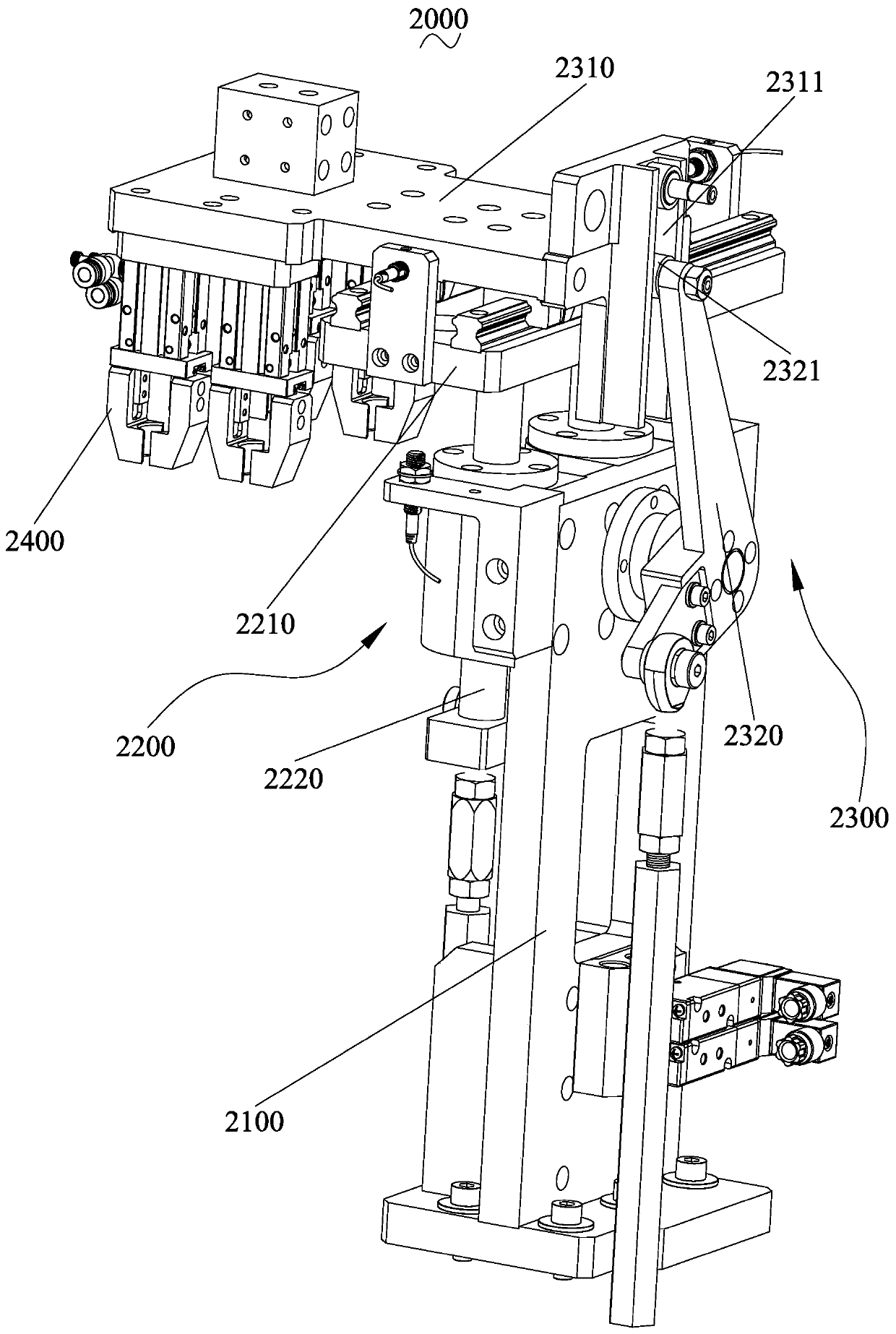

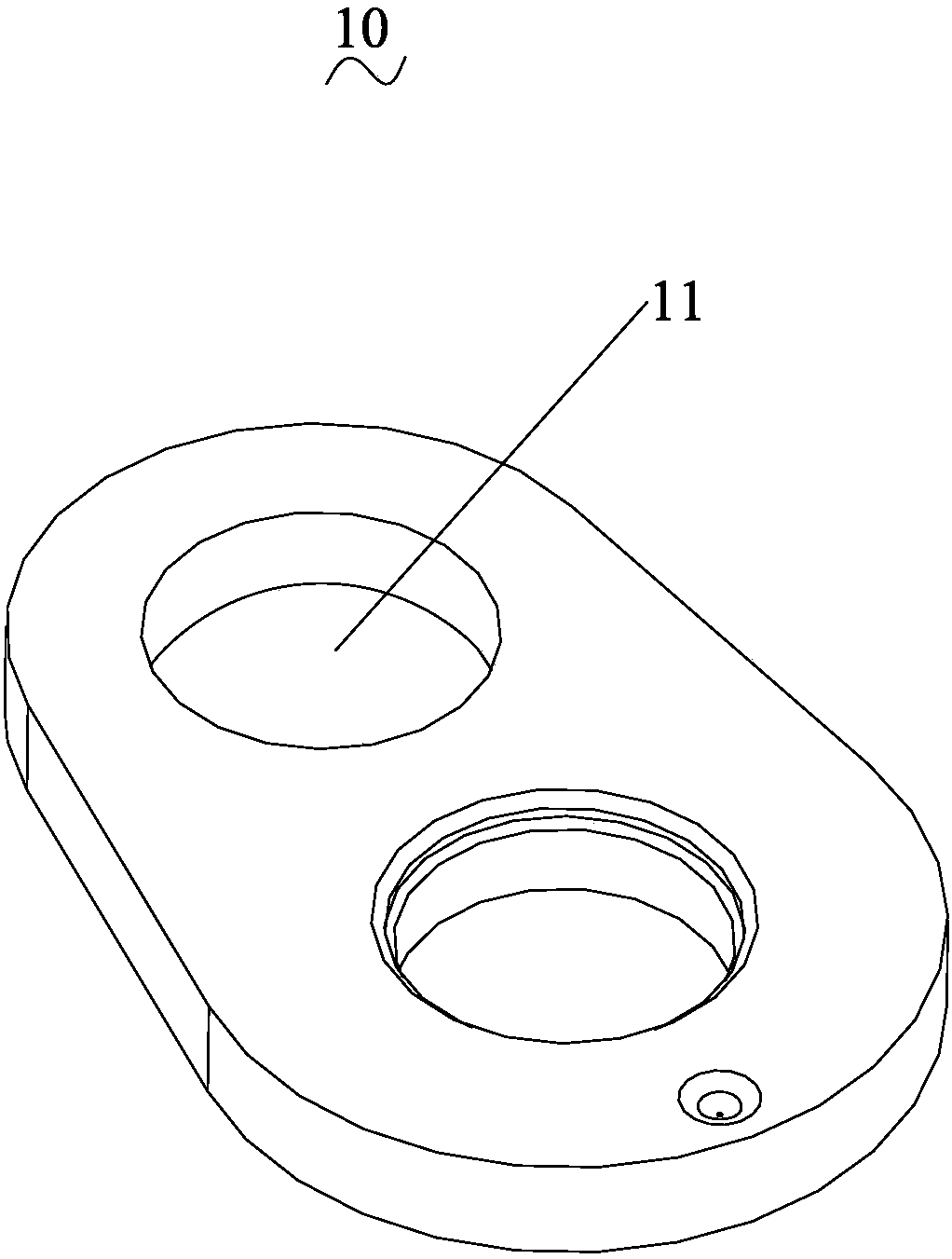

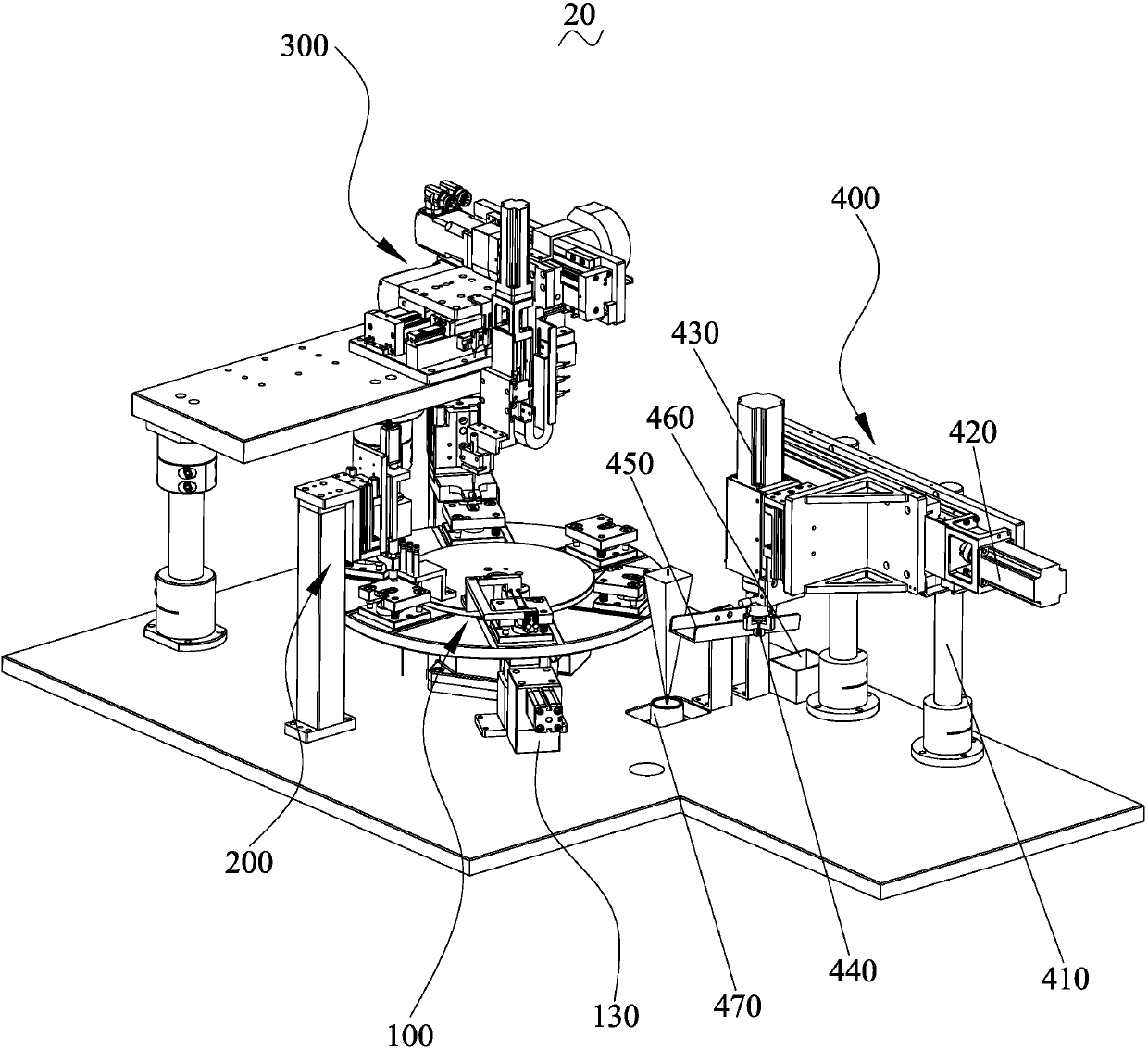

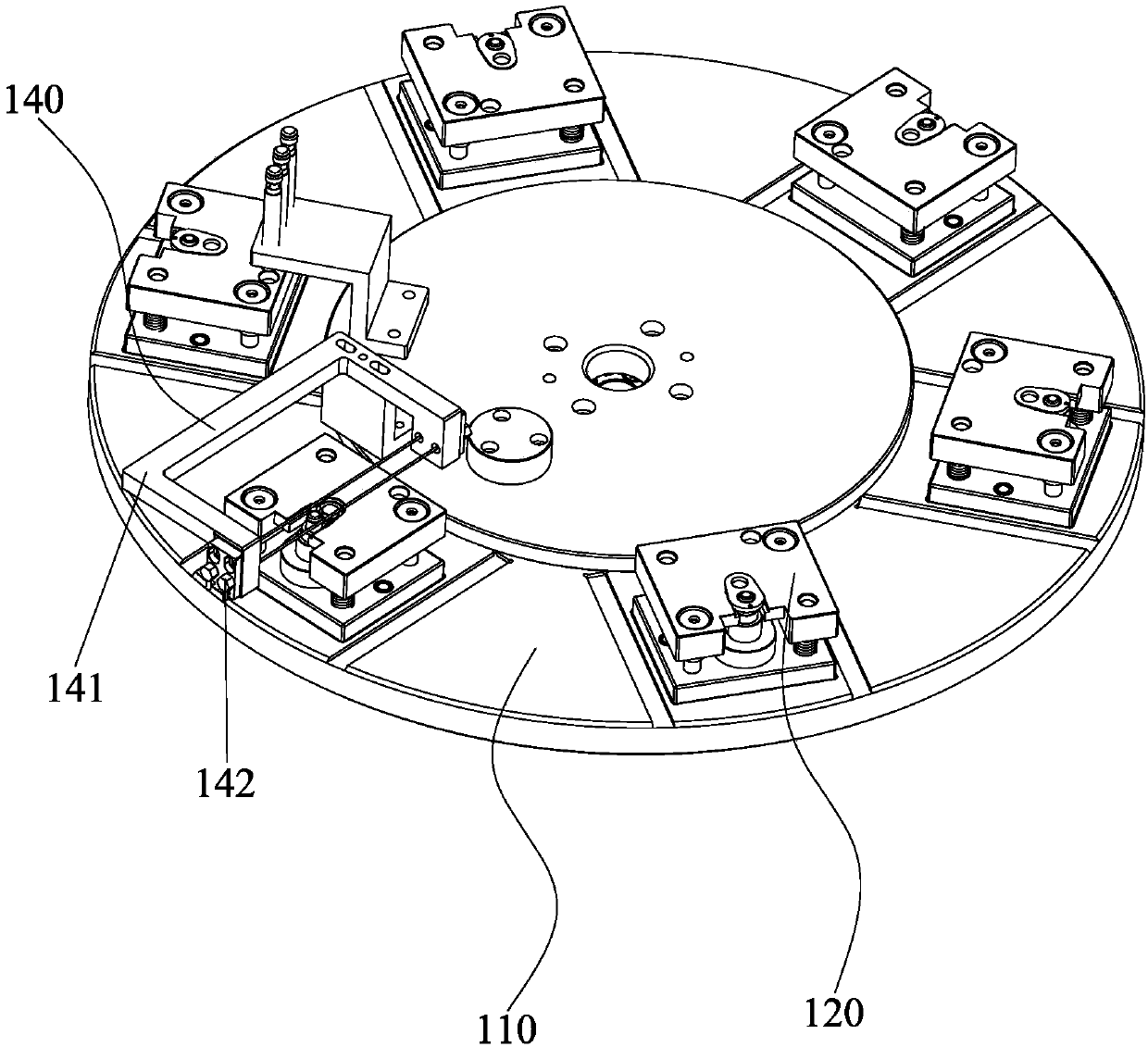

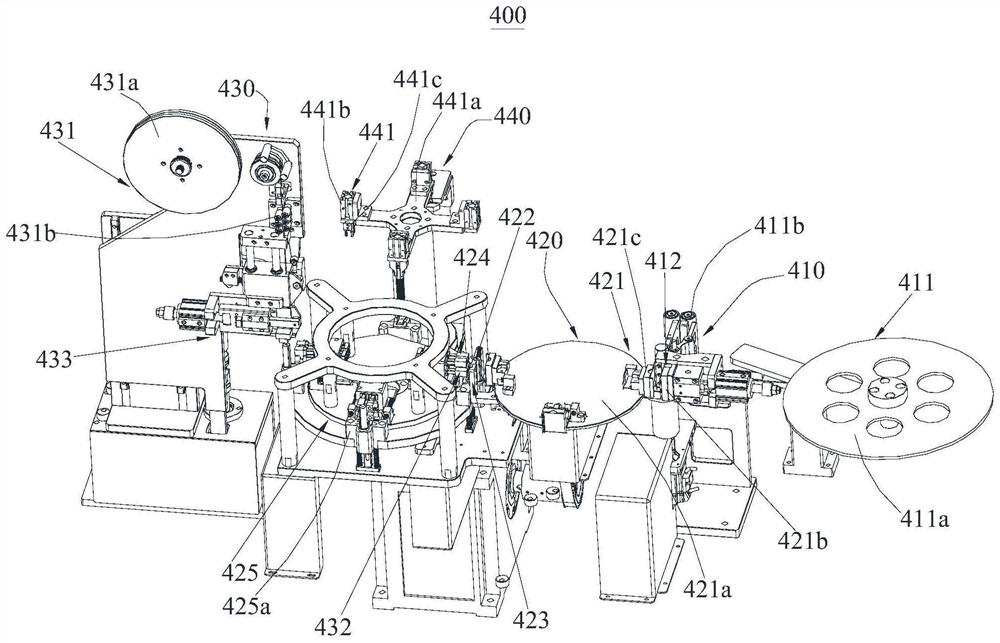

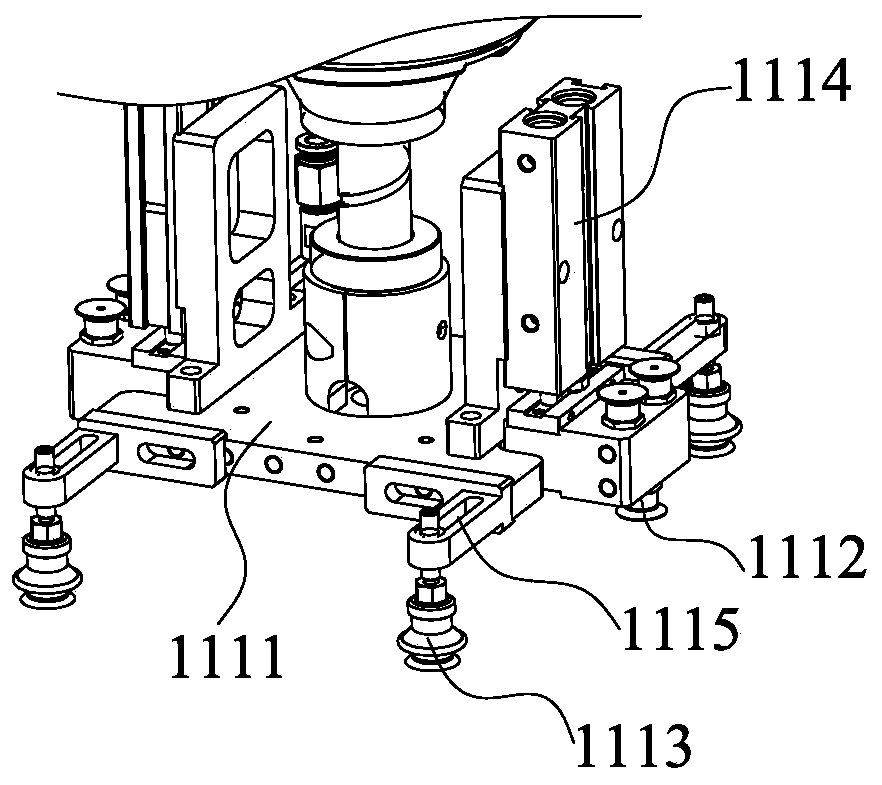

Equipment for achieving welding of plate lug at electric core bottom and steel shell

ActiveCN107598581AImprove the level of mechanical automationFinal product manufacturePrimary cellsEngineeringAssembly line

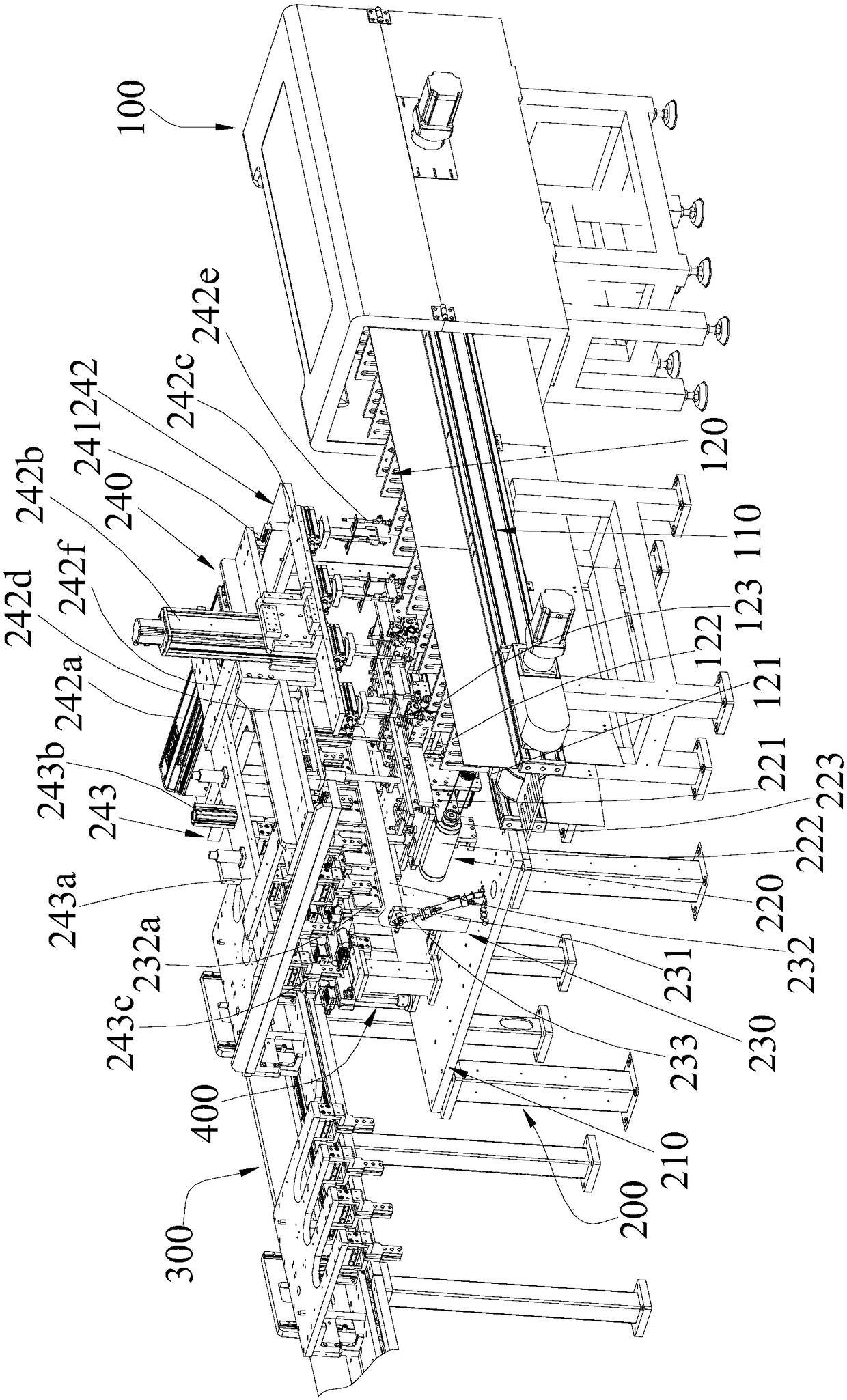

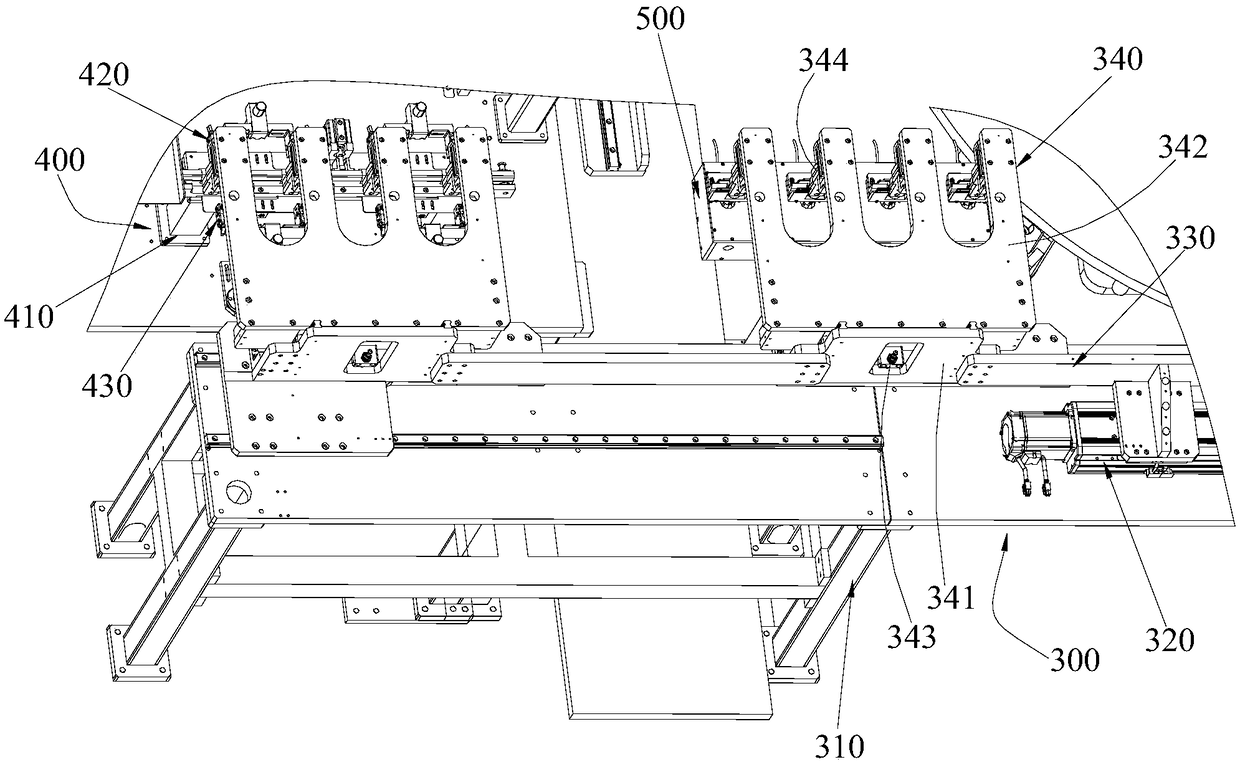

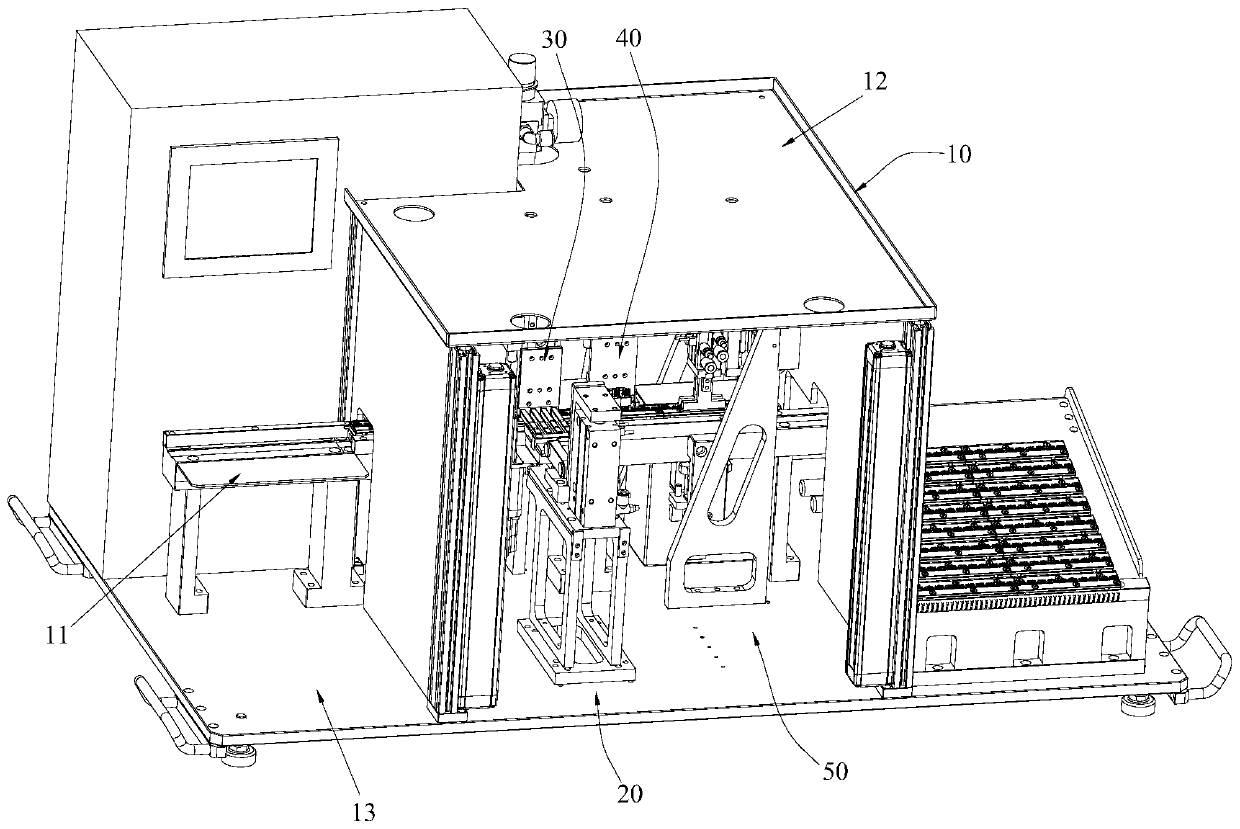

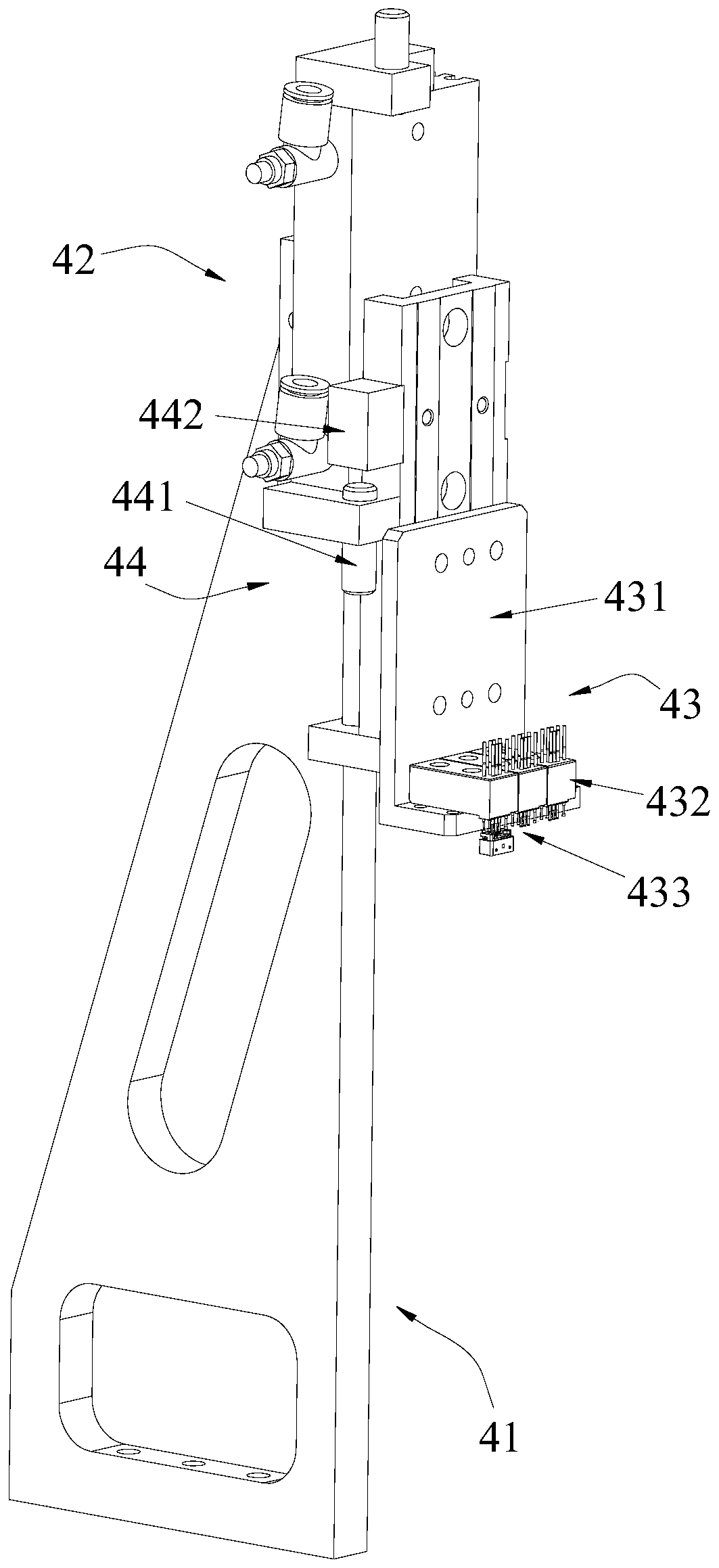

The invention provides equipment for achieving welding of a plate lug at the electric core bottom and a steel shell. By arranging an electric core feeding annular assembly line, an electric core feeding mechanism, a plate lug steel shell welding rotary disc, an electric core transfer mechanism, an insulating ring assembly rotary disc, an electric core discharging mechanism and an electric core recycling mechanism, a center hole size primary CCD detection mechanism, a center hole chambering mechanism, a center hole size secondary CCD detection mechanism and a plate lug steel shell welding mechanism are sequentially arranged around the plate lug steel shell welding rotary disc, and an electric core plate lug searching mechanism, an electric core plate lug correction mechanism, an insulatingring assembly mechanism and an electric core appearance CCD detection mechanism are sequentially arranged around the insulating ring assembly rotary disc, so that the mechanical automatic level of welding of the plate lug at the electric core bottom and the steel shell is increased overall.

Owner:HUIZHOU JINYUAN PRECISION AUTOMATION EQUIP

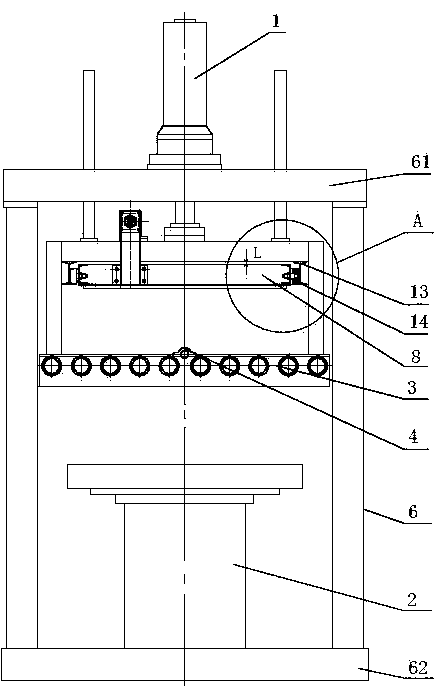

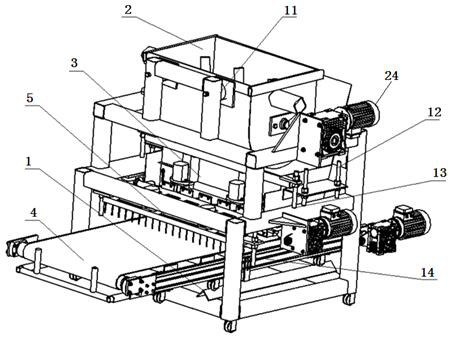

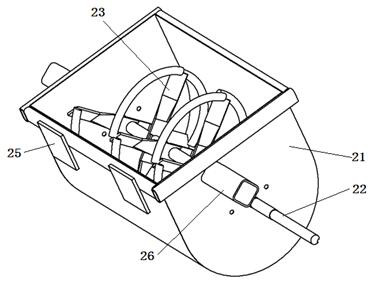

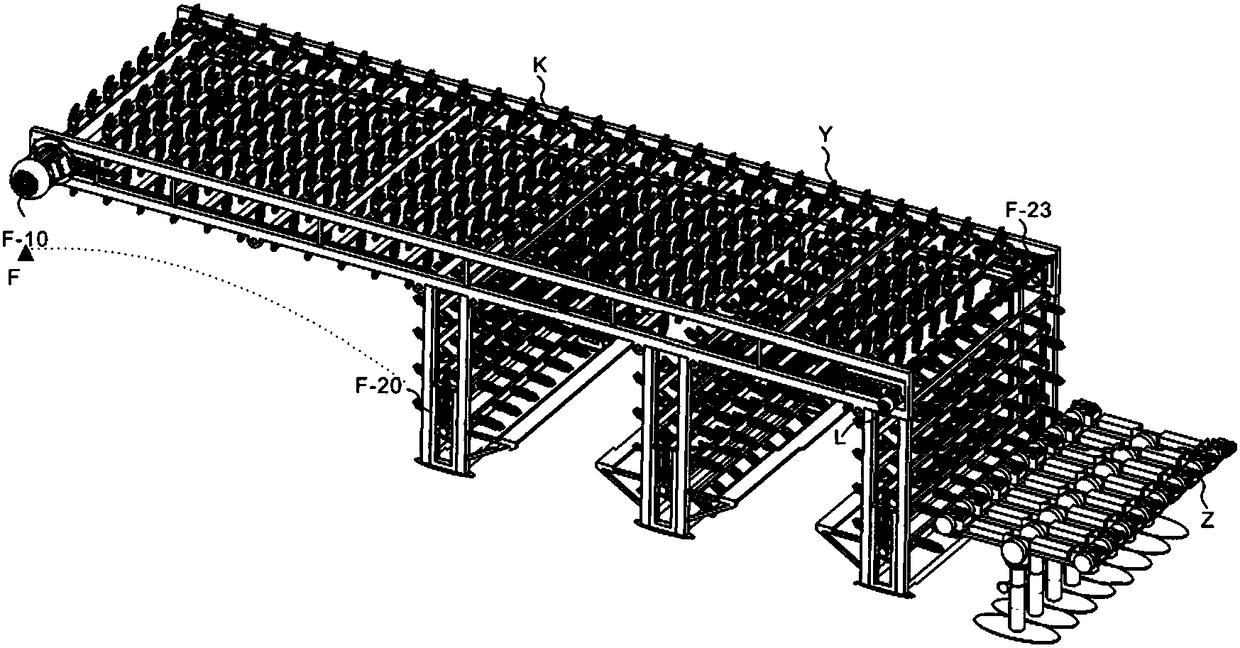

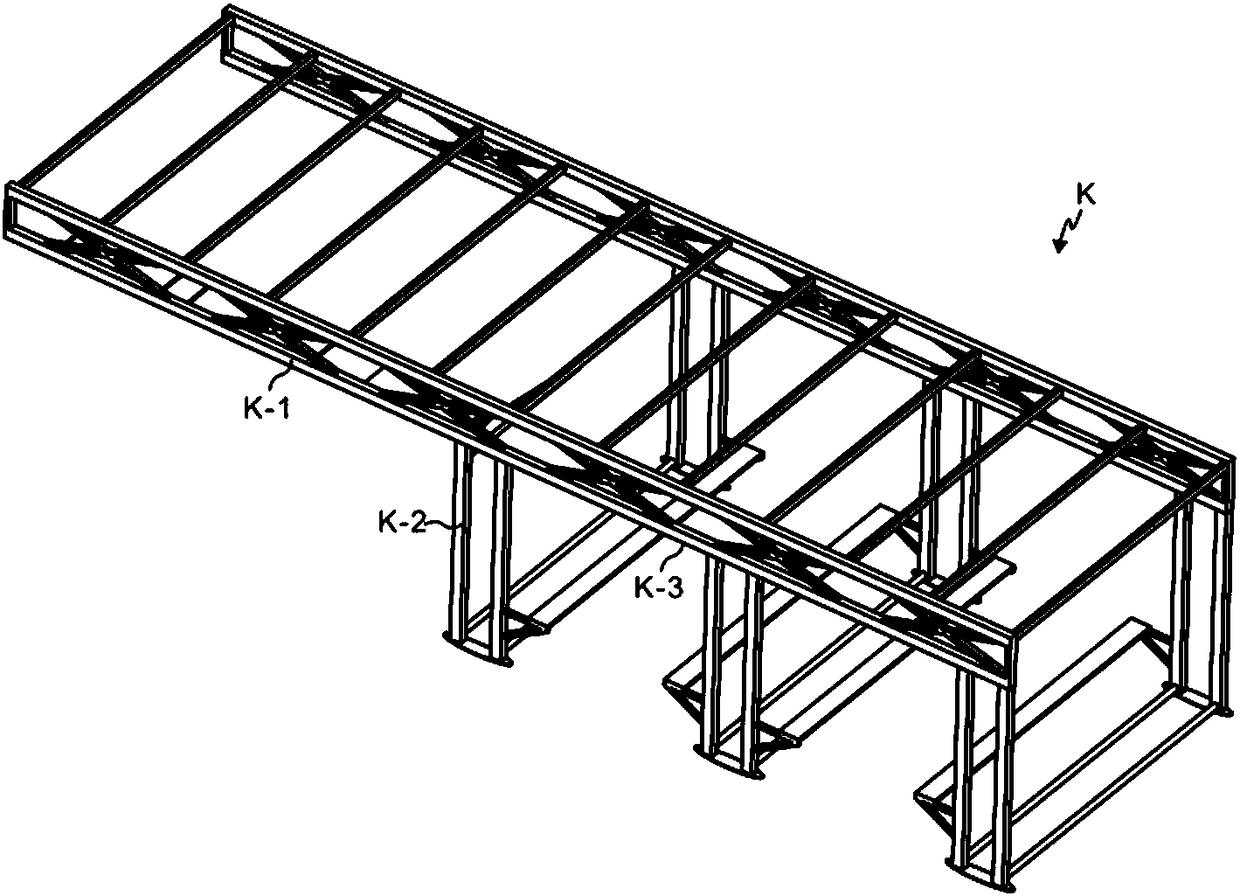

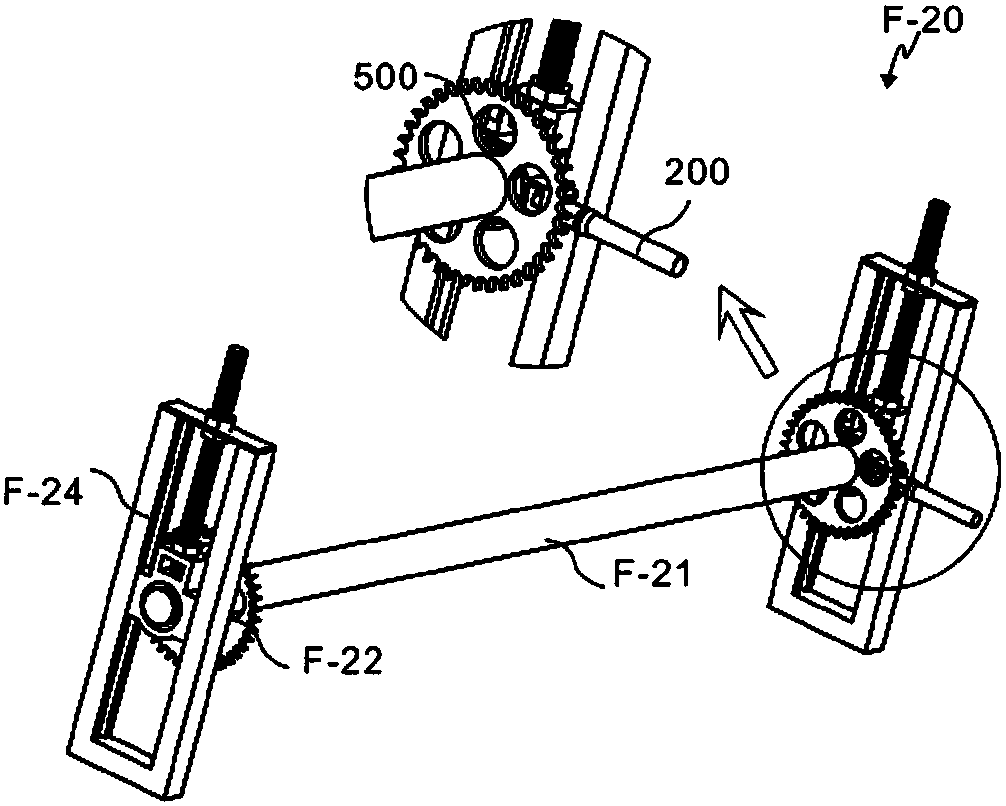

Iron section removing device and method used during iron section sand cladding casting of shuttle-type top plate

ActiveCN103506568AEasy to transportIncrease productivityMould handling/dressing devicesMoulding machinesPiston rodMaterials science

The invention relates to an iron section removing device and an iron section removing method used during iron section sand cladding casting of a shuttle-type top plate, and belongs to the field of iron section sand cladding casting equipment. The iron section removing device comprises an ejecting cylinder, a vibrating device, an iron section conveying roller way, an iron section positioning device, a sand falling bucket device, a movable beam, a trolley body, a trolley connecting plate, an upper iron section ejecting device and a lower iron section ejecting device, wherein the movable beam is connected with a piston rod of the ejecting cylinder; the iron section positioning device is arranged in the middle of the iron section conveying roller way; a workbench is arranged on the vibrating device; the sand falling bucket device is fixed on the workbench; the trolley body is connected with the piston rod of a trolley cylinder through the trolley connecting plate; a gap is formed between the upper surface of the trolley body and the lower surface of the movable beam; the upper iron section ejecting device and the lower iron section ejecting device are arranged on the movable beam. The iron section removing device is used for removing the upper iron section and the lower iron section which are different in sand ejecting holes positions, thus meeting removal of iron section sand cladding of the upper iron section and the lower iron section with inconsistent positions of the sand ejecting holes.

Owner:浙江省机电设计研究院有限公司

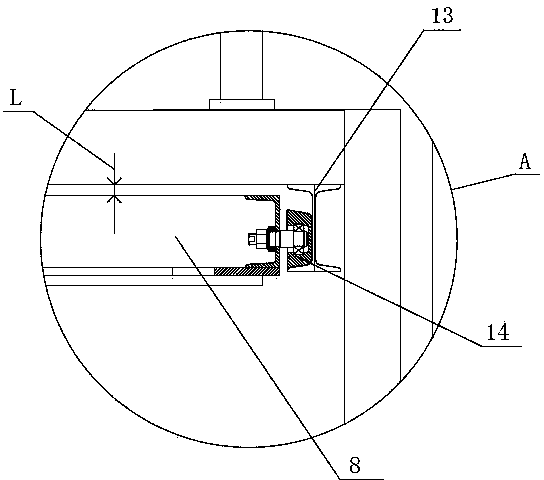

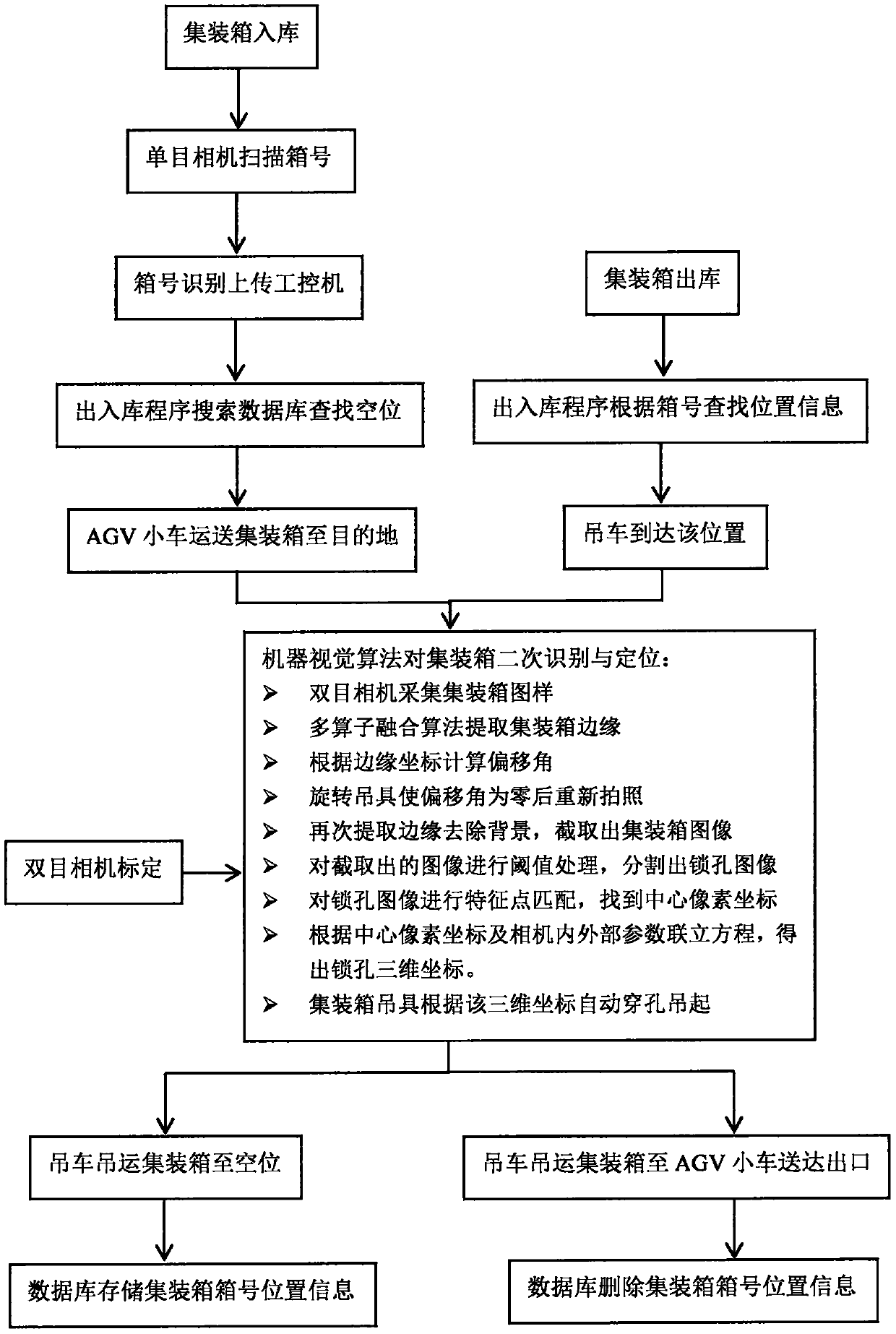

Automatic container identifying and positioning method

PendingCN111243016AImprove the level of mechanical automationImprove efficiencyImage analysisMachine visionComputer graphics (images)

The invention discloses an automatic identification and positioning method for a container. The method comprises an industrial personal computer, a binocular camera, a monocular camera and a light source, a WinCC process monitoring system application program with an SQL Server database is installed on an industrial personal computer. Container number position information of containers is stored inthe database. The WinCC process monitoring system is provided with a set of warehouse-in and warehouse-out programs. The binocular camera is installed on a container lifting appliance and used for conducting secondary recognition and positioning on a container, the monocular camera is installed at a container warehousing position and used for automatically recognizing the number of the warehousedcontainer, the light source and the camera are installed in a matched mode, and the brightness can be automatically adjusted according to changes of ambient light. Firstly, the theoretical position of a container is stored through a database; then, a binocular camera is adopted to collect container pictures, and a set of algorithm based on machine vision is designed to carry out secondary identification and positioning on the container; the method has the advantages that the positioning precision is high, the algorithm processing is simple, the efficiency is high, the applicability is high, the mechanical automation level of places such as wharfs, ports and goods yards can be improved, and the container hoisting efficiency of cranes is improved.

Owner:ZHOUKOU NORMAL UNIV

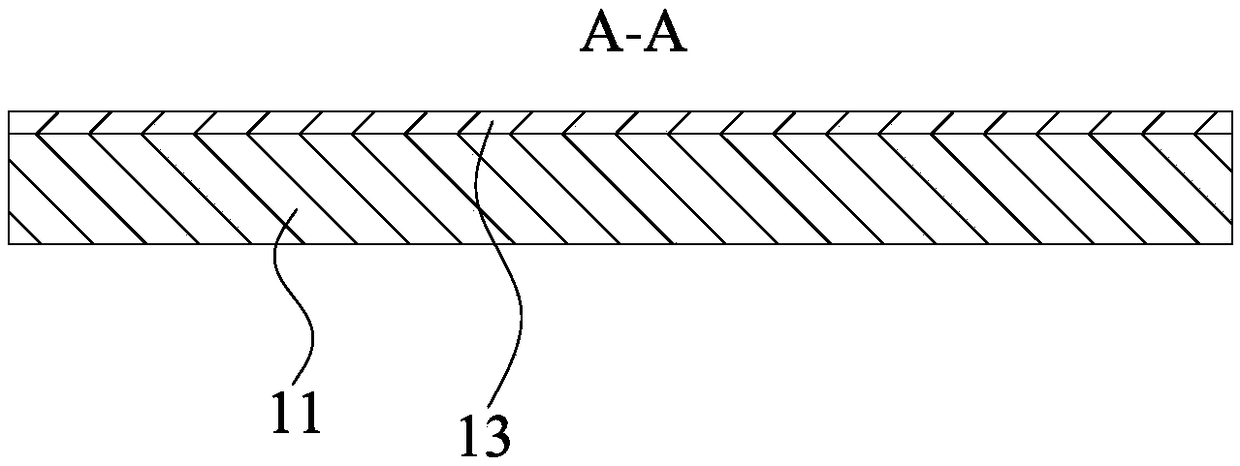

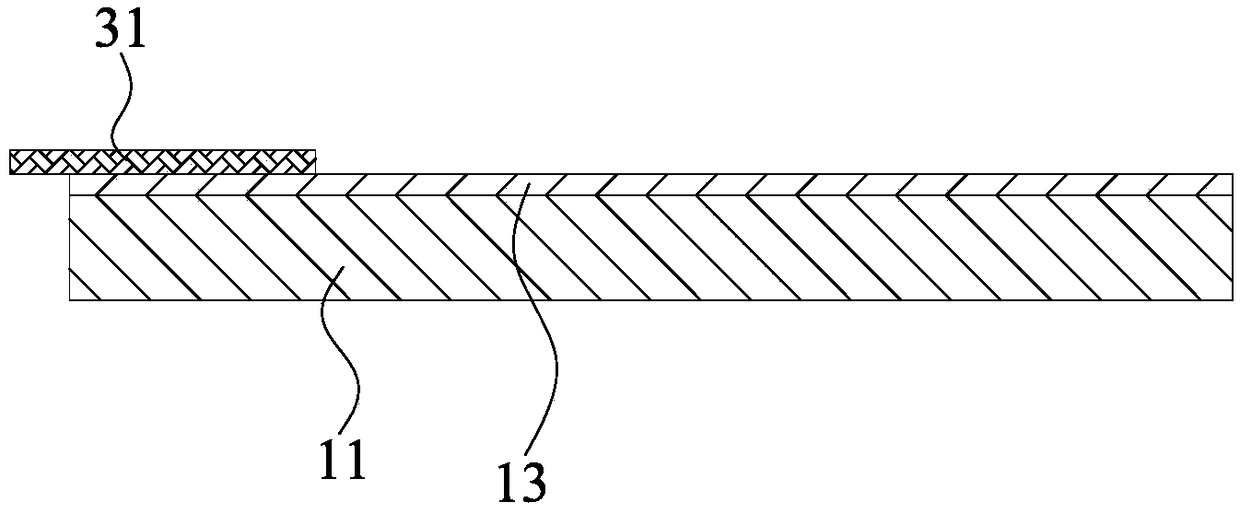

Film tearing mechanism and electronic product reworking equipment comprising film tearing mechanism

ActiveCN108724914AProtection from damageImprove the overall mechanical automation levelLamination ancillary operationsLaminationElectrical and Electronics engineeringTectorial membrane

Owner:魏东升

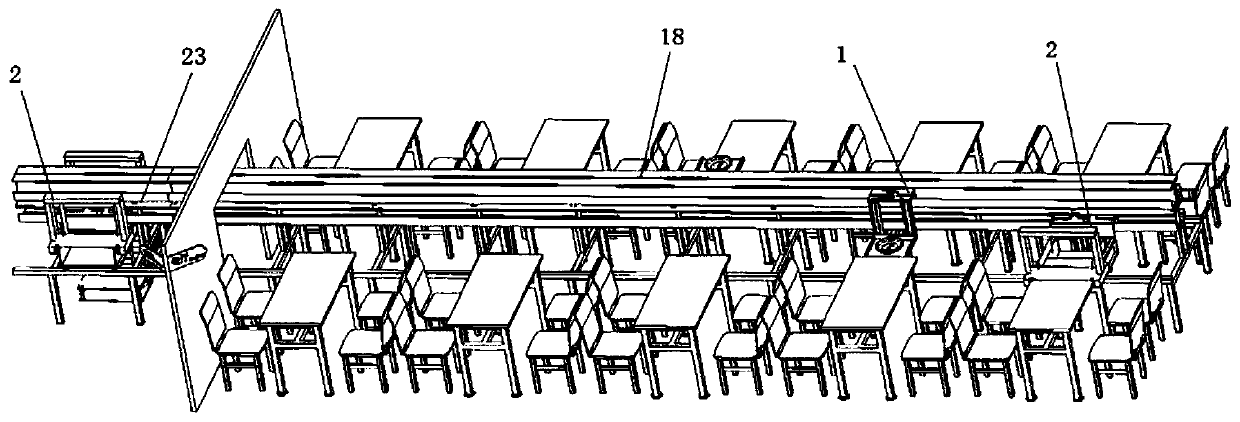

Intelligent dish-conveying and table-tidying system for restaurant

InactiveCN110638295AClean thoroughlyImprove the level of mechanical automationTable equipmentsService system furnitureEngineeringMechanical engineering

The invention relates to an intelligent dish-conveying and table-tidying system for a restaurant. The system comprises a dish-conveying device and a tableware recovery and table top cleaning device, wherein the dish-conveying device comprises a dish-conveying track, a dish-conveying trolley which is arranged on the dish-conveying track and can move along the dish-conveying track and a dish-conveying lifting mechanism installed on the dish-conveying trolley, and dish-conveying trays used for carrying dish plates are arranged on the dish-conveying lifting mechanism; and the tableware recovery and table top cleaning device comprises a table-tidying trolley track located below the dish-conveying track, a tableware recovery trolley which is arranged on the table-tidying trolley track and can move along the table-tidying trolley track and a tableware recovery box arranged on the tableware recovery trolley, robot carrying tracks are further arranged at two sides of the tableware recovery box,and a table top tidying robot capable of moving back and forth between the robot carrying tracks and tables is carried on the robot carrying tracks. Compared with the prior art, the system has both atable-tidying function and a dish-conveying function, the dish-conveying process is smooth and fast, and customer experience is comfortable.

Owner:严钟耀 +1

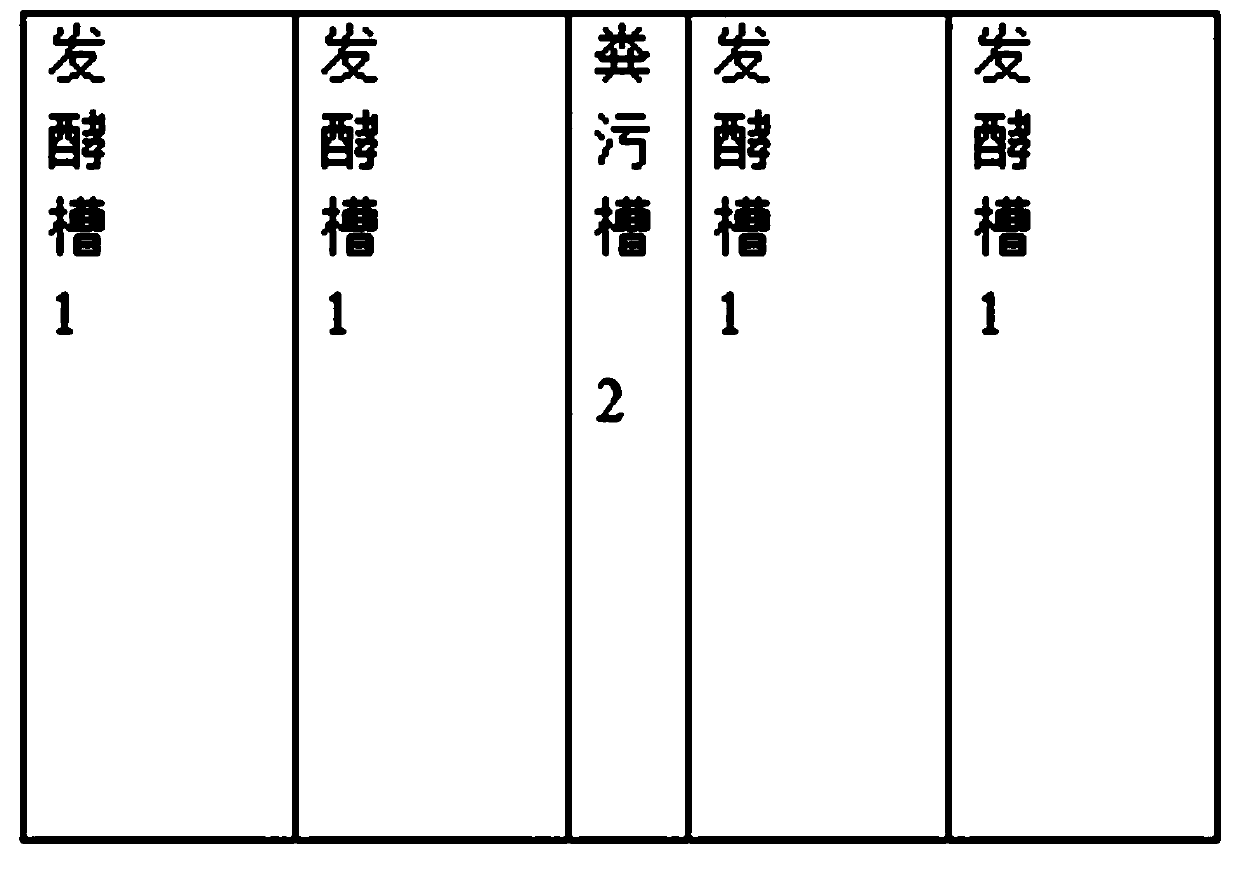

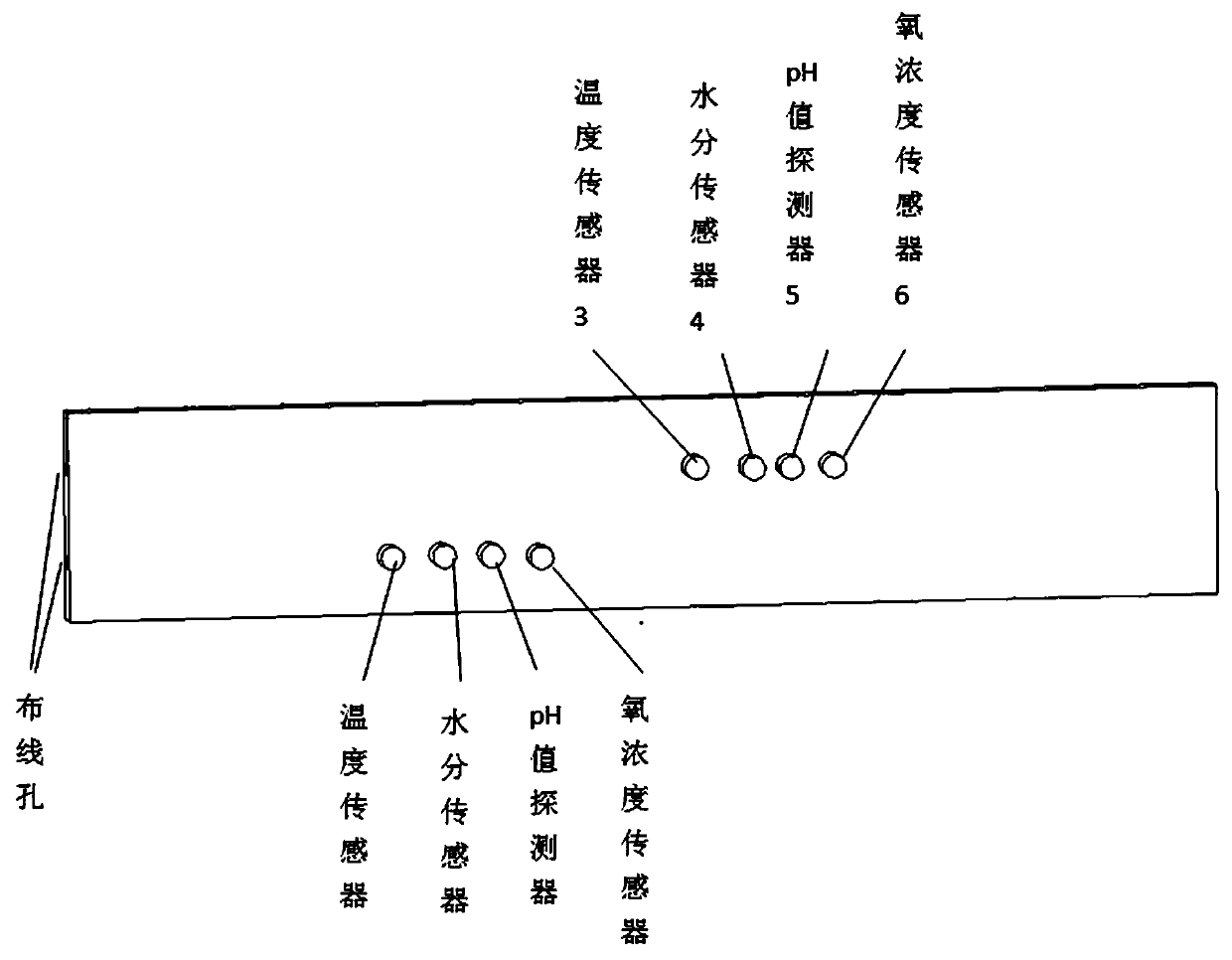

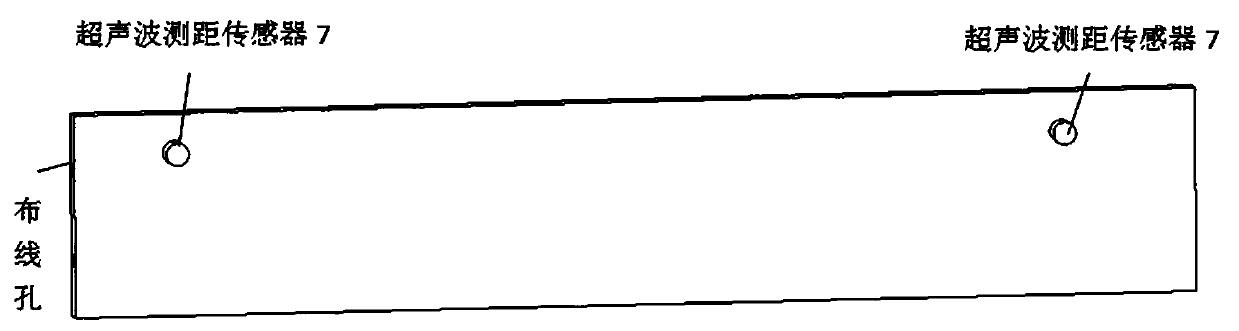

Organic waste fermentation tank information acquisition method and intelligent system of turning and throwing machine

InactiveCN109574728AImprove the level of mechanical automationEasy to detectMeasurement devicesFertiliser treatment controlAgricultural engineeringData acquisition

The invention discloses an organic waste fermentation tank information acquisition method and an intelligent system of a turning and throwing machine. The information acquisition method comprises a sensor setting scheme and a data acquisition scheme at a fermentation tank and a manure tank. The sensor setting scheme comprises a waterproof environmental sensor and a distance measuring sensor, wherein the environmental sensor is embedded into the wall of the fermentation tank, and the distance measuring sensor is arranged on the upper portion of the wall of the manure tank. The data acquisitionscheme comprises an acquisition controller which is networked with a server terminal and controlled by the server terminal, the acquisition controller acquires data from the environmental sensor through an acquisition card, the acquired data are processed by the acquisition controller and then displayed on a factory building monitoring screen or returned to the server terminal, and the acquisitioncontroller monitors the material height of the manure tank through the distance measuring sensor connected with the acquisition card and comprises a Raspberry Pi capable of initiating operation instructions to the intelligent system of the turning and throwing machine for the fermentation tank according to the detected environmental data. Information of the organic waste fermentation tank can beconveniently acquired, and turning and throwing operation can be controlled.

Owner:FUJIAN AGRI & FORESTRY UNIV

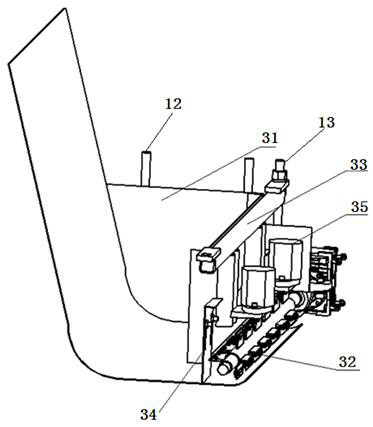

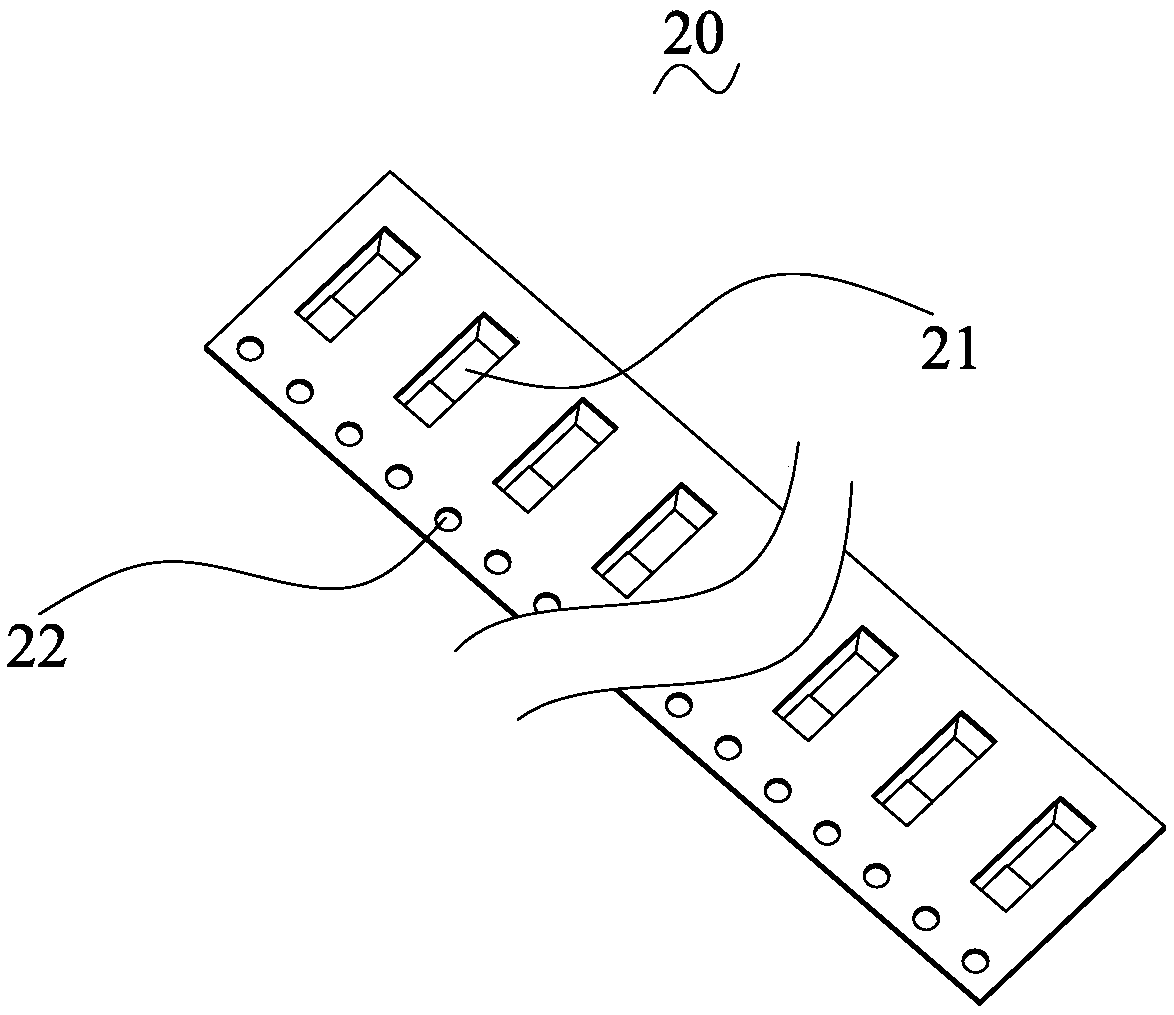

Waste band recycling mechanism and medical instrument packaging device thereof

InactiveCN108746149AEasy to handleImprove the level of mechanical automationSolid waste disposalContinuous/uninterruptedBlock structure

The invention discloses a waste band recycling mechanism and a medical instrument packaging device thereof. The waste band recycling mechanism comprises a waste band cutting base, a waste band cuttingcontaining box, a waste band cutting drive part, a waste band cutting guide block, a waste band cutting movable knife and a waste band cutting fixed knife. The waste band cutting containing box is provided with a waste band cutting cavity, a waste band cutting guide groove is formed in the wall of the waste band cutting cavity, the waste band cutting guide block is arranged in the waste band cutting guide groove in a sliding manner in the vertical direction, the waste band cutting drive part is in drive connection with the waste band cutting guide block, a cutting knife mounting groove is formed in the waste band cutting guide block, and the waste band cutting movable knife is arranged in the cutting knife mounting groove. The waste band cutting fixed knife is fixed to the wall of the waste band cutting cavity. The waste band recycling mechanism is used for cutting waste bands continuously and ceaselessly, a waste block structure with the limited length can be obtained, and recyclingis facilitated.

Owner:李雪芬

Liquid injection device for a soft-pack battery

ActiveCN109273661AImprove the level of mechanical automationIncrease productivityCell component detailsBattery cellElectrical and Electronics engineering

A liquid injection device for a soft-pack battery comprise a battery feeding mechanism, a conversion mechanism in battery, a battery transport mechanism, a battery scanning mechanism, a weighing mechanism before liquid injection, a battery liquid injection mechanism, a weighing mechanism aft liquid injection, and a discharging and loading mechanism, wherein that liquid injection device comprises abattery feeding mechanism, a battery transferring mechanism, a battery scanning mechanism, a weighing mechanism before liquid injection, a battery liquid injection mechanism, and a discharging and loading mechanism. A load mechanism of that battery is connected with a switching mechanism in the battery, a switching mechanism in the battery is connected with a battery scanning mechanism, and a battery scanning mechanism, a weighing mechanism before liquid injection, a battery liquid injection mechanism, a weighing mechanism aft liquid injection and a feeding and loading mechanism are respectively connected with a battery transporting mechanism. The soft-pack battery injection device of the invention is provided with a battery feeding mechanism, the switching mechanism, a battery transfer mechanism, a battery scanning mechanism, the weighing mechanism before liquid injection, a battery liquid injection mechanism, a weighing mechanism aft liquid injection, and a discharging and loading mechanism in that battery, so that the liquid injection processing operation of the soft-pack battery can be completed, the mechanical automation level of the liquid injection processing is high, and the production efficiency and the production quality of the liquid injection processing can be effectively improved.

Owner:HUIZHOU JINYUAN PRECISION AUTOMATION EQUIP

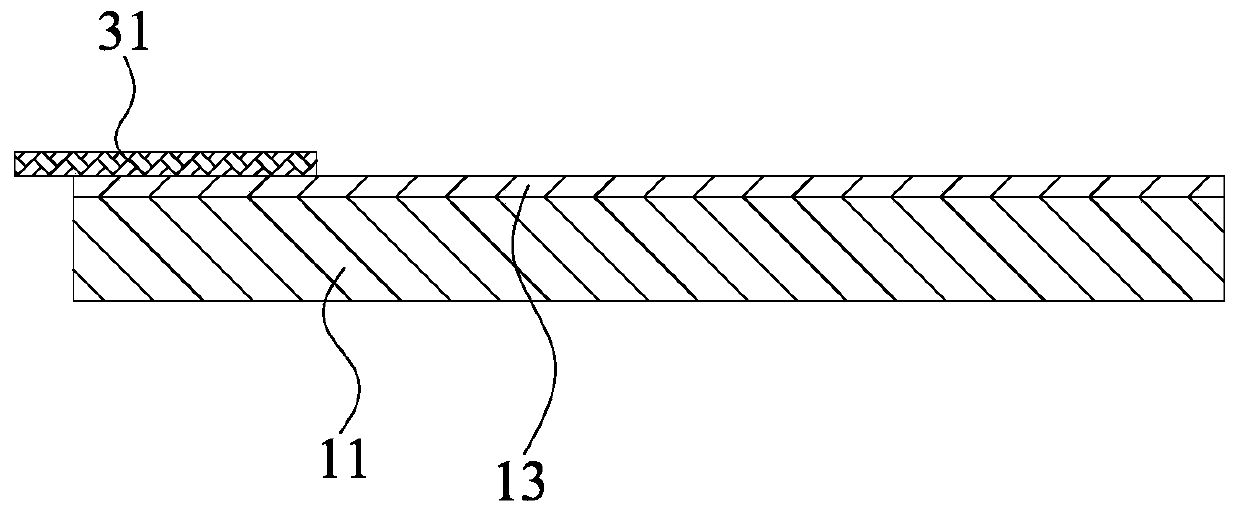

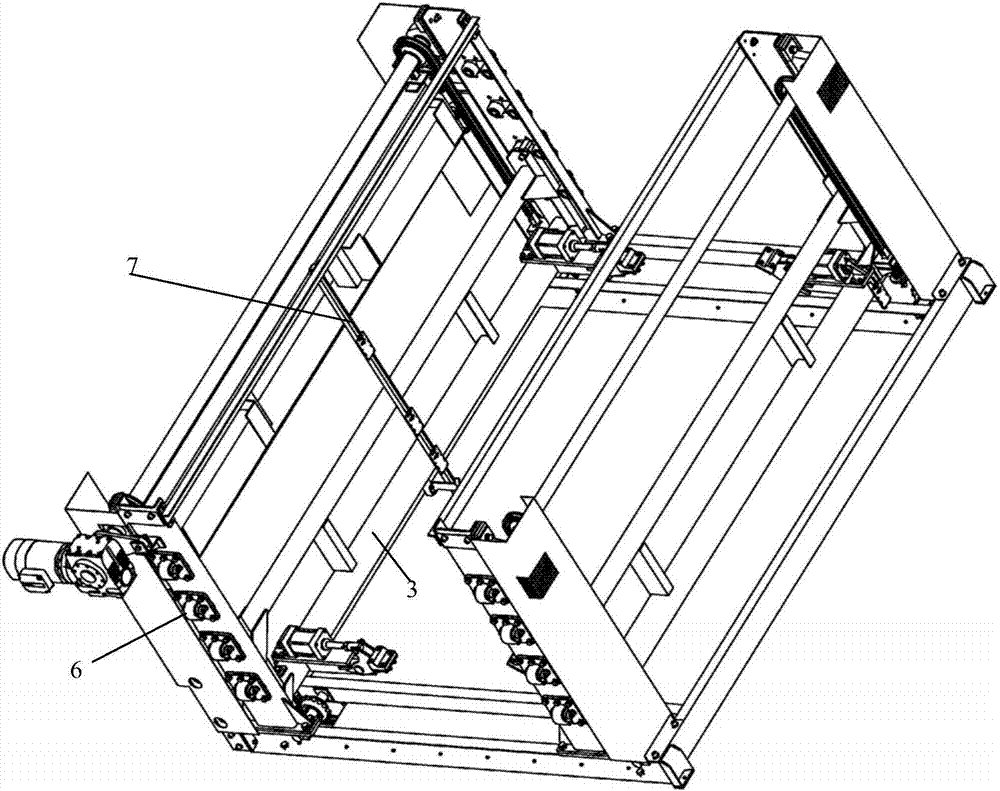

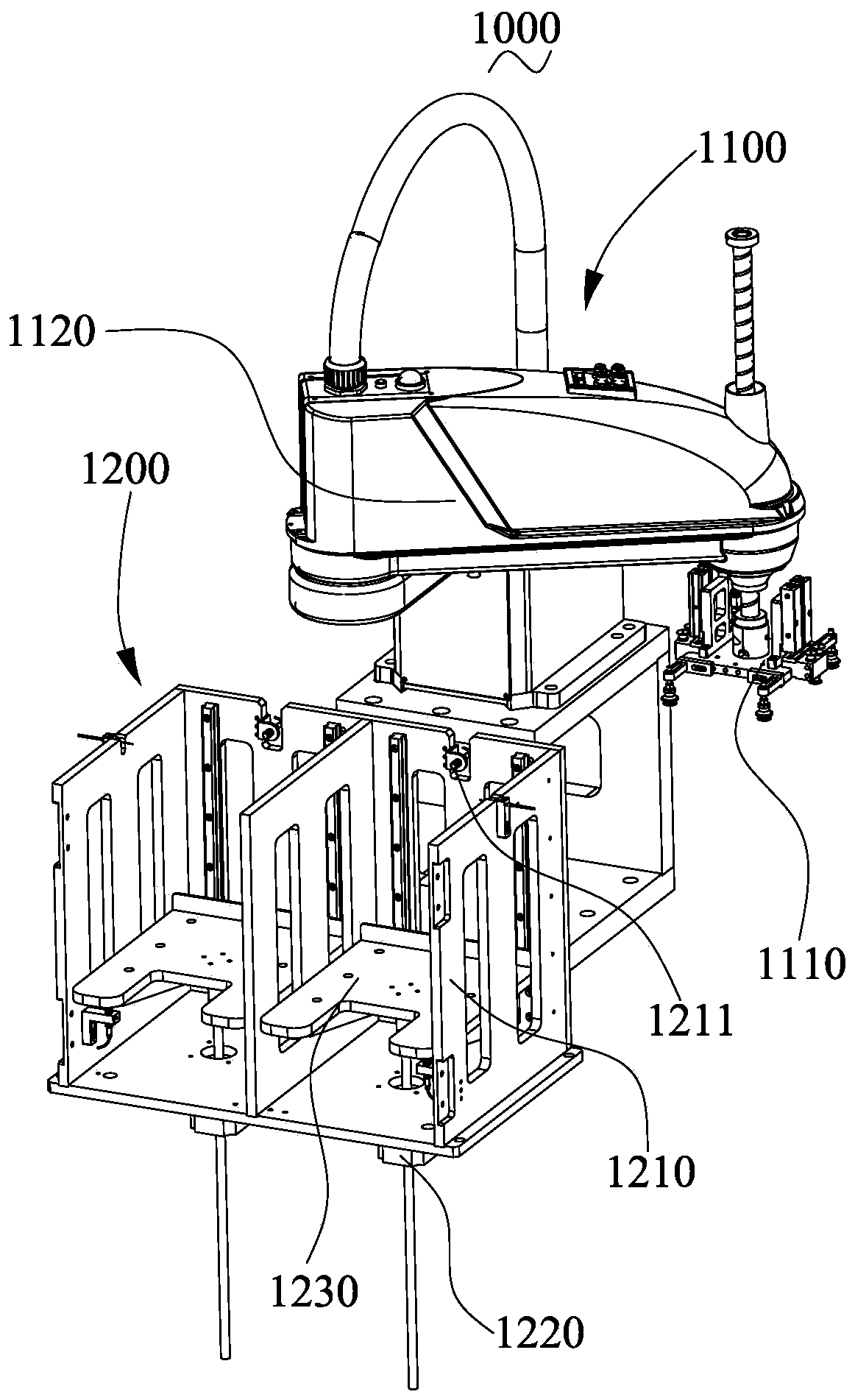

Automatic plate-shaped part feeding device and method for robot welding

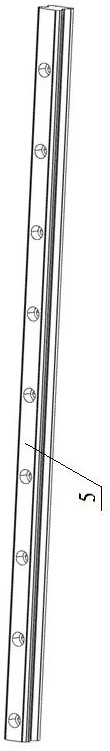

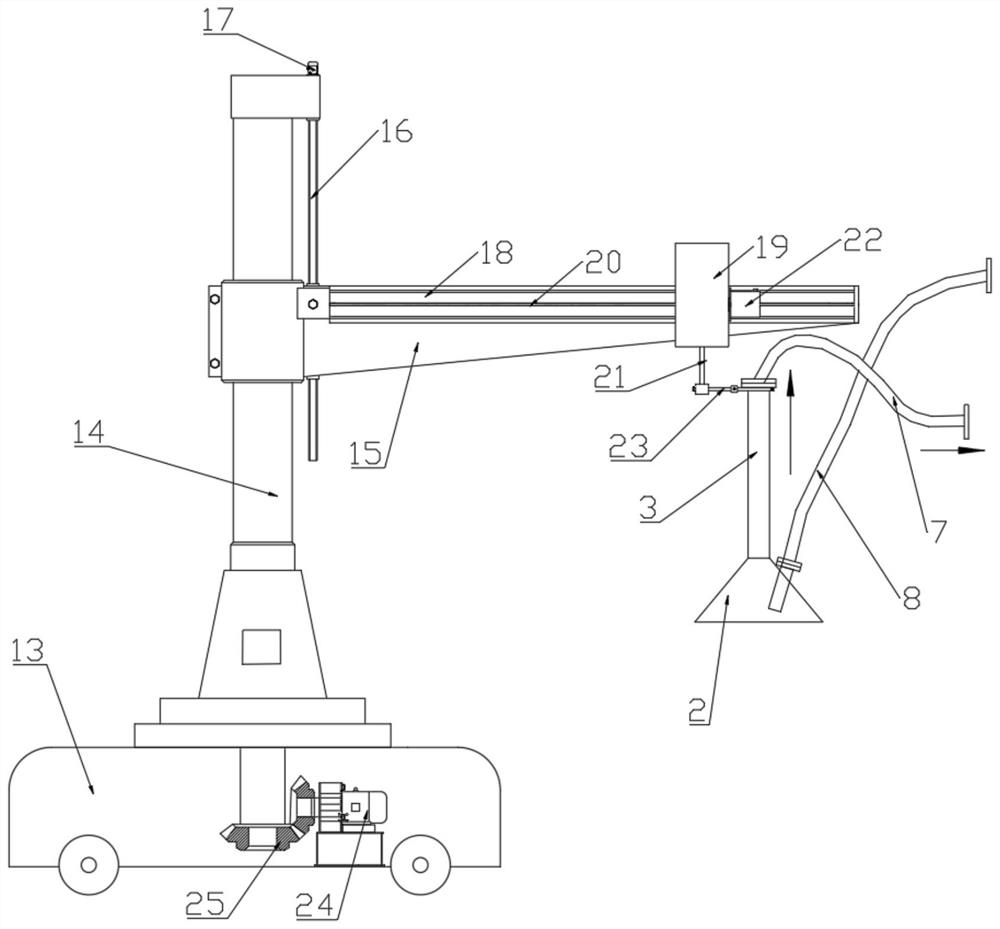

PendingCN112678475ARealize automatic cycle feeding and conveyingAchieve orderly placementWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringMechanical engineering

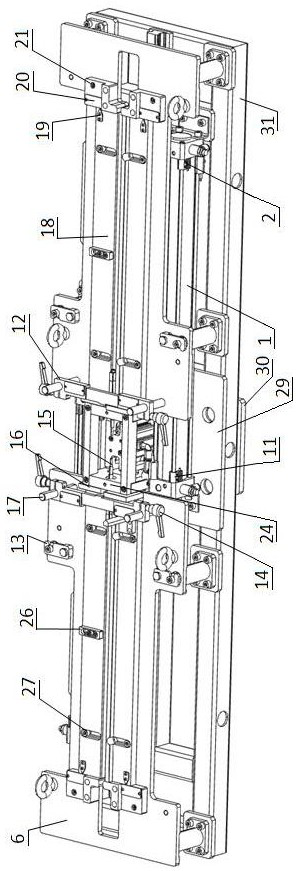

The invention discloses an automatic plate-shaped part feeding device and method for robot welding. At present, plate-shaped parts need to be fed manually and then subjected to subsequent procedures in hanging pipe assembly, the number of the plate-shaped parts is large, the labor intensity is increased in the placing and feeding process, and the production efficiency is low. The device comprises a supporting frame (31), a supporting plate (29) is fixed to the middle of the upper side of the supporting frame and connected with a guide rail (5) through screws, a jacking air cylinder (8) is fixed to the middle of the supporting plate, a pushing sliding block (4) is installed on the guide rail and connected with one end of an axial air cylinder (1) through a connecting plate (3), the axial air cylinder is fixed to the supporting frame, a jacking block (23) is installed at the front end of the pushing sliding block, a jacking assembly (7) is connected to the upper side of the jacking air cylinder, jacking blocks (9) are installed on the two sides of the jacking assembly respectively, two adjusting plates (18) are arranged in a set side by side, and a groove is formed between the two adjusting plates. The invention is applied to the automatic plate-shaped part feeding device for robot welding.

Owner:HARBIN BOILER

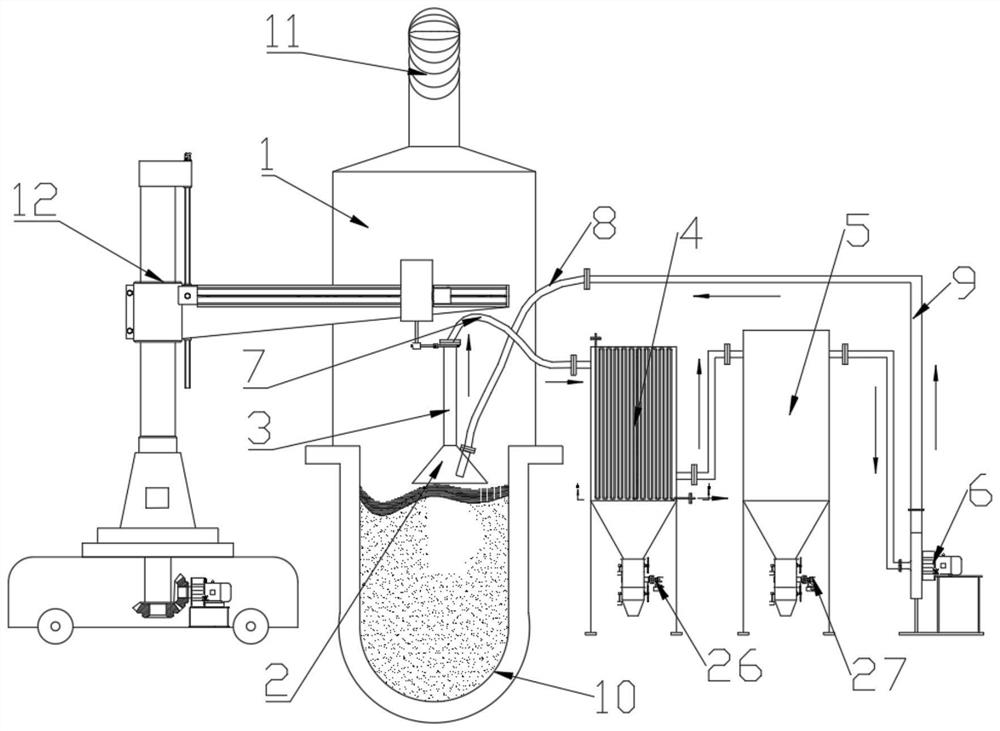

A device for removing low-density scum in metal refining process

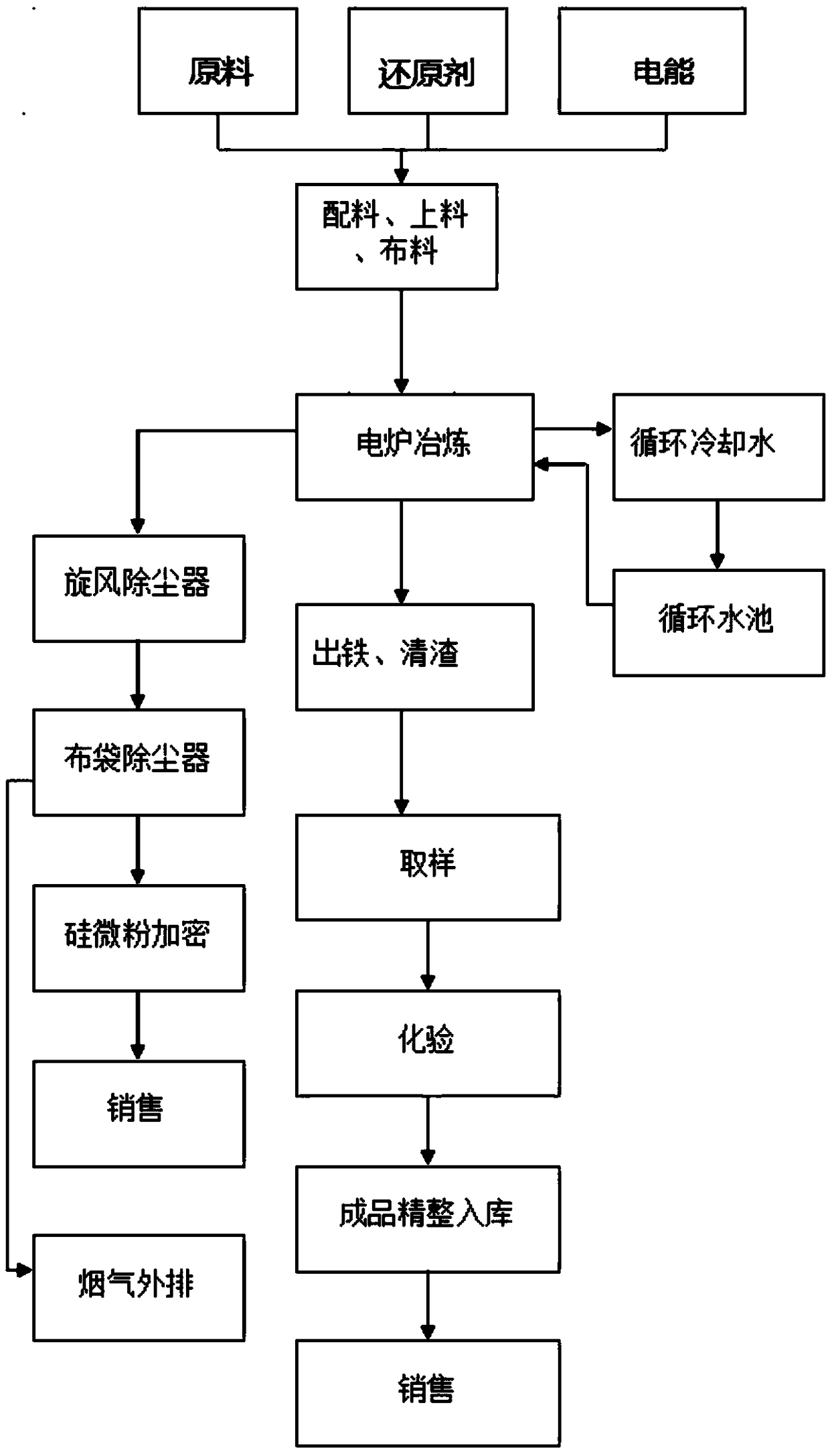

ActiveCN112143905BReduce in quantityImprove the level of mechanical automationCasting cleaning apparatusSlagFlue gas

Owner:YUNNAN TIN

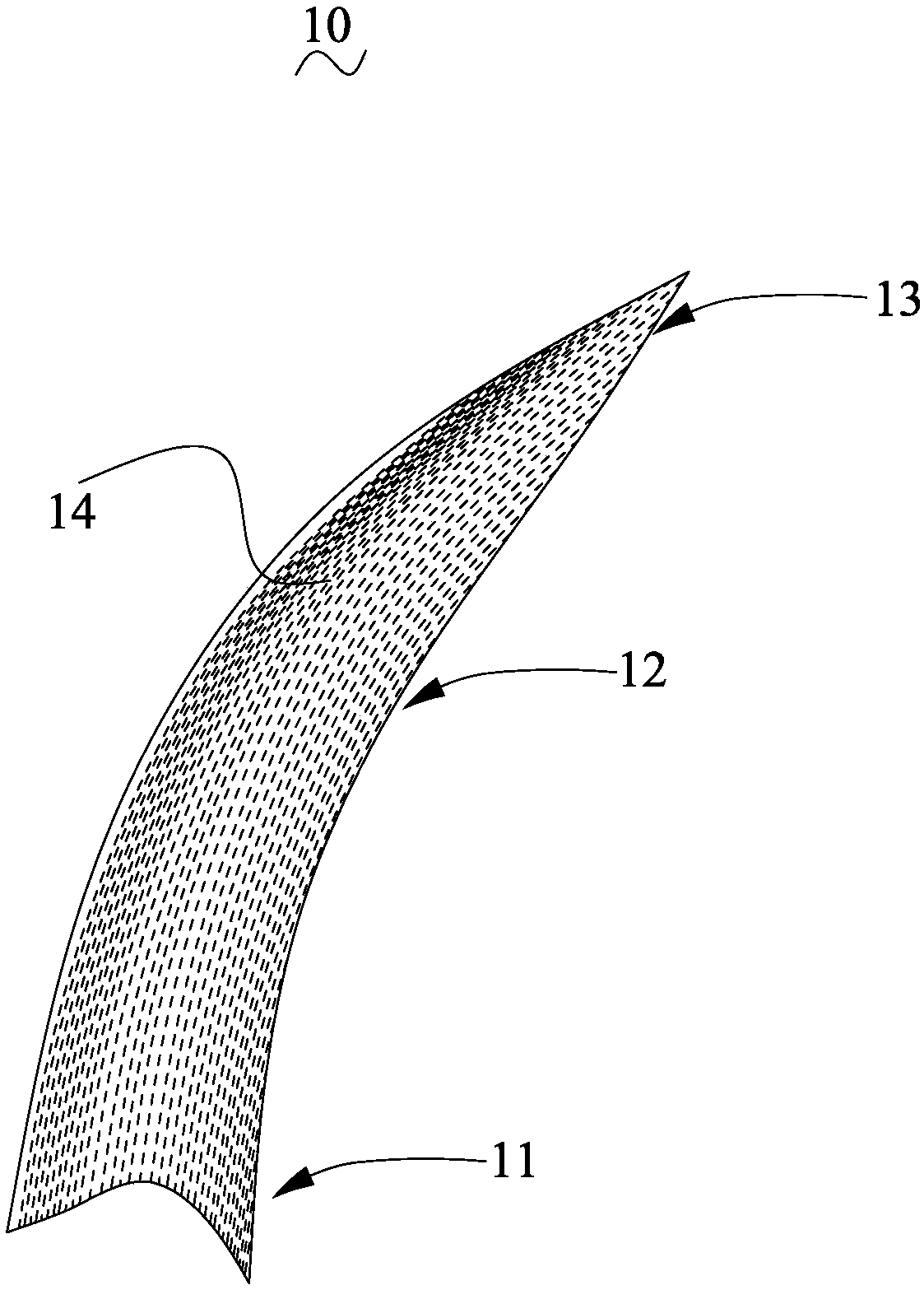

Pineapple fiber extraction equipment and method for spinning cloth and making clothes from ecological environment-friendly material

InactiveCN109594126AImprove the level of mechanical automationMechanical fibre separationLiquid/gas/vapor fibres/slivers/rovings treatmentFiberSurface moisture

The invention discloses pineapple fiber extraction equipment and a method for spinning cloth and making clothes from an ecological environment-friendly material. The method for spinning cloth and making clothes from the ecological environment-friendly material comprises the following steps: harvesting pineapple leaves in farmland; pressing the pineapple leaves by a pressing device; binding pineapple fiber with impurities; conveying the bound pineapple fiber with impurities to a cleaning device by a conveying device; cleaning the pineapple fiber with impurities by the cleaning device; fishing the pineapple fiber in the cleaning device into a dehydration device by a fishing device; removing water on the surface of the pineapple fiber by the dehydration device; hanging the pineapple fiber with surface moisture removed on a drying device; pushing the drying device with the pineapple fiber to the sun for drying so as to fully remove moisture in the pineapple fiber; spinning the pineapple fiber after the moisture is fully removed by textile equipment to obtain pineapple fiber textiles; making clothes from the pineapple fiber textiles.

Owner:邓义娇

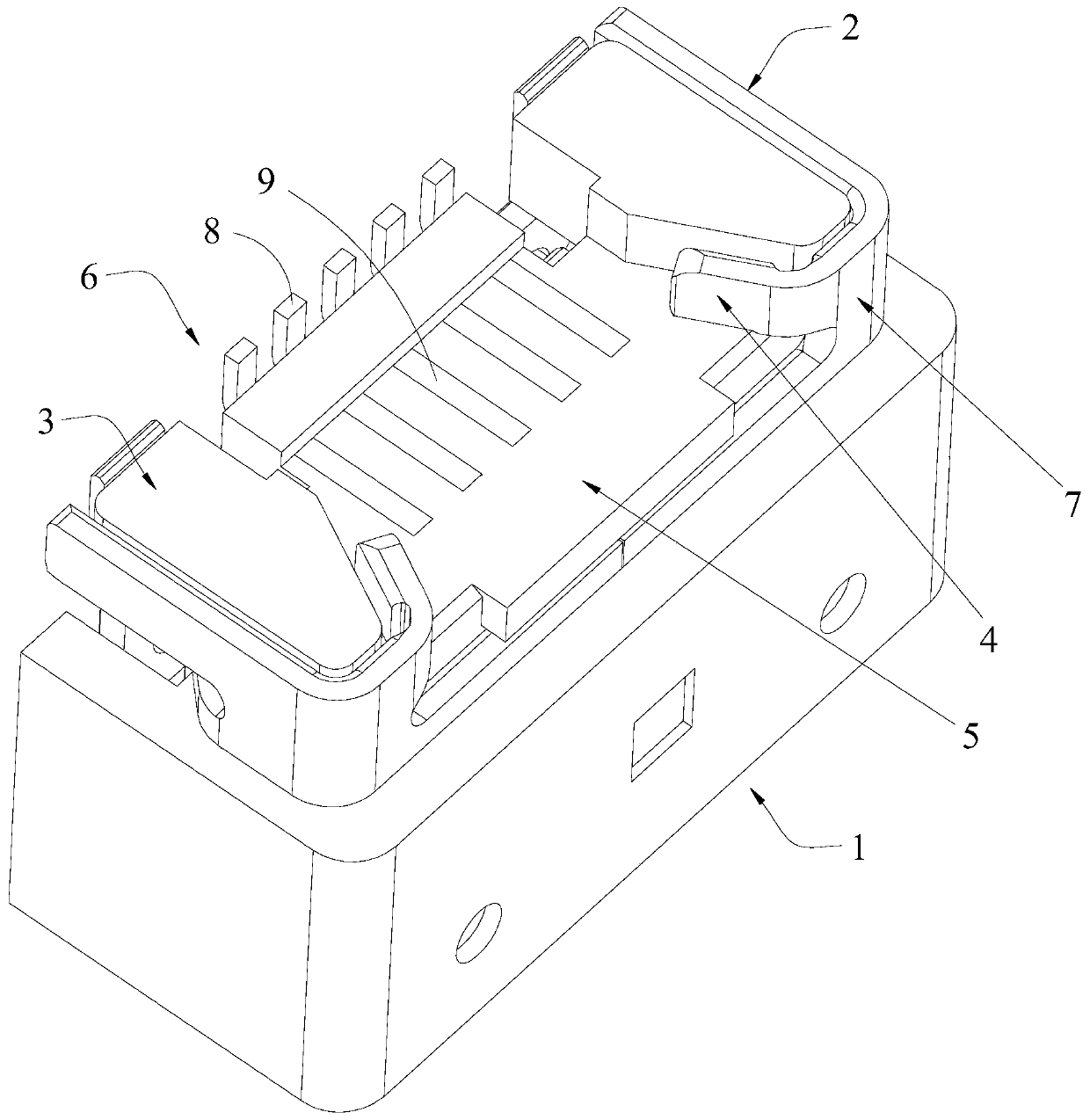

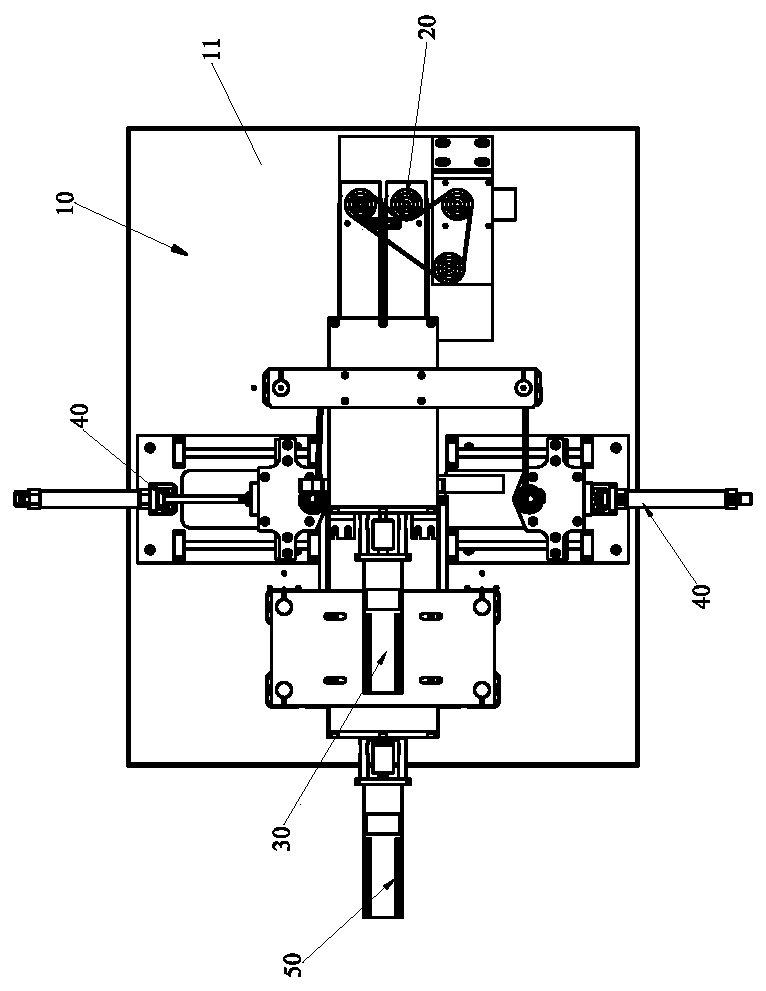

Conduction test system of USB connecting plug

InactiveCN111190124AImprove the level of mechanical automationContinuity test is convenientElectric connection testingUSBMechanical engineering

The invention discloses a conduction test system of a USB connecting plug. The conduction test system comprises a rack, a USB connecting plug conduction test device and a USB connecting plug materialtaking device. The USB connecting plug conduction test device and the USB connecting plug material taking device are respectively arranged on the rack. According to the conduction test system of the USB connecting plug, the conduction test device of the USB connecting plug and the USB connecting plug material taking device are arranged so that Mini USB can be conveniently subjected to conduction test and the mechanical automation level of USB production is improved.

Owner:杨继朗

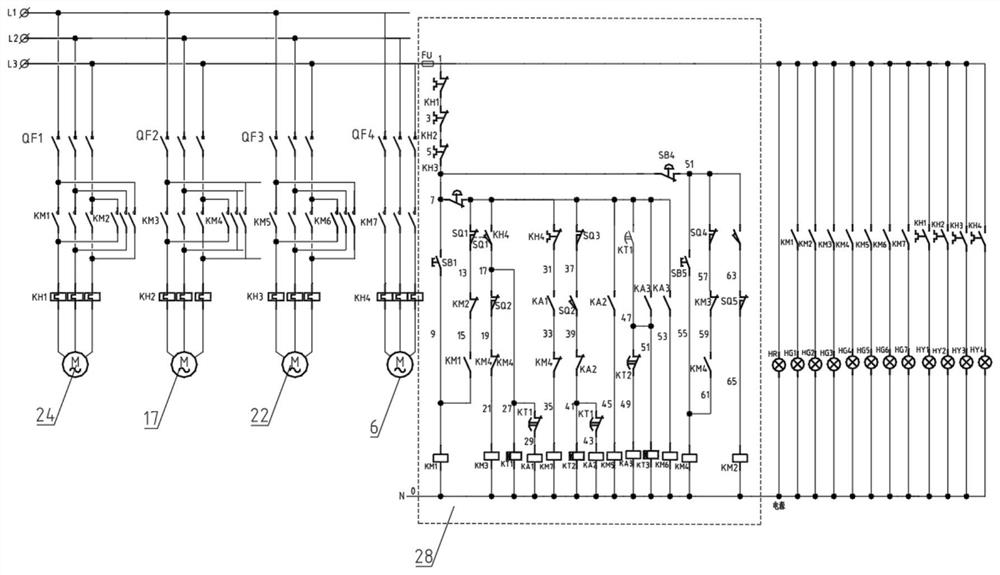

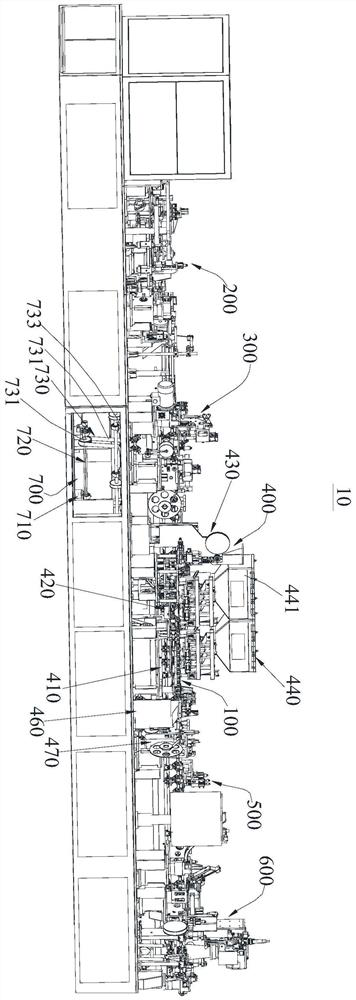

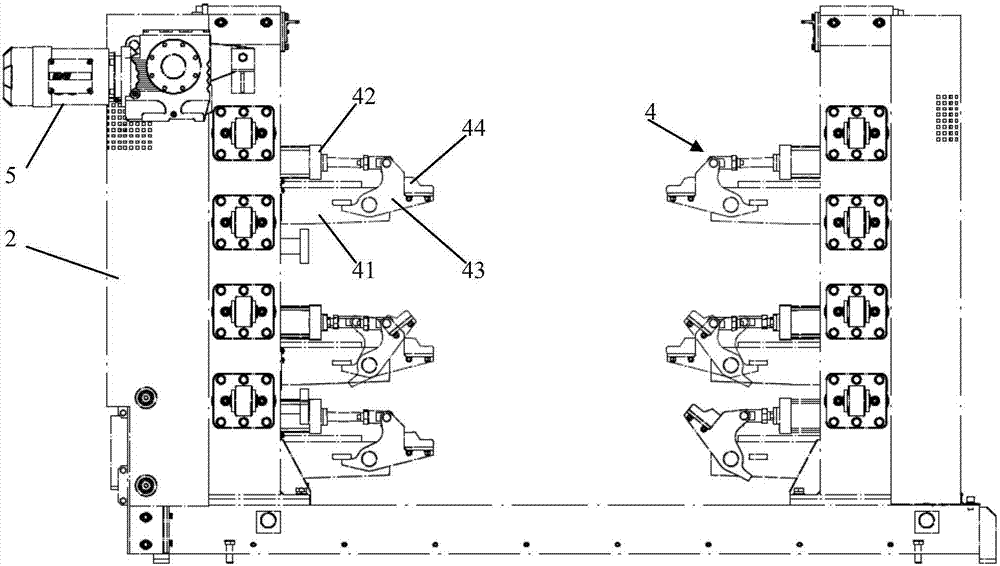

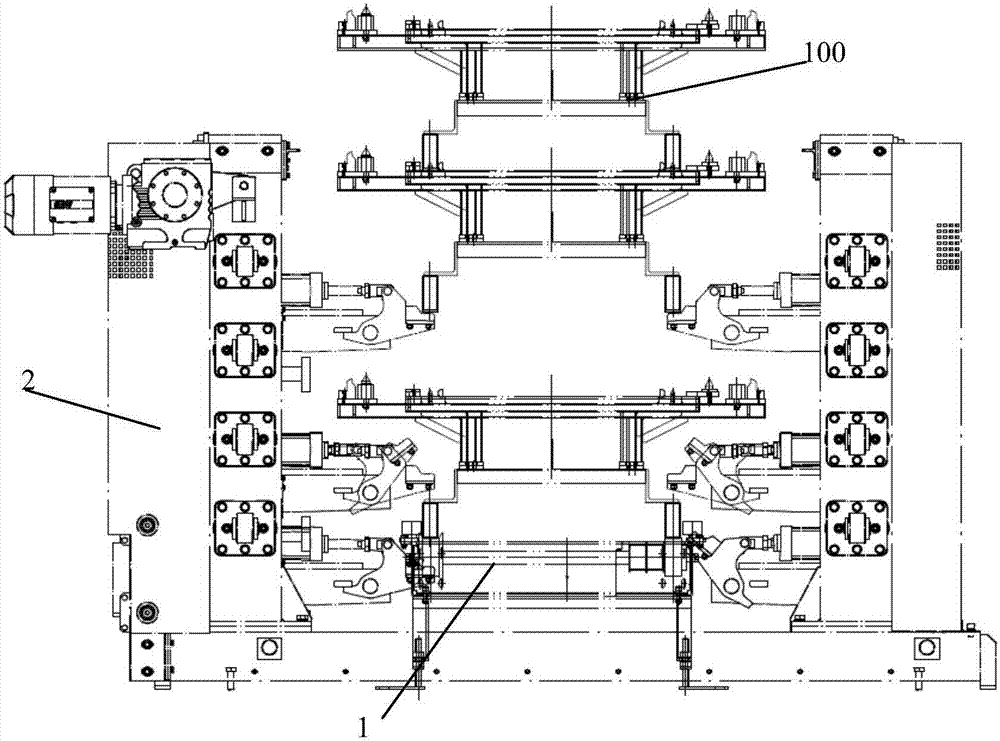

Dual-line continuous casting system and control method for dual-line continuous casting system

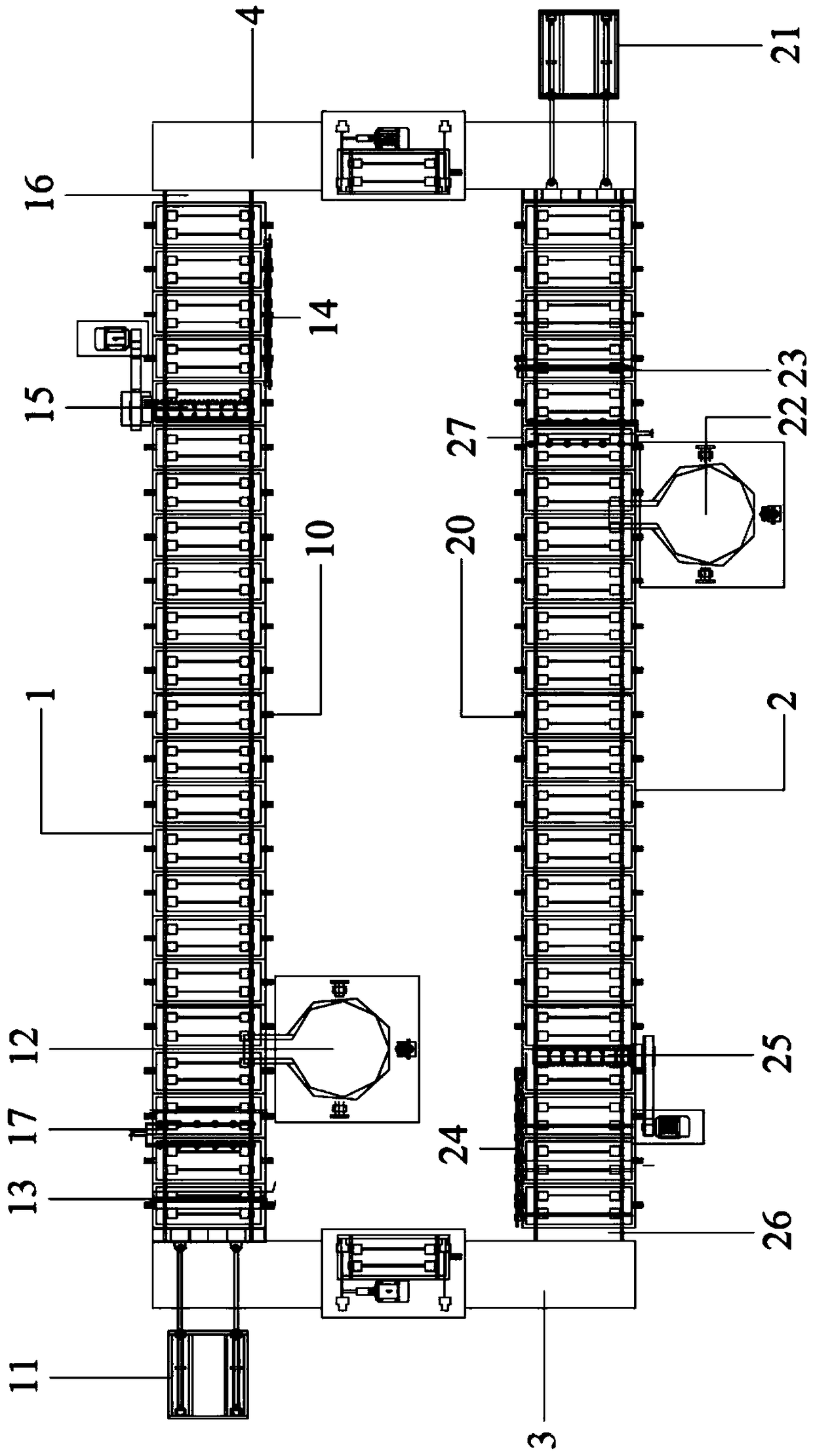

The invention relates to the technical field of alloy casting and discloses a dual-line continuous casting system and a control method for the dual-line continuous casting system. The dual-line continuous casting system comprises a first casting platform, a second casting platform, a first transferring platform and a second transferring platform, wherein both the first casting platform and the second casting platform comprise a plurality of spindle die sets and propulsion units used to move the spindle die sets respectively; the start end of the first casting platform is connected to the tailend of the second casting platform by the first transferring platform and the tail end of the first casting platform is connected to the start end of the second casting platform by the second transferrin platform; the first transferring platform is used to transfer the spindle die sets which are already moved to the tail end of the second casting platform to the start end of the first casting platform; and the second transferring platform is used to transfer the spindle die sets which are already moved to the tail end of the first casting platform to the start end of the second casting platform. According to the invention, through fixed-point casting, flue gas emission during casting is reduced; work strength during casting is reduced; hidden safety hazards existing in casting are reduced;the degree of mechanical automation of casting is increased, etc

Owner:内蒙古鄂尔多斯电力冶金集团股份有限公司 +1

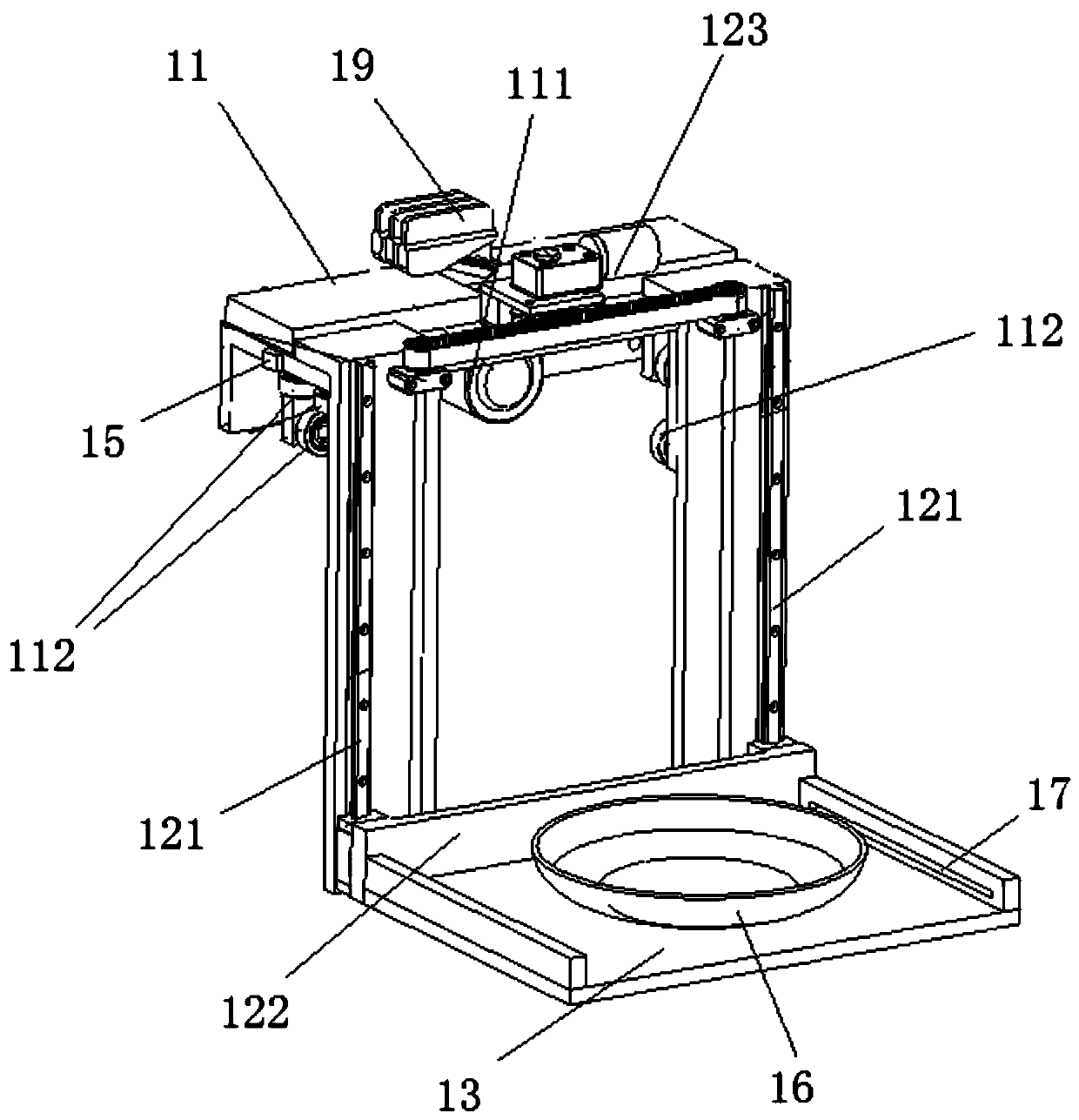

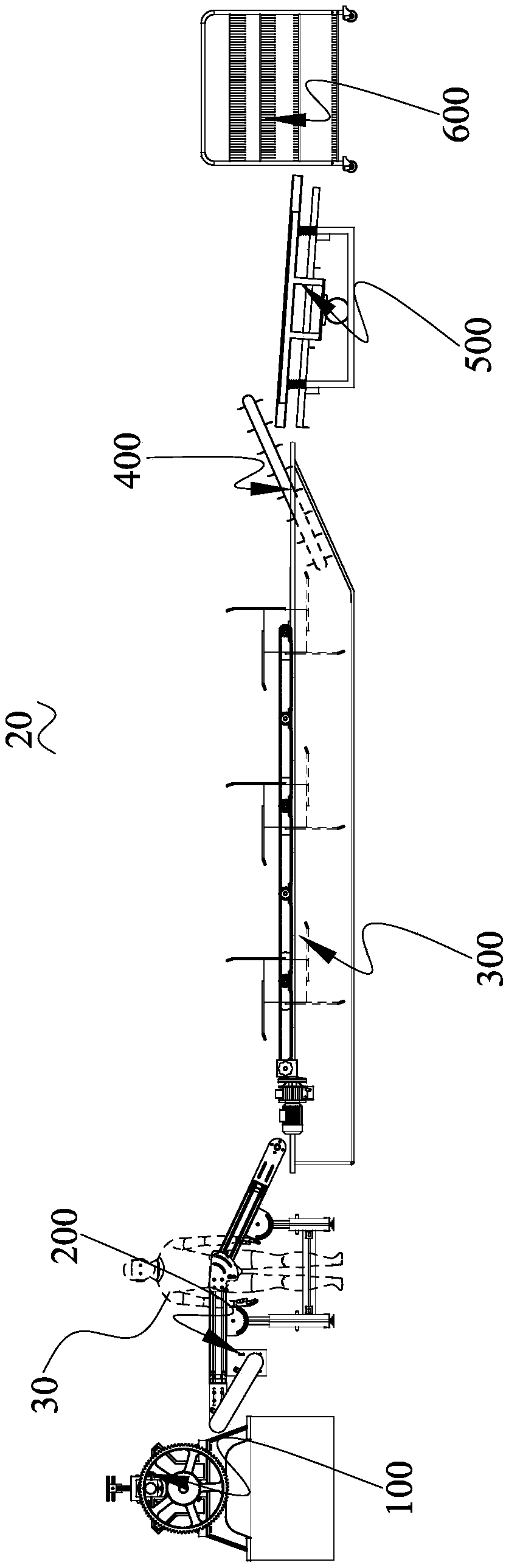

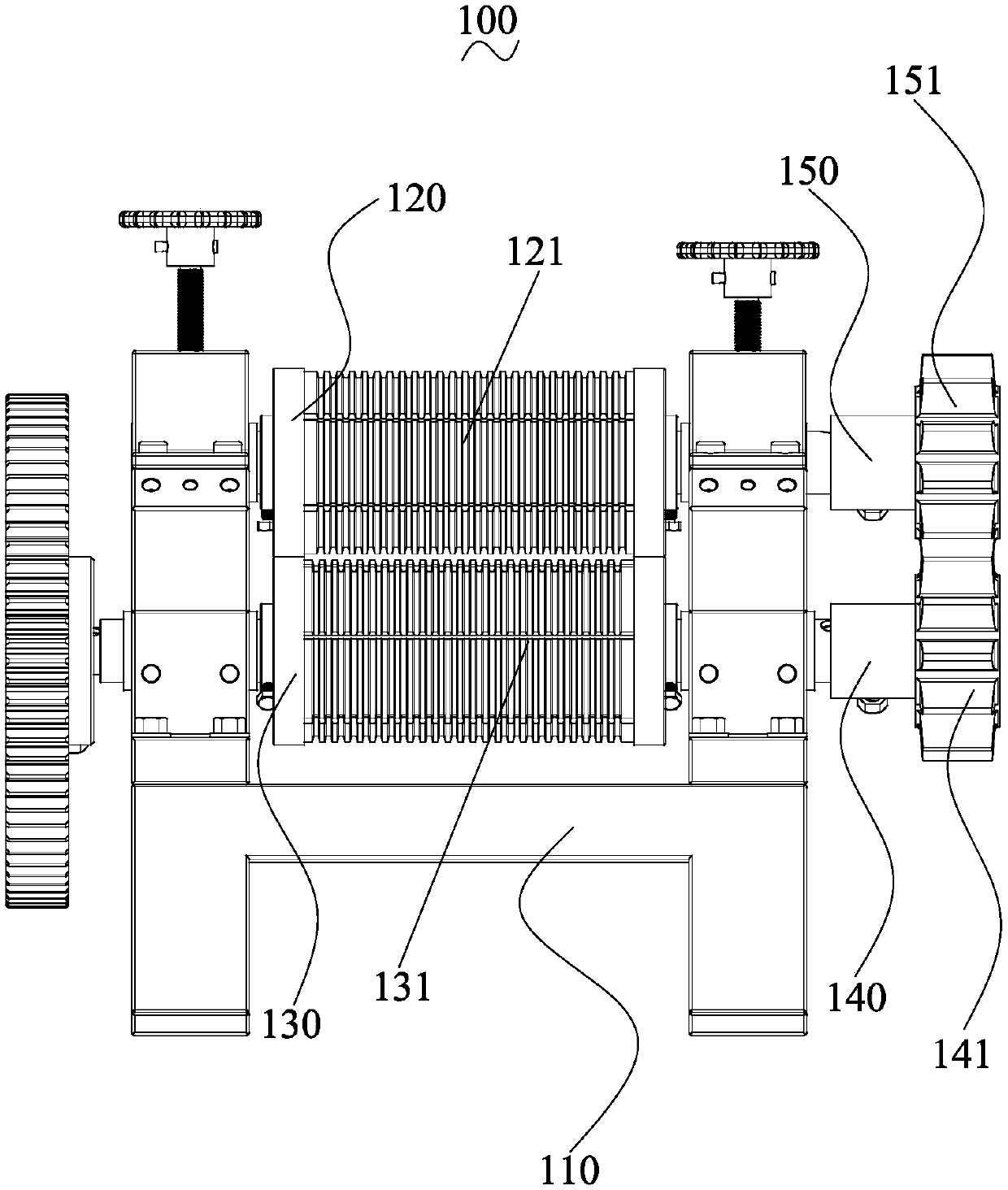

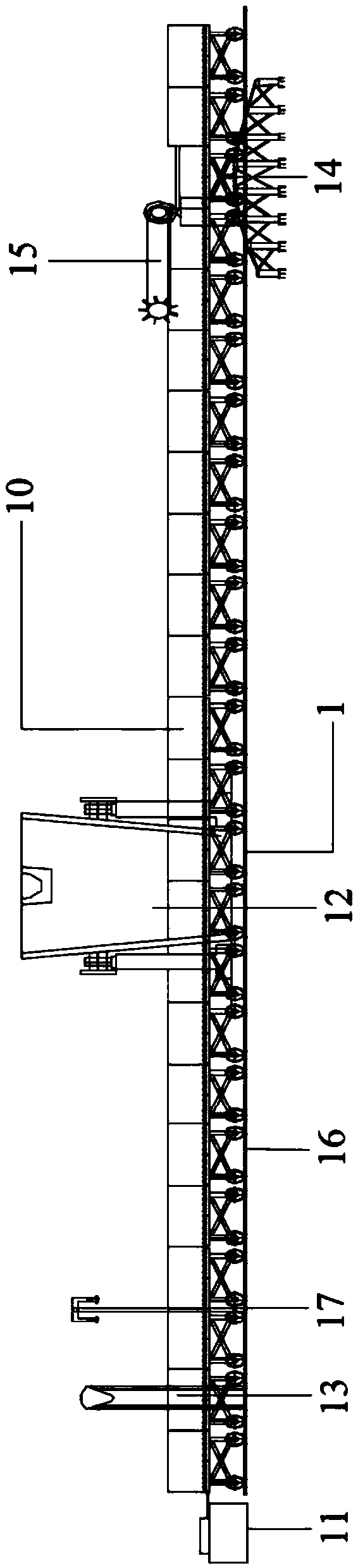

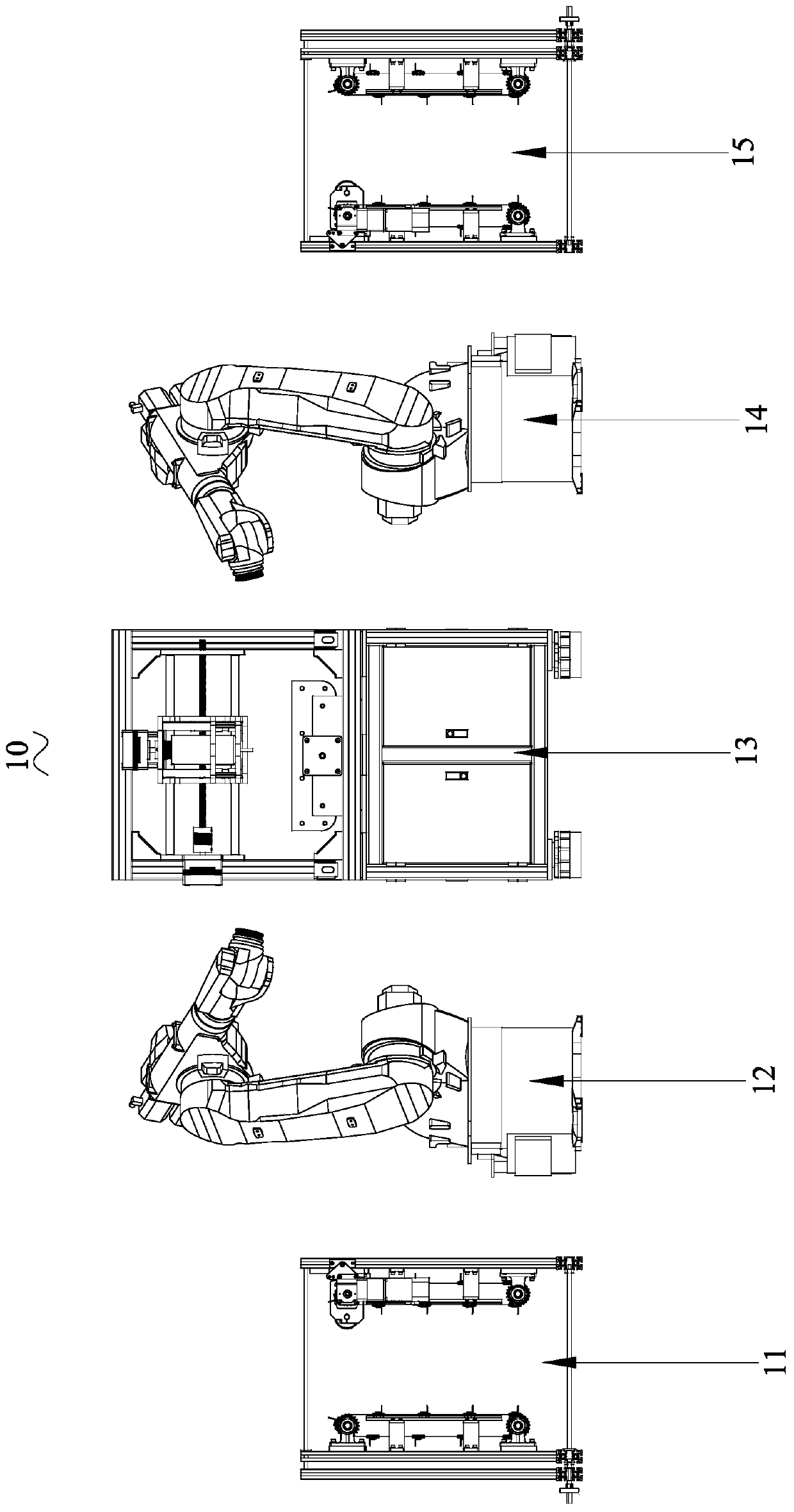

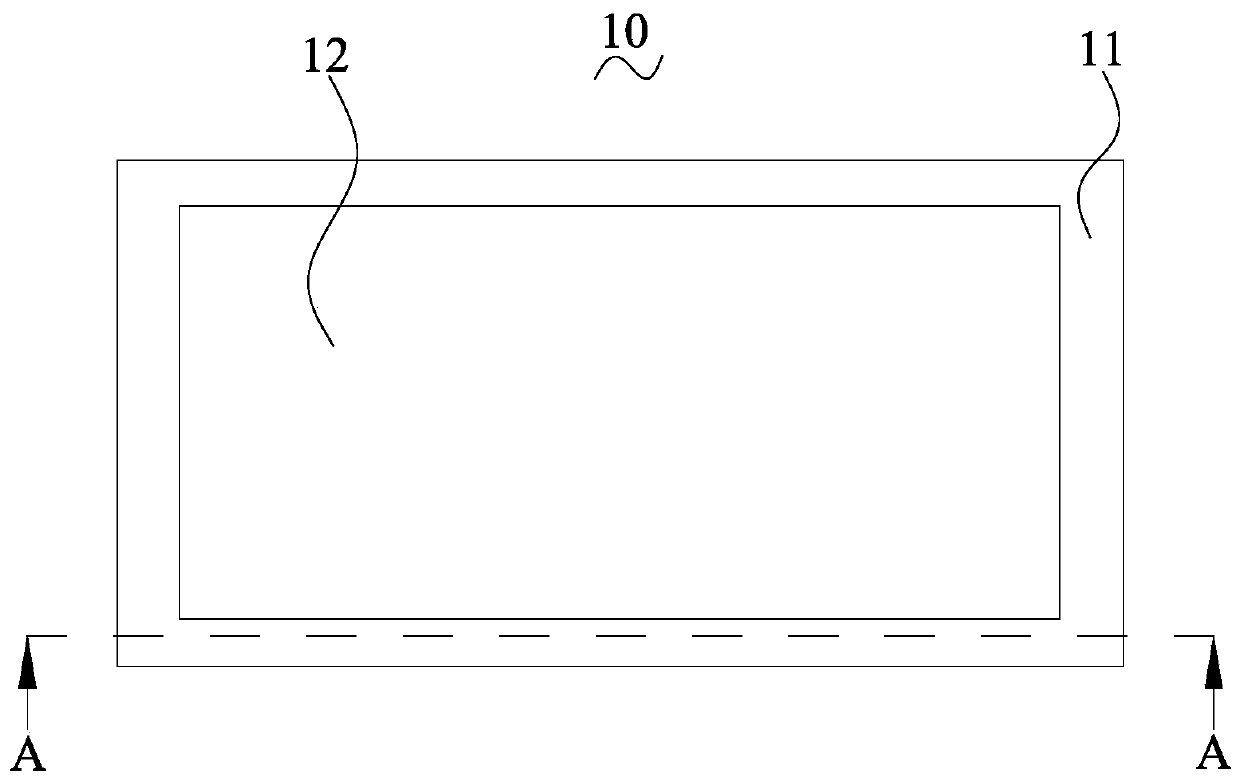

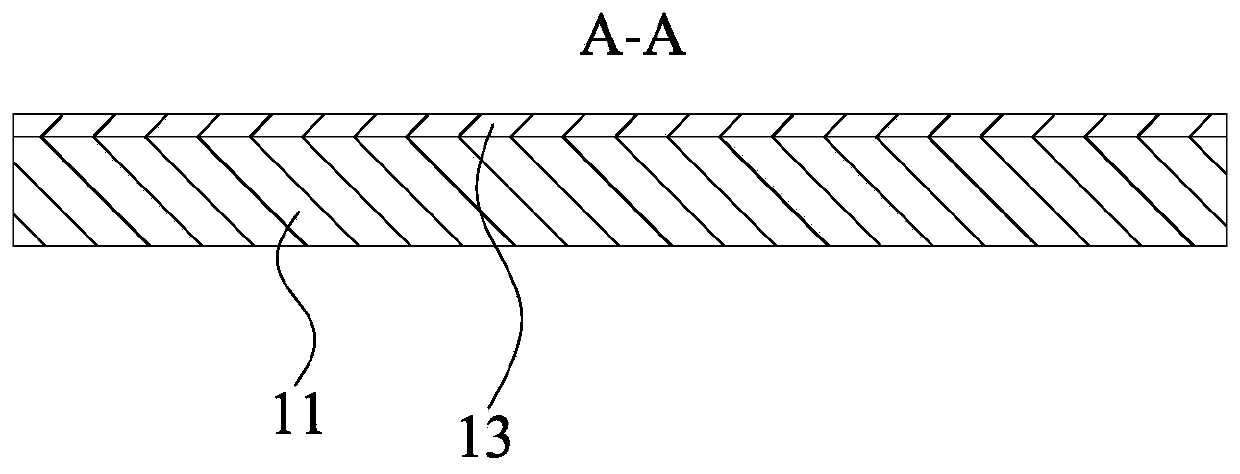

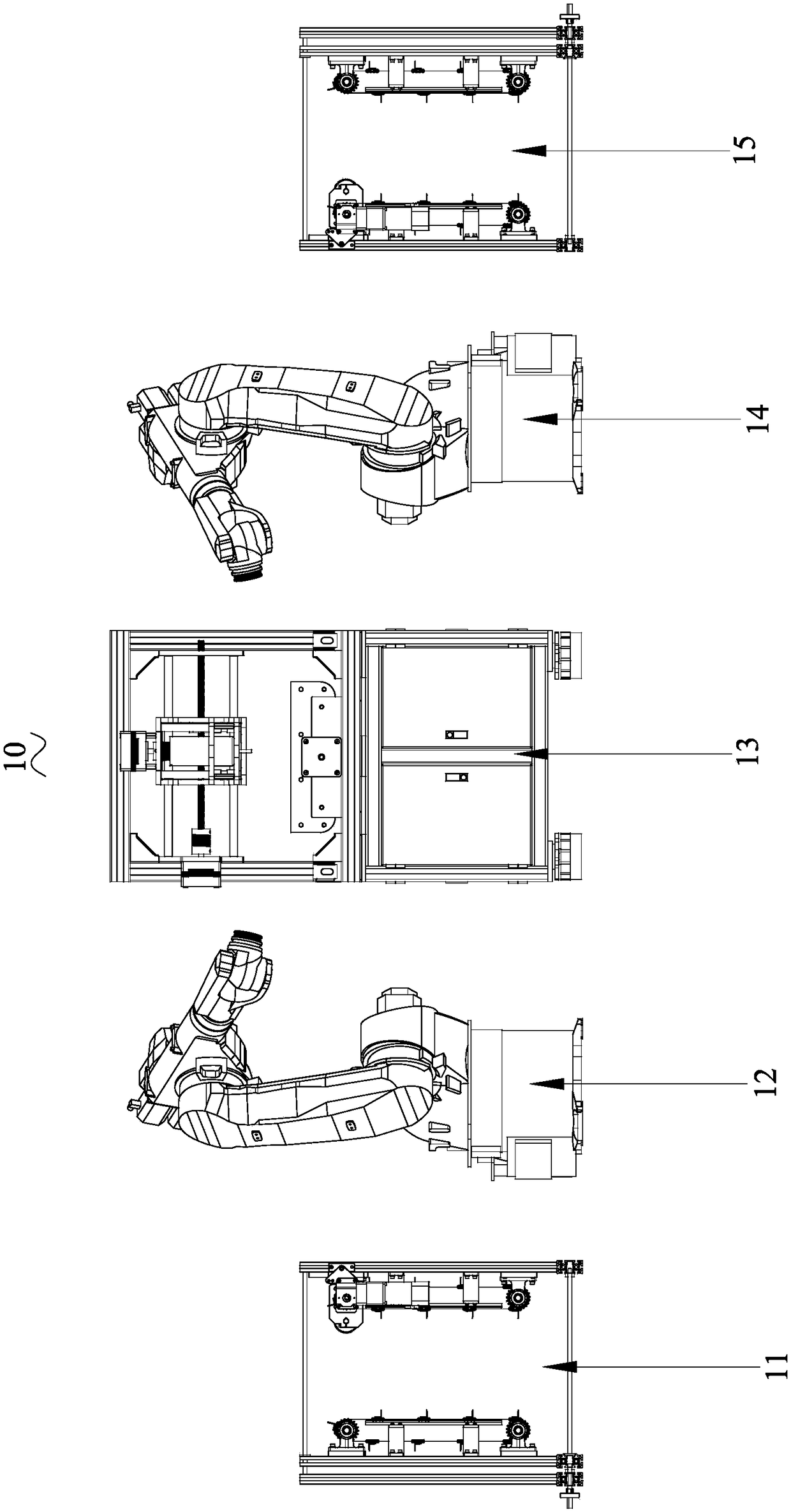

A CNC glass carving equipment

InactiveCN108297594BImprove the level of mechanical automationModel makingEngravingNumerical controlEngineering

The invention discloses numerical control glass fine carving equipment. The numerical control glass fine carving equipment comprises a glass feeding system, a glass feeding mechanical arm, a glass fine carving machine, a glass discharging mechanical arm and a glass discharging system. The glass feeding system, the glass feeding mechanical arm, the glass fine engraving machine, the glass discharging mechanical arm and the glass discharging system are sequentially arranged at intervals in a linear shape; the structure of the glass feeding system is the same as the structure of the glass discharging system; and the structure of the glass feeding mechanical arm is the same as the structure of the glass discharging mechanical arm. According to the numerical control glass fine carving equipment,the glass feeding system, the glass feeding mechanical arm, the glass fine carving machine, the glass discharging mechanical arm and the glass discharging system are arranged, so that the structure of each part is optimally designed and used for feeding, carving and blanking operations on glass, and the overall mechanical automation level of equipment is improved.

Owner:SHENZHEN DINGTAI INTELLIGENT EQUIP CO LTD

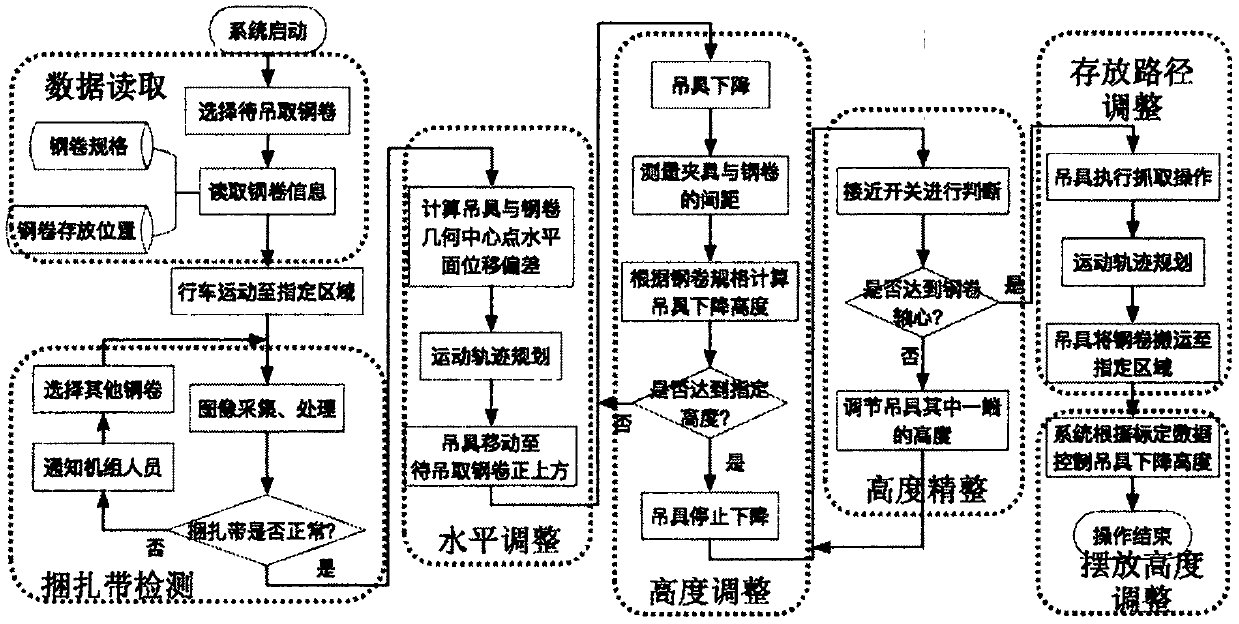

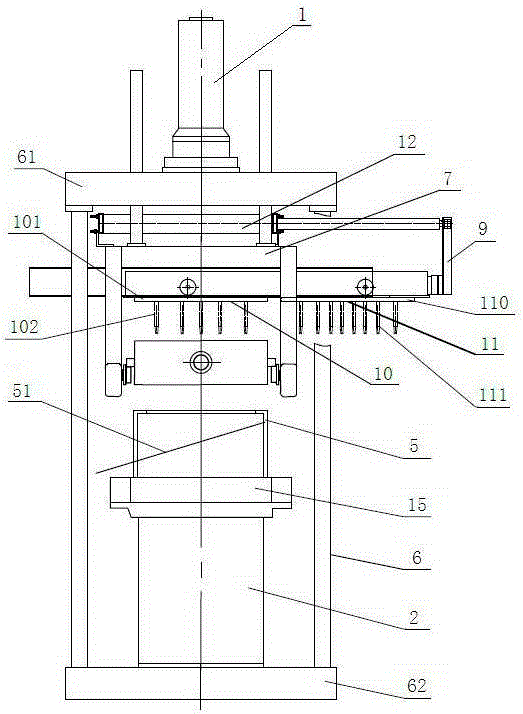

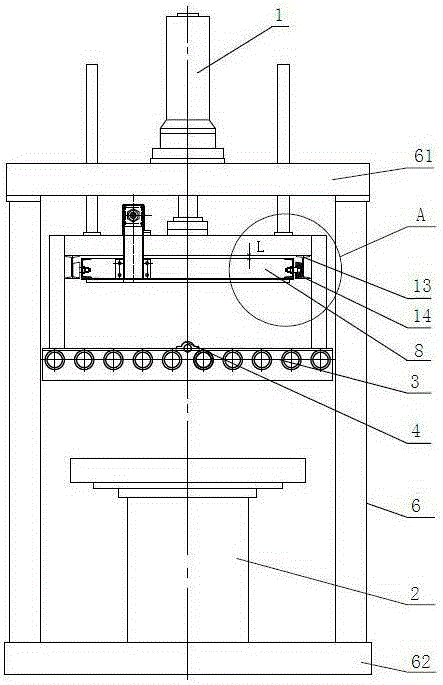

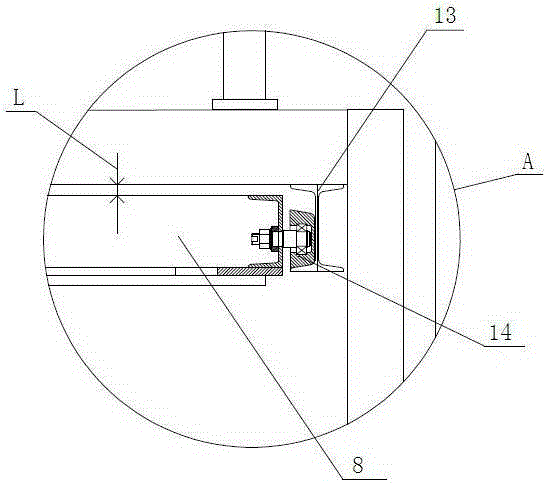

Machine vision based automatic grabbing algorithm for steel coil crane

InactiveCN111232845AImprove the level of mechanical automationGuaranteed positioning accuracyLoad-engaging elementsStructural engineeringAlgorithm

The invention discloses a machine vision based automatic grabbing algorithm for a steel coil crane. The machine vision based automatic grabbing algorithm for the steel coil crane comprises the following steps of data reading, strapping tape detection, horizontal adjustment of a lifting appliance, height adjustment of the lifting appliance, height finishing of the lifting appliance, storage path adjustment and placement height adjustment. The method is characterized in that the machine vision is adopted to process a steel coil, and the position deviation between the lifting appliance and a geometric center point of the steel coil is calculated, which is the important link for realizing the automatic grabbing of the steel coil crane. The machine vision based automatic grabbing algorithm forthe steel coil crane has the advantages of high positioning precision, high automation degree and high processing efficiency, and can greatly improve the working efficiency of the steel coil crane.

Owner:ZHOUKOU NORMAL UNIV

Iron mold cleaning device and method in iron mold sand-covered casting of shuttle roof

ActiveCN103506568BEasy to transportIncrease productivityMould handling/dressing devicesMoulding machinesSand castingPiston rod

The invention relates to an iron section removing device and an iron section removing method used during iron section sand cladding casting of a shuttle-type top plate, and belongs to the field of iron section sand cladding casting equipment. The iron section removing device comprises an ejecting cylinder, a vibrating device, an iron section conveying roller way, an iron section positioning device, a sand falling bucket device, a movable beam, a trolley body, a trolley connecting plate, an upper iron section ejecting device and a lower iron section ejecting device, wherein the movable beam is connected with a piston rod of the ejecting cylinder; the iron section positioning device is arranged in the middle of the iron section conveying roller way; a workbench is arranged on the vibrating device; the sand falling bucket device is fixed on the workbench; the trolley body is connected with the piston rod of a trolley cylinder through the trolley connecting plate; a gap is formed between the upper surface of the trolley body and the lower surface of the movable beam; the upper iron section ejecting device and the lower iron section ejecting device are arranged on the movable beam. The iron section removing device is used for removing the upper iron section and the lower iron section which are different in sand ejecting holes positions, thus meeting removal of iron section sand cladding of the upper iron section and the lower iron section with inconsistent positions of the sand ejecting holes.

Owner:浙江省机电设计研究院有限公司

A device for welding the tabs at the bottom of the cell and the steel case

ActiveCN107598581BImprove the level of mechanical automationFinal product manufacturePrimary cellsEngineeringAssembly machine

Owner:HUIZHOU JINYUAN PRECISION AUTOMATION EQUIP

Mechanism and method for automatically mixing mortar and coating tiles

InactiveCN109435055BImprove the level of mechanical automationImprove efficiencyBuilding constructionsCement mixing apparatusControl systemMachine

The invention discloses an automatic stirring mortar and tile coating mechanism and method. The mechanism comprises a machine frame with universal casters at the bottom; the machine frame is providedwith a stirring hopper assembly, a discharging hopper assembly, a horizontal conveying assembly and a scraping plate assembly, the stirring hopper assembly is used for stirring mortar raw materials toform mortar and pouring the mortar out, the discharging hopper assembly is used for receiving the mortar poured out by the stirring hopper assembly and outputting the mortar to tiles, the horizontalconveying assembly is located below the discharging hopper assembly and is used for driving the tiles to horizontally move, and the scraping plate assembly is used for scraping the mortar on the tiles; the scraping plate assembly locates above the horizontal conveying assembly and locates in front of a discharge port of the stirring hopper assembly, the back surfaces of the tiles face upwards andare placed on the horizontal conveying assembly, and the tiles are used for receiving the mortar which is output by the discharging hopper assembly along with the movement of the horizontal conveyingassembly; and the scraping plate assembly is used for scraping the mortar on the tiles during the movement process of the tiles, and the actions of the stirring hopper assembly, the discharging hopperassembly and the horizontal transmission assembly are uniformly coordinated and controlled through a control system. According to the mechanism and method, the mechanical automation level, the efficiency and the quality of the tile coating operation are improved, and the labor intensity of tile coating operation is reduced.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Punching device for blister product and blister system including punching device

InactiveCN107718521AAvoid compromising qualityImprove the level of mechanical automationPlastic materialsEngineering

The invention discloses a perforating device for plastic-absorbing products and a plastic-absorbing system comprising the perforating device. The perforating device includes a material fixing component, a material perforating component, a transport turntable, and a transport jig. Material fixing components include: material fixing support frame, material fixing driving part, material fixing lifting slider, material fixing sheet; material perforating component includes: material perforating support frame, material perforating horizontal horizontal driving part, material perforating horizontal longitudinal driving part, material Perforation vertical lifting drive unit, material perforation elastic needle. By optimizing the design of the related structure of the perforating device, a material fixing component for fixing the semi-finished product and a perforating component for perforating the semi-finished product are set up to prevent the semi-finished product from breaking through during the perforation process. Product quality, and then improve the overall level of mechanical automation.

Owner:惠州市联顺包装制品有限公司

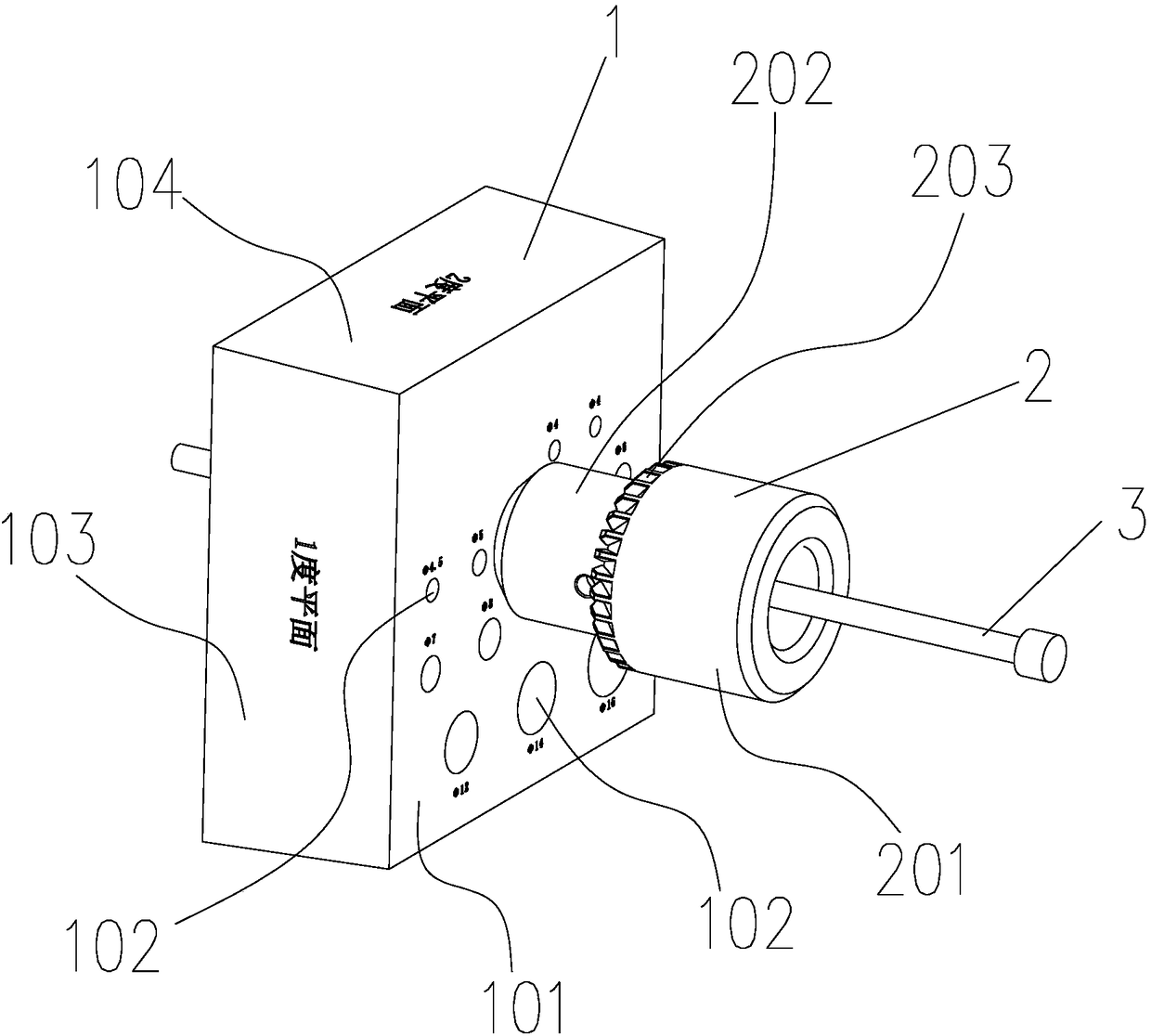

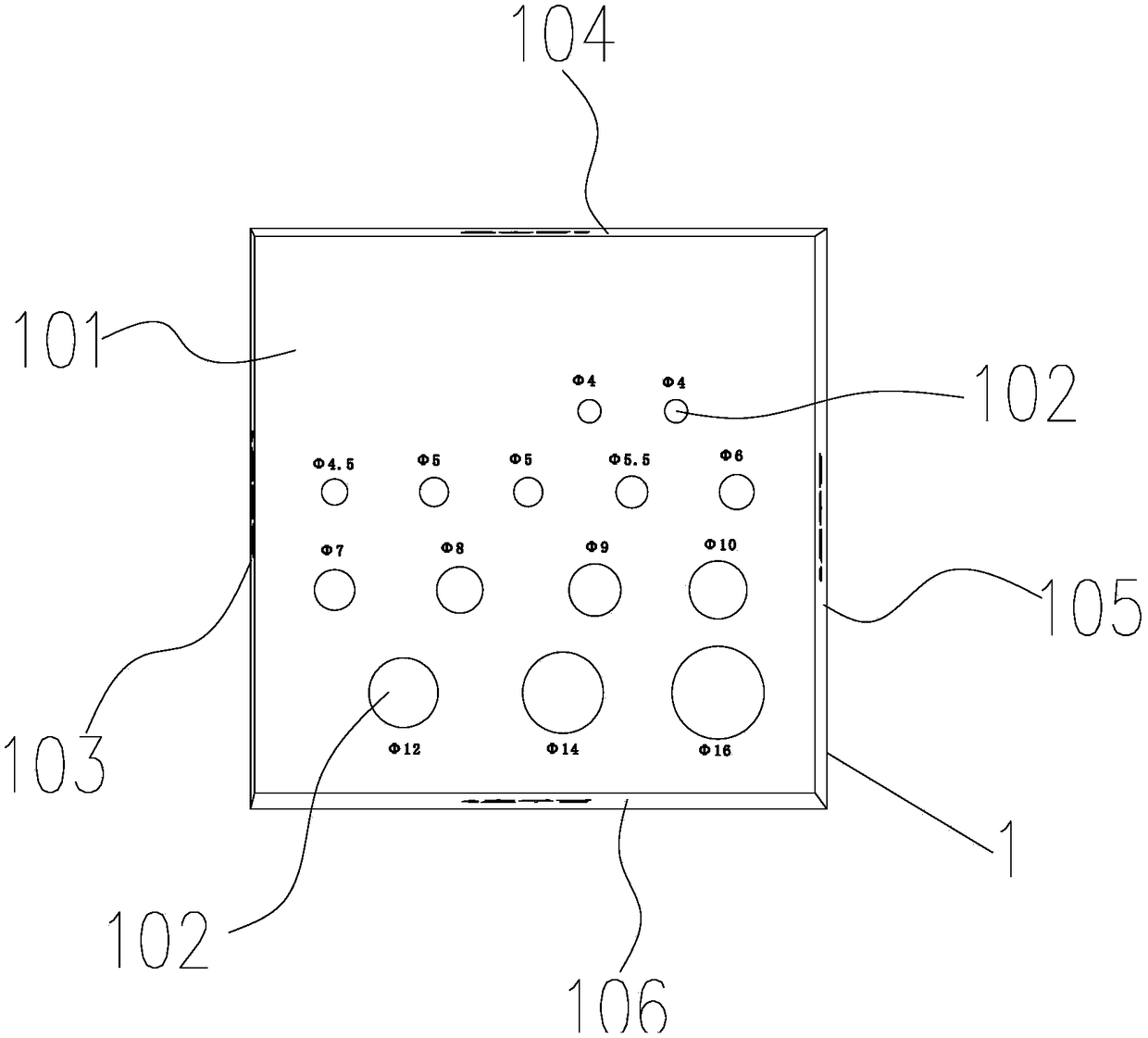

Mold core grinding tool

PendingCN108145598AEasy to operateEasy to installEdge grinding machinesGrinding work supportsBody areaEngineering

The invention relates to the technical field of die mold core machining devices, in particular to a mold core grinding tool. The mold core grinding tool comprises a tool body and a limiting clamp, thefront face of the tool body is an installing face, the installing face is provided with a plurality of through holes in different specifications, the end faces of the four sides of the tool body area one-degree slope, a two-degree slope, a third-degree slope and a fourth-degree slope, included angles between the installing face and the one-degree slope, the two-degree slope, the third-degree slope and the fourth-degree slope are 91 degrees, 92 degrees, 93 degrees and 94 degrees; and mold cores penetrate the through holes, and the back end face of the limiting clamp is attached to the installing face. The mold core grinding tool has the beneficial effects that a terminal needle grinding machine and a sine angular magnetic disk are not needed, a dialgage is not needed for manually adjusting the concentricity during mold core rotation motion, the size requirement of the mold core molding section is guaranteed by setting the fixed angle of the tool body, and operation is convenient; installing is convenient, the structure is simple, and the construction cost is low; and the preparing time is short, operation of multiple equipment is not needed, the manual accuracy influence factors are fewer, and the machining efficiency is high.

Owner:CHANGZHOU XINGYU AUTOMOTIVE LIGHTING SYST CO LTD

Film tearing mechanism and electronic product rework equipment including the film tearing mechanism

InactiveCN108724914BImprove the level of mechanical automationFree from damageLamination ancillary operationsLaminationReworkStructural engineering

Owner:魏东升

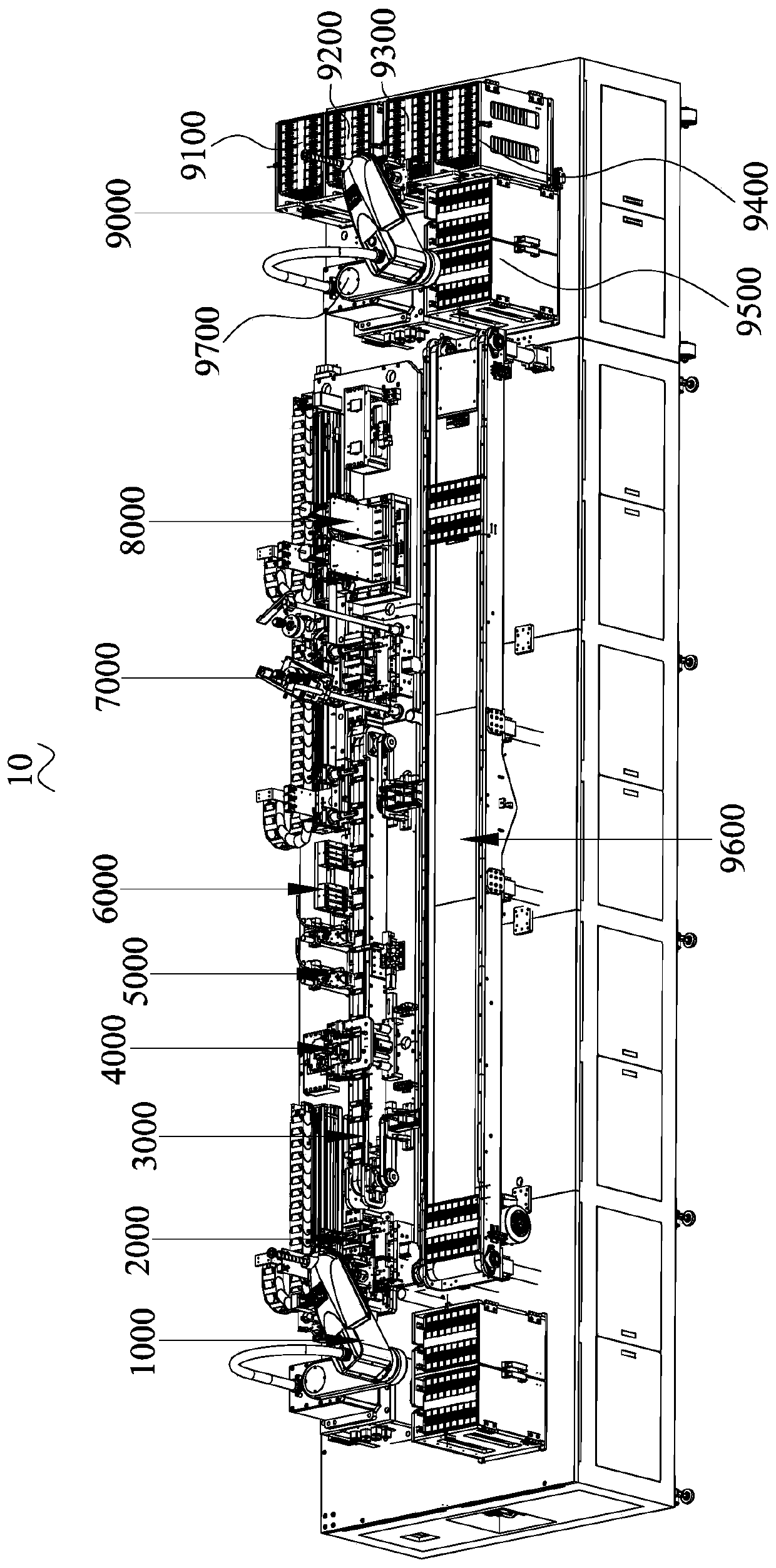

Numerical control glass fine carving equipment

InactiveCN108297594AImprove the level of mechanical automationModel makingEngravingNumerical controlManipulator

The invention discloses numerical control glass fine carving equipment. The numerical control glass fine carving equipment comprises a glass feeding system, a glass feeding mechanical arm, a glass fine carving machine, a glass discharging mechanical arm and a glass discharging system. The glass feeding system, the glass feeding mechanical arm, the glass fine engraving machine, the glass discharging mechanical arm and the glass discharging system are sequentially arranged at intervals in a linear shape; the structure of the glass feeding system is the same as the structure of the glass discharging system; and the structure of the glass feeding mechanical arm is the same as the structure of the glass discharging mechanical arm. According to the numerical control glass fine carving equipment,the glass feeding system, the glass feeding mechanical arm, the glass fine carving machine, the glass discharging mechanical arm and the glass discharging system are arranged, so that the structure of each part is optimally designed and used for feeding, carving and blanking operations on glass, and the overall mechanical automation level of equipment is improved.

Owner:SHENZHEN DINGTAI INTELLIGENT EQUIP CO LTD

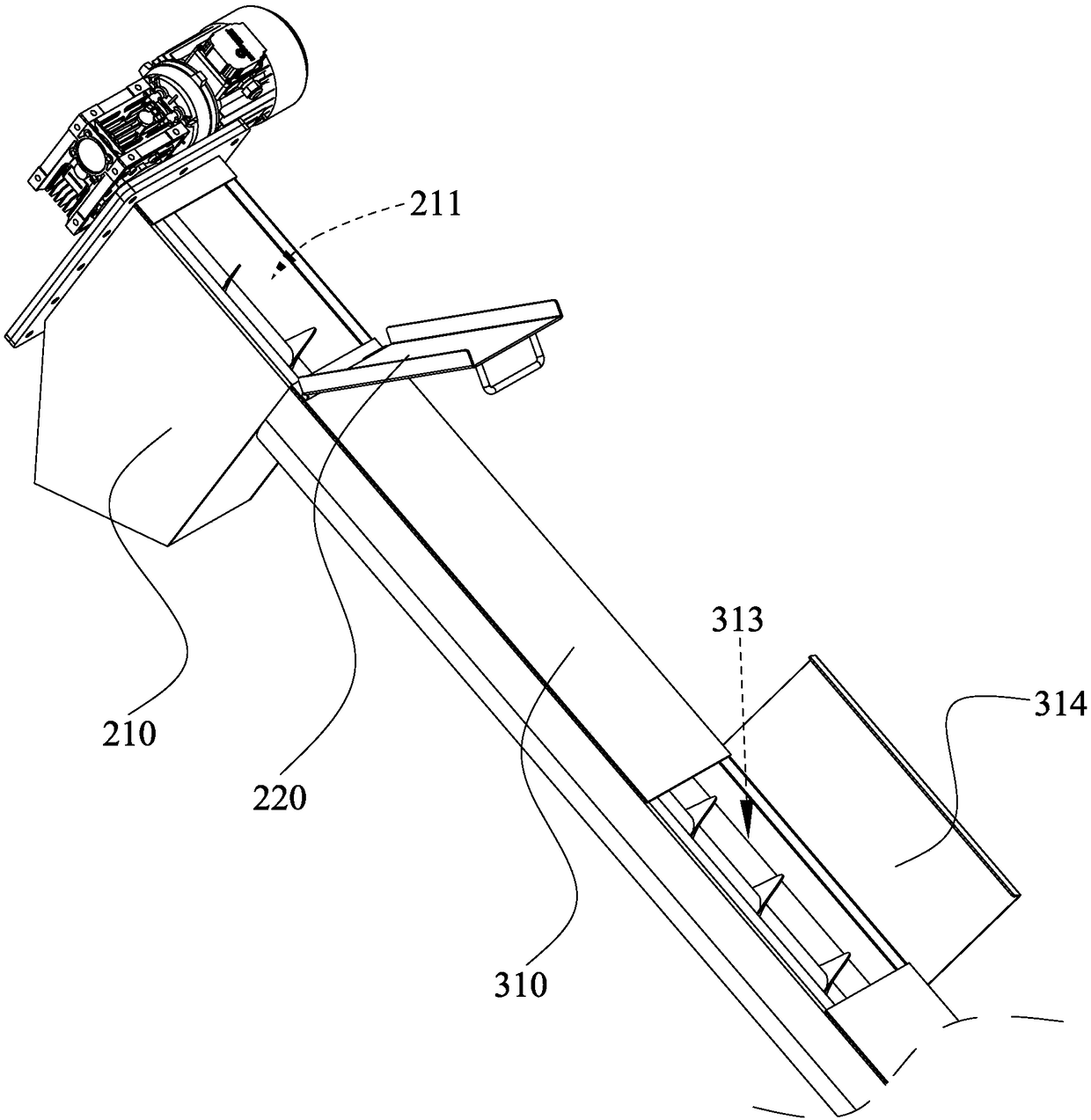

Chemical agent spirally feeding device and industrial wastewater treatment device thereof

ActiveCN108892182APrevent clogging the outletImprove the level of mechanical automationPackagingWater/sewage treatment apparatusIndustrial wastewater treatmentChemical agents

The invention discloses a chemical agent spirally feeding device and an industrial wastewater treatment device thereof. The chemical agent spirally feeding device comprises an agent storage mechanism,an agent discharging mechanism and an agent spirally conveying mechanism, wherein the agent storage mechanism comprises an agent storage bin and an agent storage cover; the agent discharging mechanism comprises an agent discharging bin and an agent discharging bin cover plate; the agent spirally conveying mechanism is composed of an agent conveying pipe, a spiral feeding rod and a conveying driving unit; the two open ends of the agent conveying pipe are a feeding port and a discharging port, the feeding port is communicated with an agent accommodating tank, and the discharging port is communicated with an agent discharging tank; the spiral feeding rod penetrates through the agent conveying pipe; the conveying driving unit is drivingly connected with the spiral feeding rod. The chemical agent spirally feeding device can effectively clean clotted chemical agent to avoid blocking the discharging port, lift the chemical agent from a low lying position to a high lying position and then feed the chemical agent into a wastewater treatment tank, and accordingly improve the mechanical automation degree of agent feeding.

Owner:广州博睿水处理科技有限公司

Folding box-in-box packaging machine with small bags

ActiveCN108945664BLoop folded neatlyAccurate countIndividual articlesIndustrial engineeringFully automated

The invention discloses a folding type packaging box for connected small packaging bags. The folding type packaging box comprises a rack, a conveying mechanism used for conveying the connected small packaging bags, a bag clamping mechanism used for clamping the connected small packaging bags to move, two folding mechanisms used for folding the connected small packaging bags left and right, a moving mechanism used for moving the connected small packaging bags backwards and a discharging mechanism; the bag clamping mechanism is located above the back portion of the output end of the conveying mechanism; the two folding mechanisms are located on the two sides of the bag clamping mechanism; the moving mechanism is located behind the bag clamping mechanism; and the discharging mechanism is located under the moving mechanism. By arranging the conveying mechanism, the bag clamping mechanism, the two folding mechanisms, the moving mechanism and the discharging mechanism, full automation of conveying, automatic folding and discharging of the connected small packaging bags is achieved; and compared with a traditional method that the connected small packaging bags are manually folded, and then the folded connected small packaging bags are put into folding packaging boxes, the labor cost is reduced, and the production efficiency and the mechanical automation level are improved.

Owner:GUANGZHOU V PACK IND CO LTD

Glove conveying and open mouth feeding device

InactiveCN108341213AQuick installationReasonable designConveyorsDrum brakesCombined methodEngineering

The invention discloses a glove conveying and open mouth feeding device. The glove conveying and open mouth feeding device comprises a bearing unit, a power unit, a hand model unit, an open mouth feeding unit and an enclasping unit, wherein the bearing unit comprises extending parts, vertical top placing parts and horizontal support parts, the extending parts are connected with one ends of the horizontal support parts, and the horizontal support parts and the vertical top placing parts are perpendicularly arranged; the power unit is arranged on the periphery of the bearing unit in a surrounding manner and comprises a first driving part and a transmission part, and the transmission part is connected with the first driving part; the hand model unit is connected with a chain of the transmission part; the open mouth feeding unit is arranged on one sides of the vertical top placing parts; and the enclasping unit is arranged on gear shafts of the transmission part, and the transmission partfurther comprises transmission gears and the chain. According to the glove conveying and open mouth feeding device, by means of a combined method of mechanical transmission and hydraulic transmission,the emergency enclasping and braking effect can be effectively realized, the glove conveying and open mouth feeding device is convenient to operate and has excellent braking effect, meanwhile, the one-to-many enclasping function can also be realized, and braking performed on multiple structures at the same time is realized.

Owner:新朗思(新沂)智能科技有限公司

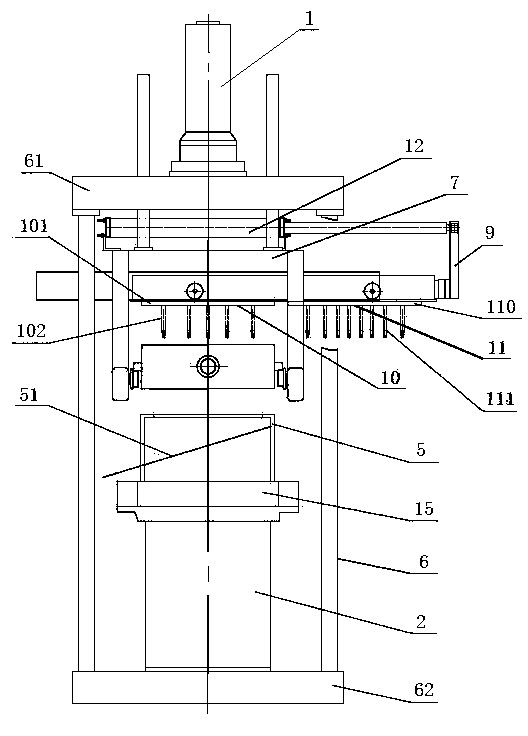

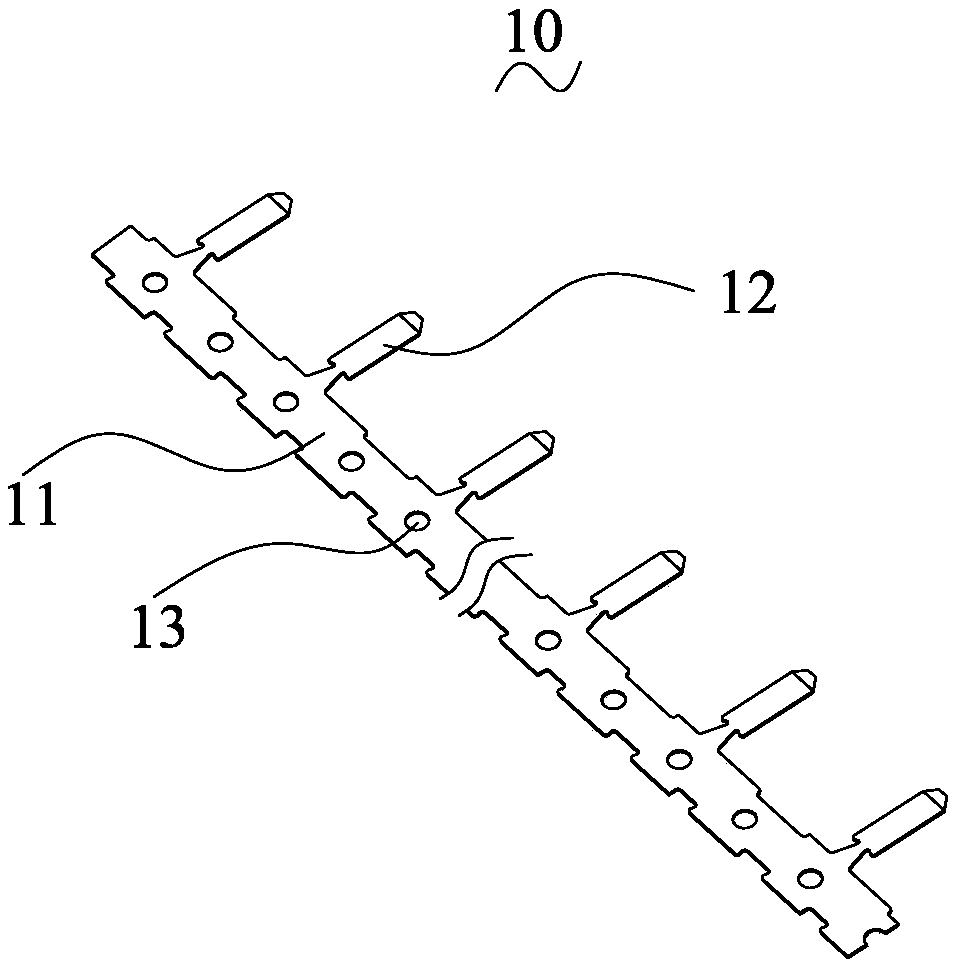

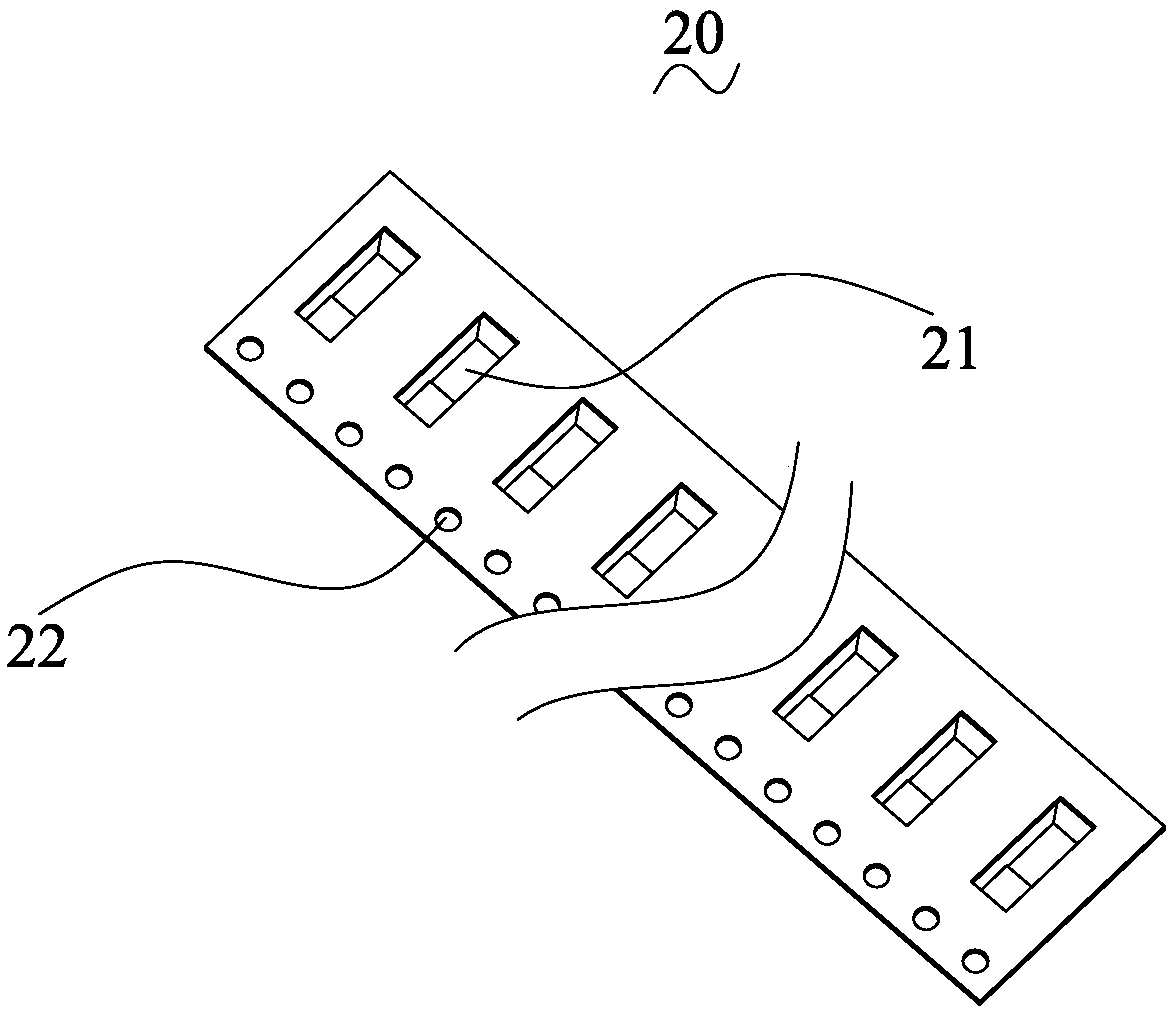

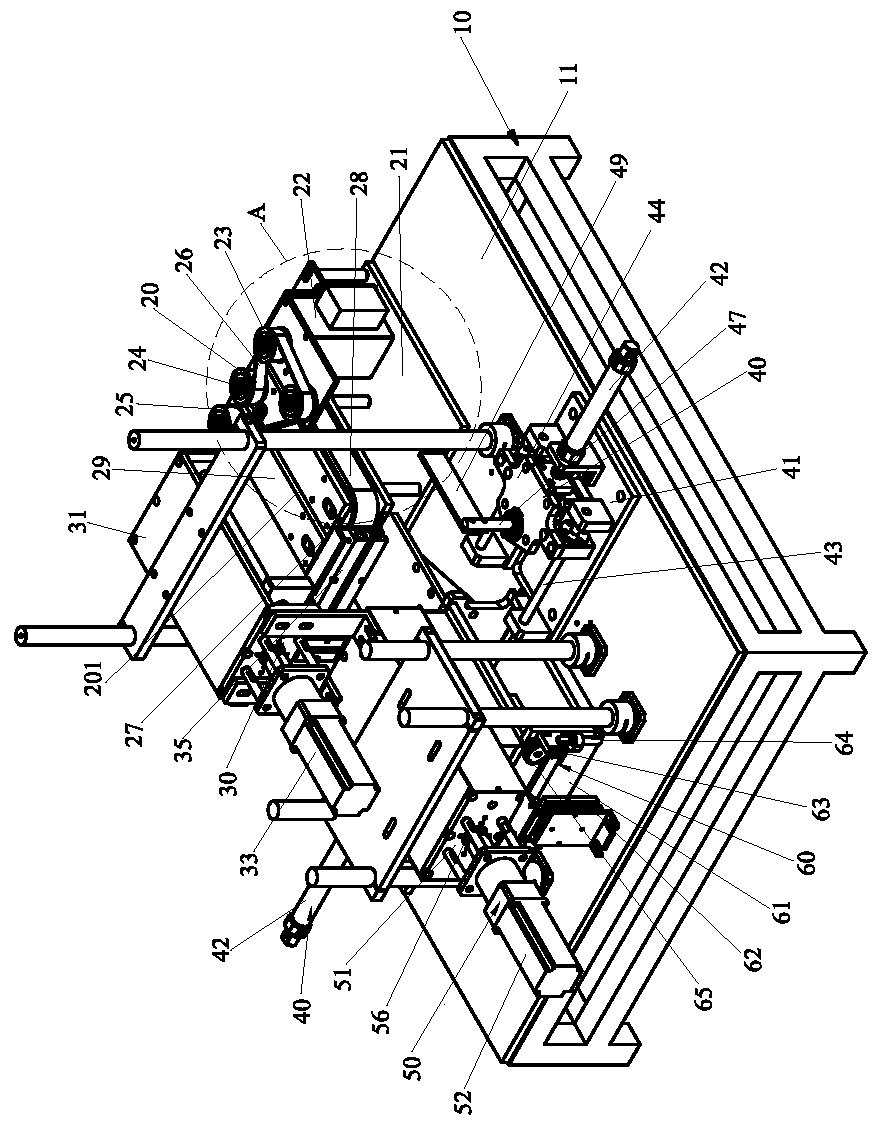

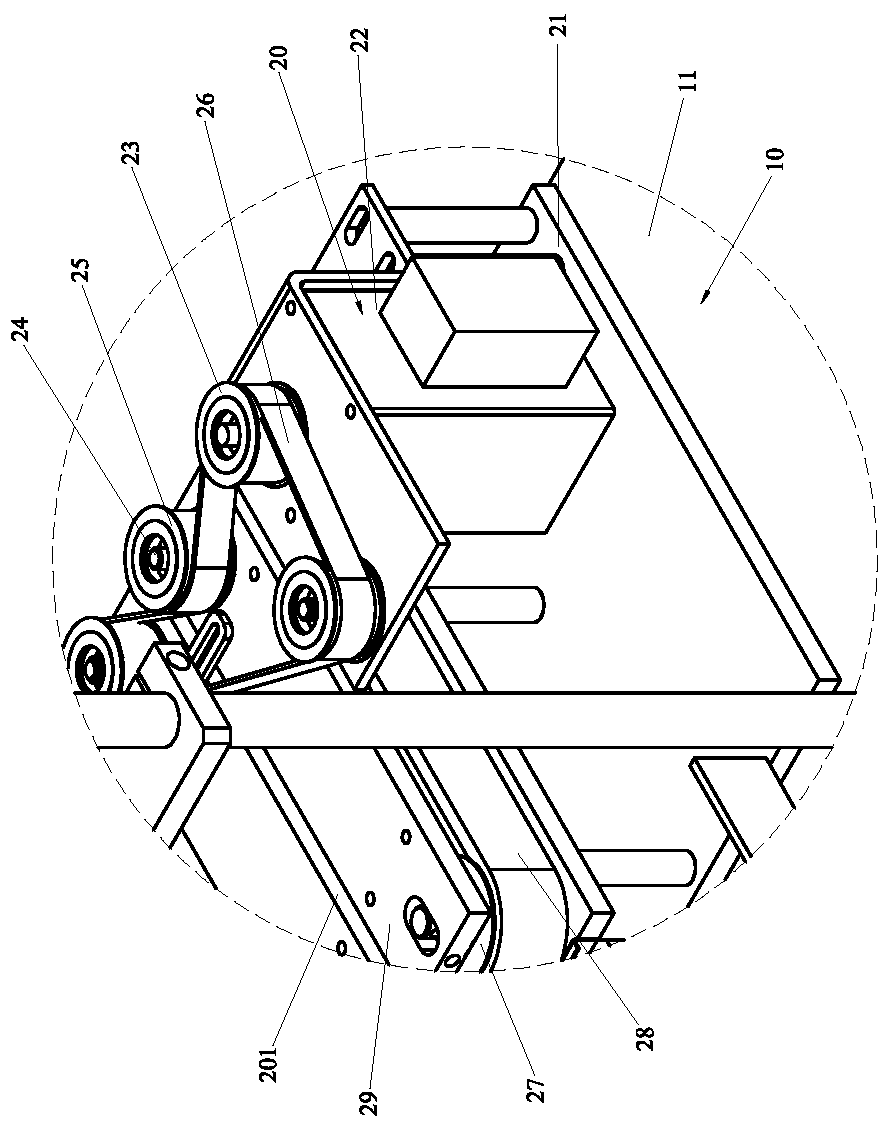

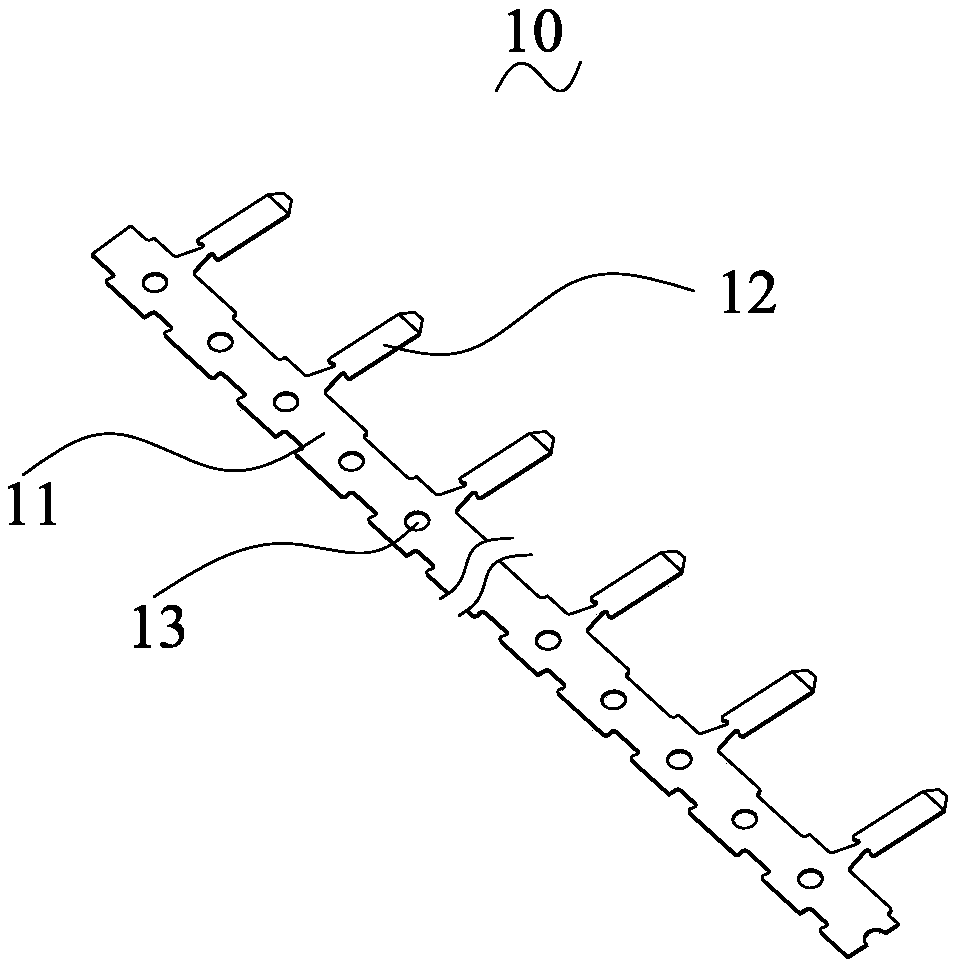

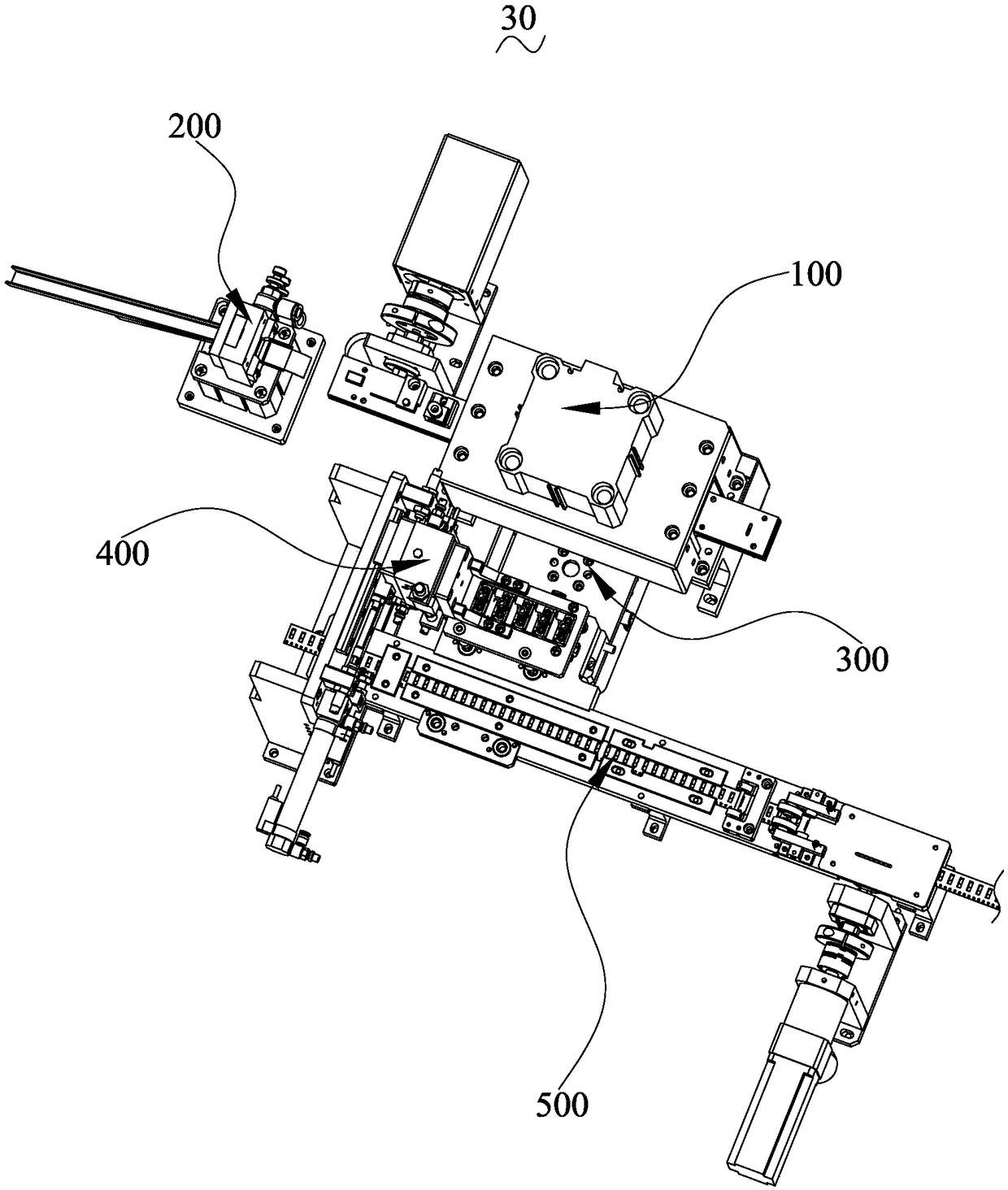

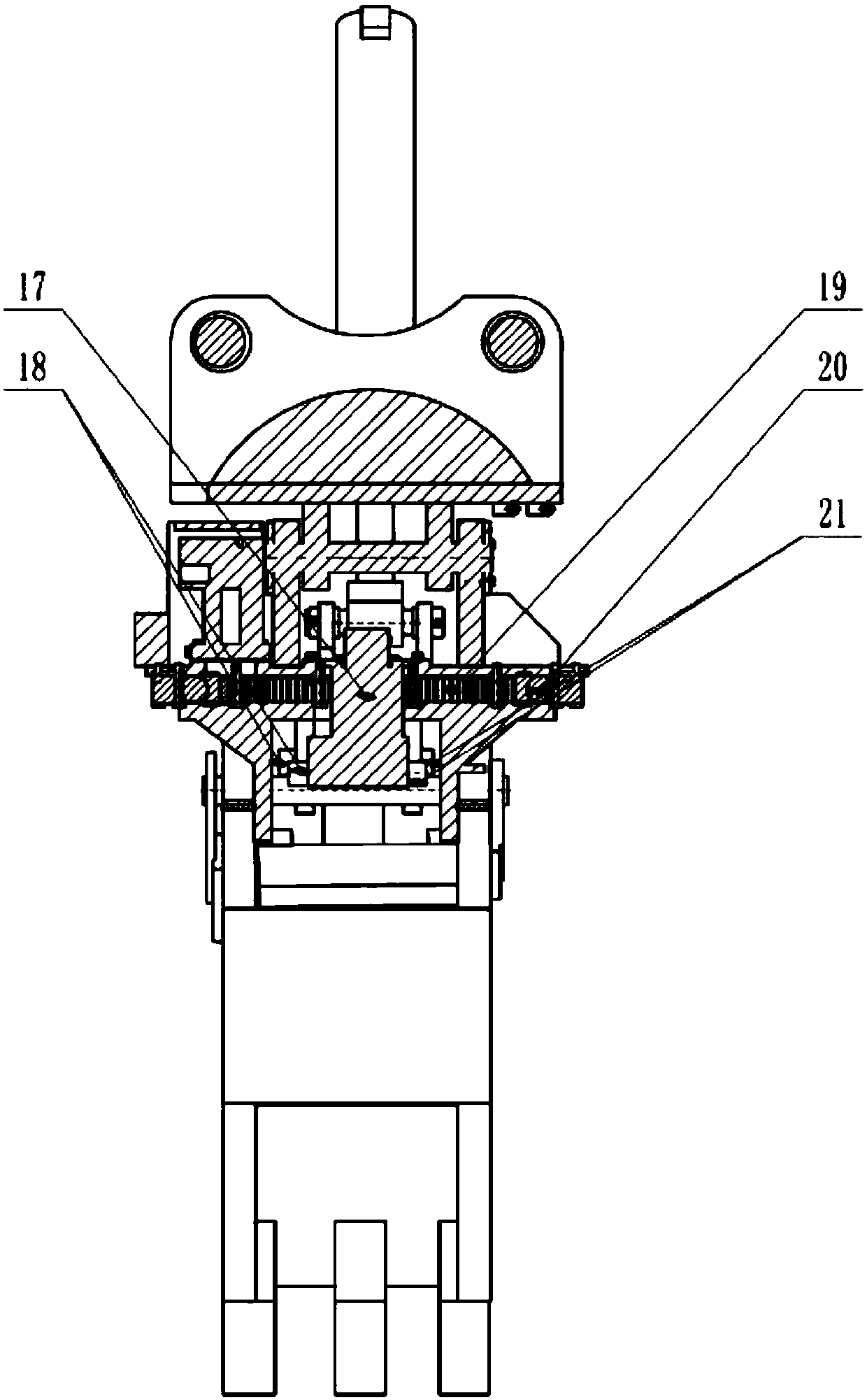

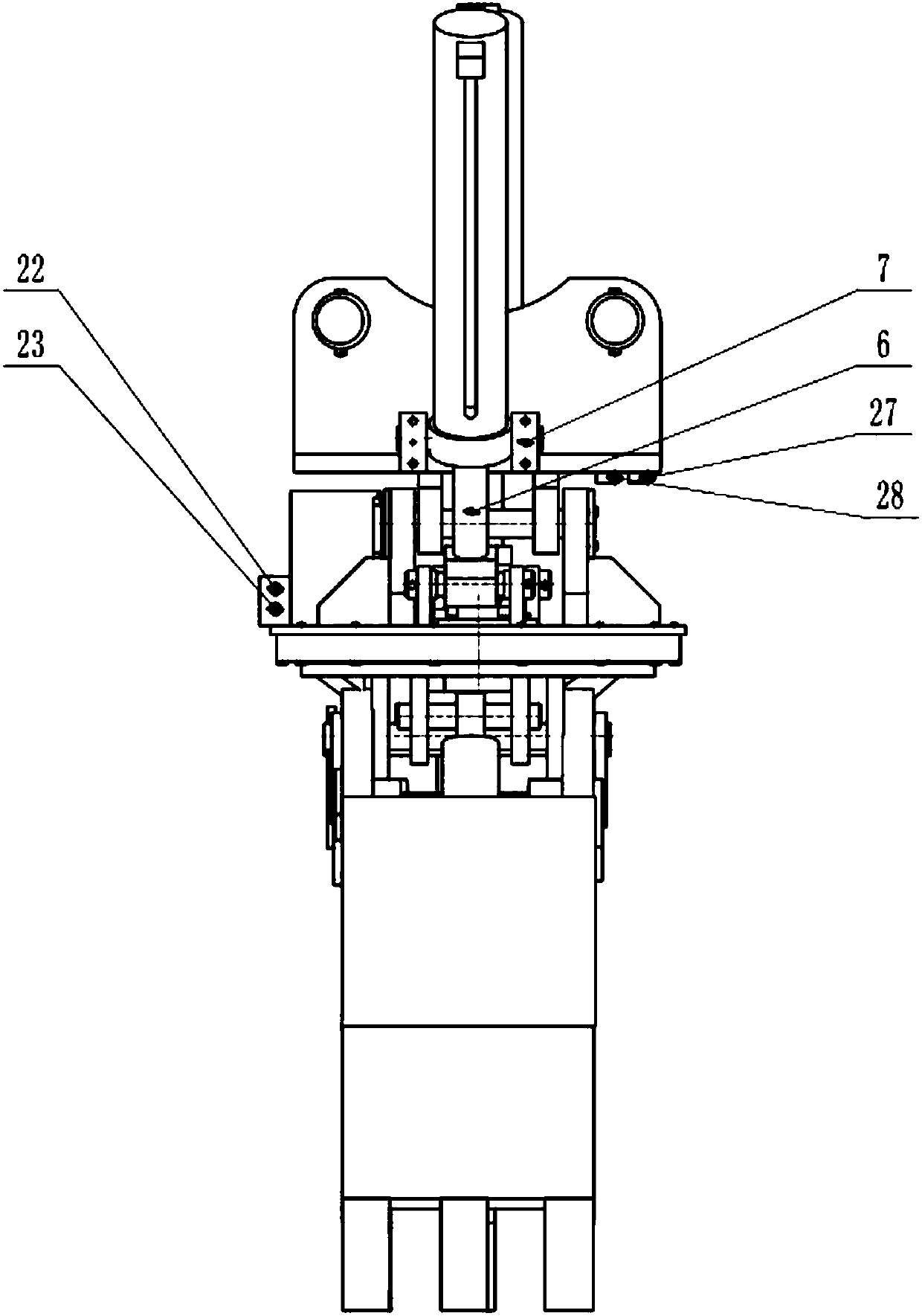

Battery positive electrode assembly mechanism and its primary lithium battery manufacturing equipment

ActiveCN109980176BImprove the level of mechanical automationImprove machining accuracyPrimary cell manufactureElectrode manufacturing processesCell fabricationEngineering

A battery positive electrode assembly mechanism and its primary lithium battery manufacturing equipment. The battery positive electrode assembly mechanism includes: a nickel mesh belt cutting device, a nickel mesh tube forming device, a tab welding device, a positive electrode material particle filling device, and a nickel mesh belt cutting device. Including nickel mesh belt feeding parts and cutters, nickel mesh tube forming device includes nickel mesh pressing parts, centering positioning column, tube pressing parts and welding parts, tab welding device includes tab feeding parts, tabs Welding parts and lug cutters, and the positive electrode material particle filling device include lifting parts and positive electrode material particle filling parts. The battery positive electrode assembly mechanism of the present invention is provided with a nickel mesh belt cutting device, a nickel mesh tube forming device, a tab welding device and a positive electrode material particle filling device, so as to be able to complete the forming and placement of the nickel mesh tube, the filling of the positive electrode particles and the tab filling. Positive electrode assembly operations such as welding, and high processing accuracy and processing efficiency have improved the mechanical automation level of battery manufacturing.

Owner:EVE ENERGY CO LTD

Variable-spacing feeding box mechanism of medical blades and medical instrument packaging equipment

InactiveCN108860746AImprove the level ofWiden or shrink the intervalPackagingPush pullMedical instruments

Owner:李雪芬

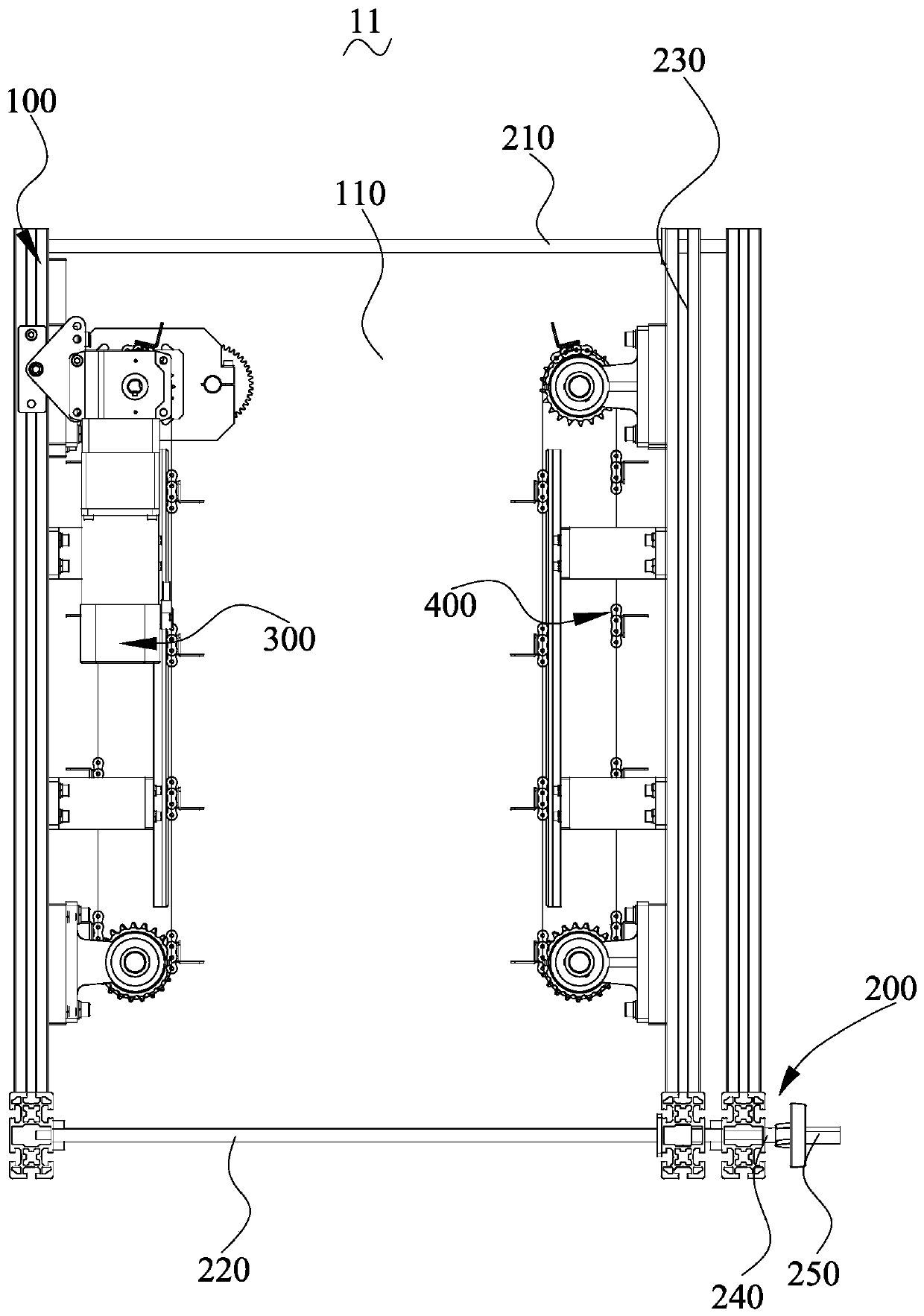

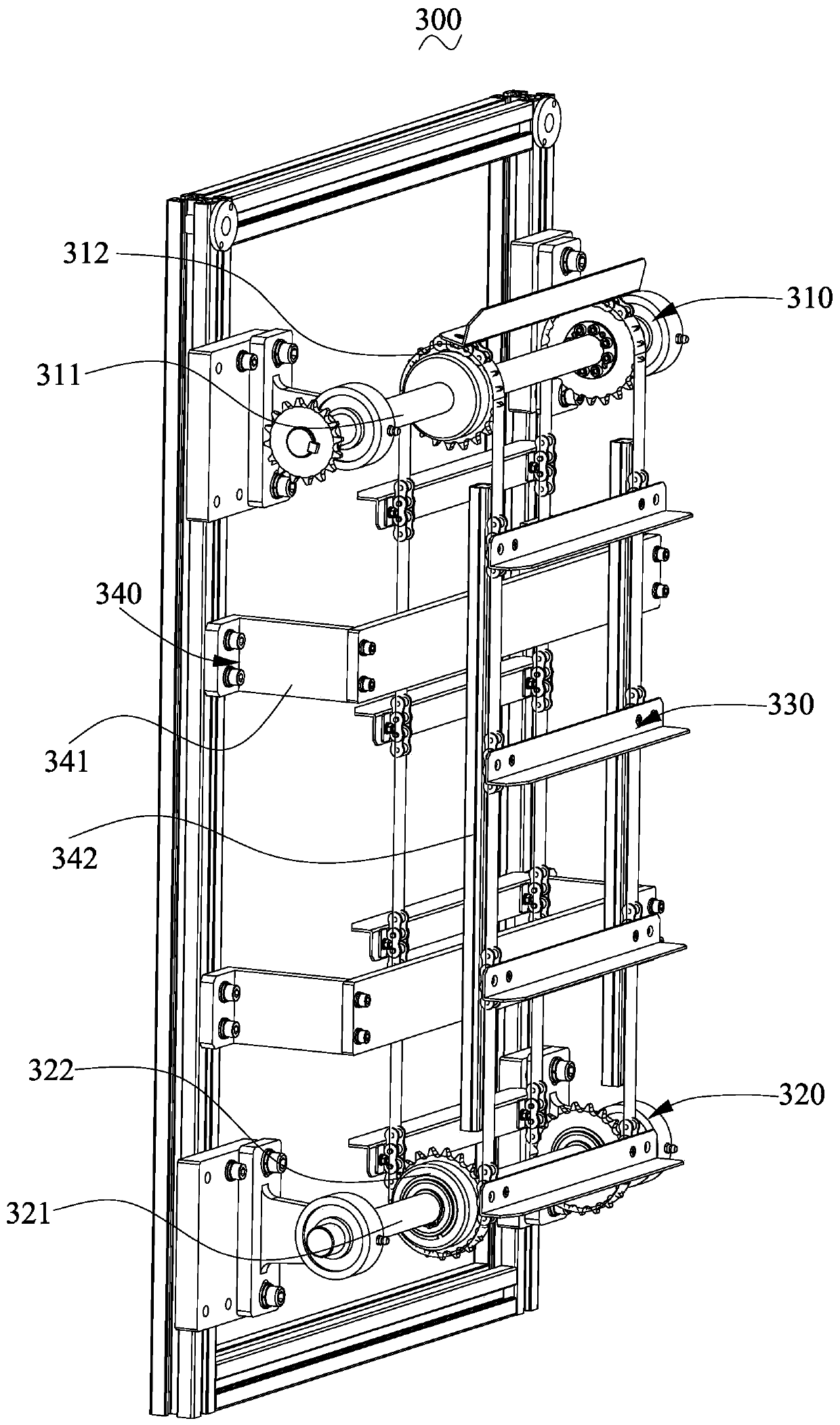

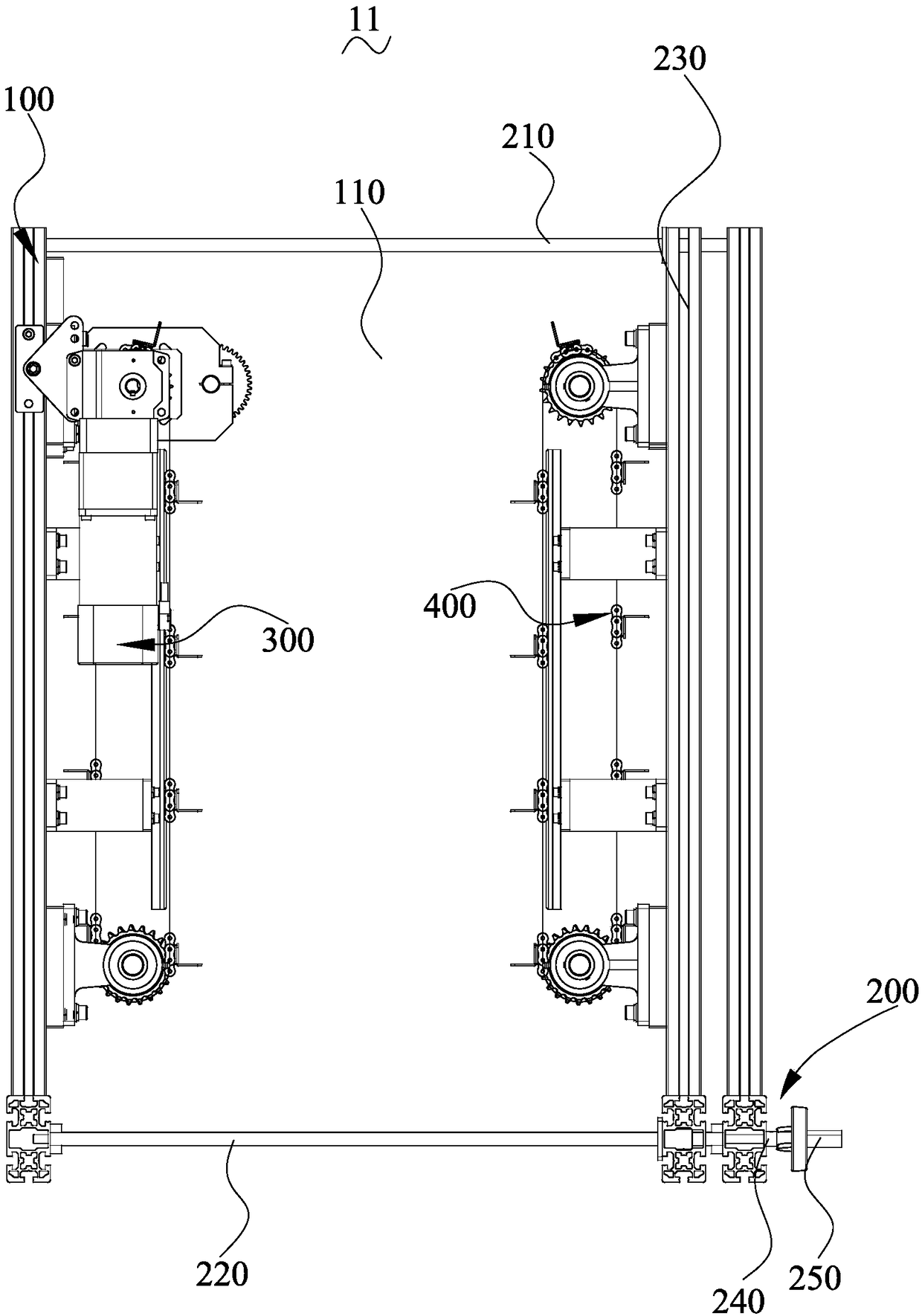

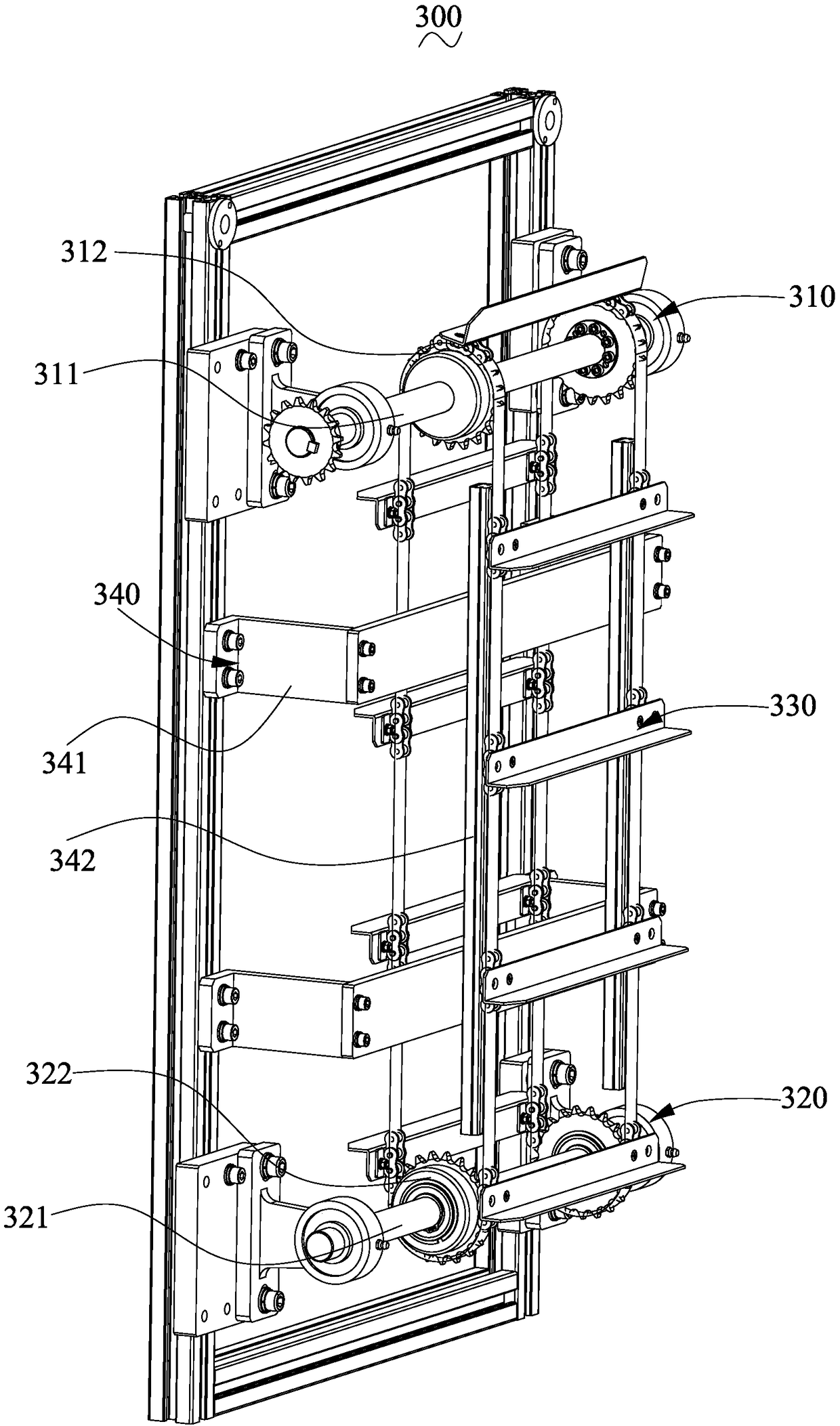

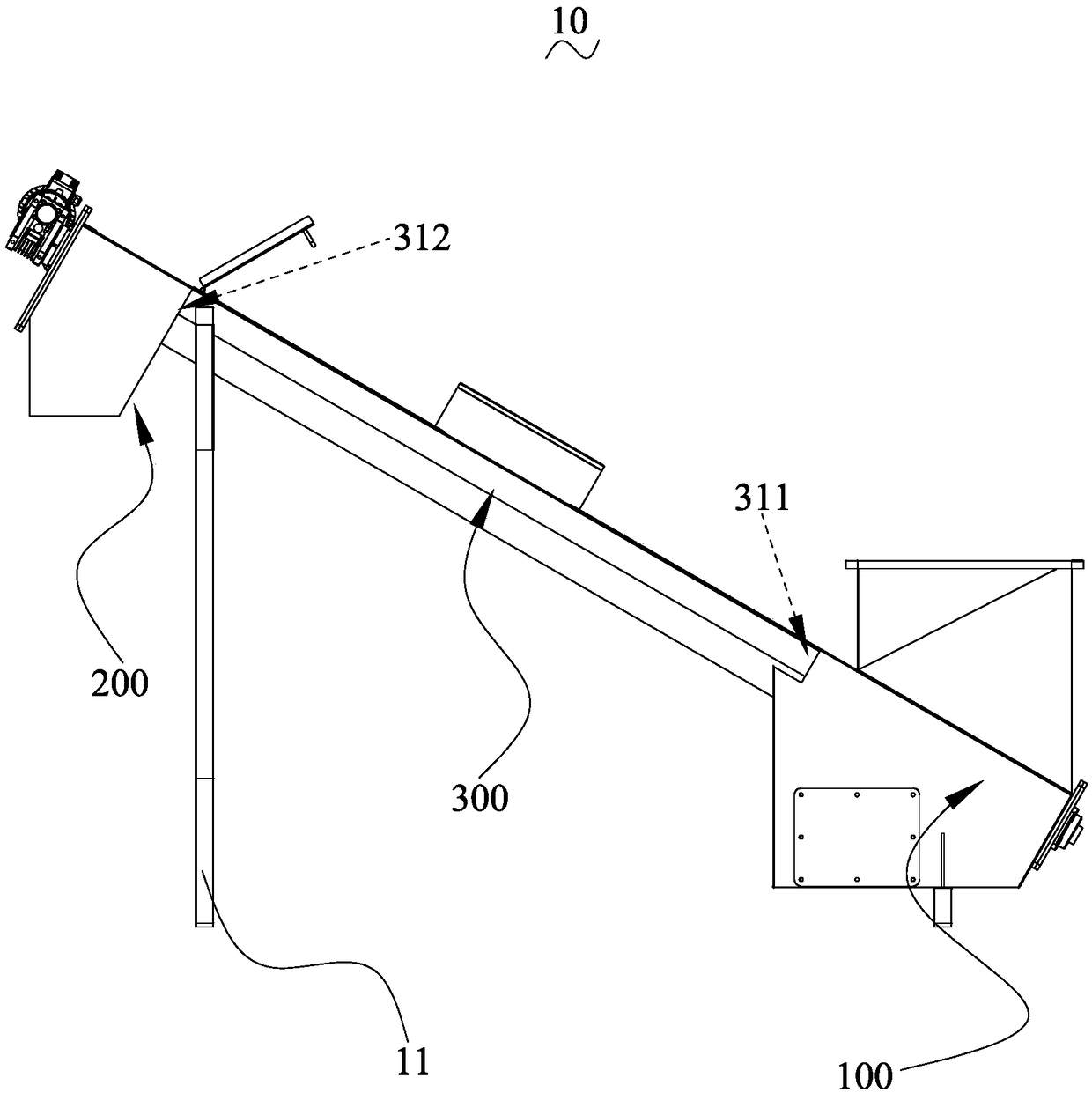

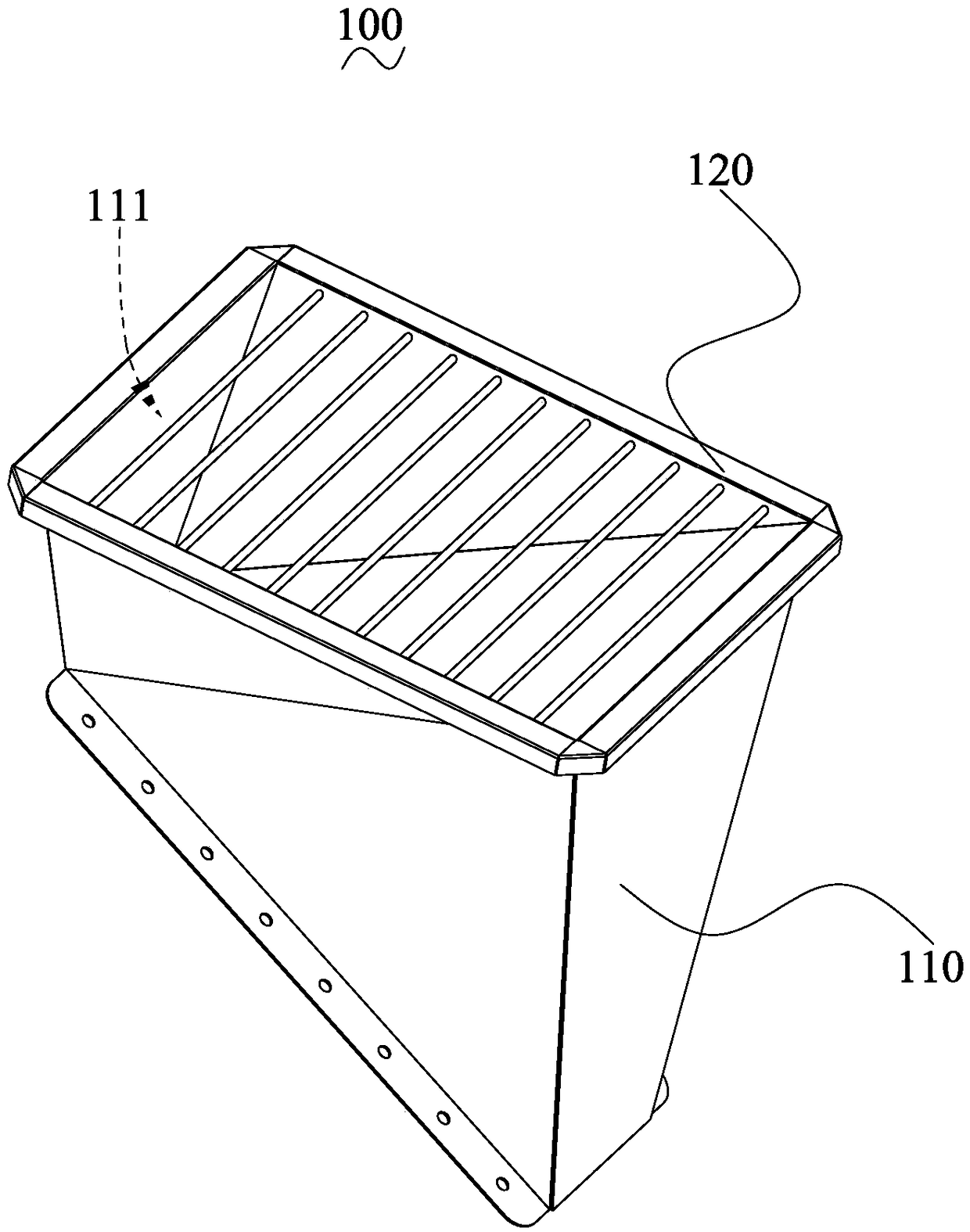

Stacking and unstacking device for conveying skids

ActiveCN104828448BImprove securityImprove the level of mechanical automationStorage devicesEngineeringDrive motor

The invention discloses a stacking and unstacking device for conveying skids. A turnover mechanism arranged on the lifting frame to be driven to support or release the conveying skid. The stacker of the present invention utilizes the drive motor to cooperate with the chain to realize the synchronous drive of the support frames on both sides, which can realize the automatic stacking and unstacking of the conveying skid, effectively improves the level of mechanical automation, saves manpower, and improves the safety of operation , improve the efficiency of stacking and unstacking, increase the stacking height, and reduce storage costs.

Owner:AUTOMOTIVE ENG CORP +1

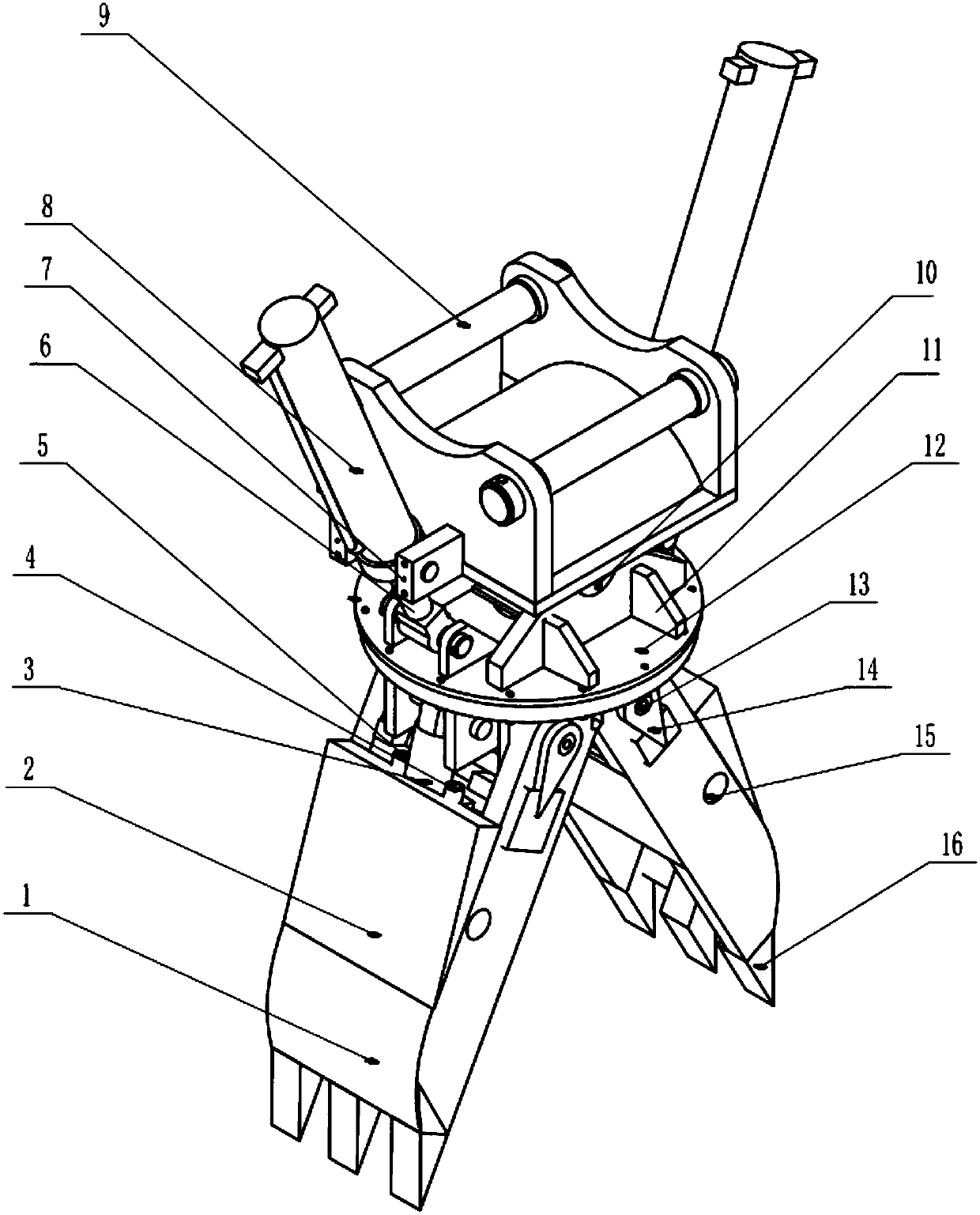

Railway sleeper single drawing and replacing machine

PendingCN110552261AGuaranteed safe operationSave time at workRailway track constructionHydraulic cylinderEngineering

The invention relates to a railway sleeper single drawing and replacing machine. The railway sleeper single drawing and replacing machine comprises a motor, manipulators and hydraulic cylinders; bearing gears are driven to rotate by the motor; a bearing is arranged on each bearing gear which drives the corresponding manipulator to rotate; a manipulator shaft is arranged on one end of each manipulator, and the other ends of the manipulators are rotatably connected to two sides of the railway sleeper drawing and replacing machine; the hydraulic cylinders are separately connected to the manipulators and control clamping or releasing of the manipulators; the tops of the manipulators are separately connected to guiding hydraulic cylinders; the electric rotary motor and the hydraulic cylinders are adopted for separately driving the manipulators to rotate and clamp; the top ends of the manipulators are provided with the guiding hydraulic cylinders and guiding hydraulic rods for controlling the manipulators to swing leftwards and rightwards, so that rotary clamping and lateral swinging are realized, and railway sleepers are drawn and replaced stably; the working time of railway sleeper drawing and replacing is shortened, and working efficiency is improved; the mechanical automation level is improved, and labor is saved; and safety operation of railways is ensured.

Owner:魏春慧

Cell tab shaping system and cell ocv testing equipment

The invention discloses an electrical core tab shaping system and an electrical core OCV tester thereof. The electrical core tab shaping system comprises a tab fixing device and a tab smoothing device. The tab fixing device comprises a tab fixing driving part and a table fixing pressure block, the tab fixing driving part drives the table fixing pressure block to move reciprocally, the tab smoothing device comprises a first clamping roller, a second clamping roller, a tab clamping driving part and a tab pulling driving part, the tab clamping driving part drives the first clamping roller to be close to or far from the second clamping roller, and the tab pulling driving part drives the first and second clamping driving parts to move reciprocally. The electrical core tab shaping system shapesa tab of an electrical core and smoothes the tab, ensures the reliability of subsequent test stations, and improves the total mechanical automatic level of equipment.

Owner:HUIZHOU JINYUAN PRECISION AUTOMATION EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com