Waste band recycling mechanism and medical instrument packaging device thereof

A technology of recycling mechanism and waste belt, applied in the field of medical device production, can solve the problems of difficult recycling and processing, and achieve the effect of improving the level of mechanical automation and facilitating recycling and processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

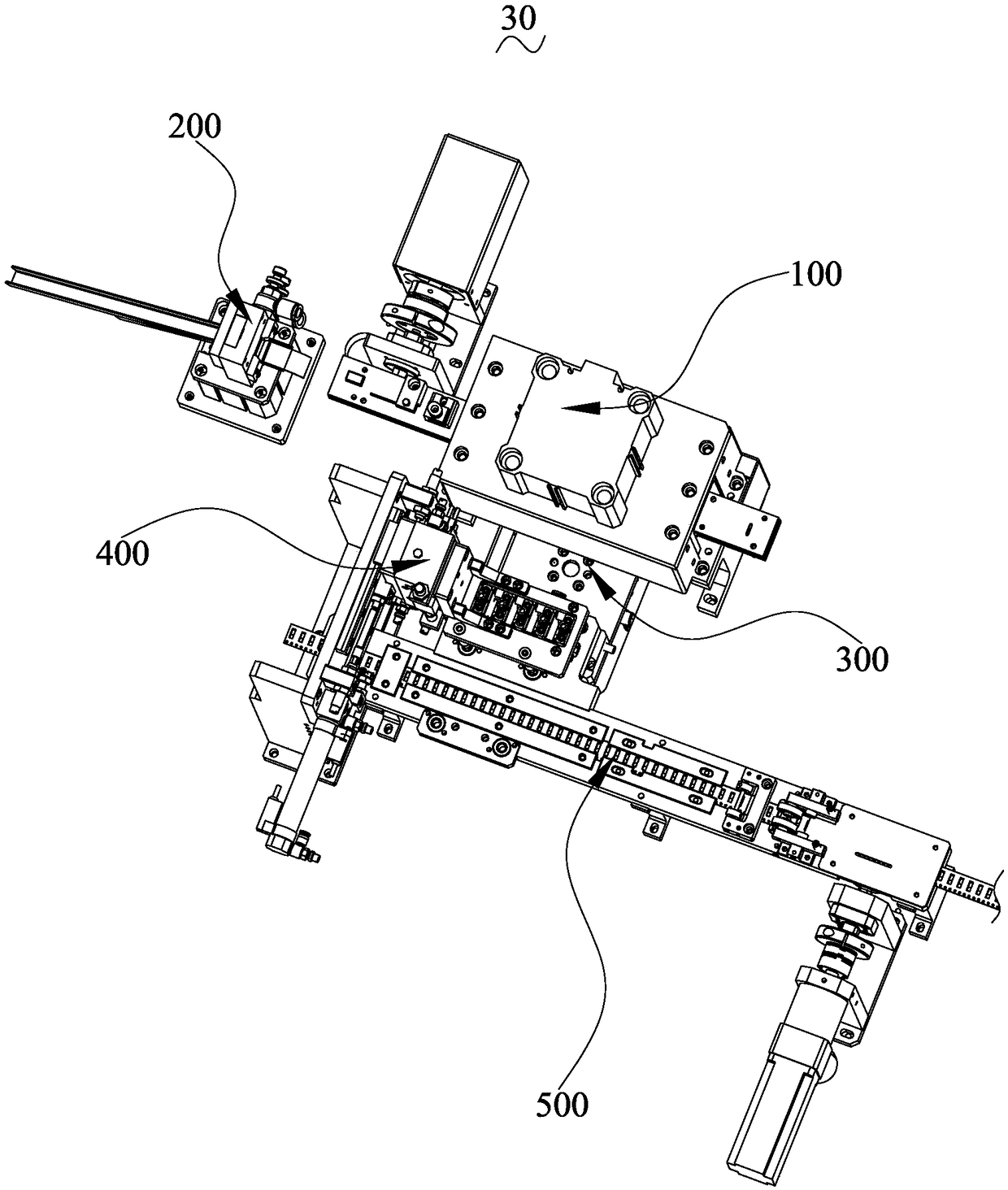

[0043] Such as image 3 As shown, the present invention discloses a medical device packaging device 30, including: a medical blade cutting mechanism 100, a waste belt recovery mechanism 200, a medical blade transfer mechanism 300, a medical blade variable distance feeding box mechanism 400, and a medical blade packaging mechanism 500 .

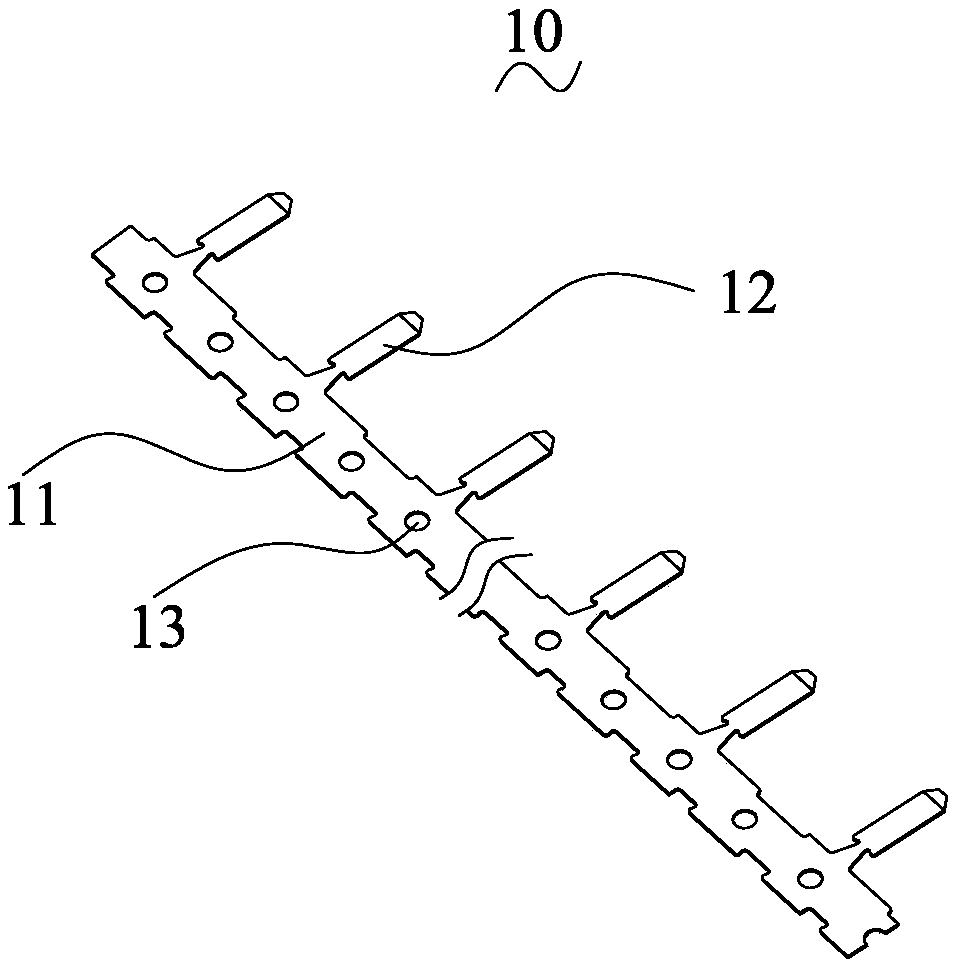

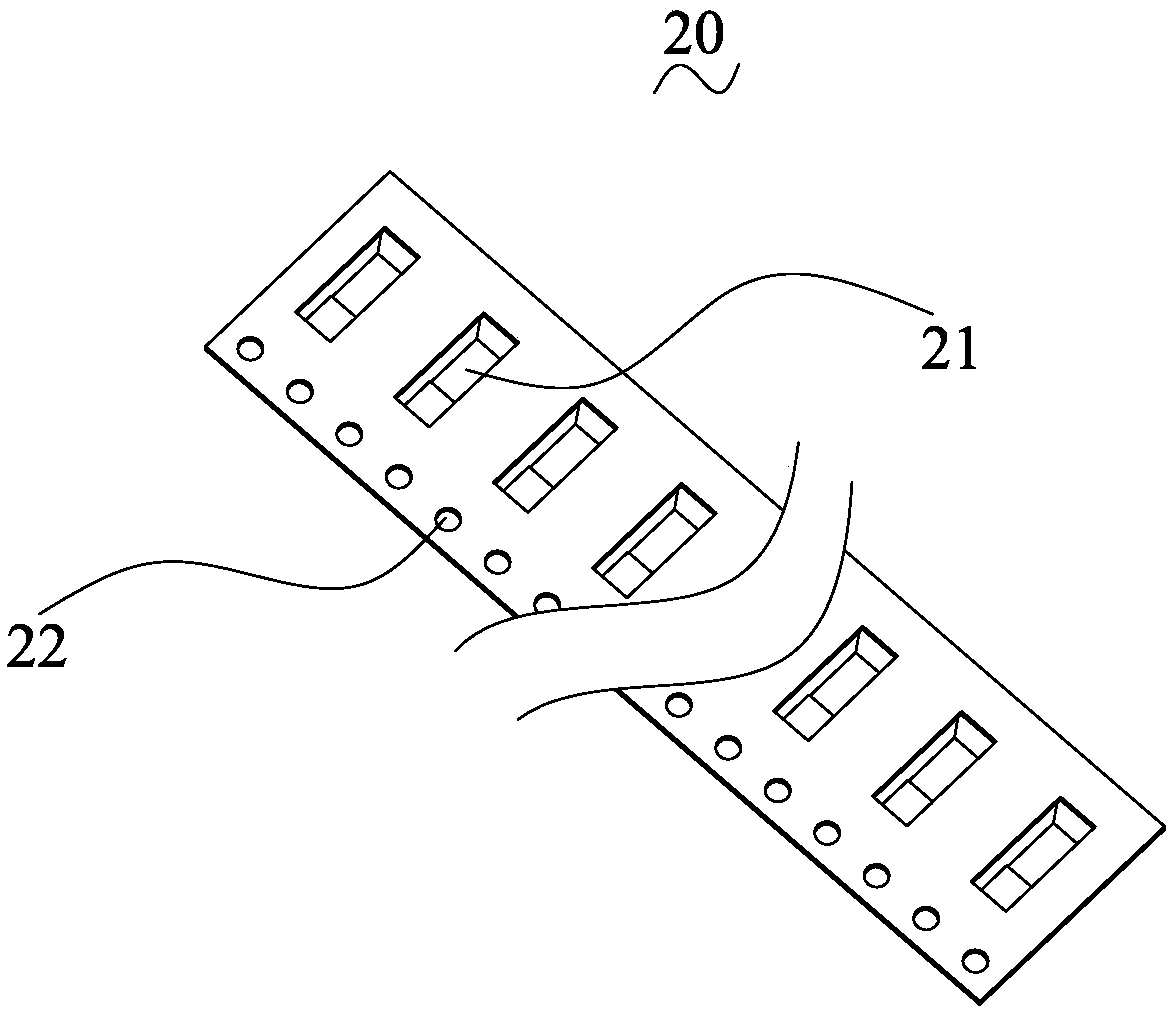

[0044] A plurality of medical blades 12 are successively arranged at intervals along the extension line direction of the material belt 11, and the medical blade cutting mechanism 100 is used to cut the medical blades 12 from the material belt 11; After leaving, the original material belt 11 is no longer connected with the medical blade 12, so the material belt 11 has just formed a waste material belt, and the waste material belt recovery mechanism 200 is used to cut and recycle the continuous uninterrupted waste material belt; The medical blade transfer mechanism 300 is used to take out the medical blade 12 from the medical blade cutting mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com