Railway sleeper single drawing and replacing machine

A railway rail and replacement machine technology, applied to roads, tracks, laying tracks, etc., can solve the problems of high labor intensity, difficulty in pulling out sleepers, and difficulty in replacing bad sleepers, so as to increase the level of mechanical automation, increase work efficiency, The effect of ensuring safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

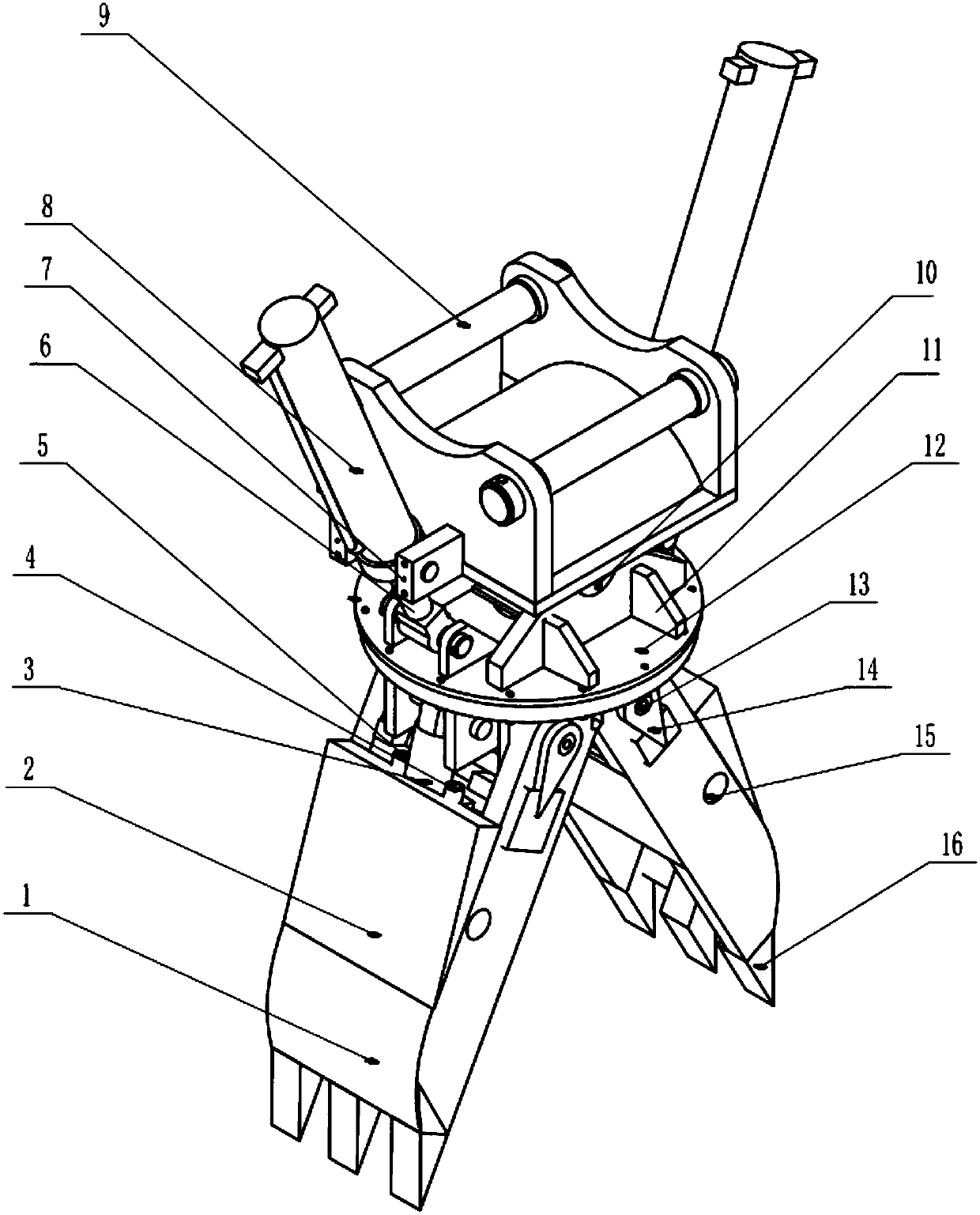

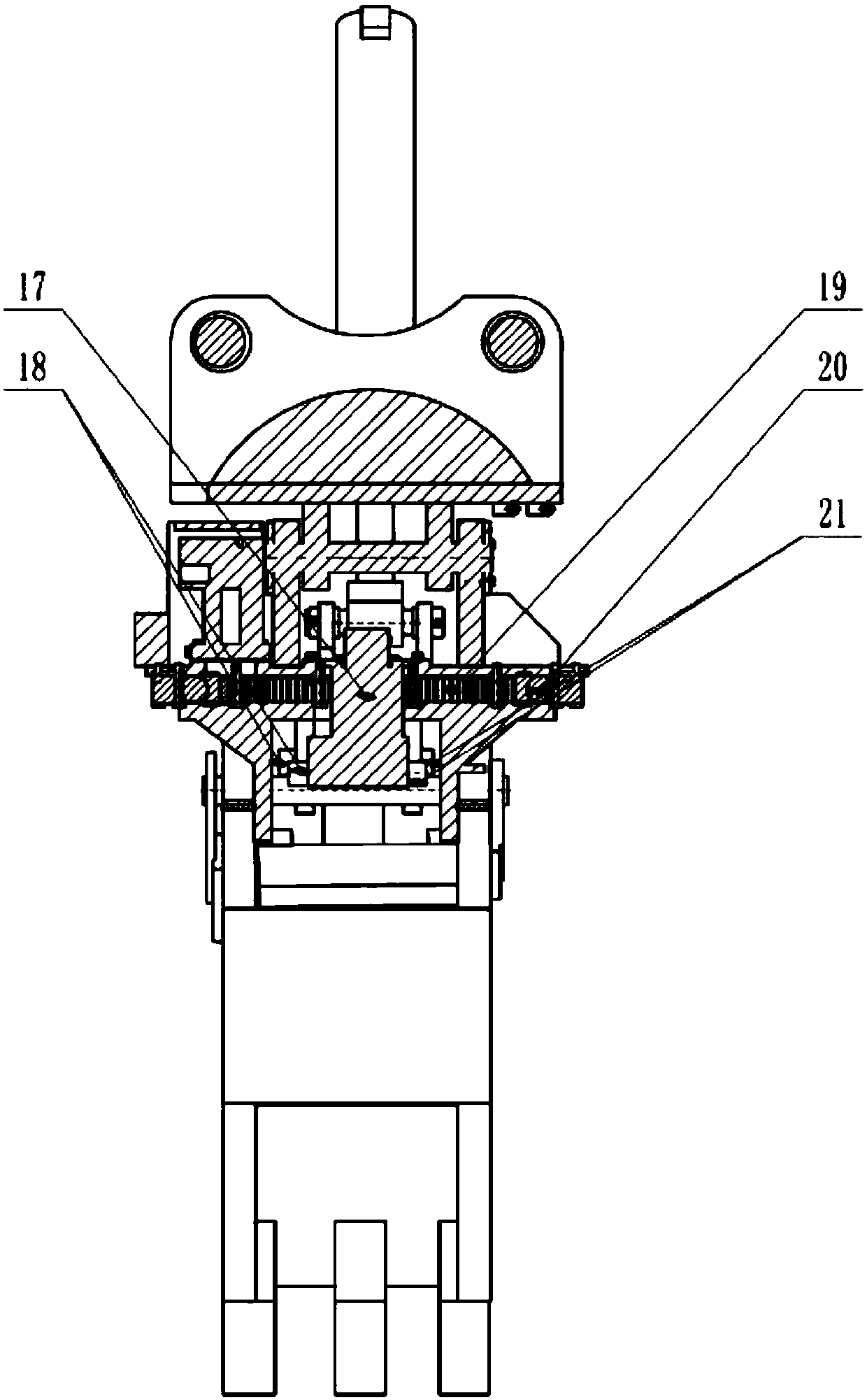

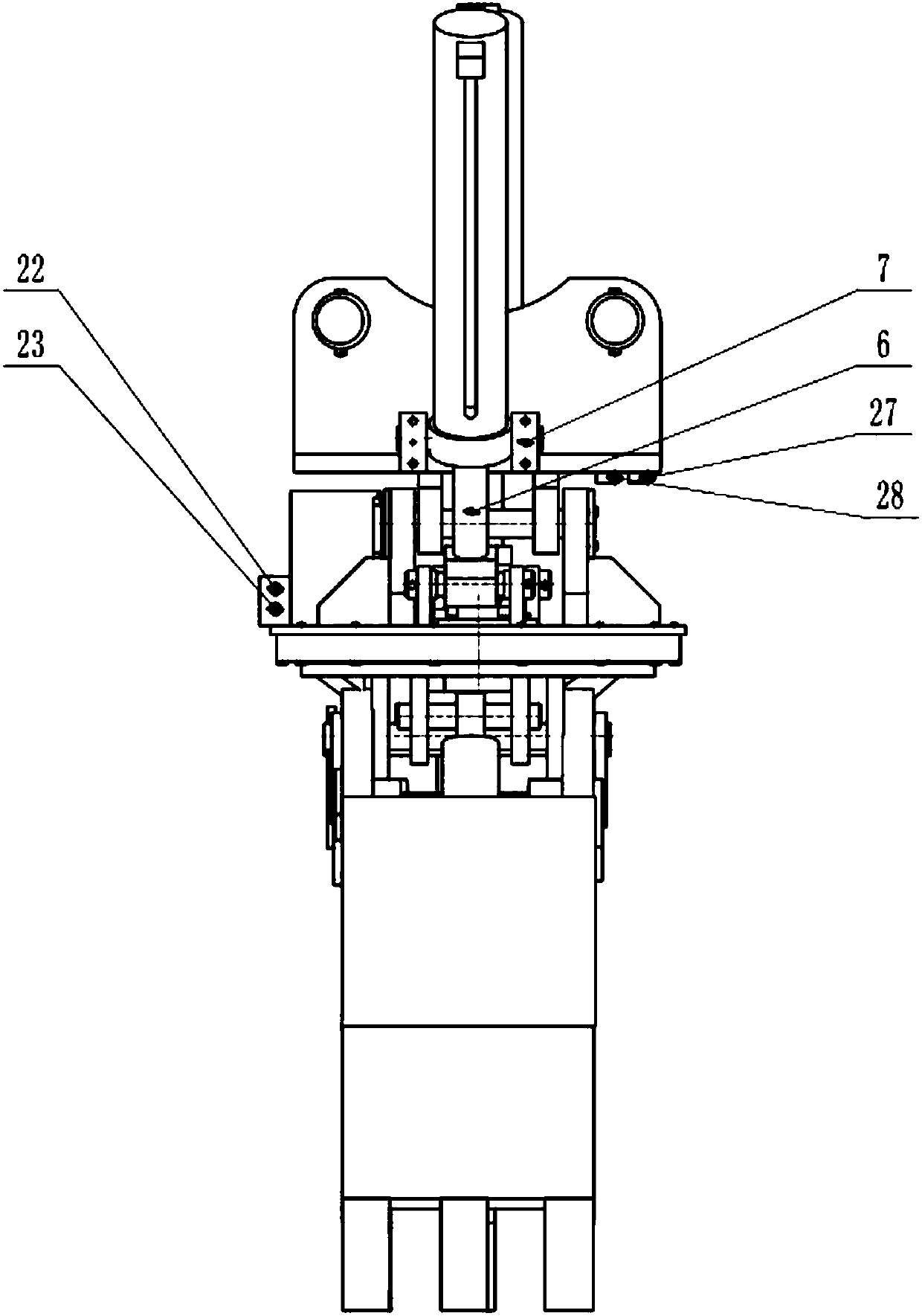

[0019] Such as Figure 1 to Figure 3 As shown, the specific embodiment of the present invention comprises motor, manipulator 1 and hydraulic cylinder 3; Motor drives bearing gear 19 to rotate, and bearing gear 19 is provided with bearing 20, and drives manipulator 1 to rotate, and manipulator 1 one end is provided with manipulator shaft 13, The other end is rotatably connected to both sides of the single railway sleeper replacement machine. The hydraulic cylinders 3 are respectively connected to the manipulator 1 to control the clamping or releasing of the manipulator 1. The top of the manipulator 1 is connected to the guiding hydraulic cylinder 8 respectively.

[0020] Further, there are two guiding hydraulic cylinders 8, which are respectively connected to the guiding hydraulic rods 6, and the guiding hydraulic rods 6 are respectively connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com