Automatic plate-shaped part feeding device and method for robot welding

A robot welding and automatic feeding technology, which is applied to auxiliary devices, welding equipment, conveyor objects, etc., can solve the problems of inability to realize automatic production, low production efficiency, and high manual labor intensity, so as to improve the level of mechanical automation and improve efficiency , Reduce the effect of manual labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

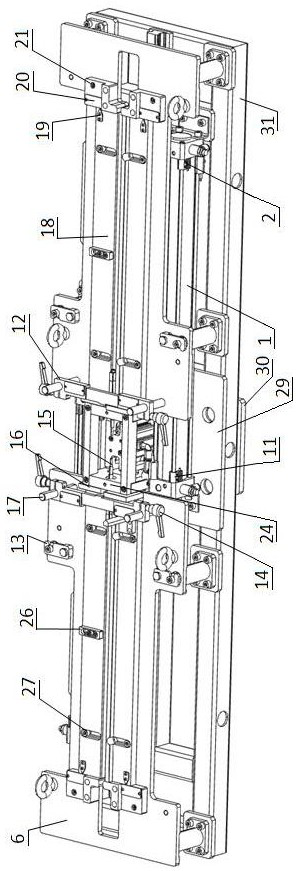

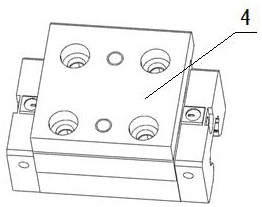

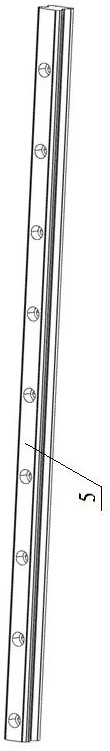

[0047] An automatic feeding device for plate-shaped parts for robot welding, which consists of: a support frame, a support plate 29 is fixed at the middle position above the support frame 31, and the support plate is connected to the guide rail 5 through screws, and the support plate A jacking cylinder 8 is fixed at the middle position of the guide rail, and a propulsion slider 4 is installed on the guide rail. The propulsion slider is connected with one end of the axial cylinder 1 through the connecting plate 3, and the axial cylinder is fixed on the On the support frame described above, a jacking block 23 is installed at the front end of the pushing slider, a jacking assembly 7 is connected above the jacking cylinder, and jacking blocks 9 and 2 are respectively installed on both sides of the jacking assembly. The adjustment plates 18 are arranged side by side in a group with grooves formed between them, and are respectively installed on the cover plate 6 by bolts. One end of ...

Embodiment 2

[0049] According to the automatic feeding device for plate-shaped parts for robot welding described in Embodiment 1, the lower part of the cover plate is connected to the support frame through a set of support columns 28, and the fixed frame 24 is installed in the middle of the support plate , positioning plates 12 are respectively installed on both sides of the fixed frame, and guide shafts 17 are installed at both ends of the plane on the positioning plate, and the side of the positioning plate is screwed to the adjustable position tightening handle 14, and the guide shafts are installed on the cover plate 6 on.

Embodiment 3

[0051] According to the automatic feeding device for plate-shaped parts for robot welding described in Embodiment 2, a group of plate-shaped parts are placed in the groove formed between the adjustment plate and the cover plate, and the bolts are passed on the cover plate Connected with the fixing device 13, two pneumatic connectors A22 are installed on the jacking cylinder, the pneumatic connector B32 is installed on the end of the axial cylinder, and the backing plate 30 is installed in the middle of the bottom of the support frame.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com