Storage device for textile machine

A material storage device and textile machinery technology, applied in the field of storage silos, can solve the problems of increasing the labor intensity of workers, unfavorable protection of finished fabrics, and easily soiling roll fabrics, etc., achieving simple structure, satisfying use requirements, and saving occupation land area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The content of the present invention will be described below in conjunction with specific embodiments.

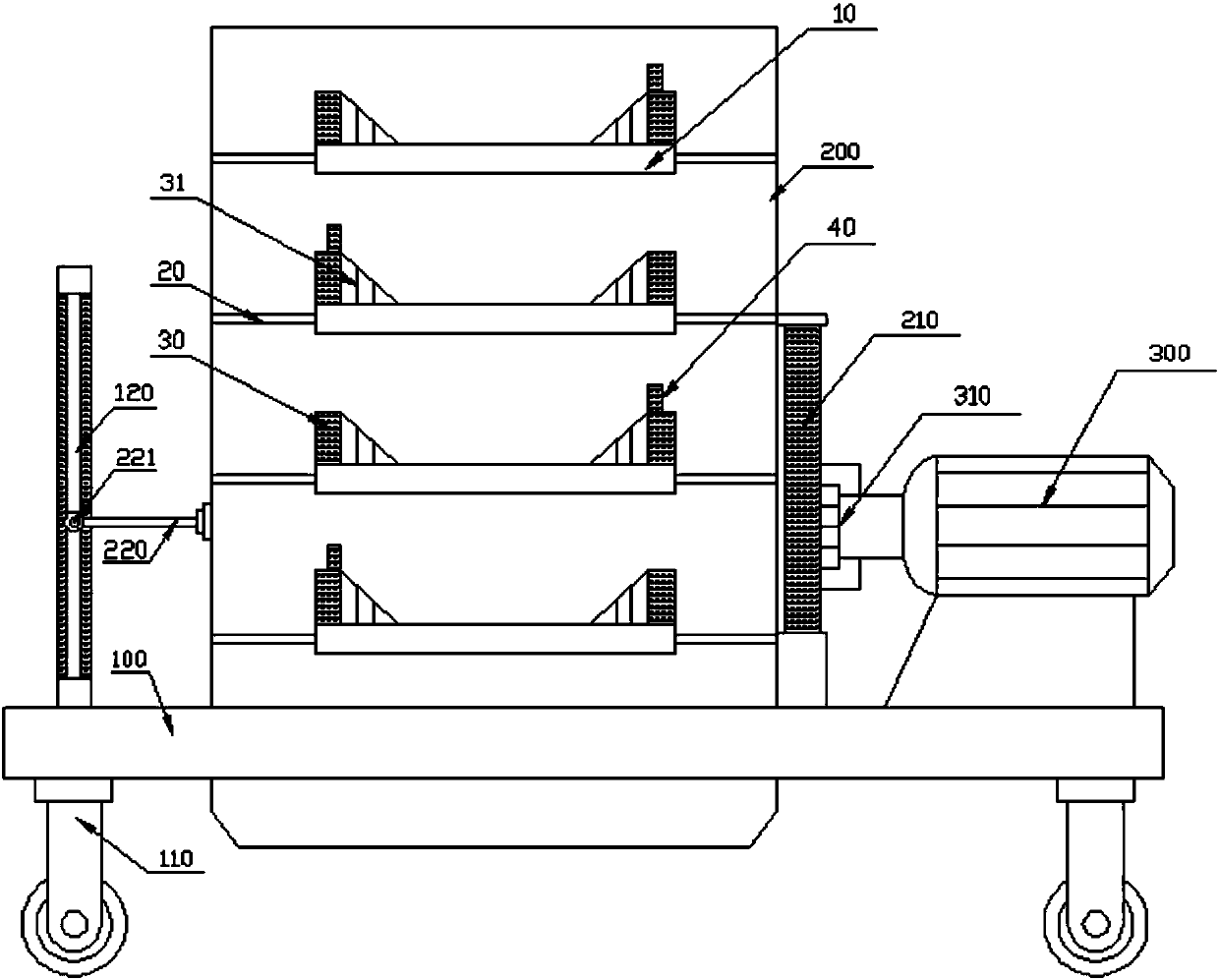

[0015] Such as figure 1 with figure 2 As shown, it is a structural schematic diagram of the storage device for textile machinery according to the present invention.

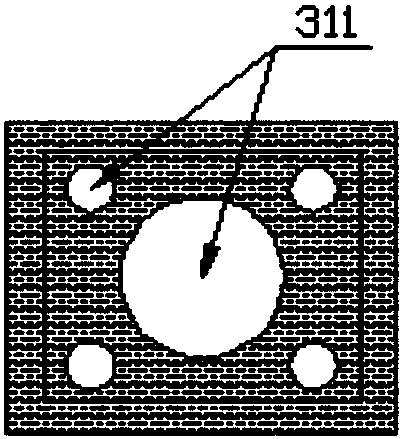

[0016] The storage device for textile machinery according to the present invention includes a base 100 provided with a universal wheel 110, a storage bin 200 is movable on the base 100, and a sprocket 210 is provided on one side of the storage bin 200, adjacent to the chain The base 100 on one side of the wheel 210 is provided with a stepper motor 300, the stepper motor 300 is provided with a cam gear 310 that cooperates with the sprocket 210, and the other side of the storage bin 200 is provided with a support rod 220, and the free movement of the support rod 220 There is a pulley 221 at the end, and the base 100 adjacent to the support bar 220 is vertically provided with a slide rail 120 for use in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com