Iron section removing device and method used during iron section sand cladding casting of shuttle-type top plate

A technology of sand-covered iron casting and cleaning device, which is applied in the direction of casting molding equipment, cleaning/processing machinery of casting mold materials, molding machines, etc., to achieve the effects of improving utilization rate, reasonable structure design, and facilitating logistics layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

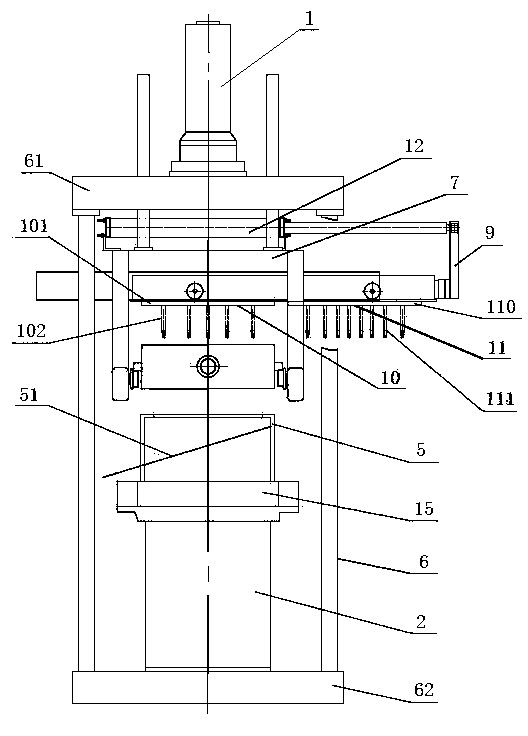

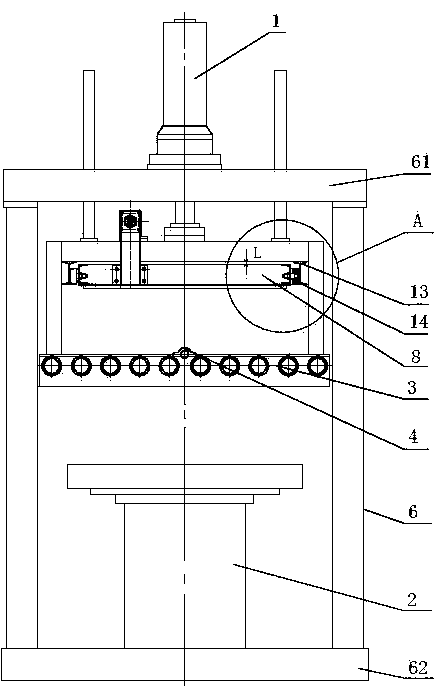

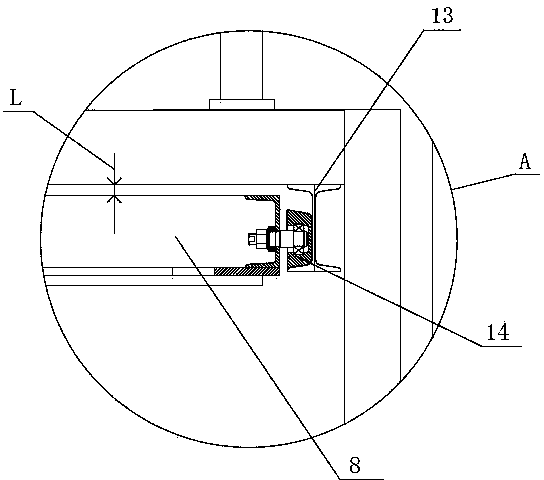

[0029] see Figure 1-Figure 7 , the present invention mainly includes ejection cylinder 1, vibrating device 2, iron type conveying roller table 3, iron type positioning device 4, sand falling bucket device 5, frame 6, moving beam 7, trolley body 8, trolley connecting plate 9 , Upper iron type ejector device 10, lower iron type ejector device 11, trolley cylinder 12, trolley guide rail 13, trolley moving wheel 14, workbench 15, upper iron type 16, lower iron type 17, upper top plate 101, upper top Rod 102 , lower top plate 110 , lower ejector rod 111 , slide plate 51 , upper beam 61 and base 62 .

[0030] The frame 6 in the present embodiment comprises an upper beam 61 and a base 62. The ejecting cylinder body 1 ado...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com