Automatic container identifying and positioning method

A technology of automatic identification and positioning method, applied in the field of automation, can solve the problems of high operation requirements and time-consuming of drivers, and achieve the effect of simple processing, high efficiency and improved efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

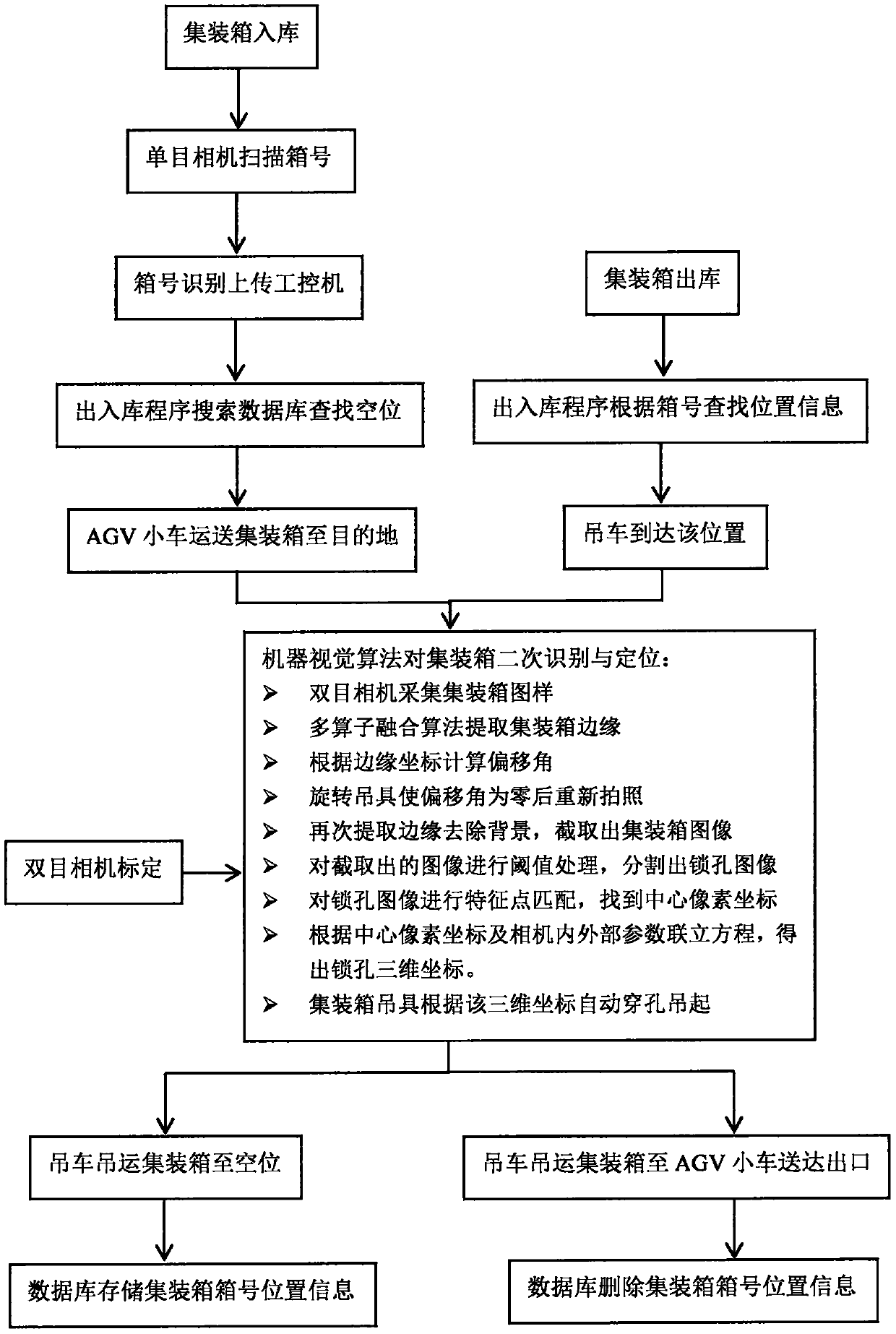

[0014] The specific implementation process of the present invention is described as follows below:

[0015] A method for automatic container identification and positioning, comprising an industrial computer, a binocular camera, a monocular camera, and a light source. The industrial computer is installed with a WinCC process monitoring system application program with a SQL Server database, and the binocular camera is installed on the container spreader. It is used for secondary identification and positioning of the container. The monocular camera is installed at the storage place of the container to automatically identify the number of the storage container. The light source and the camera are installed together, and the brightness can be automatically adjusted according to the change of the ambient light.

[0016] Specifically include the following steps:

[0017] Step 1: Adjust the focal length and aperture of the binocular camera and the monocular camera respectively, and ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com