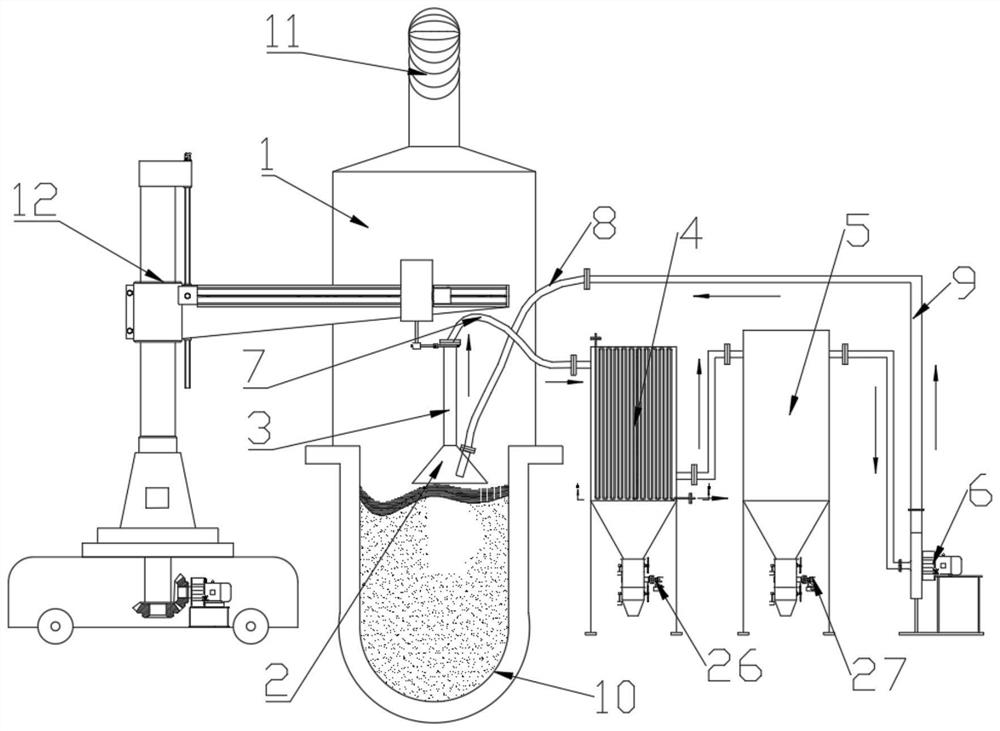

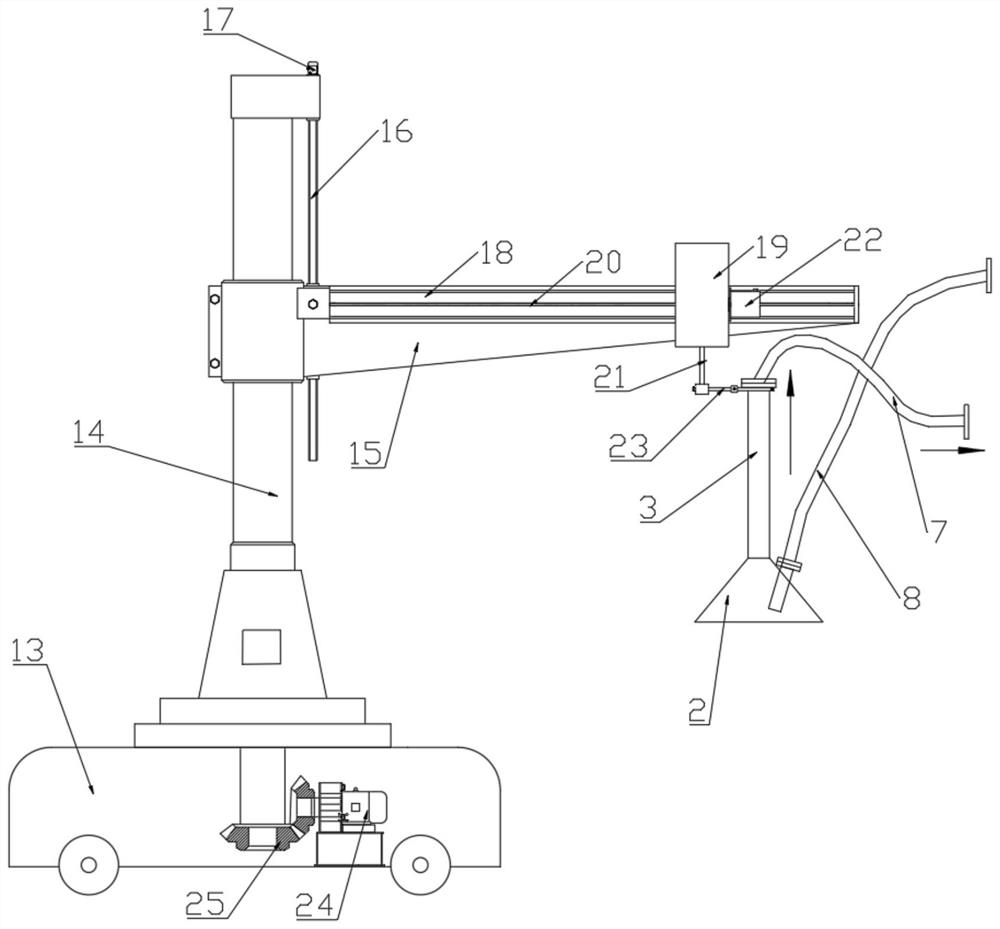

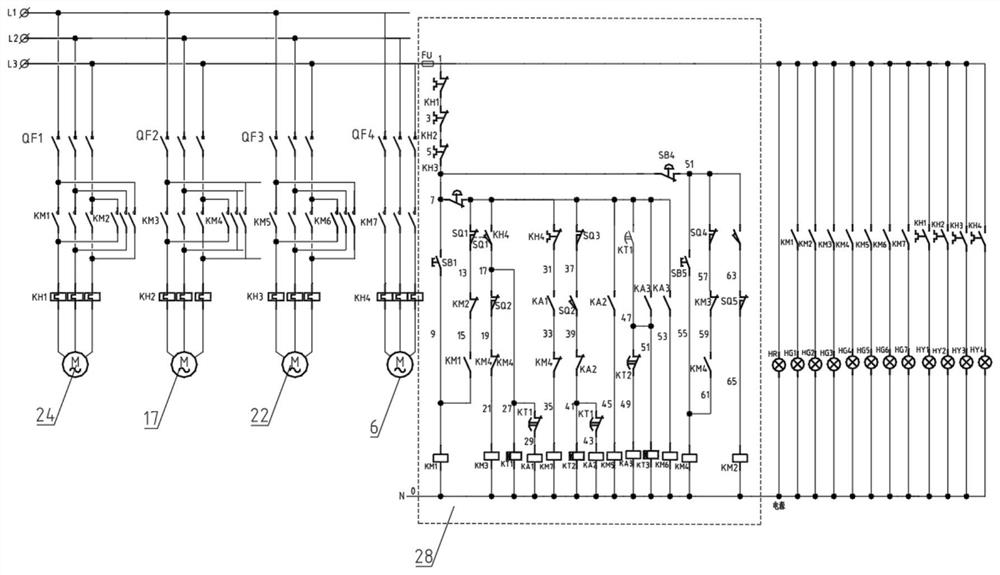

A device for removing low-density scum in metal refining process

A metal refining and low-density technology, used in metal processing equipment, manufacturing tools, mechanical cleaning, etc., can solve problems such as unfavorable physical and mental health of employees, high work intensity, low efficiency, etc. The level of automation and the effect of reducing the cost of production operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] Using this device to remove impurities from crude tin as an example, the output of crude tin is 50t / shift, and the tin content of the slag produced by the crude tin removal is 10t / shift. The following is the percentage of high-density slag and scum produced by tin-containing slag in each process:

[0026]

[0027] According to the statistics in the above table, each shift produces 4.71t of high-density slag and 5.29t of low-density slag. If working in three shifts, the high-density slag produced every day is 14.13t; the low-density slag is 15.87t.

[0028] The effective operation time is 300 days per year, and the total amount of high-density slag produced is: 14.13×300=4239t, the tin content of high-density slag is 60% to 65%, and it is sent to centrifuges and other processes for processing; low-density slag: 15.87×300 = 4761t, the tin content of the low-density slag is about 40% to 50%, and it is returned to the metallurgical furnace for secondary treatment.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com