Improved low-temperature rectisol and improved low-temperature rectisol device

A low-temperature methanol washing and improved technology, which is applied in the process of purifying water gas and water gas purification process, can solve the problems of high production operation cost, large amount of circulating methanol, and large investment in equipment, so as to reduce production operation cost and reduce Pipeline and equipment size, the effect of reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

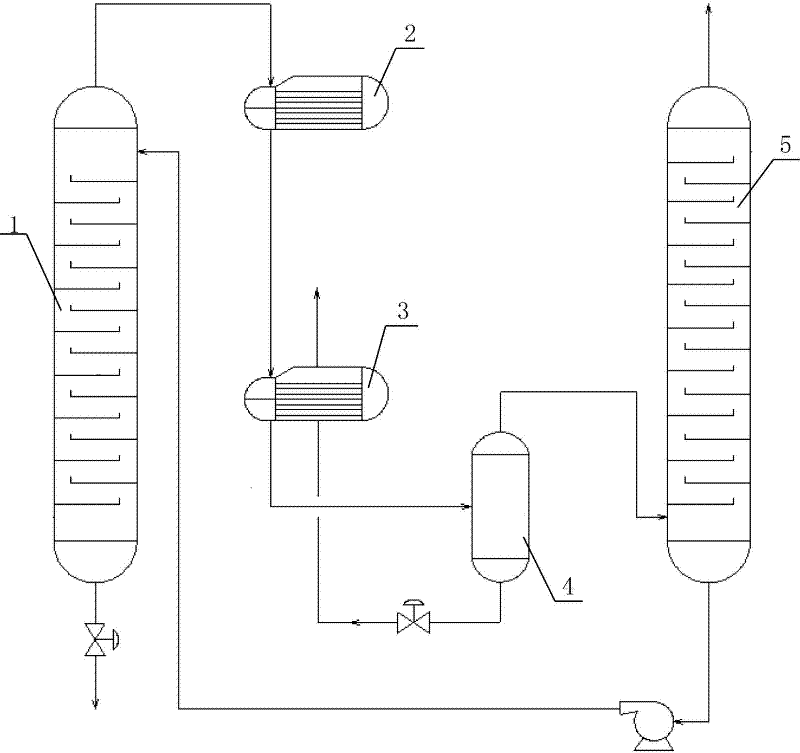

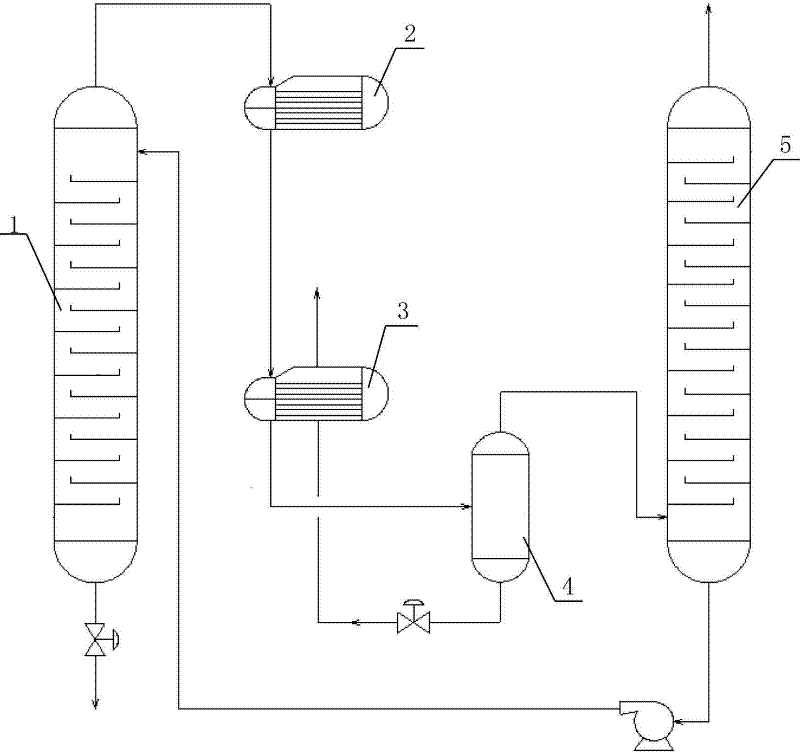

[0020] The device structure of the present invention is as figure 1 Shown: a device for low-temperature methanol washing, including a sulfide absorption tower 1, the sulfide absorption tower 1 is connected to a process gas quencher 2, and the process gas quencher 2 is connected to a carbon dioxide quencher 3. A carbon dioxide separation tank 4 is arranged between the chiller 3 and the carbon dioxide absorption tower 5. The carbon dioxide separation tank 4 communicates with the carbon dioxide chiller 3 through pipelines, and the carbon dioxide absorption tower 5 communicates with the sulfide absorption tower 1 through pipelines.

[0021] The principle of the present invention is as follows: firstly, the sulfide is removed, and the process gas after the sulfide removal is cooled to liquefy part of the carbon dioxide, and then the liquid carbon dioxide is separated by a separation device. Part of the carbon dioxide remaining in the process gas is removed by using methanol. Due t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com