Reinforcement protective cover cushion block fixing method

A technology of reinforcing steel protective layer and fixing method, applied in construction, building structure, processing of building materials, etc., can solve problems such as too late to correct, can not be corrected, can not be corrected, etc., to speed up construction progress, save project investment, Significant technical and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] combine figure 1 , figure 2 and image 3 , a method for fixing steel bar protective layer pads, comprising the following steps:

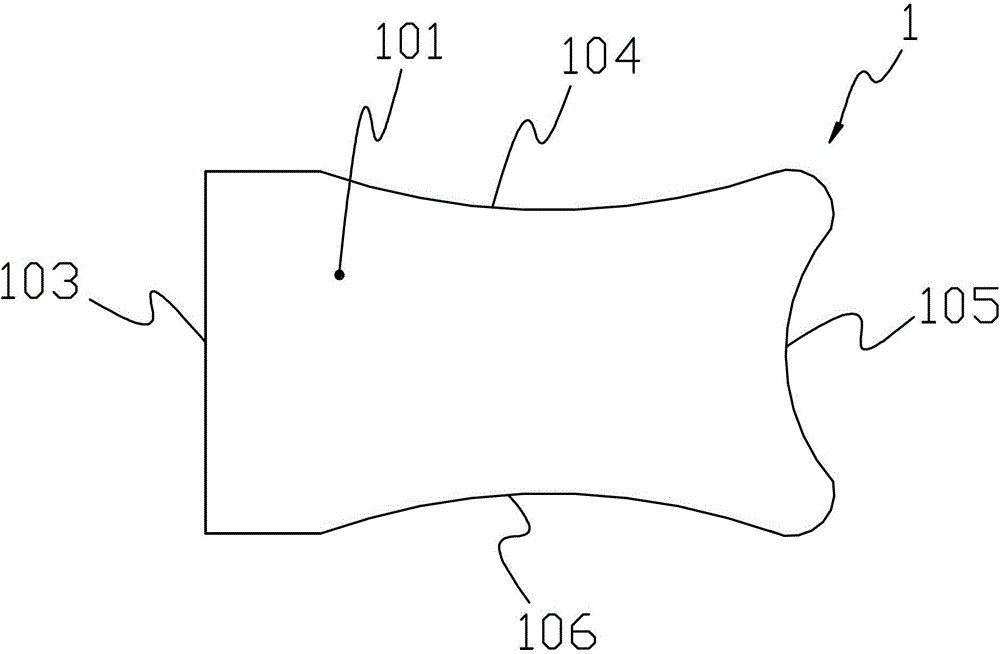

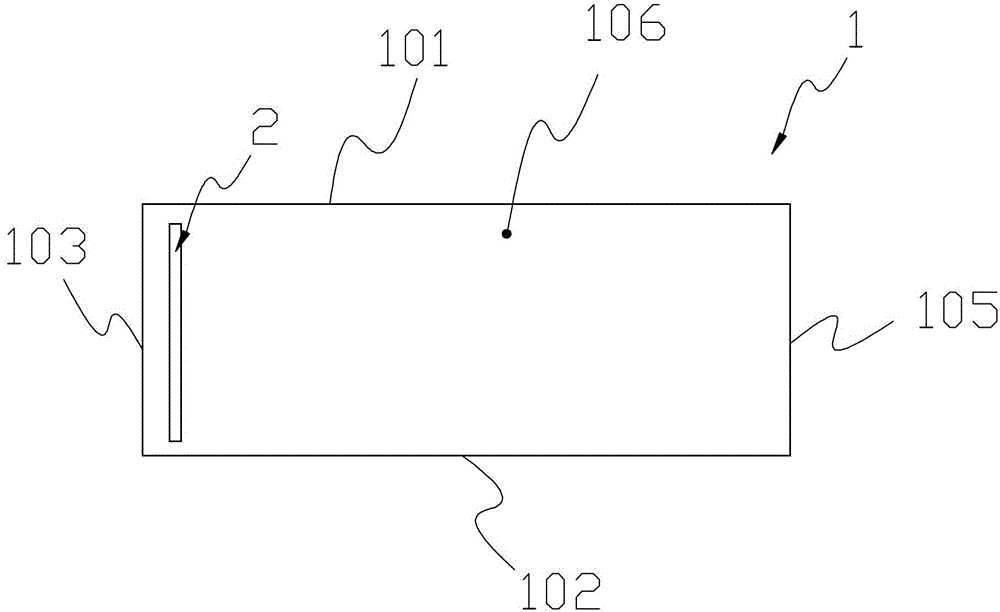

[0020] Step 1, preparing several blocks 1 with the same structure, each block includes an upper wall surface 101, a lower wall surface 102 and four side wall surfaces, the four side wall surfaces are respectively side wall surface one 103, side wall surface two 104, side wall surface three 105 and Side wall four 106, wherein the upper wall, lower wall and side wall one are planes, and side two, side three and side wall four are arc-shaped. The steel channel 2 is pre-embedded on the side close to the side wall surface 1, and the steel channel is a hollow structure with a rectangular cross section.

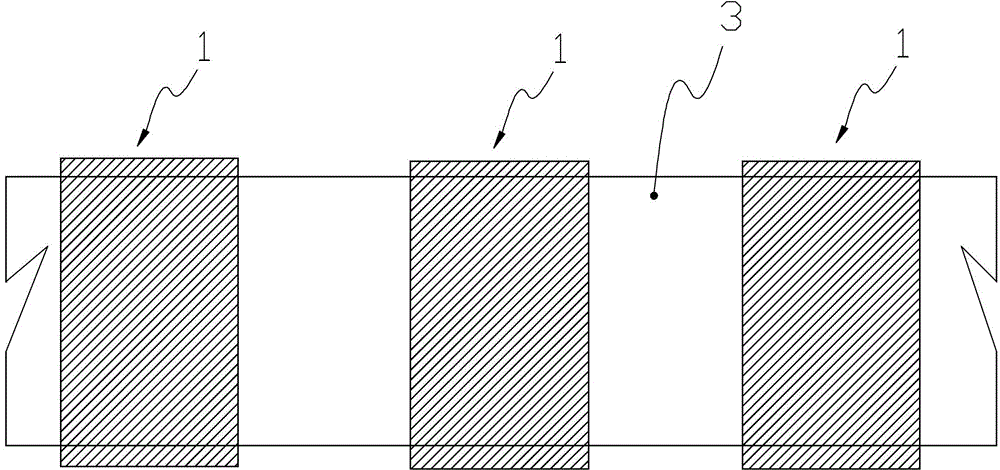

[0021] Step 2, take the matching steel belt 3 to pass through the steel channel, connect the pads in series to form a string of pads, after determining the set position of each pad on the steel belt, place a section of steel on both sides of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com