Prefabricated wall, prefabricated wallboard, construction method of prefabricated wall and production method of prefabricated wallboard

A prefabricated wall panel and prefabricated wall technology, which is applied in the field of building walls, can solve the problems of cracking and falling off of the outer layer board, unreasonable structure, high construction cost, etc., and achieve the reduction of on-site operation time, stable and reliable quality, and smooth construction. The effect of increasing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

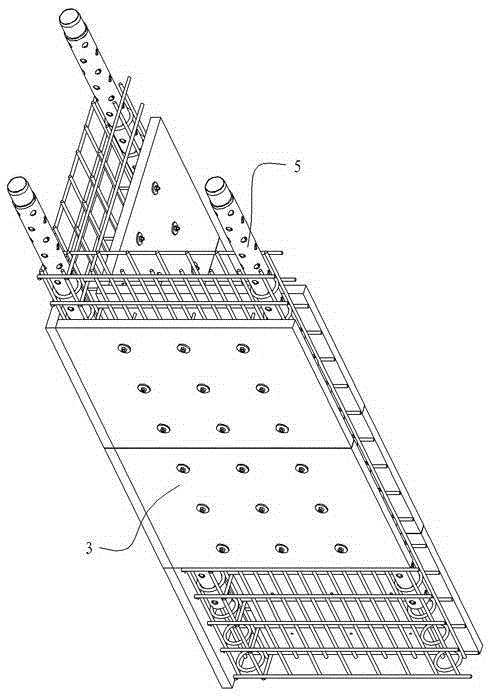

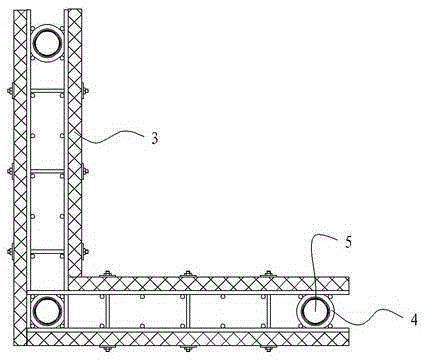

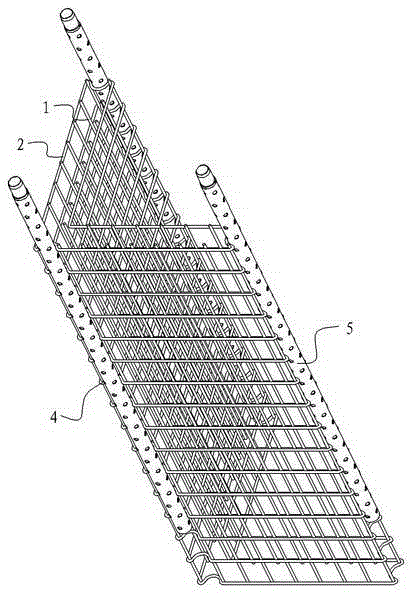

[0052] The prefabricated wall body of this embodiment, as figure 1 , figure 2 and image 3 shown, including reinforcement cages at the floors. The reinforcement cage includes a longitudinal main reinforcement 1 and a stirrup 2 fixed on the main reinforcement, and a first dismantling-free thermal insulation template 3 is fixed on the outer surface of the reinforcement cage. A limit ring 4 and a positioning steel pipe 5 extending along the length direction of the main reinforcement 1 are arranged in the reinforcement cage.

[0053] The positioning steel pipe 5 is arranged in the limit ring 4, and the positioning steel pipe 5 in the reinforcement cage at the upper floor is connected with the positioning pipe sleeve between the positioning steel pipe 5 in the reinforcement cage at the adjacent place on the lower floor, and the reinforcement cage at the upper floor is connected with the lower reinforcement cage. The mutually butted main reinforcements 1 of the reinforcement cag...

Embodiment 2

[0069] The prefabricated wall panel of this embodiment is an improvement on the basis of Embodiment 1, such as Figure 4 to Figure 11 As shown, the difference from the first embodiment is that it includes two concrete panels 6 arranged front and back, and a positioning steel pipe column 7 and an insulating material layer 8 filled with cement-based cement are fixed between the two concrete panels 6 . Two soil-mixed wallboards 6 and insulation material layers 8 are connected and fixed by connecting pins 9 .

[0070] Each prefabricated wall panel is provided with a ring beam steel pipe 10 fixed on the top of the positioning steel pipe column 7, and the ring beam steel pipe 10 is provided with perforations. The wallboard body is inserted into the steel pipe hole of the positioning steel pipe column 7 in the adjacent prefabricated wallboard below through the perforated tenon of the ring beam steel pipe 10 . In the two concrete panels 6 of the present embodiment, the thermal insula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com