Column gradient measuring device and measuring method thereof

A technology of inclination and measuring instruments, which is applied in the direction of measuring inclination, measuring devices, instruments, etc., can solve the problems of difficulty in finding the outermost ridge line quickly, lack of conventional conditions, and low measurement efficiency, so as to improve the measurement work efficiency, The effect of shortening the on-site work time and spreading the value widely

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

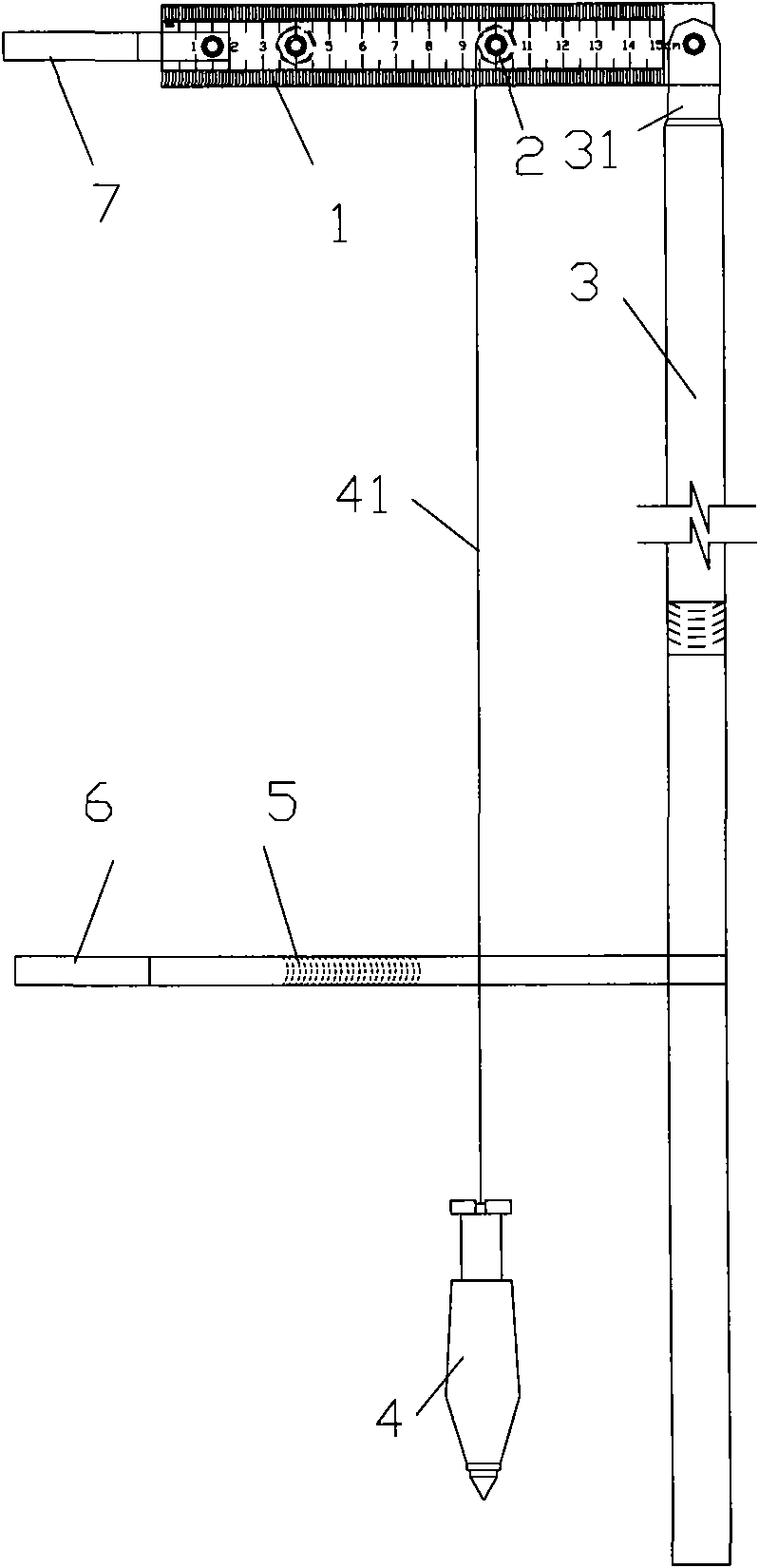

[0031] Such as figure 1 Shown: a cylindrical inclinometer, it includes a steel ruler 1 with scale, it also includes:

[0032] A column 3, its top has a joint 31 and one end of the large scale of the steel ruler 1 is fixedly connected;

[0033] Two bolts 2, each with a nut and a washer, are fixedly connected and penetrate the steel ruler 1, one is close to the small scale end of the steel ruler 1, and the other is located at the middle section of the steel ruler 1;

[0034] A telescopic sleeve 5, which is arranged parallel to the steel ruler 1, and is fixedly connected to the lower section of the column 3 with one end thereof;

[0035] Two arc clamping plates 6, 7 are respectively connected to the ends of the steel ruler 1 and the telescopic sleeve 5 and are arranged facing away from the column 3.

[0036] A hammer ball 4, it is suspended on the bolt 2 that is positioned at steel ruler 1 middle section by lanyard 41.

[0037] In one embodiment of the present invention, the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com