Patents

Literature

106results about How to "Improve measurement productivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Surface-profile measuring instrument

ActiveUS20080065341A1Improve measurement productivityMechanical counters/curvatures measurementsMeasurement/indication equipmentsObservational errorMeasuring instrument

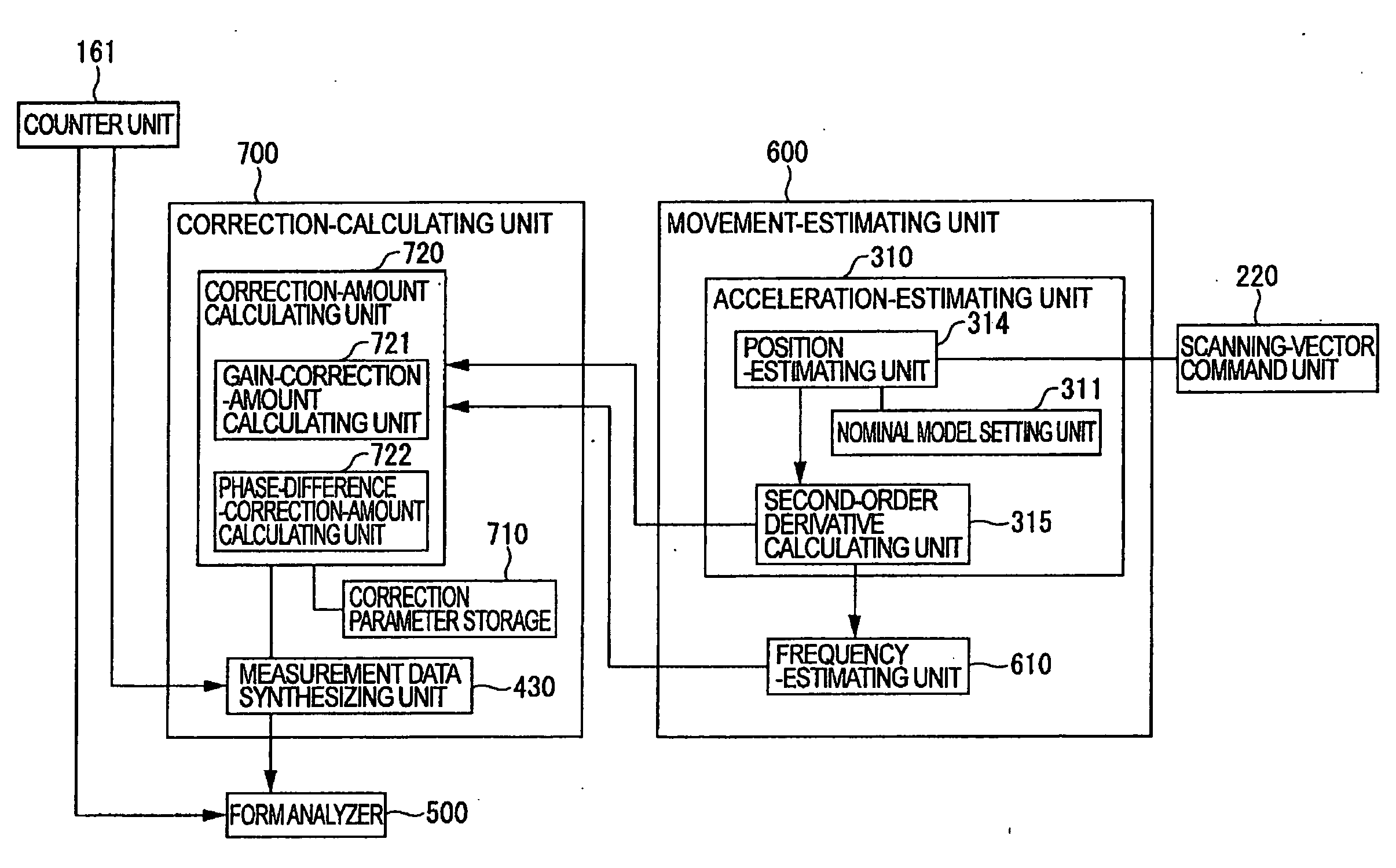

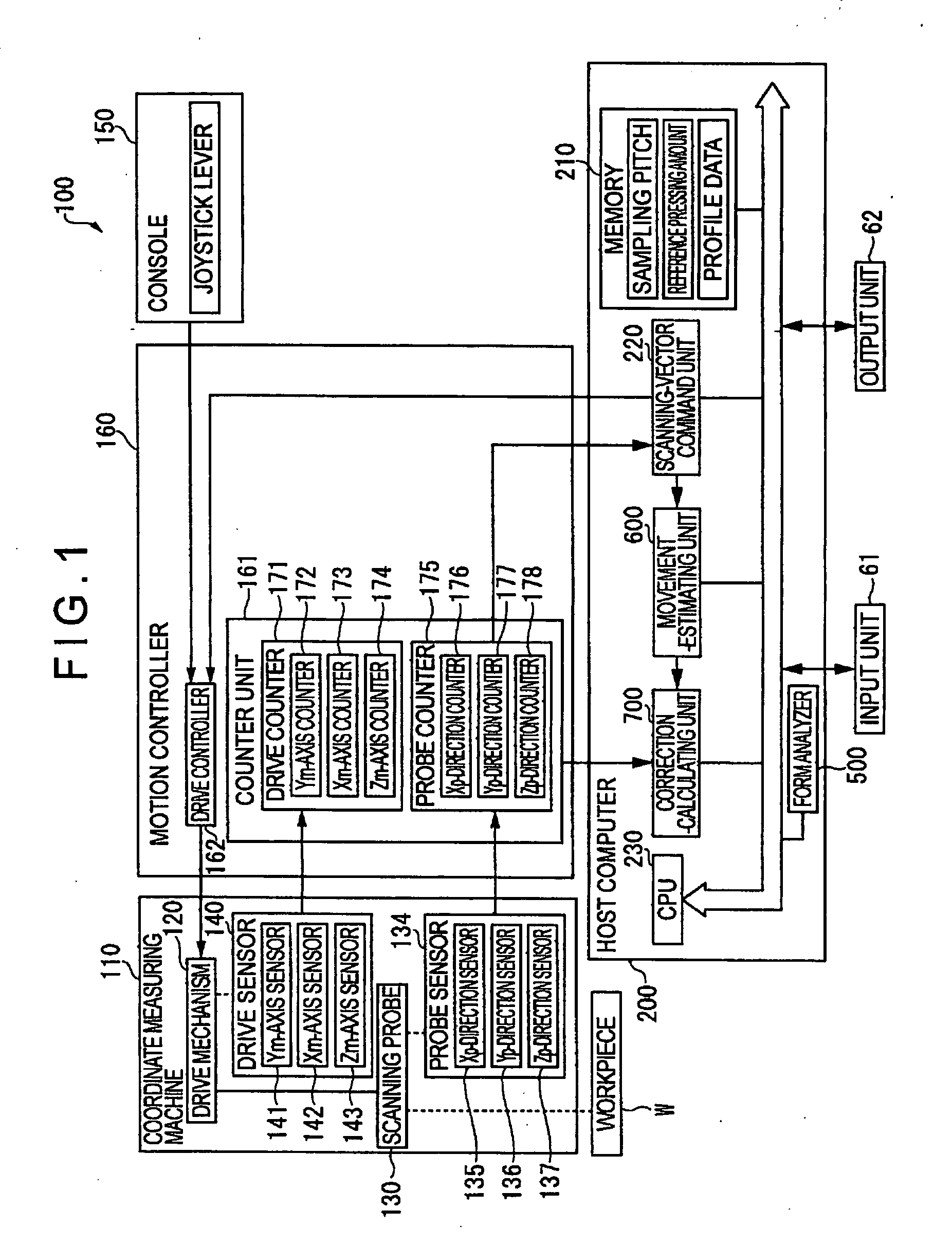

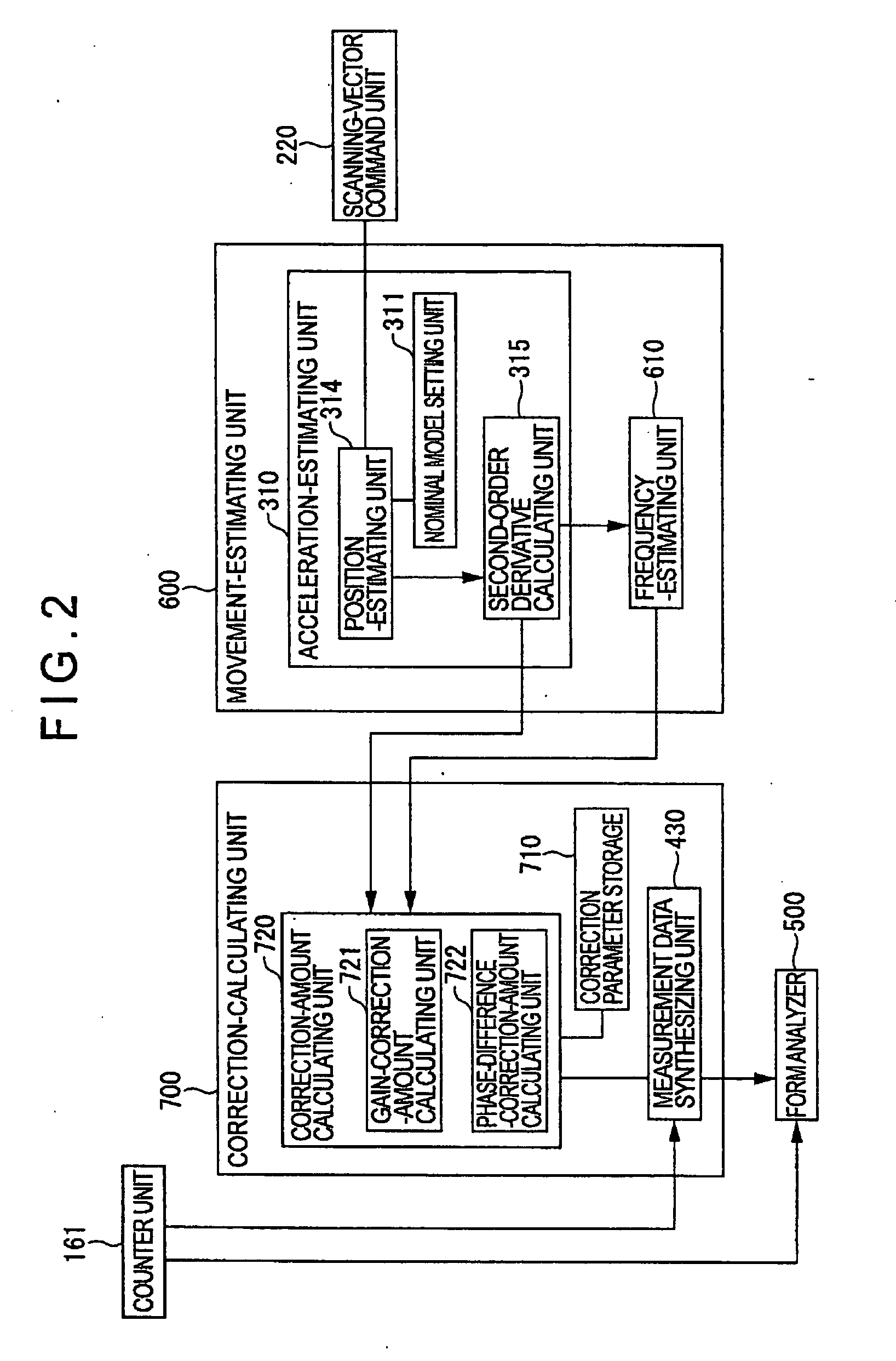

A surface-profile measuring instrument includes a movement-estimating unit (600) that estimates an movement state of a drive mechanism in accordance with a scanning vector command issued by a scanning vector commanding unit (220) to calculate an estimated movement state quantity, and a correction calculating unit (700) that corrects a detection value of a drive sensor in accordance with the estimated movement state quantity calculated by the movement estimating unit (600).The movement-estimating unit (600) has a nominal model setting unit (311) in which a nominal model as a frequency transfer characteristics from the scanning vector commanding unit to the probe of the scanning probe is set. The correction-calculating unit (700) includes a correction-amount calculating unit (720) that calculates a correction amount for correcting a measurement error generated by a deformation of the drive mechanism in accordance with the movement thereof and a measurement data synthesizing unit (430) that synthesizes the detection value of the drive sensor and the displacement sensor and the calculated correction-amount calculated by the correction-amount calculating unit (720).

Owner:MITUTOYO CORP

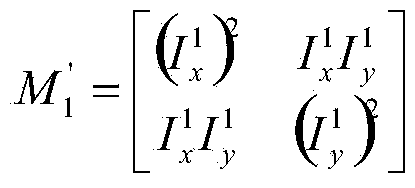

Open-pit mine mining and stripping quantity calculating method utilizing plane image aerial-photographing

InactiveCN104376598ARealization of stripping amount calculationImprove measurement productivityData processing applicationsSpecial data processing applicationsPoint cloudEarth surface

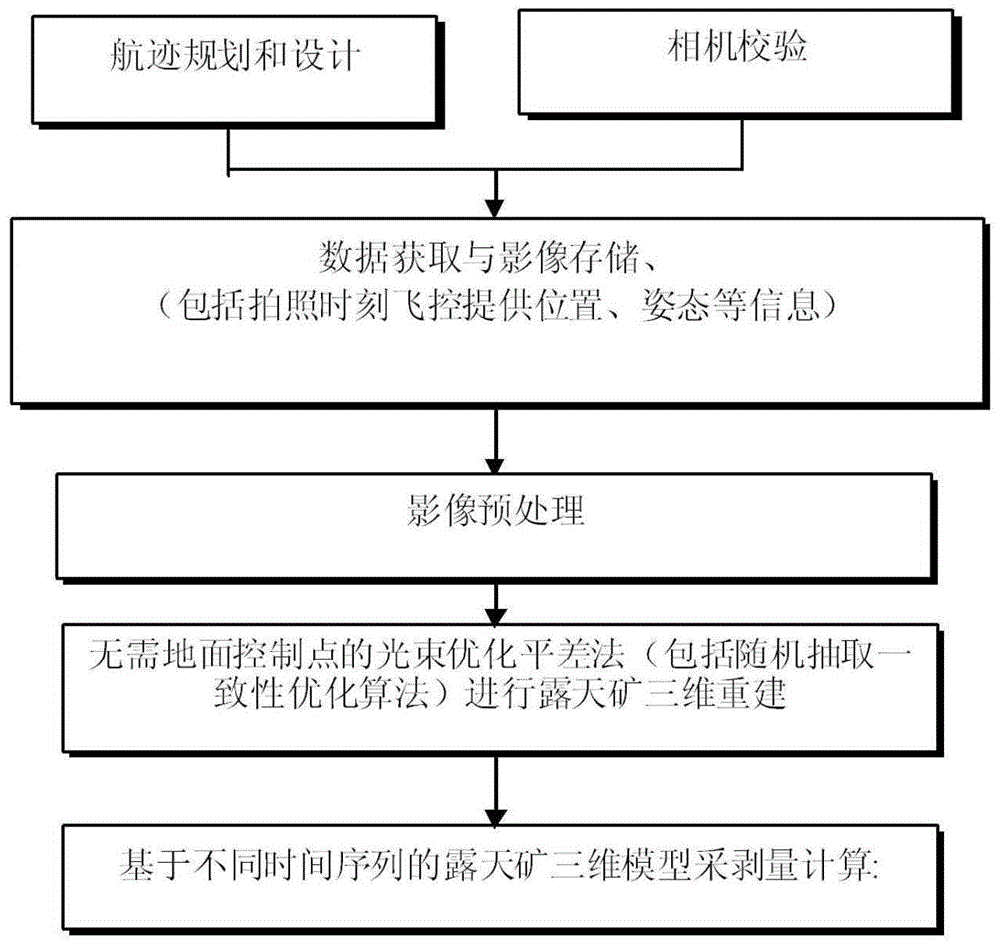

The invention belongs to the technical field of mine production management, and particularly relates to an open-pit mine mining and stripping quantity calculating method utilizing plane image aerial-photographing. The method includes utilizing plane image aerial-photographing technology; performing plane flight path planning and designing according to geographic conditions of an open-pit mine; checking a digital camera carried by a plane; controlling the digital camera for aerial photographing and image acquiring and storing at the same time; recording plane position and posture information provided during photographing; building an open-pit mine earth surface three-dimensional point cloud model. The open-pit mine earth surface three-dimensional point cloud model can be built without adopting a bundle adjustment method of control points, an open-pit mine earth surface irregular triangular net model is built, mining quantity and rock discharging quantity are automatically measured and recorded, accumulated volume values of the open-pit mine earth surface triangular net model at different times are subtracted to accurately calculate earth-rock quantity of an excavating or backfilling body, calculating of open-pit mine mining and stripping quantity is realized, open-pit mine measuring work efficiency is improved, and statistical accuracy of mining and stripping quantity is improved.

Owner:ANSTEEL GRP MINING CO LTD

Plant leaf area lossless measuring method

InactiveCN103791861AEasy to carryImprove discriminationUsing optical meansImage resolutionSignificant difference

The invention discloses a plant leaf area lossless measuring method. According to the plant leaf area lossless measuring method, a leaf blade image collection method and an indoor leaf area measurement calculation method are mainly used for carrying out measurement and calculation; according to the leaf blade image collection method, a digital camera, a shooting background base plate, coordinate paper, a steel tape and other tools are used as tools, and are easy to operate and convenient to carry, especially when shooting is carried out on the situation that the shooting resolution and the image storage pixel level set when the digital camera leaves the factory are utilized, and the shooting angle is close to 90 degrees, a clear leaf blade image can be obtained, and leaf area measuring accuracy does not have significant difference; according to the indoor leaf area measurement calculation method, the shot leaf blade image is stored in a computer preloaded with AutoCAD software, and the leaf area of a plant is measured and calculated by running the AutoCAD software. Lossless measurement of the leaf area can be achieved by combining the digital camera and the AutoCAD software; compared with a popular leaf area determinator at present, the plant leaf area lossless measuring method has the advantages of being easy and convenient to operate and low in cost.

Owner:黑龙江省森林与环境科学研究院

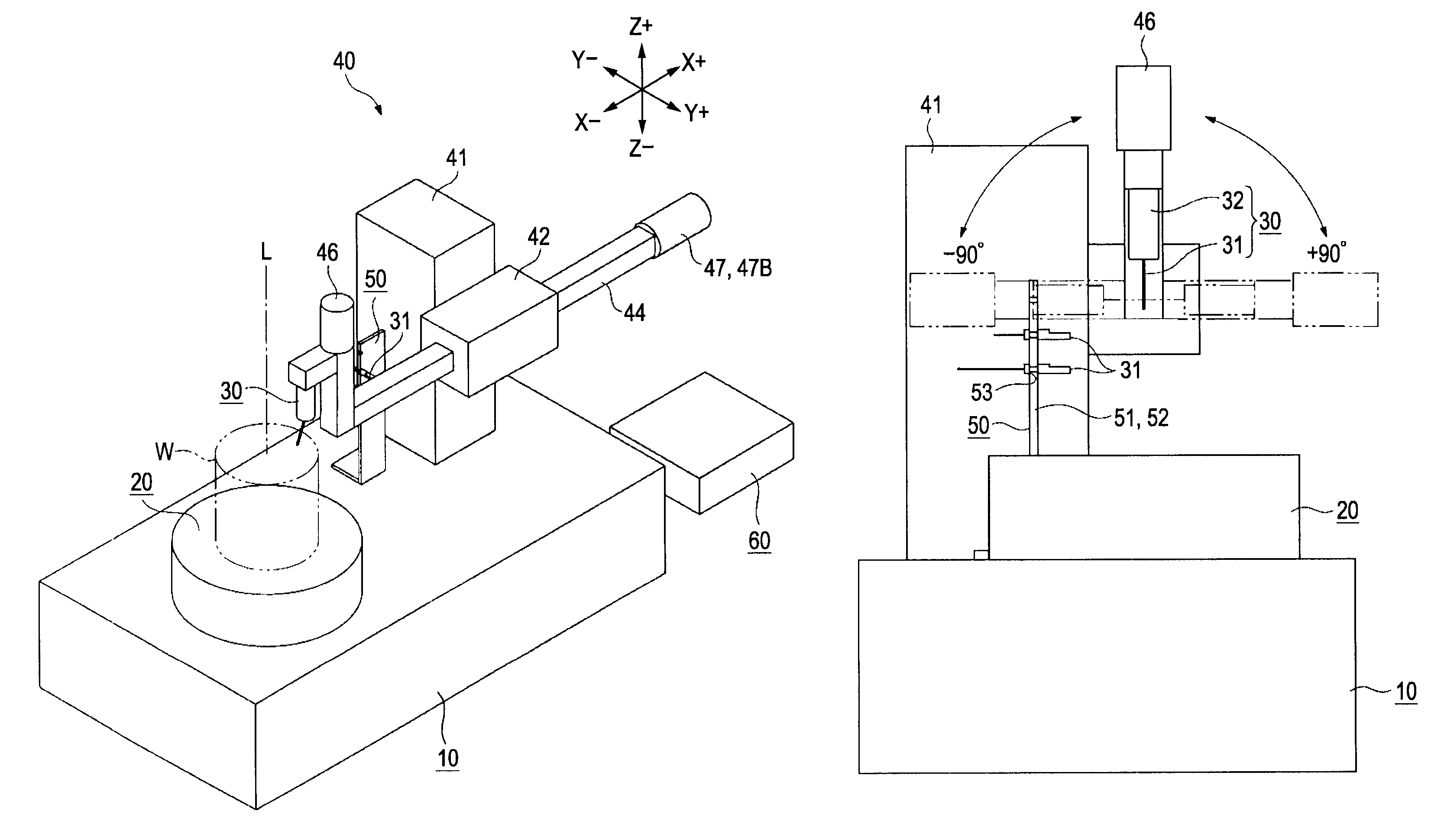

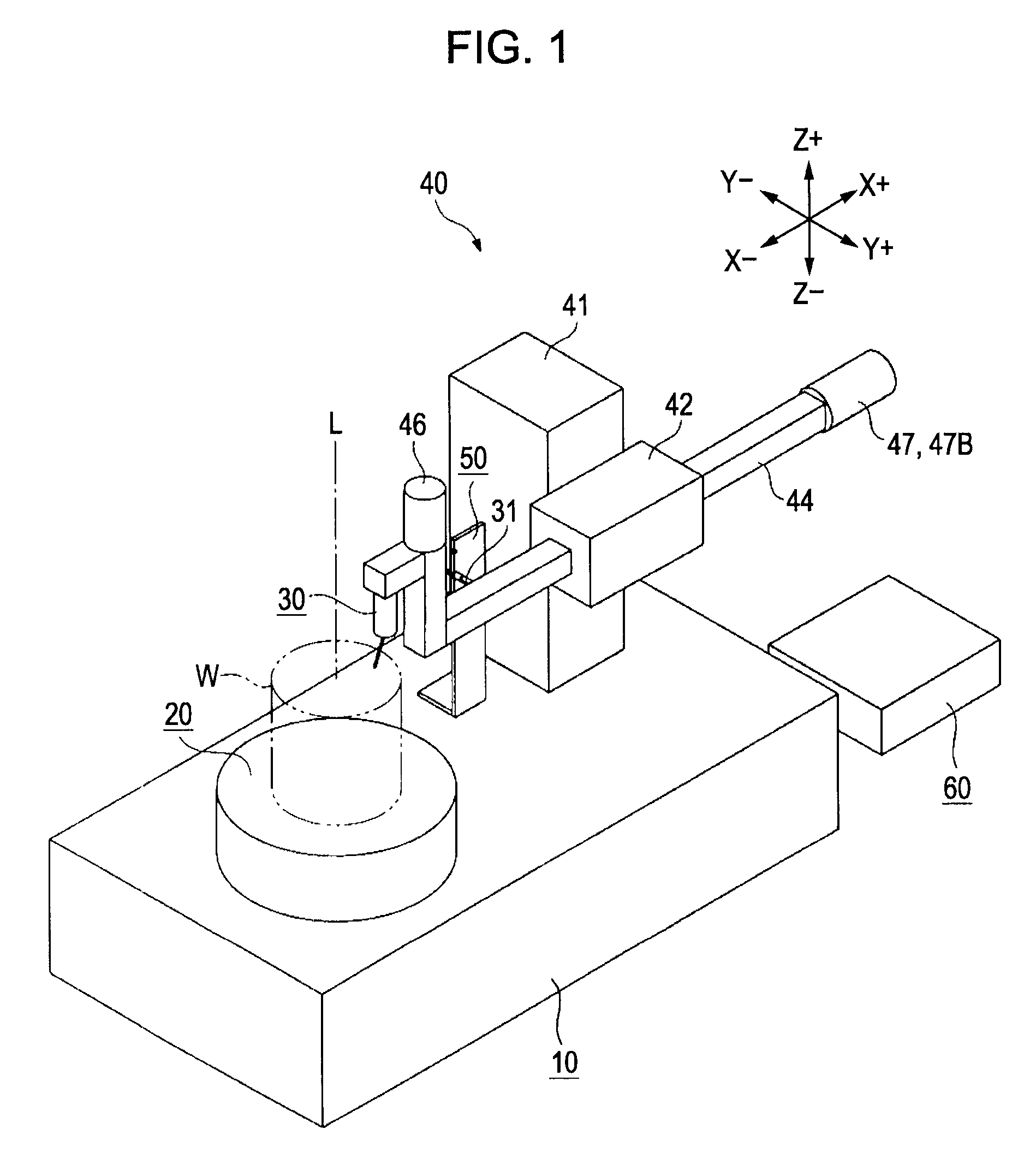

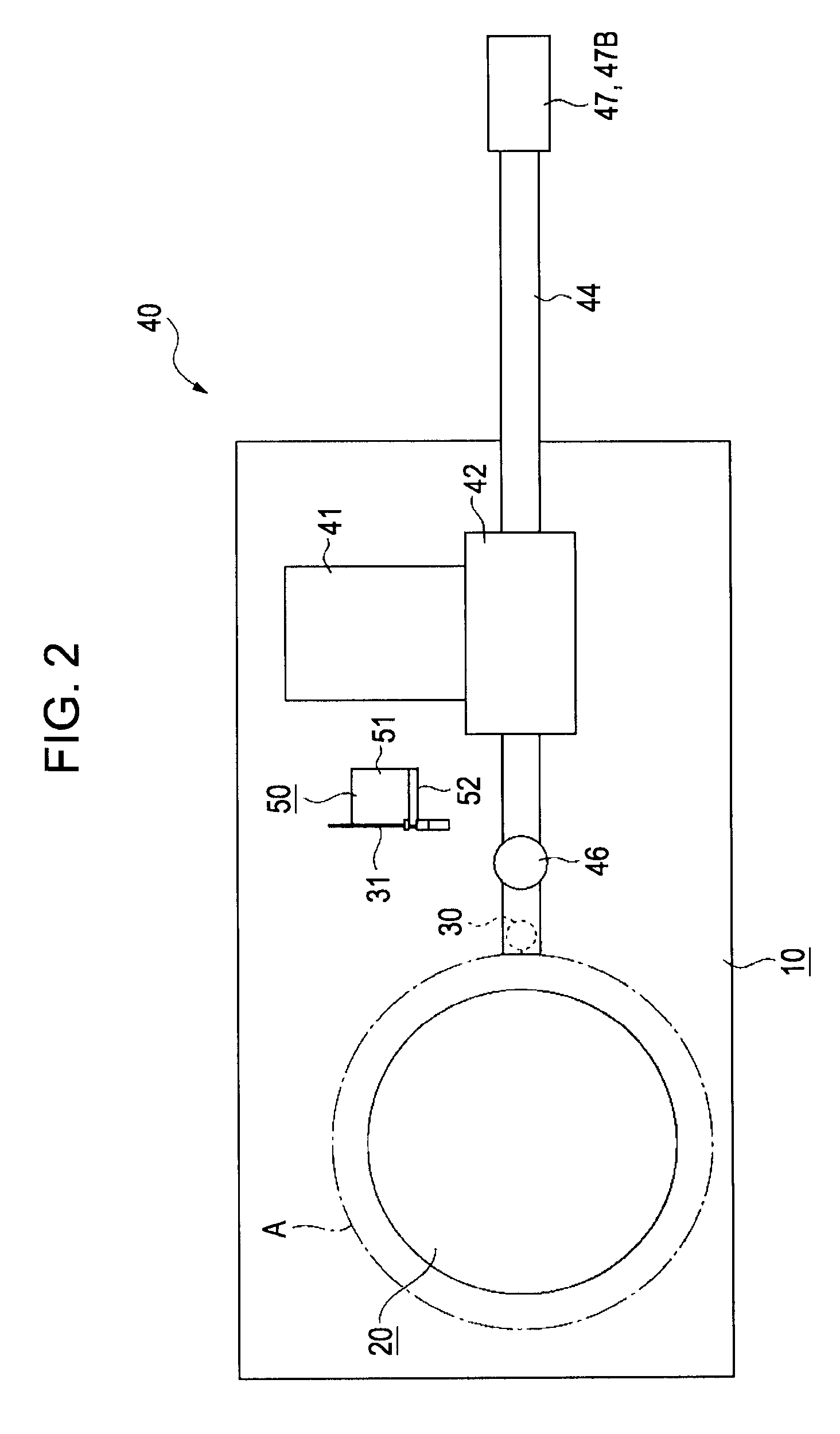

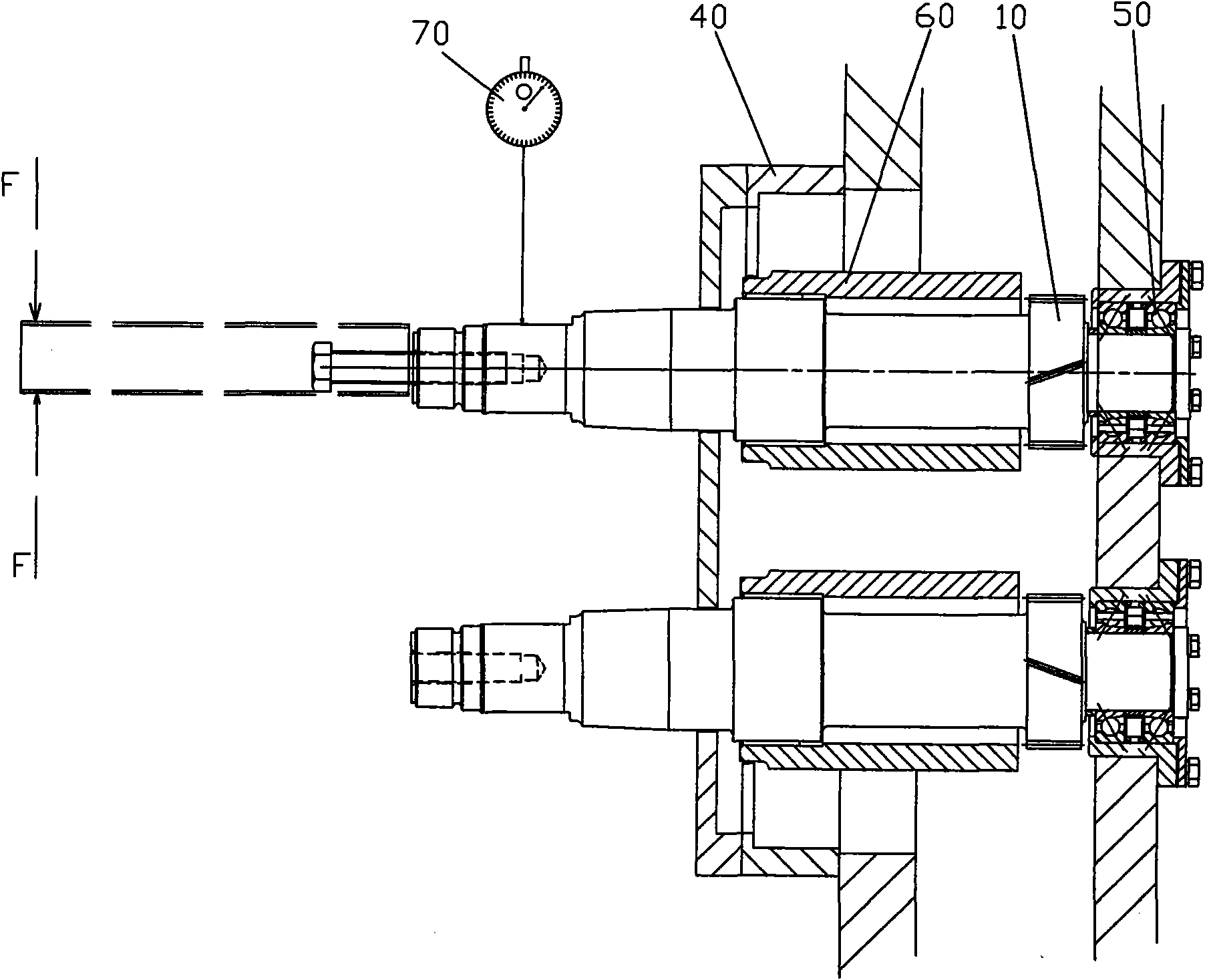

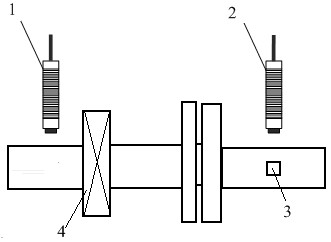

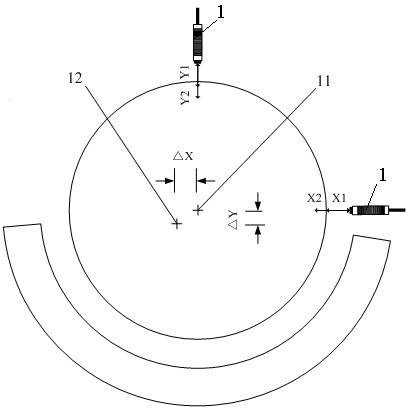

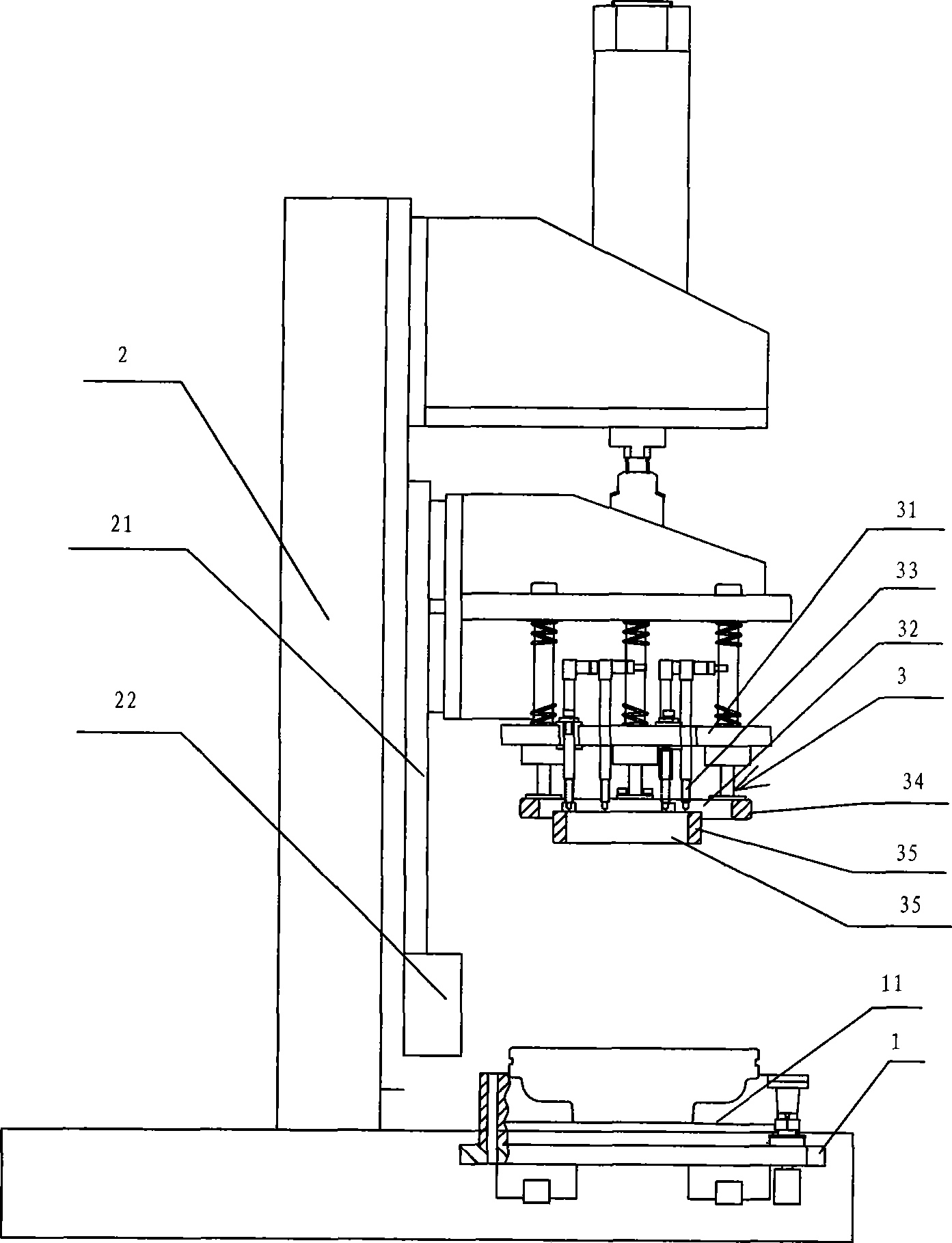

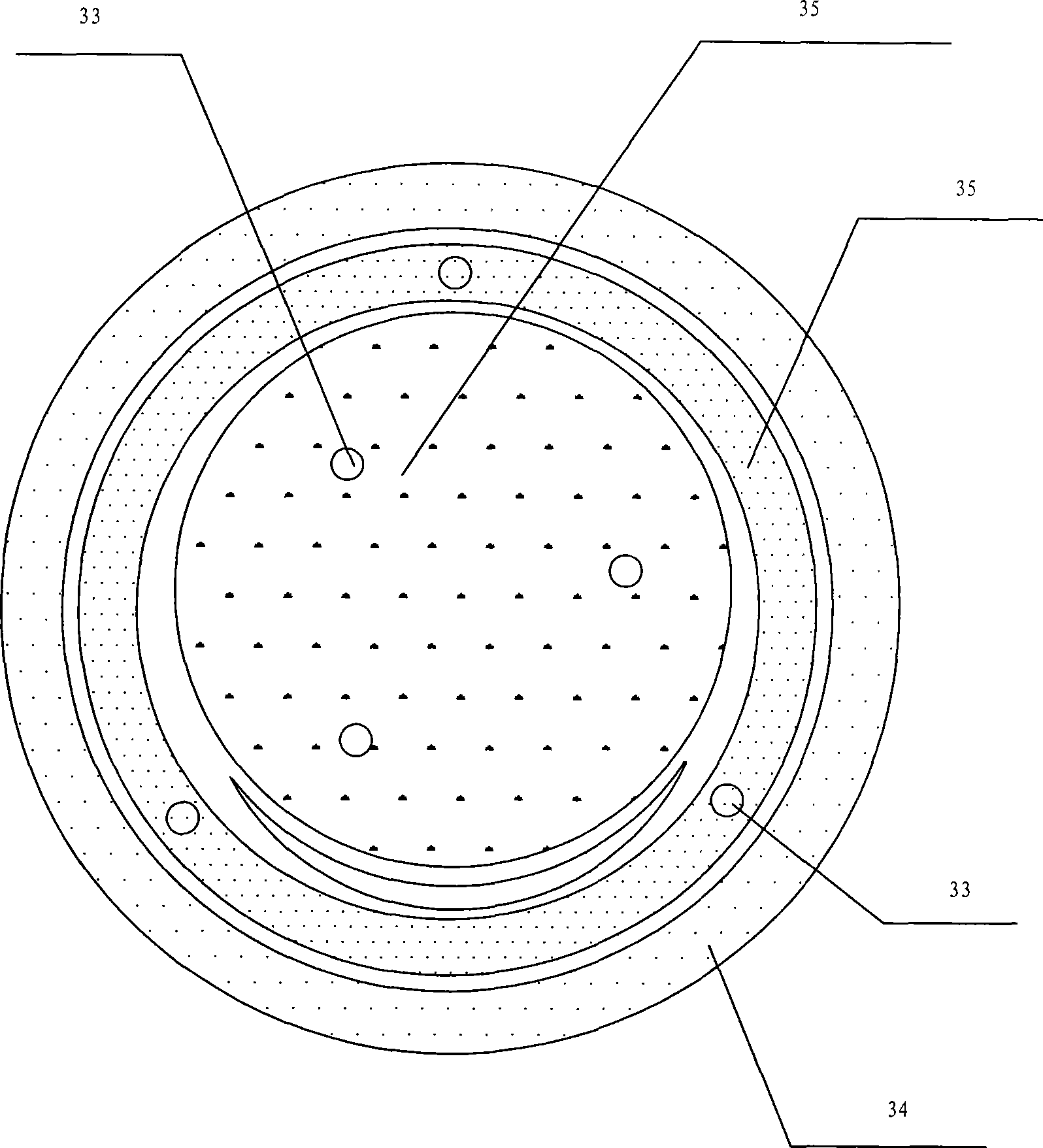

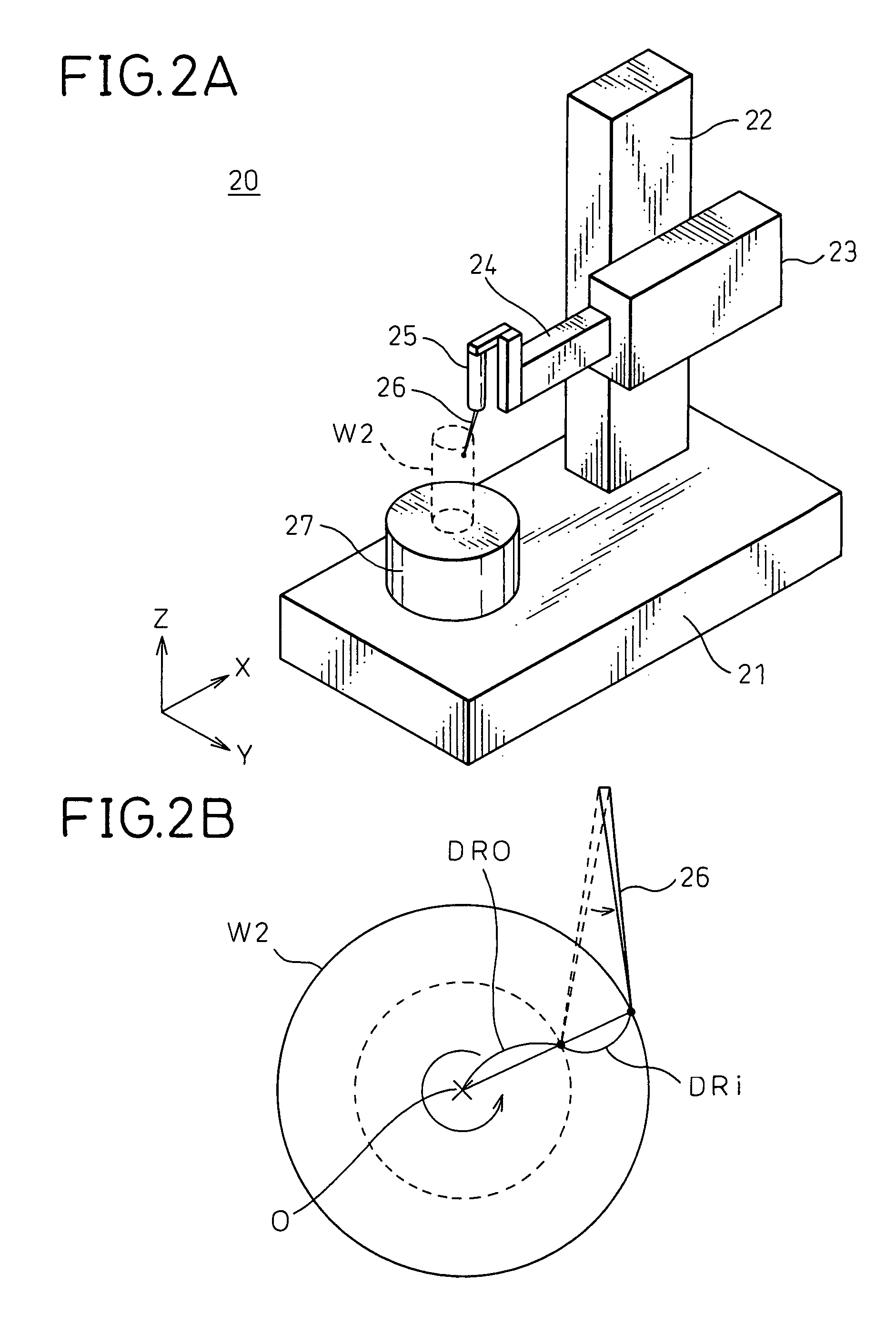

Roundness measuring apparatus

ActiveUS8336223B2Improve measurement productivityReduce measurementMechanical counters/curvatures measurementsWind musical instrumentsEngineeringMeasurement site

A roundness measuring apparatus includes a stylus stocker and a controller. The stylus stocker stores plural types of styli prepared corresponding to shapes of measurement sites of a measurement target object. The stylus stocker can store styli in such a manner that each stylus can be held thereon and taken out thereof. The stylus stocker is provided outside a measurement region, which is determined on the basis of the operation range of a turntable and a detector driving mechanism. The detector driving mechanism can move the detector to the outside of the measurement region. When a measurement command is given, the controller carries out roundness measurement of the object while controlling the turntable and the detector driving mechanism. When a stylus replacement command is given, the controller carries out stylus replacement operation between a detector main unit and the stylus stocker while controlling the detector driving mechanism.

Owner:MITUTOYO CORP

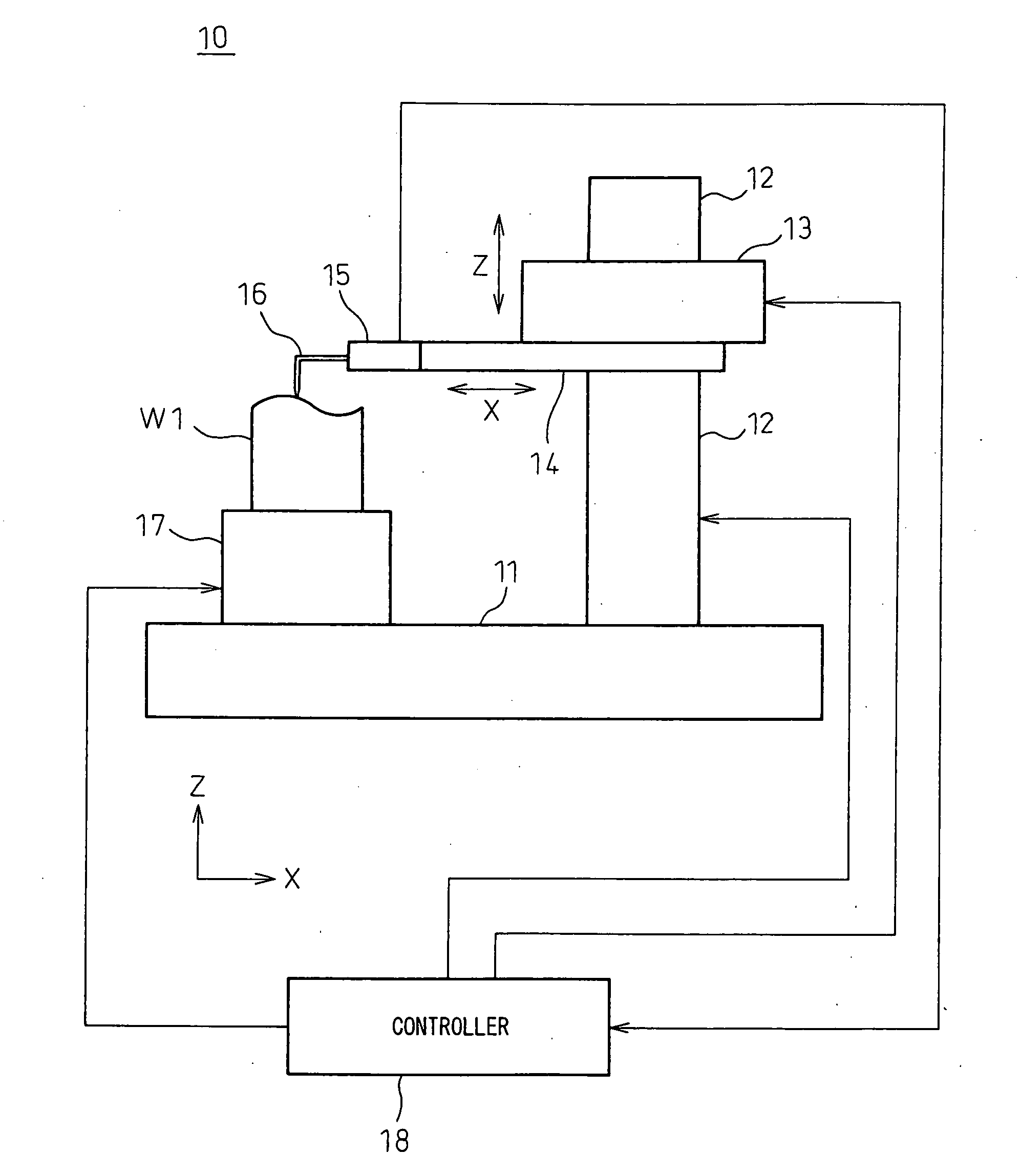

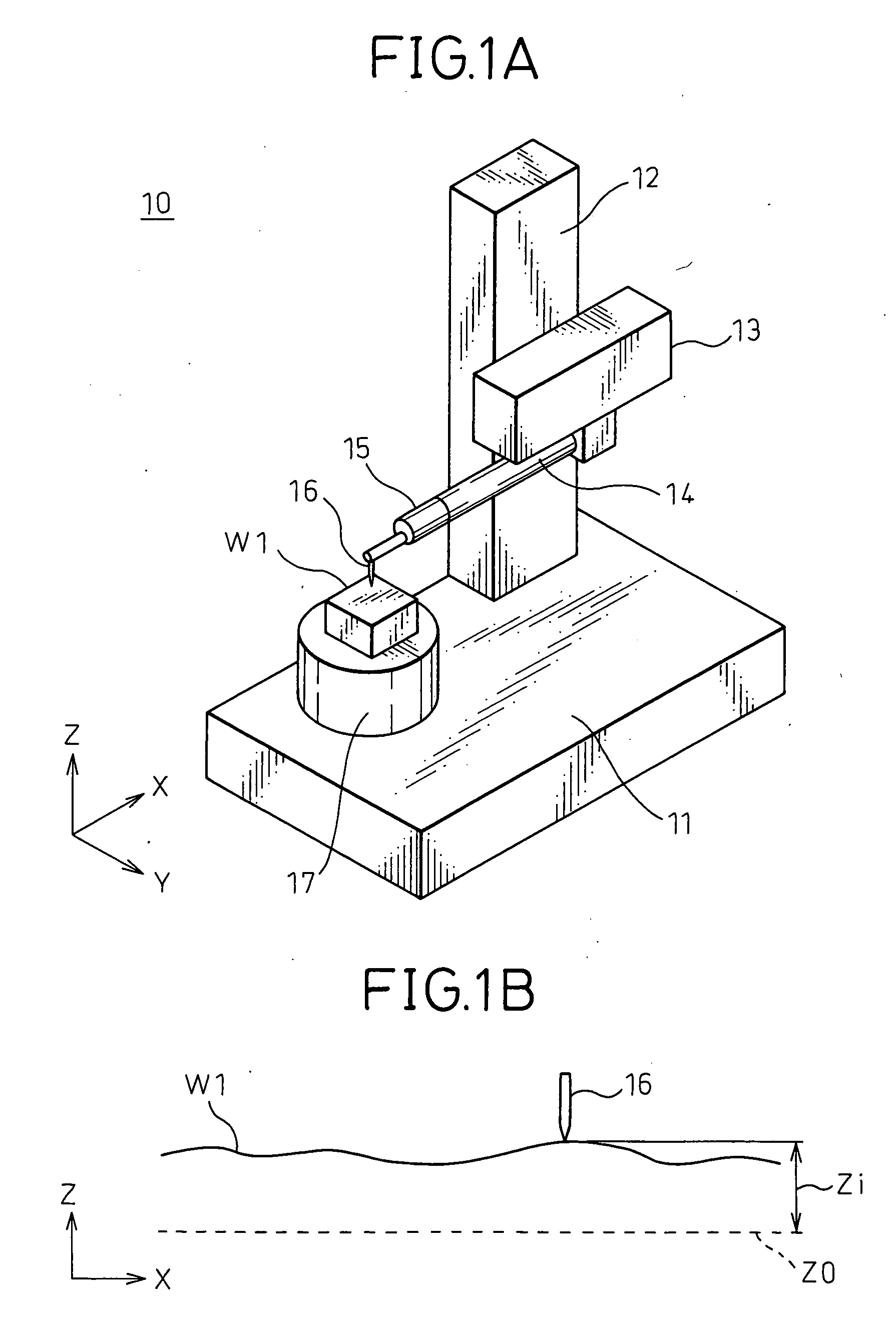

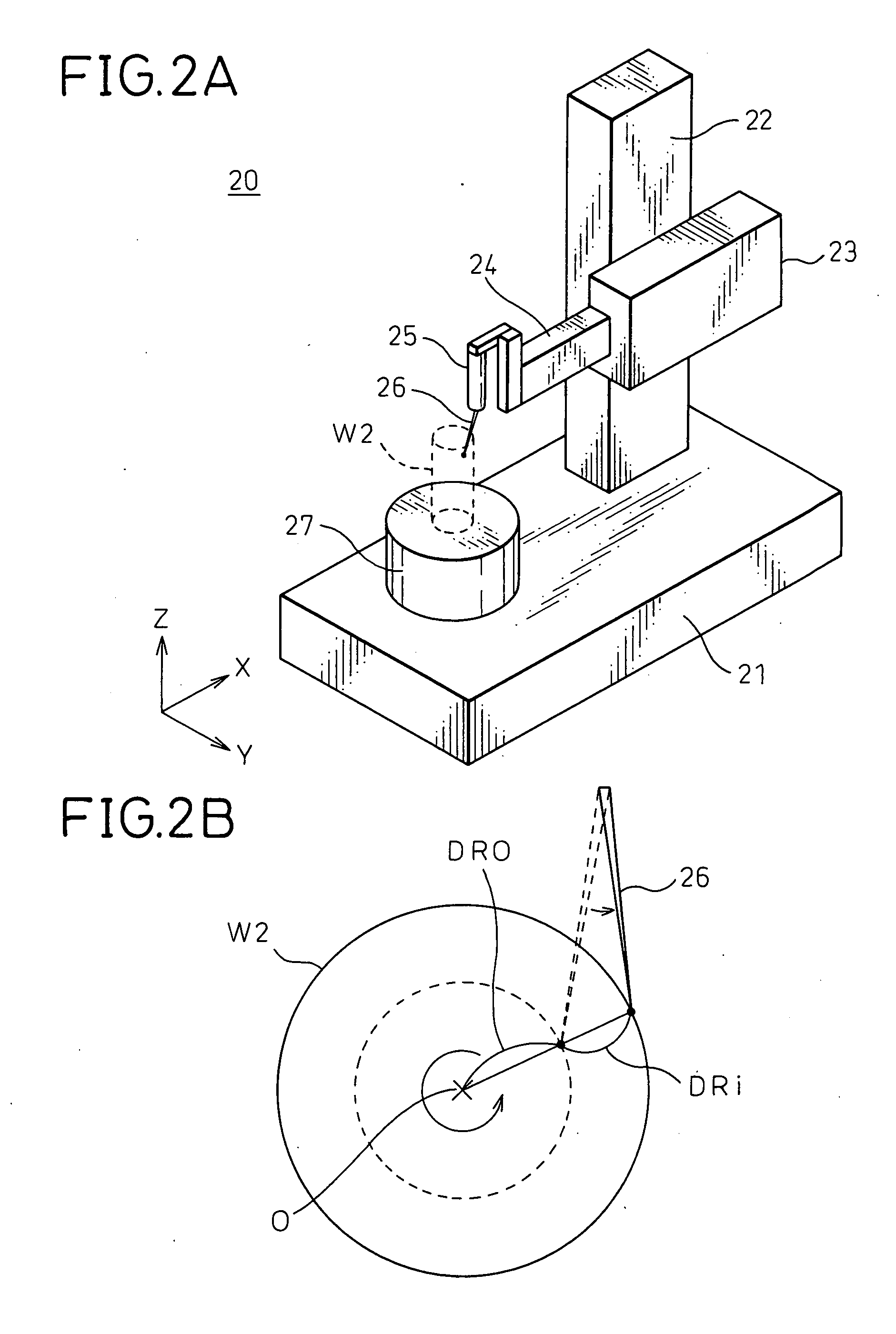

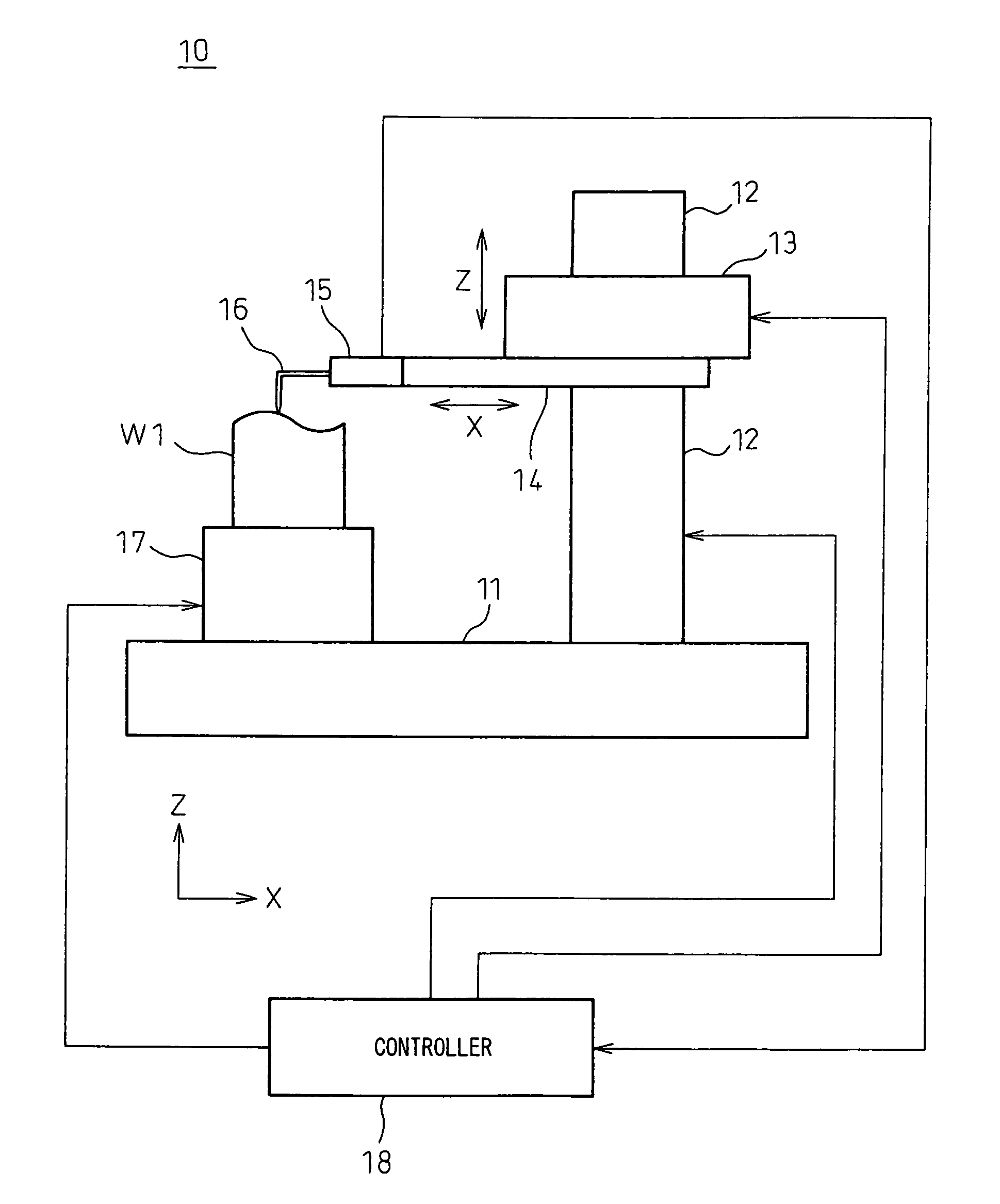

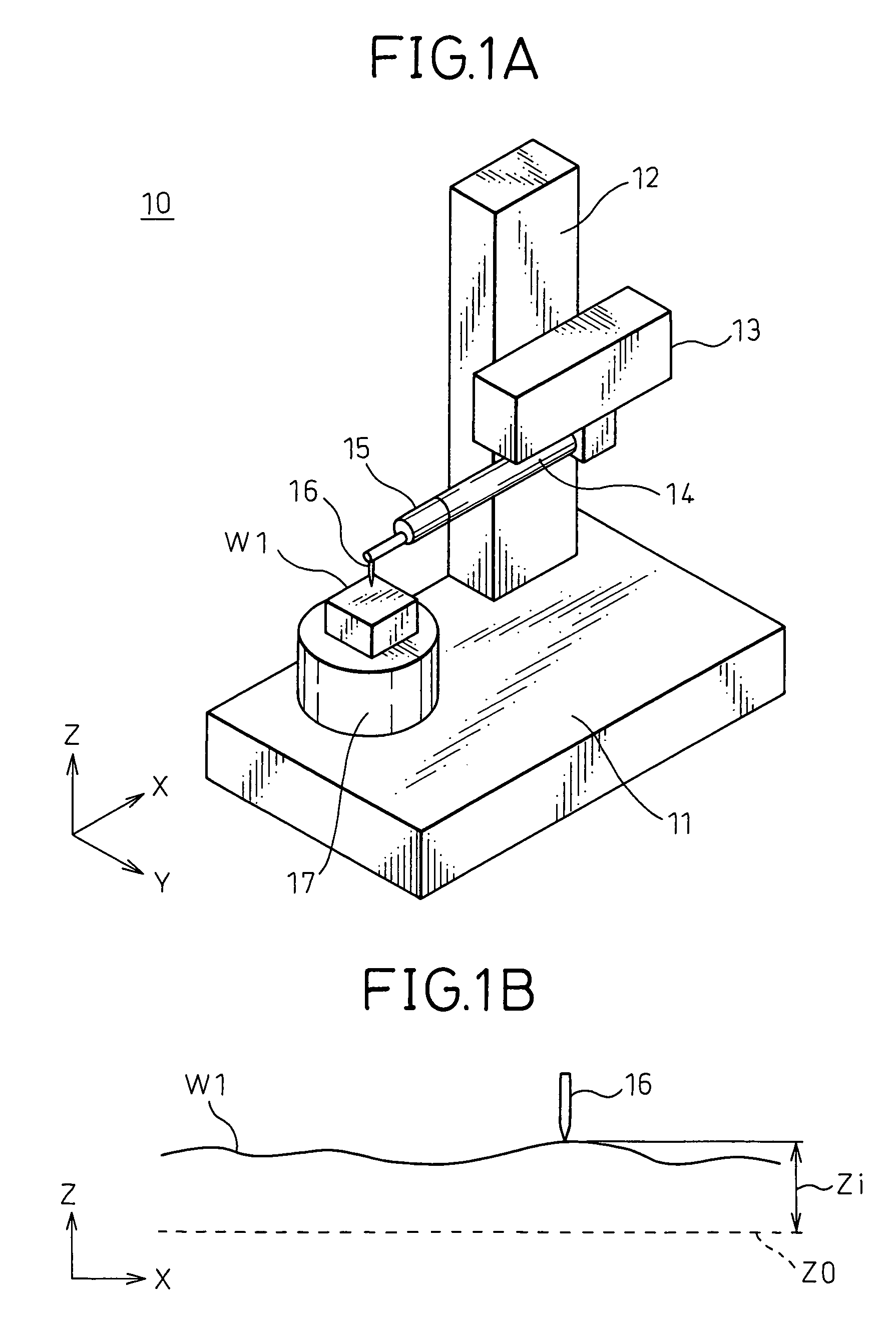

Surface shape measuring apparatus and surface shape measuring method

ActiveUS20090300930A1Simplify workImprove measurement productivityFeeler-pin gaugesMechanical counters/curvatures measurementsMeasurement deviceSurface shape

In a surface shape measurement device that measures the surface shape of a sample (W1, W2) by moving a probe (16, 26) in a sliding fashion along the surface of the sample (W1, W2) and thereby detecting the amount of displacement of the probe (16, 26) caused by irregularities on the surface, an initial amount of displacement is detected which is the amount of displacement of the probe (16, 26) when the probe is first placed in contact with a measurement start point on the surface of the sample (W1, W2), and the amount of displacement of the probe (16, 26), detected as it is moved in a sliding fashion along the surface, is compared with the initial amount of displacement to determine whether the probe (16, 26) has reached a measurement end point.

Owner:TOKYO SEIMITSU

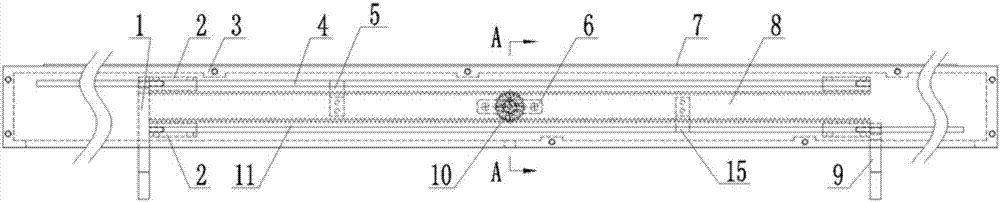

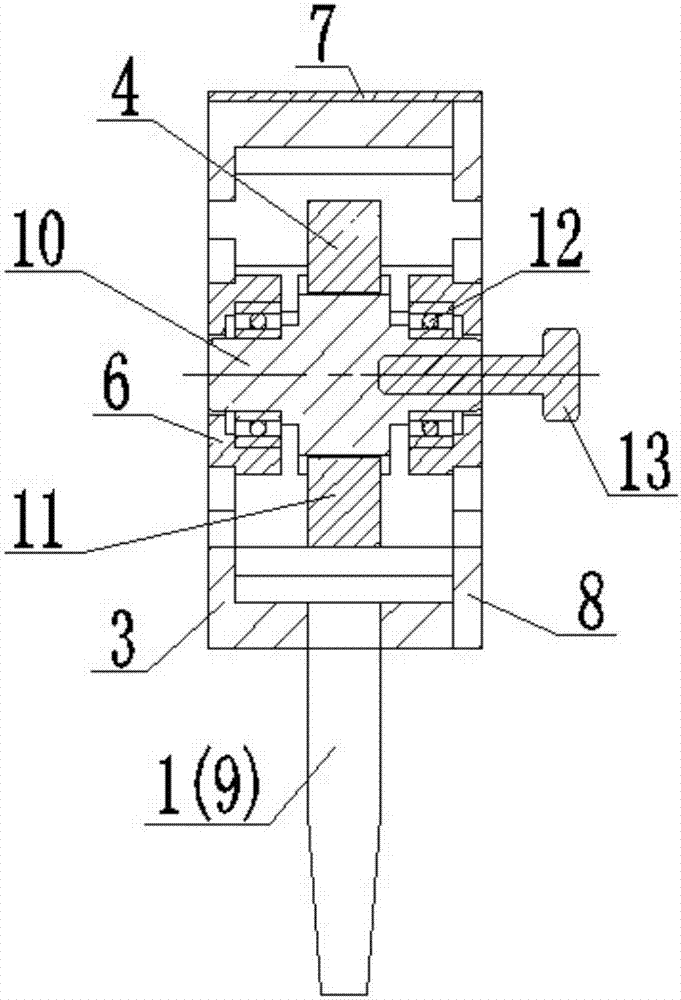

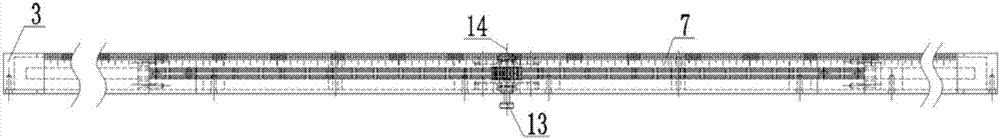

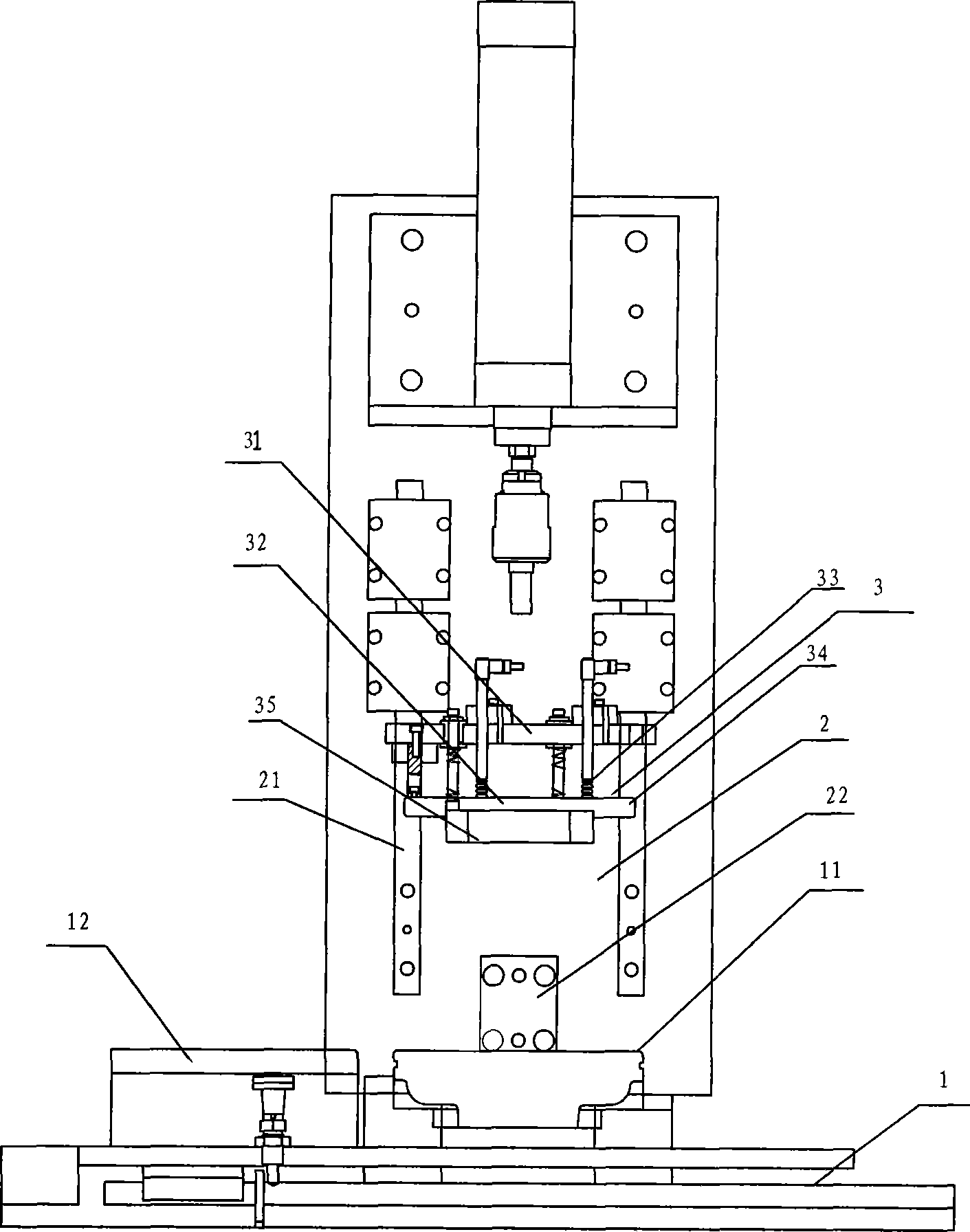

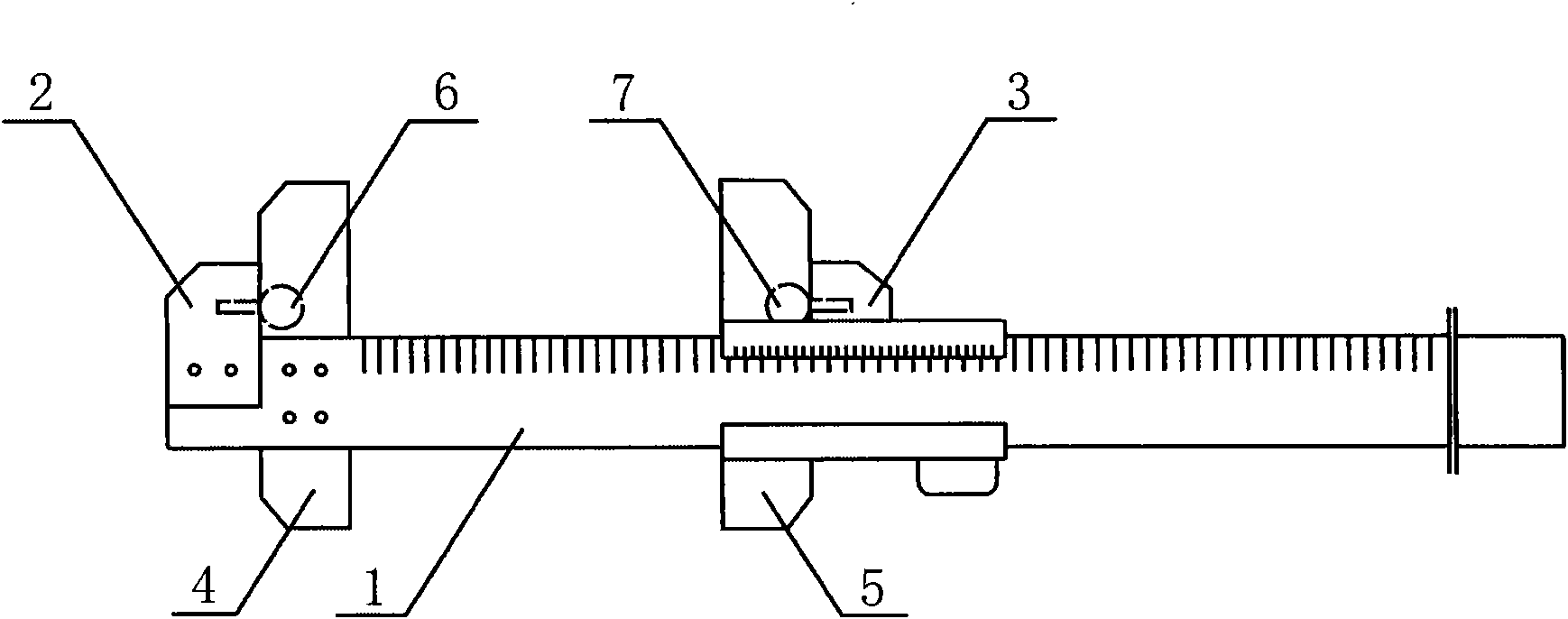

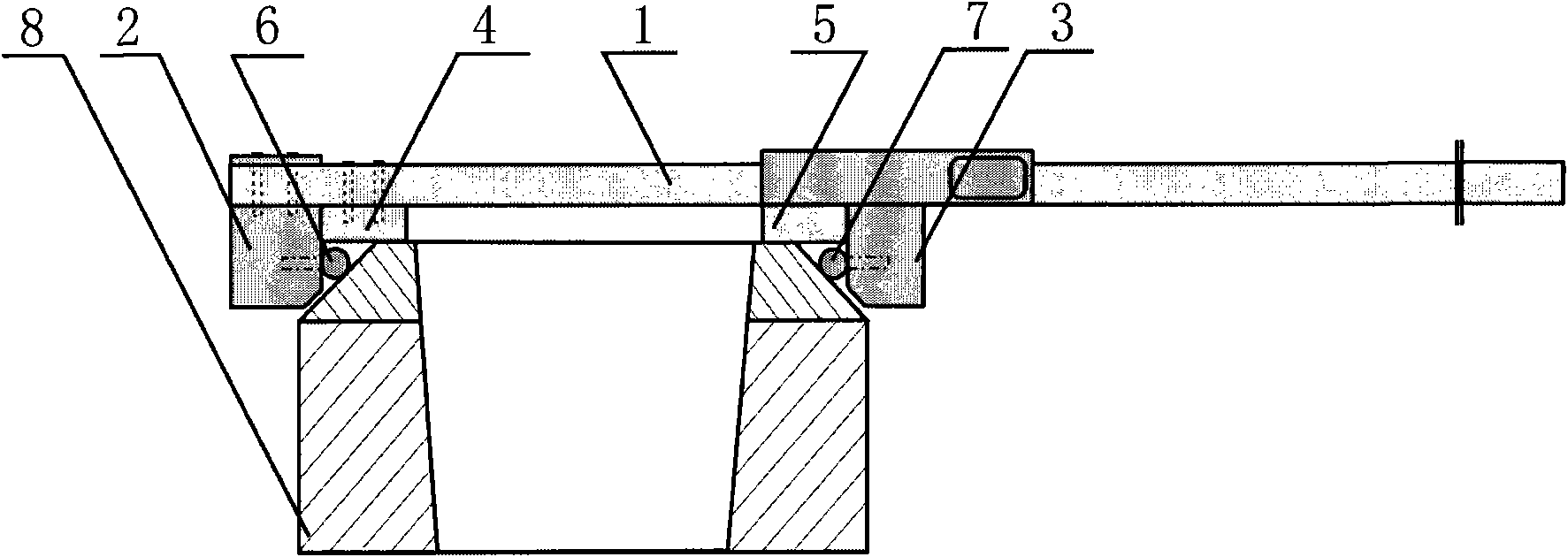

Integrated center measurement device for sleeper beam and traction beam and measurement method thereof

PendingCN107449338AImprove measurement productivityReduce measurement errorMechanical measuring arrangementsGear wheelRack and pinion

The invention provides an integrated center measurement device for a sleeper beam and a traction beam and a measurement method thereof. The integrated center measurement device for the sleeper beam and the traction beam includes a base, a first rack and a second rack. A center gear rotating relative to the base is mounted on the base and a center mark line is formed between a middle plane passing through the center of the center gear and the base. A first clip is connected to the first rack and a second clip is connected to the second rack. The first rack and the second rack are arranged on two opposite sides of the center gear and are respectively in engaged transmission with the center gear. The first clip and the second clip are disposed on two opposite sides of the center gear. The first rack and the second rack are driven by the center gear, so that the first clip and the second clip are enabled to move symmetrically and synchronously. The center position of the sleeper beam or the traction beam is determined through indication via the center mark line, so that the measurement working efficiency is improved and measurement error is reduced. The measurement device has prominent advantages of being accurate, reliable, simple and convenient in measurement and the like.

Owner:CSR CHENGDU

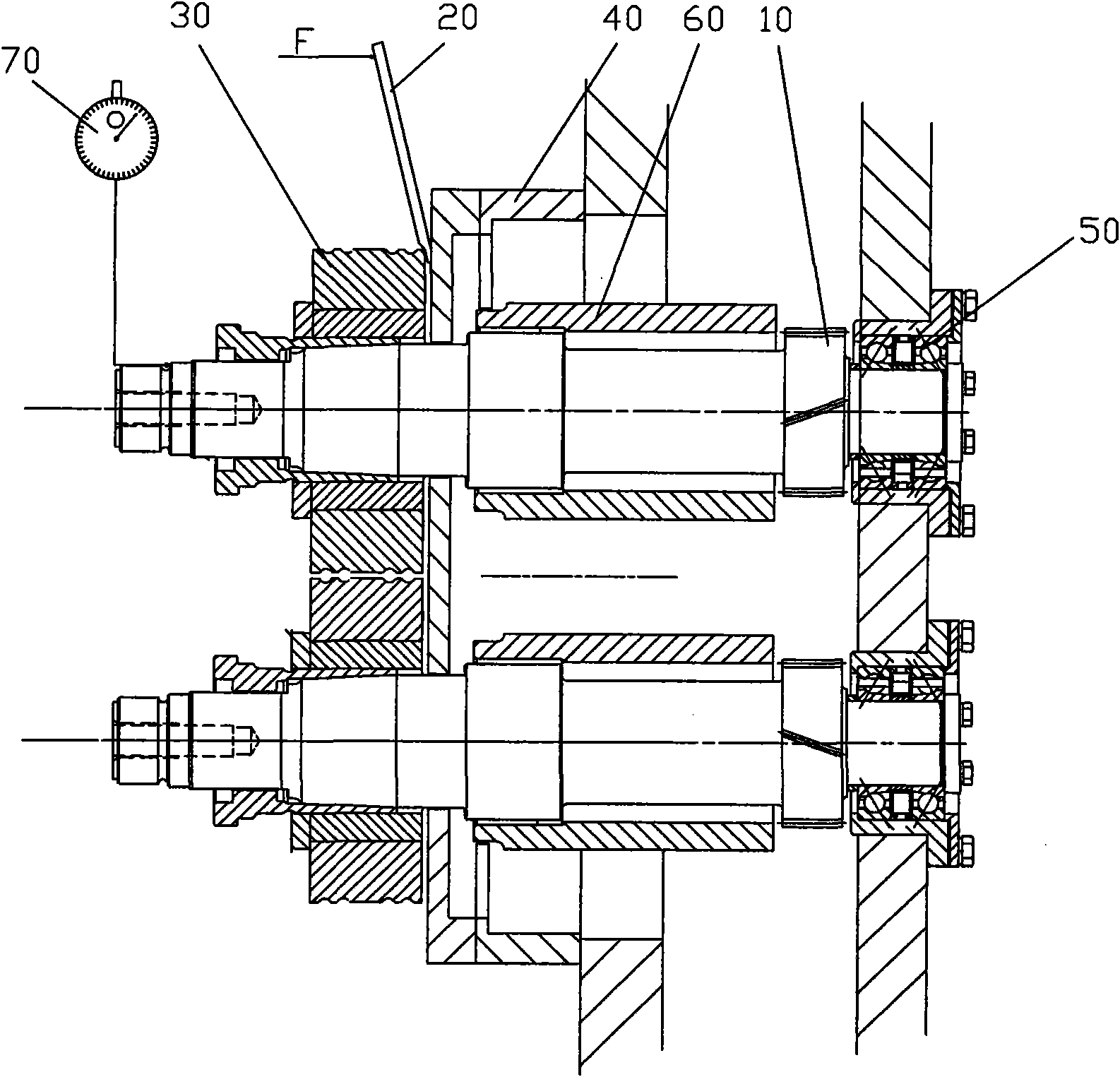

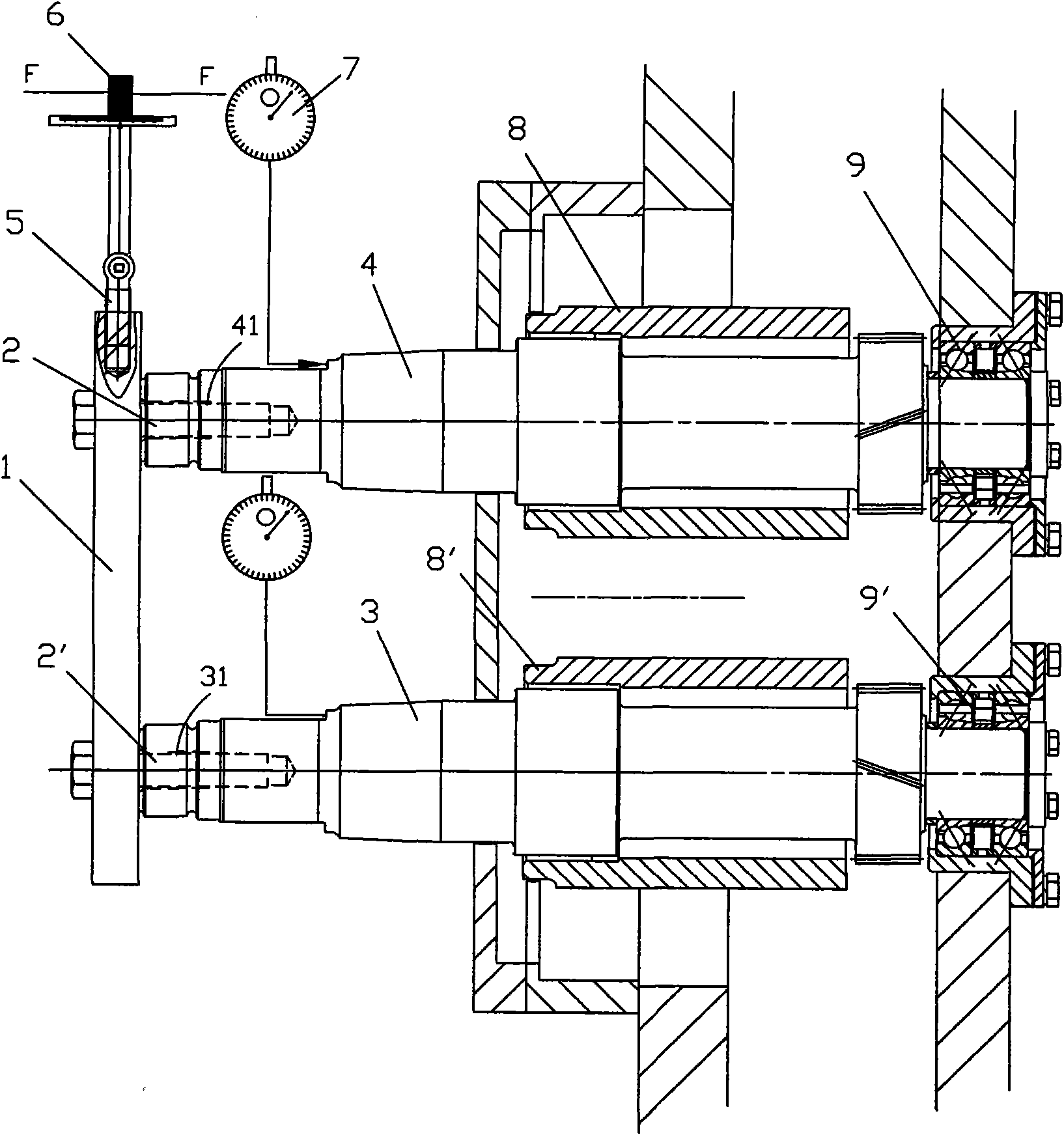

Method for measuring gap between bearings of roll shafts of pinch rolls

ActiveCN101929830AGuaranteed accuracyEasy to operateMechanical clearance measurementsEngineeringTorque wrench

The invention relates to a method for measuring a gap between bearings of roll shafts of punch rolls, which comprises the following steps: 1) vertically taking up a measuring connecting rod, and leading the upper part and the lower part of the measuring connecting rod to be connected with the shaft ends of the upper roll shaft and the lower roll shaft; 2) screwing the top end of the connecting rod into a measuring connecting bolt; 3) inserting one end of a pointer type torque wrench into the measuring connecting bolt; and placing dial indicators on the upper roll shaft and the lower roll shaft; 4) pulling the pointer type torque wrench to the right side by using the hand, and respectively recording values on the dial indicators when the pointer scale value on the pointer type torque wrench achieves the set value, wherein the value measured by the lower roll shaft is the gap between the bearings produced during the action of the left side; 5) pulling the pointer type torque wrench to the left side, and measuring the values of the dial indicators; and 6) adding the values measured by the upper roll shaft and the lower roll shaft during the two actions, and obtaining the accurate actual gap value between the bearings of the upper roll shaft and the lower roll shaft. The method can ensure the precision of the measured value at each time and improve the working efficiency of the measurement by quantifying the control during the measurement process, that is carrying out constant operation on the torque applied during the measurement and carrying out fixed point control on force application points.

Owner:BAOSHAN IRON & STEEL CO LTD

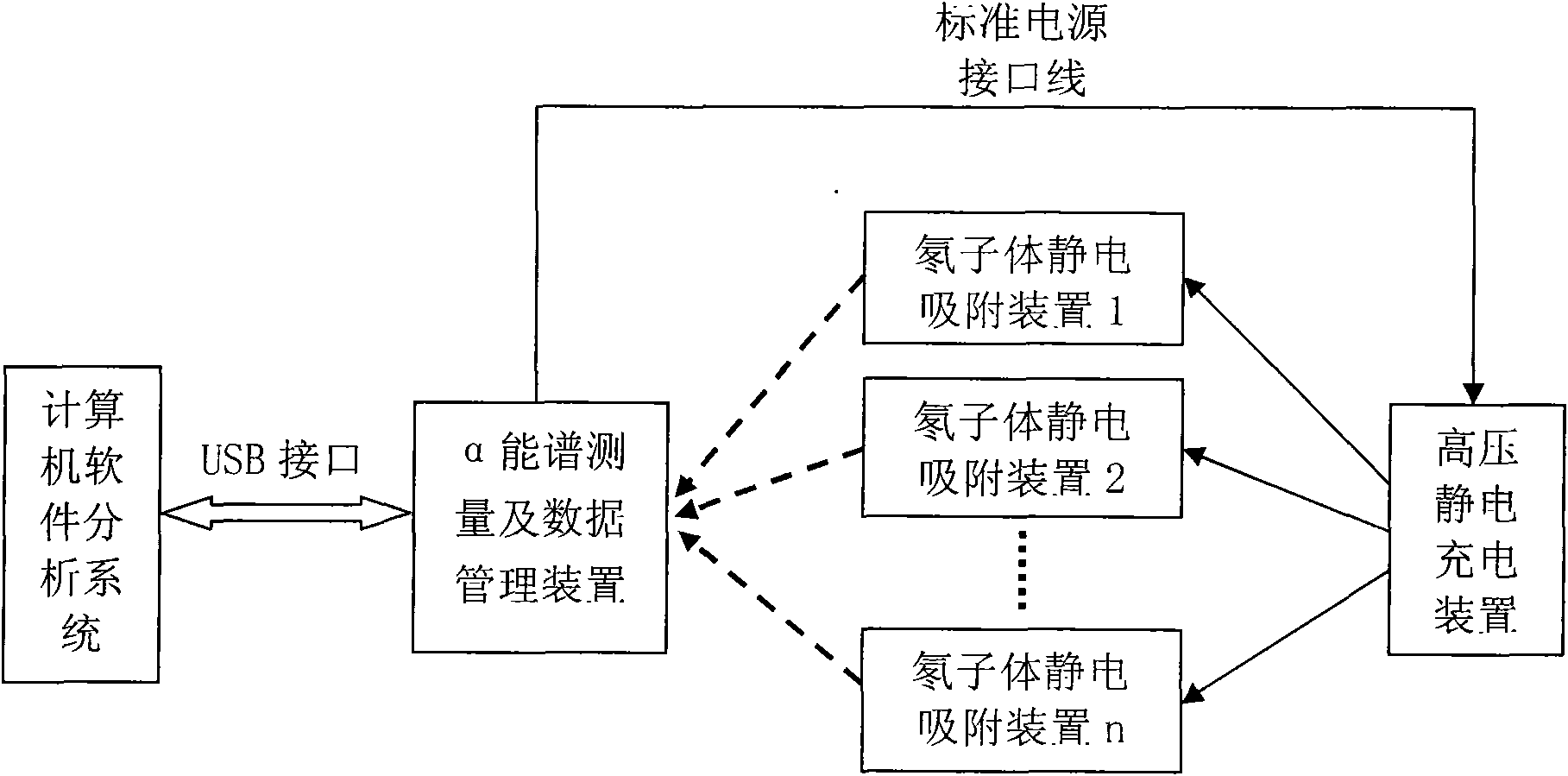

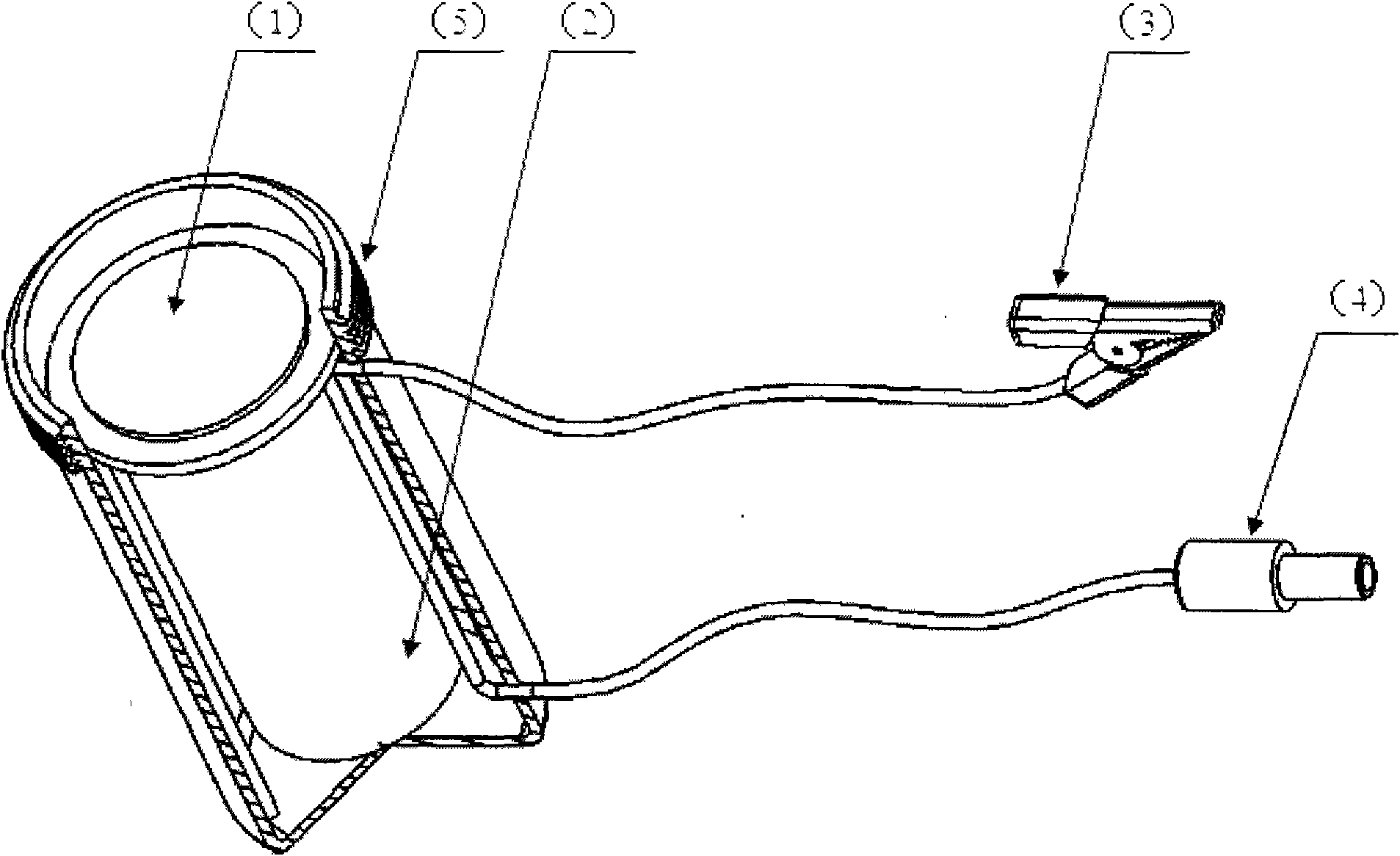

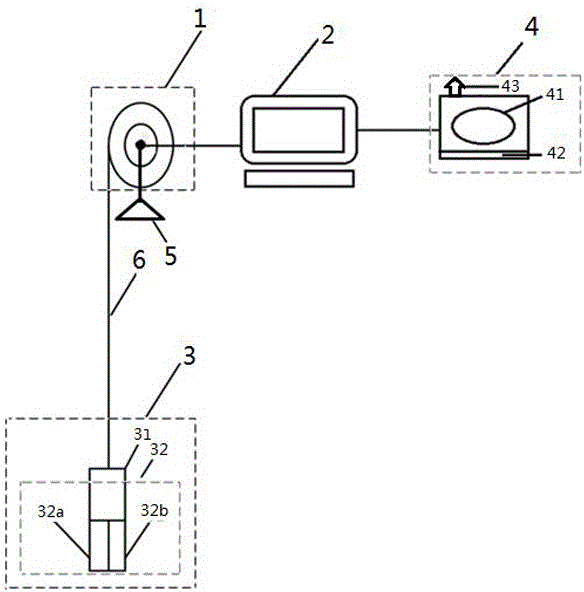

Alpha energy spectrum measuring method of radon in soil based on static diffusion and electrostatic adsorption principle of radon in soil

InactiveCN101620274AEliminate pollutionRealize measurementX-ray spectral distribution measurementNuclear radiation detectionHigh pressureHigh voltage

The invention discloses an alpha energy spectrum measuring method of radon in soil based on a static diffusion and electrostatic adsorption principle of the radon in soil, which comprises the following steps: (A) during measuring, burying a radon daughter electrostatic adsorption device in soil for a period of time, and then taking the radon daughter electrostatic adsorption device out and using an alpha energy spectrum measuring device to measure adsorbed radon daughters; (B) using a high-voltage electrostatic charging device to charge the radon daughter electrostatic adsorption device so as to enable the radon daughter electrostatic adsorption device to have high-voltage static electricity; (C) using an alpha energy spectrum measuring and data managing device to measure the alpha energy spectrum information of the adsorbed radon daughters of the radon daughter electrostatic adsorption device and concentratively managing the data; and (D) using a computer software analysis system to detailedly analyze the measuring data. The method can overcome the defects of the prior measuring method of the radon in soil, solve the problems of low soil radon measurement efficiency, precision, accuracy and reliability, and the like, indirectly measure the radon in soil by measuring nuclides of the radon daughters in soil, overcome the influences of thoron and meet the urgent requirement on the measurement of the radon the soil of the geological survey field and the environmental evaluation field at present.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

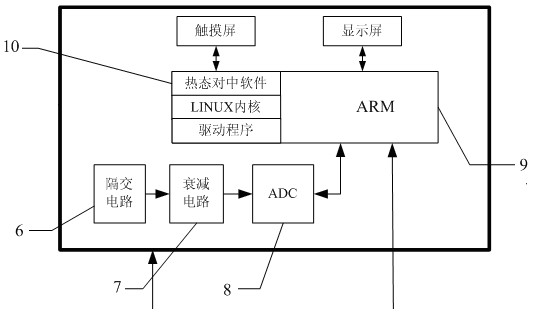

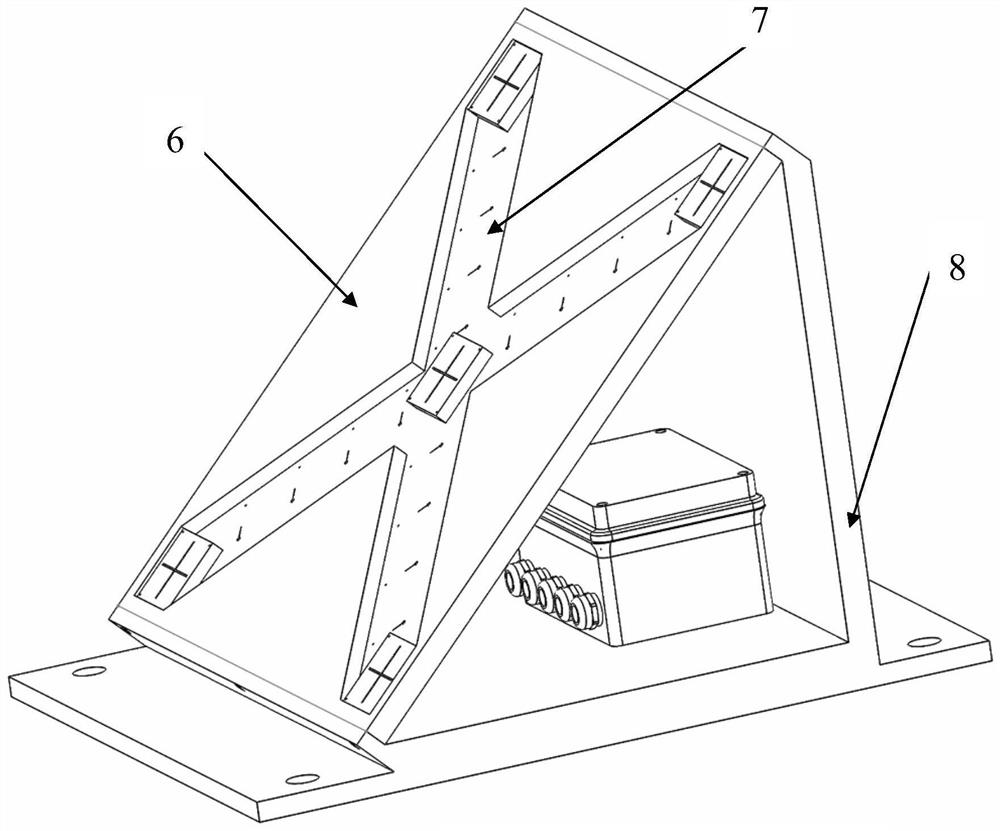

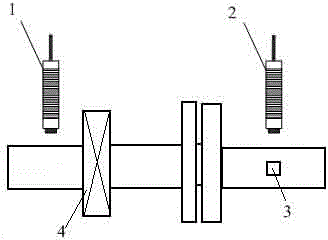

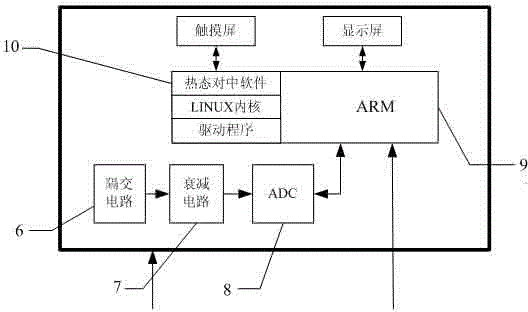

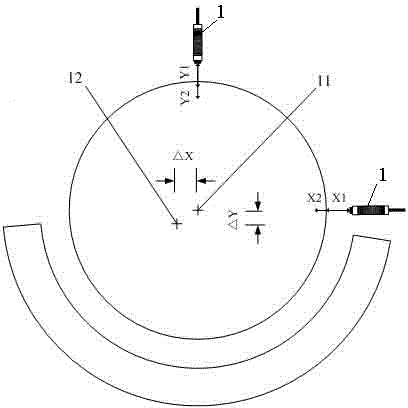

Shafting hot alignment device and shafting hot alignment method

ActiveCN102692180AEliminate time differenceHigh-resolutionUsing electrical meansUltrasound attenuationElectricity

The invention relates to a shafting hot alignment device and a shafting hot alignment method. Horizontal and vertical eddy current sensors are disposed at shafting bearing positions or alignment required positions of a unit around a journal. The horizontal and vertical eddy current sensors are used to measure shafting lateral clearance and vertical clearance respectively. Reflecting paper is adhered to a shaft at the alignment required position, and a revolution speed sensor corresponds to the reflecting paper is used for keyway-phase angle marking. Lateral clearance and vertical clearance value signals of the shafting of the eddy current sensor acquisition unit are processed by an alternating current blocking circuit and a signal attenuation circuit and are then transmitted into an ADC (analog to digital converter) and converted into digital signals, and the digital signals are transmitted to a rear-end ARM (advanced RISC machines) master control chip. When the shafting of the revolution speed sensor acquisition unit rotates to the reflecting paper, a signal of instant phase marking angle value is output, a square signal is output to the ARM master control chip, the signals are subjected to difference calculation by the ARM master control chip through hot alignment software, and data signal of shafting position compensation value required by hot alignment is output to a data output device.

Owner:SHANGHAI HENGTUO IND DEV

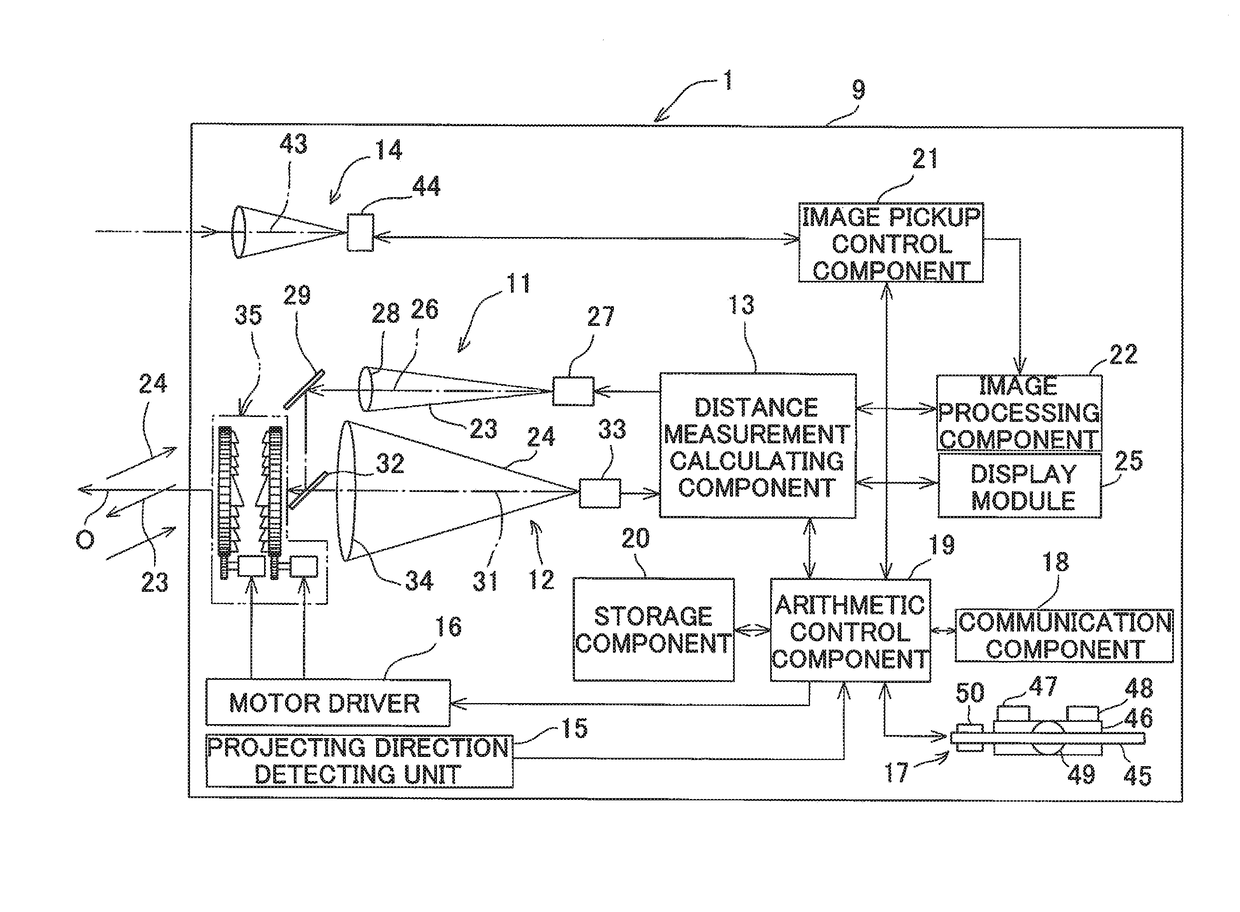

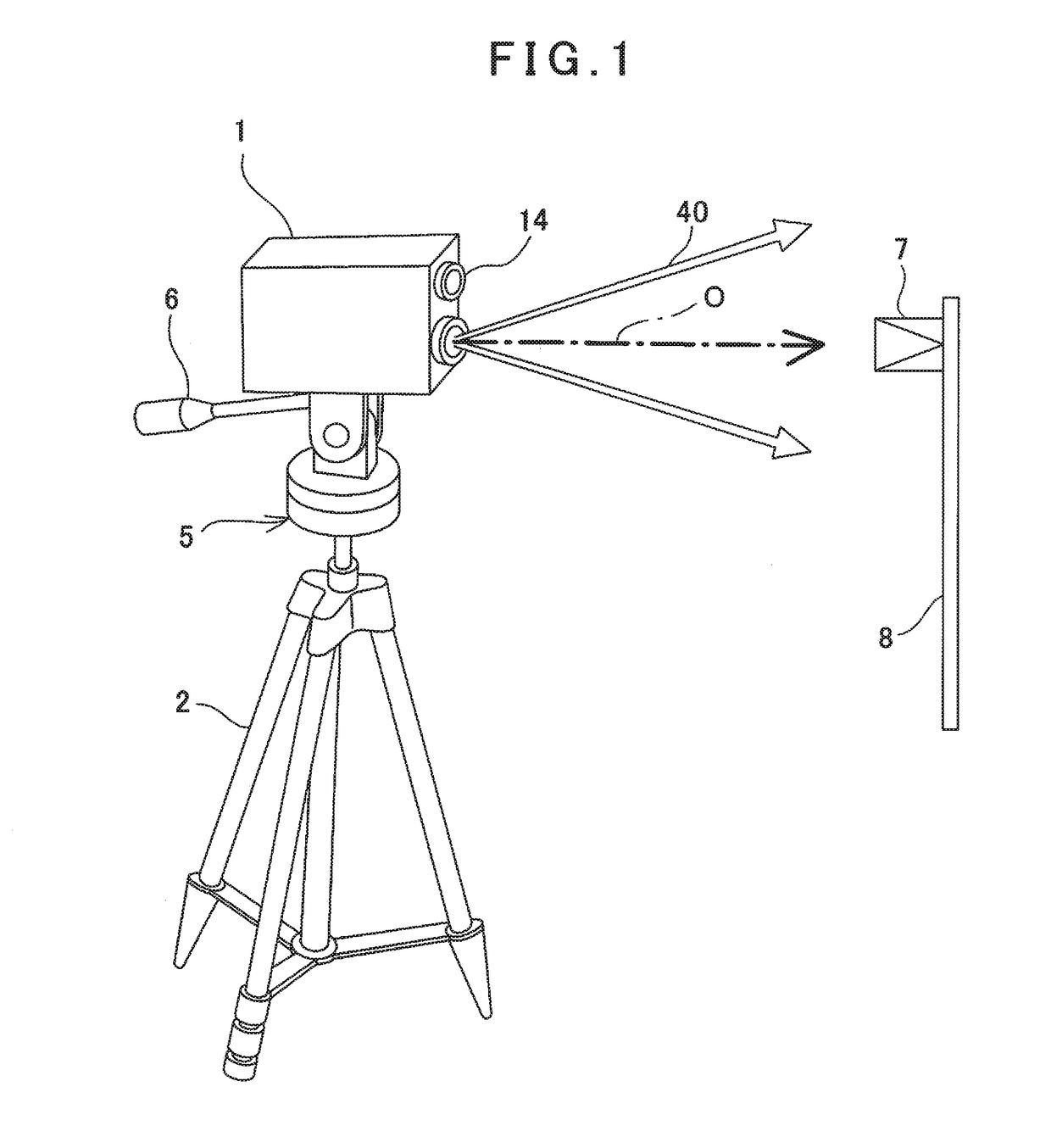

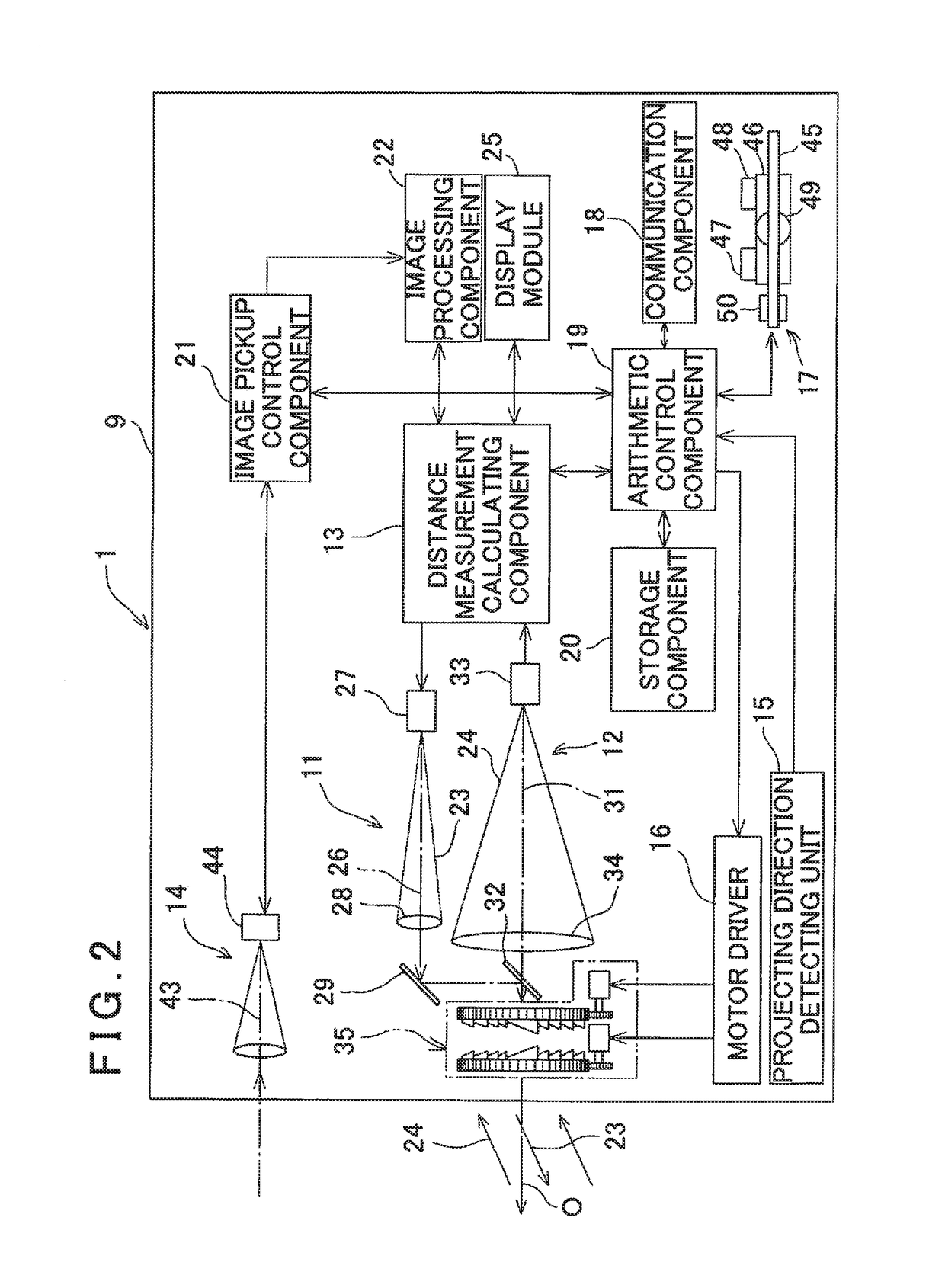

Measuring Instrument

ActiveUS20180231639A1Easy to seeEasily sight objectActive open surveying meansElectromagnetic wave reradiationMeasuring instrumentSurvey instrument

A surveying instrument comprises a distance measuring unit which includes a light emitting element, a distance measuring light projecting unit, a light receiving unit and a photodetector for producing a light receiving signal, and which performs a distance measurement of an object to be measured based on the light receiving signal, an optical axis deflecting unit for deflecting the distance measuring optical axis, a projecting direction detecting unit for detecting a deflection angle of the distance measuring optical axis and an arithmetic control component, wherein the optical axis deflecting unit comprises a pair of optical prisms capable of rotating and motors which individually and independently rotate the optical prisms, and wherein the arithmetic control component is configured to control the optical axis deflecting unit, to perform a two-dimensional scanning of the distance measuring light, to perform a distance measurement of when the light receiving signal is detected, to measure a horizontal angle and a vertical angle of the object to be measured, and to obtain three-dimensional coordinates of the object to be measured based on a distance value, and the horizontal angle and the vertical angle.

Owner:KK TOPCON

Measuring method and measuring apparatus for depth or end-face clearance of mechanical product cavity

ActiveCN101464127AEasy to detectImprove measurement efficiencyUsing electrical meansElectric/magnetic depth measurementMicrocomputerMeasurement device

The invention discloses a method for measuring the cavity depth or the end surface gap of mechanical products and a measuring device thereof. The measuring method comprises the following steps: fixing a product to be measured; determining a contrastive datum plane; building a contrastive reference surface; creating contrastive reference data; arranging a plane disk sheet between an electronic probe and an end surface to be measured; clinging the bottom surface of the plane disk sheet to the end surface of the product; acquiring a measured data signal by the electronic probe; calculating the contrastive reference data of the contrastive reference surface in a microcomputer; and displaying the measuring result on a display screen. The measuring device mainly comprises a working table, a workpiece clamping seat, a vertical ledge, an electrical control mechanism and a measuring component; and the measuring component which comprises a position block and the electronic probe is arranged at the top of the workpiece clamping seat. The invention has the advantages that the measuring result for the first time is very close to the minimum value; the measuring data is accurate; and the measuring efficiency is high.

Owner:NINGBO SHENGLONG AUTOMOTIVE POWERTRAIN SYSTEM CO LTD

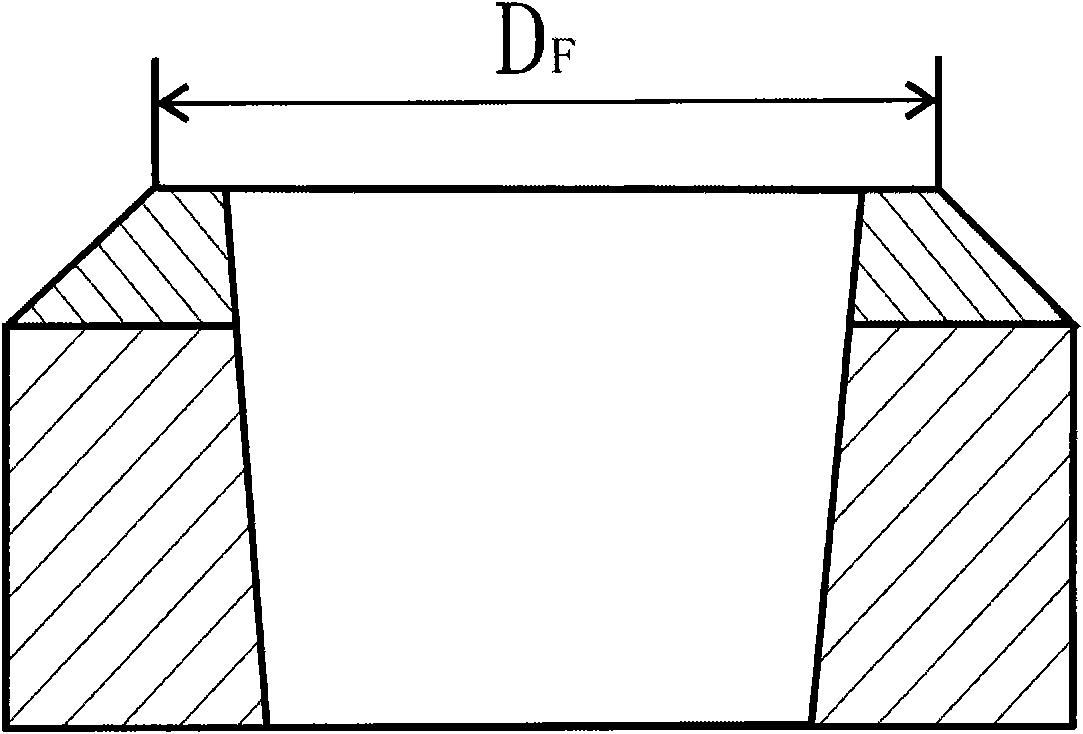

Chamfer diameter measurement method for oil drilling tool connector

ActiveCN102384709AGuaranteed measurement accuracySolve problems that cannot be measured directly and accuratelyMechanical diameter measurementsMeasurement pointOil drilling

The invention relates to a chamfer diameter measurement method for an oil drilling tool connector. A measurement tool is formed by a main measurement scale, a fixed end measurement arm, a sliding end measurement arm, a fixed end measurement datum plane, a sliding end measurement datum plane, a fixed end steel sphere measurement head and a sliding end steel sphere measurement head. The fixed end measurement datum plane is tightly attached to one end of a sealing end face of the drilling tool connector, the fixed end steel sphere measurement head is tightly attached to a chamfer face of the drilling tool connector, and a maximum value is read. According to the 45-degree chamfer face of the drilling tool connector, compensation quantity L1 between a corresponding measurement point and a true DF value is calculated, namely DF = (L + 20 + 2*L1) (mm). The L in the formula is the actual measurement value. The measurement of the DF value of the chamfer diameter is achieved by previously compensating the compensation value on a pair of calipers. The method resolves the problem that the chamfer diameter DF of the oil drilling tool connector cannot be directly and accurately measured, and improves accuracy and efficiency of measurement.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Surface shape measuring apparatus and surface shape measuring method

ActiveUS7918036B2Improve measurement productivitySimplify workFeeler-pin gaugesMechanical counters/curvatures measurementsMeasurement deviceSurface shape

Owner:TOKYO SEIMITSU

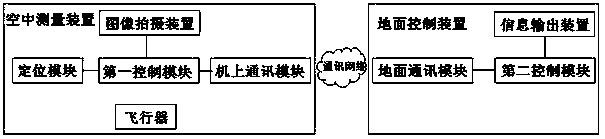

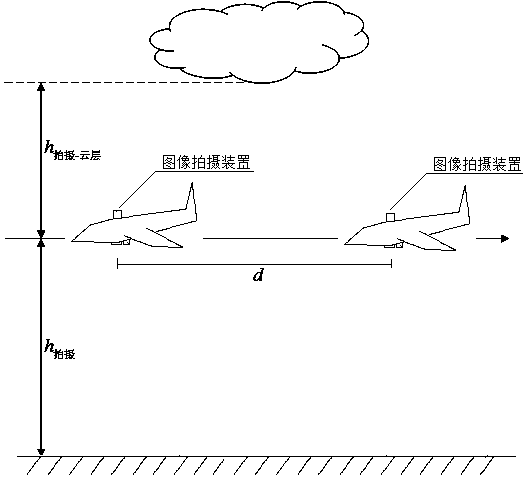

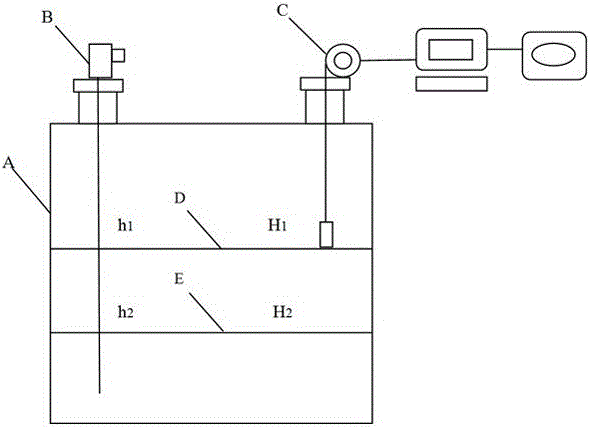

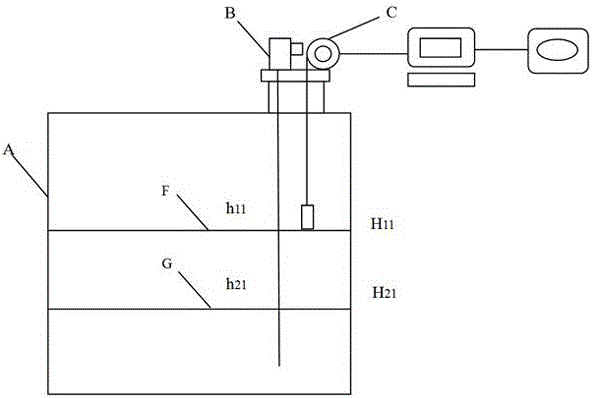

Cloud layer height measurement system and cloud layer height measurement method based on aircraft

ActiveCN103453882ASimple structureFlexible and accurate measurementHeight/levelling measurementMeasurement deviceCloud base

The invention relates to a cloud layer height measurement system based on an aircraft. The cloud layer height measurement system comprises an air measuring device and a ground control device. The air measuring device comprises the aircraft, a first control module, a location module, an airborne communication module and an image shooting device, wherein the first control module, the location module, the airborne communication module and the image shooting device are arranged on the aircraft, the image shooting device is perpendicularly arranged on the surface of the aircraft upwards in the shooting direction, the ground control module comprises a second control module, a ground communication module and an information output device, and the ground communication module and the information output device are connected with the second control module. The invention meanwhile relates to a cloud layer height measurement method. By means of the cloud layer height measurement system and the cloud layer height measurement device based on the aircraft, the cloud top height or the cloud base height can be flexibly and accurately measured according to measurement requirements, and the measurement work efficiency is effectively improved.

Owner:PLA UNIV OF SCI & TECH

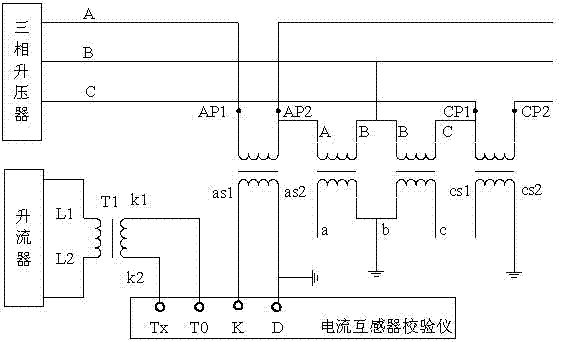

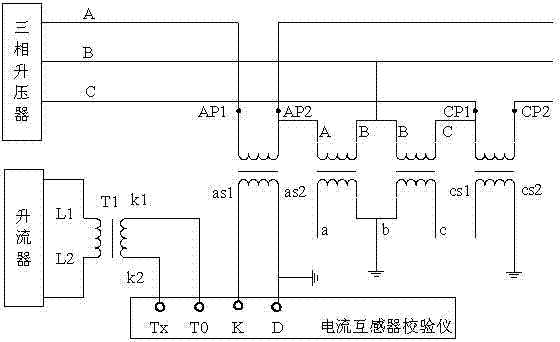

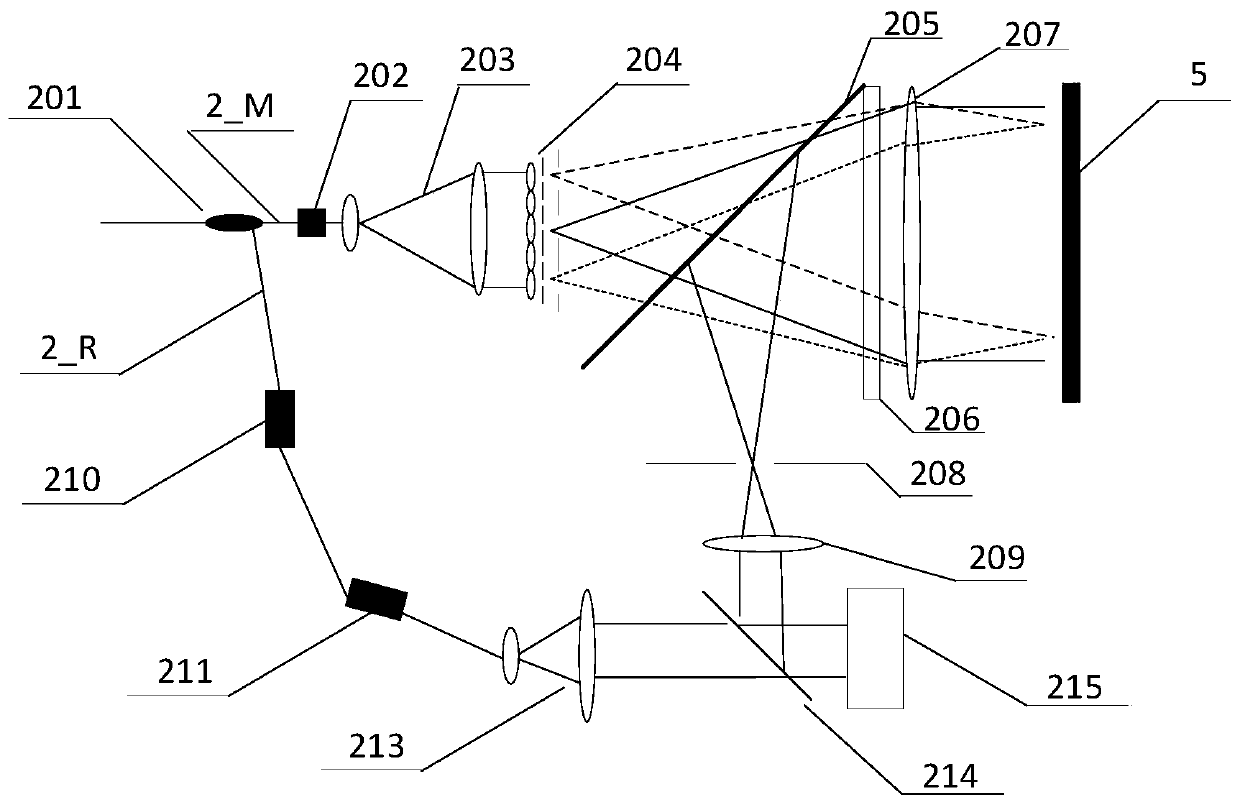

Method for testing error influence quantity to high-voltage three-phase current transformer from high-voltage leakage current

InactiveCN102508190AImprove accuracyThe direct test method is simple and convenientTransformers testingTest efficiencyCurrent point

The invention discloses a method for testing error influence quantity to a high-voltage three-phase current transformer from high voltage leakage current, which comprises the following steps of adopting a booster to implement three-phase symmetric rated voltage on a primary terminal of the high-voltage three-phase current transformer, inputing the leakage current output by a secondary terminal of the current transformer into a transformer calibrator as differential current, and inputing one percent rated current of the secondary output of the tested current transformer which is generated by the booster and the current transformer for test into the transformer calibrator as working current, so that the transformer calibrator can directly measure the error influence quantity of the high-voltage leakage current to the high-voltage three-phase current transformer at the one percent rated current point. The phase position of the working current of the transformer calibrator is in accordance with the phase position of the voltage implemented by the primary terminal of the tested current transformer, so that the operation performance of the high-voltage three-phase current transformer under an actual operation condition is truly realized; and the accuracy of the test results and test efficiency are improved.

Owner:STATE GRID SICHUAN ELECTRIC POWER CORP ELECTRIC POWER RES INST +1

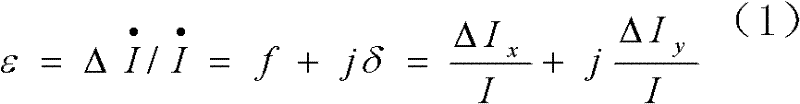

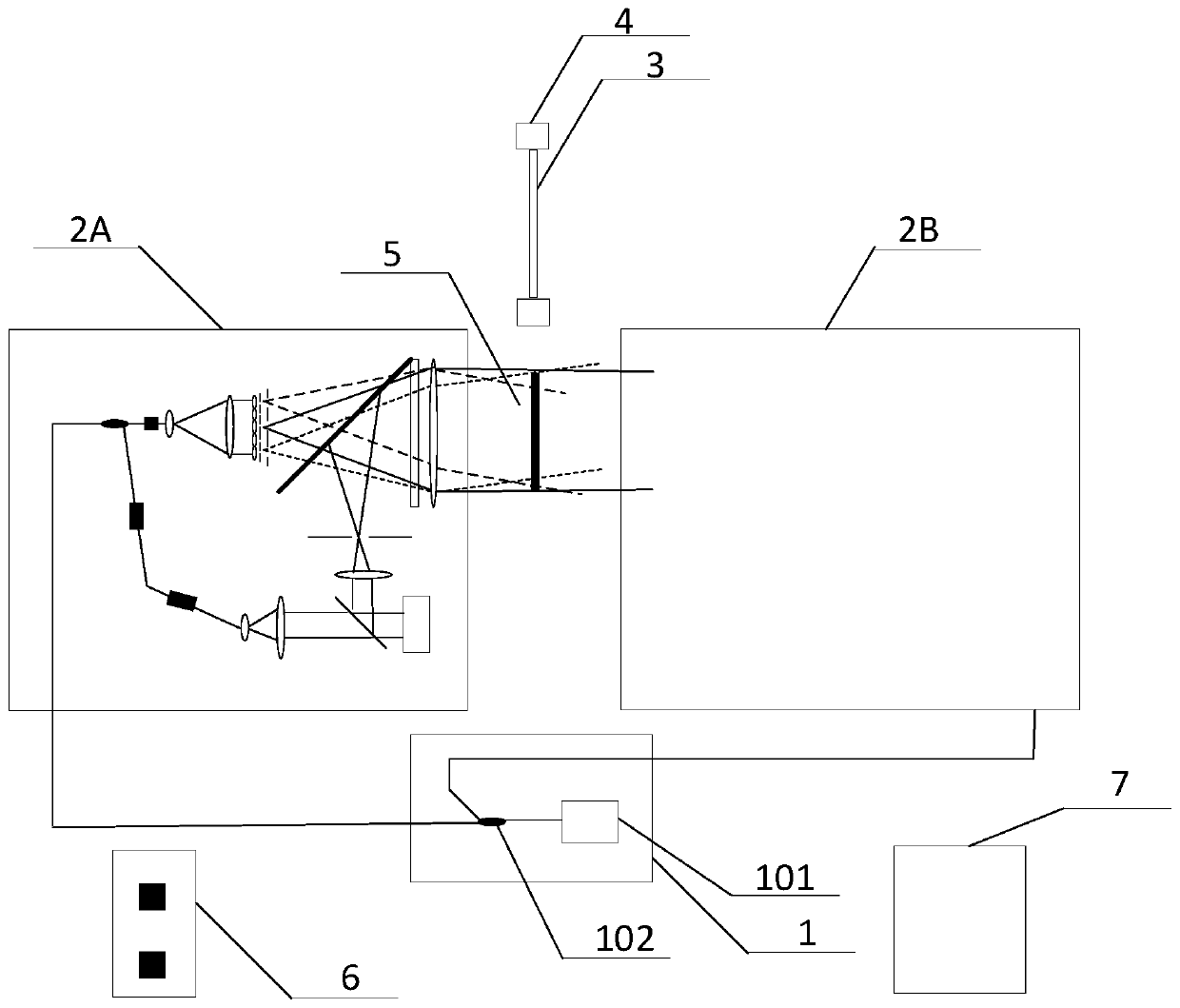

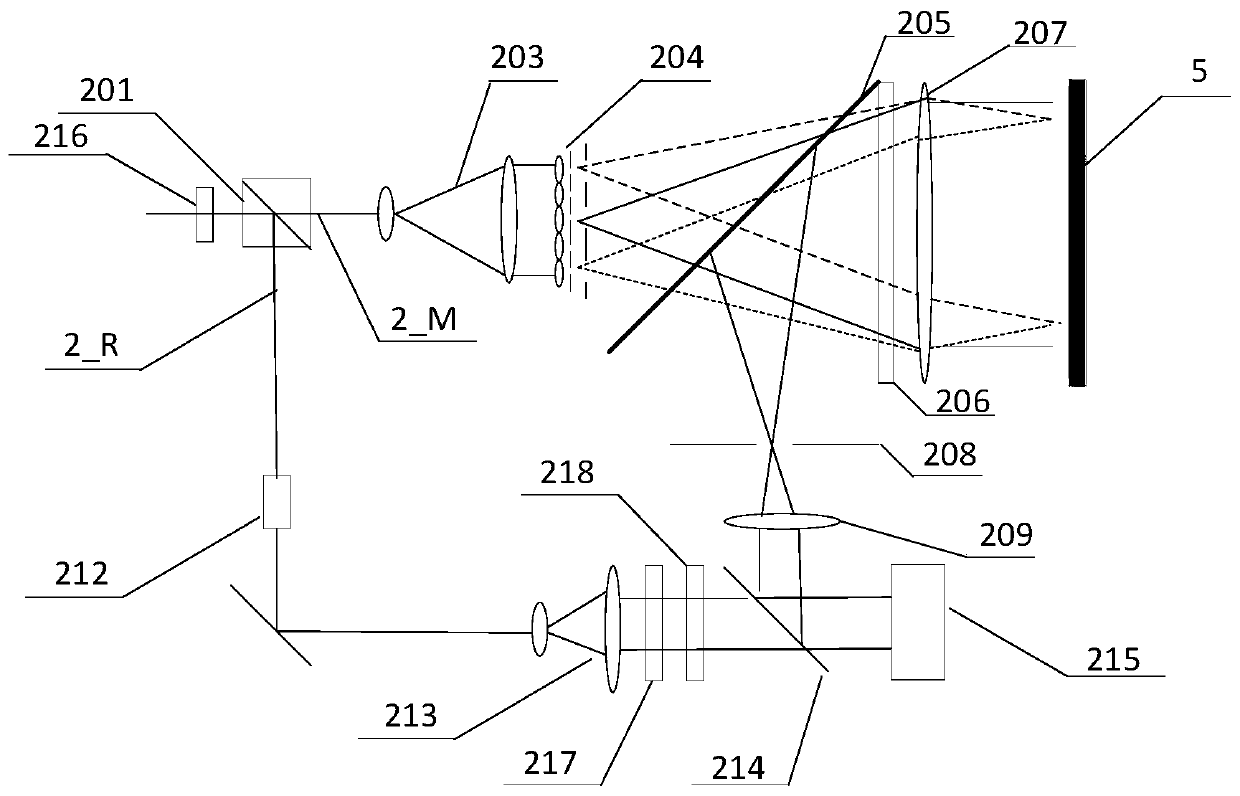

Bilateral multi-plane inclined wave surface interferometer and detection method thereof

ActiveCN111207844AImprove measurement productivityLarge measurement dynamic rangeOptical measurementsUsing optical meansPhase shiftedEngineering

The invention relates to a bilateral multi-plane inclined wave surface interferometer. The system comprises a light source module, a first interferometer host, a second interferometer host, a double-sided standard flat plate, a double-sided standard flat plate adjusting frame, a measured non-transparent flat plate element, a single-point thickness measuring sensor and a control processing unit, wherein the first interferometer host and the second interferometer host are both multi-plane inclined wave surface interferometers. The interferometer is advantaged in that parallel measurement light in multiple directions is emitted through a point source array generator to measure the bilateral morphology and thickness of the measured non-transparent flat plate element, and the interferometer hasadvantages of being large in measurement dynamic range, high in measurement precision and efficiency, flexible in phase shift mode and capable of achieving in-situ calibration of system errors.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

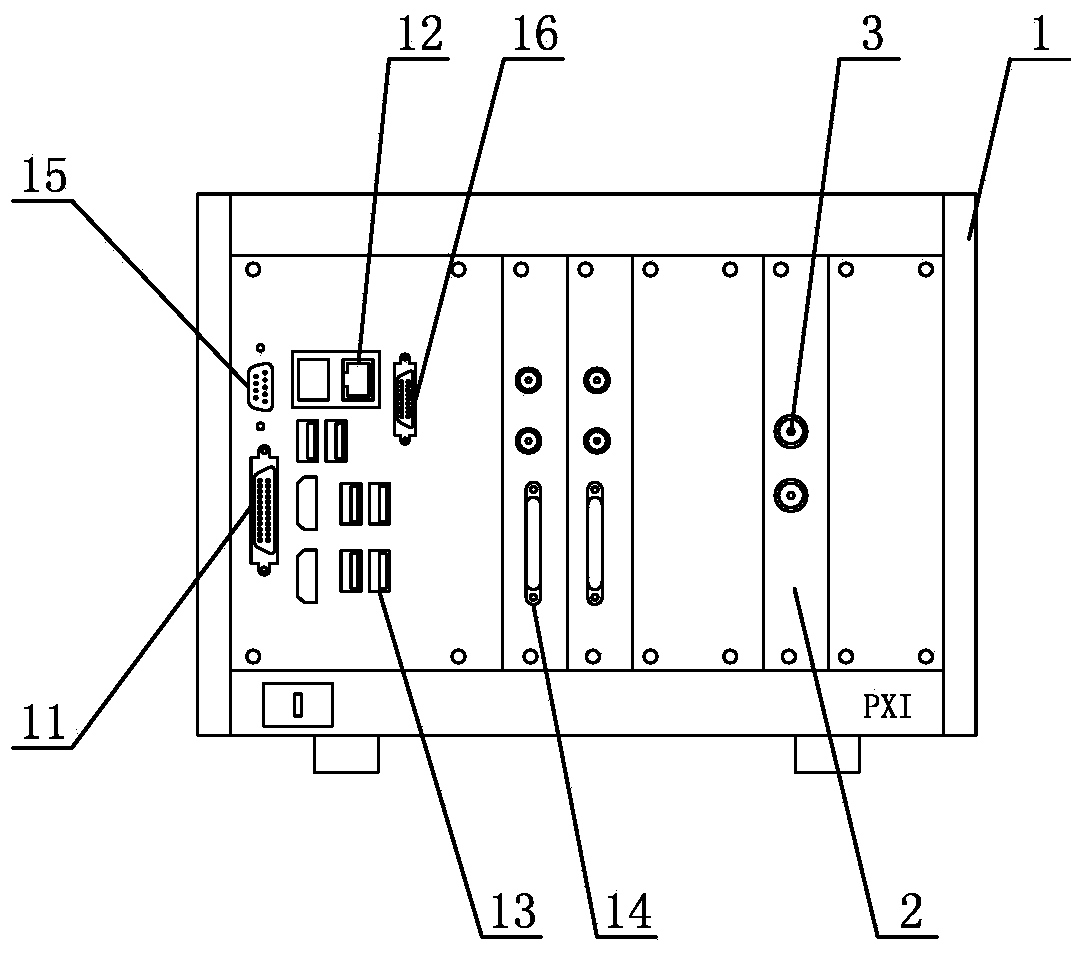

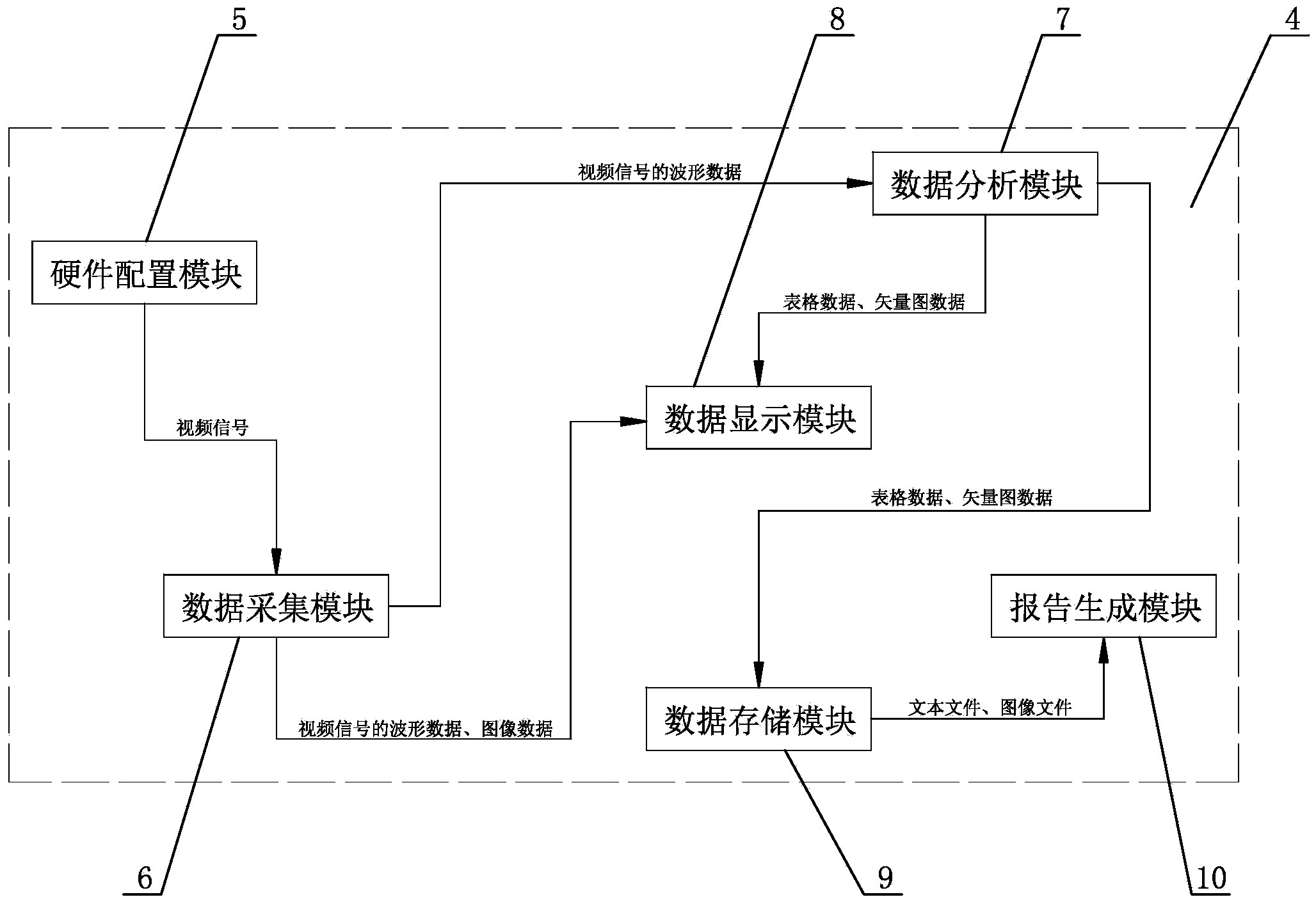

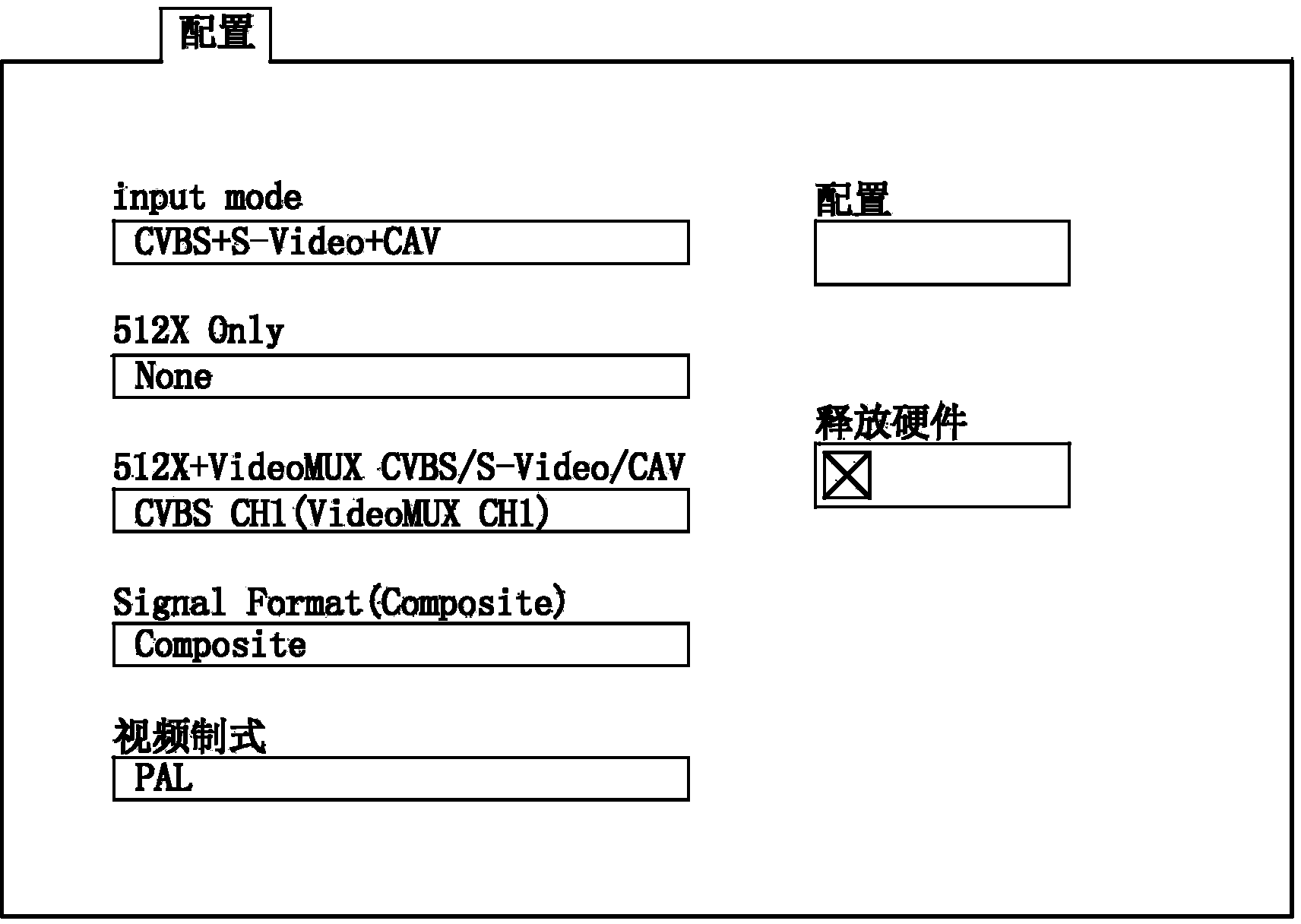

Automatic video measuring system based on LabVIEW and VideoMASTER

ActiveCN103905817ANew measurement interfaceImprove measurement confidenceTelevision system detailsColor television detailsData displayHDMI

The invention relates to an automatic video measuring system based on LabVIEW and VideMASTER. The automatic video measuring system comprises a VideoMASTER video measuring instrument. The VideoMASTER video measuring instrument comprises a measuring computer mainframe, a plurality of data collecting cards and a displayer. Each data collecting card is provided with two video signal input ports. A LabVIEW-based video measuring platform is arranged in the measuring computer mainframe and comprises a hardware configuration module, a data collecting module, a data analysis module, a data display module, a data storge module, and a report generation module. The measuring system can automatically measure formats such as simulation composition, standard high definition components and VGA and formats such as digital HDMI and DVI.

Owner:THE THIRD RES INST OF CHINA ELECTRONICS TECH GRP CORP

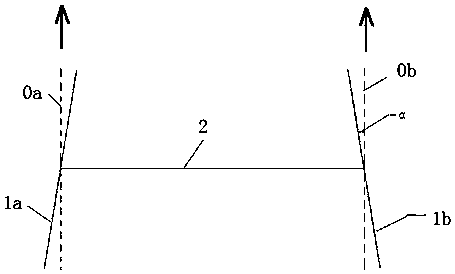

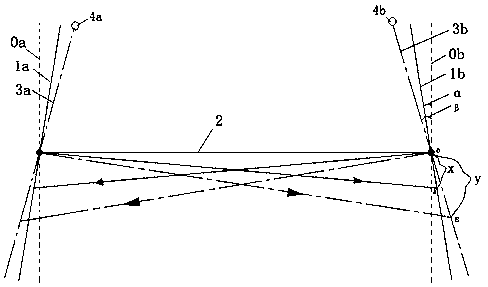

Method for measuring front toe angle of automobile front wheels

InactiveCN108303042AAvoid lossAvoid security issuesUsing optical meansVehicle wheel testingLaser rangingLaser transmitter

The invention discloses a method for measuring the front toe angle of automobile front wheels. The method comprises the steps that (1) the measurement center point of a left front wheel and a right front wheel is determined; (2) the measurement center point and an infrared laser transmitter are used to determine the offset distance of the front wheels; (3) through the offset distance Y read by a camera, the offset distance of the front wheels is further converted into the measurement angle value of the front toe angle of the front wheels; and (4) the measurement angle value is compared with afactory-set threshold of an automobile, and the front toe angle is corrected according to the comparison result. According to the invention, the principle of laser ranging is used to accurately calculate the offset of the front toe angle of the automobile front wheels, which fills the blank of the front toe angle measurement technology of the automobile at home and abroad; the measurement method provided by the invention is simple, and the measurement accuracy is high; the measurement efficiency is effectively improved; and the method provides a strong basis for the precise adjustment of the front toe angle of the automobile, and at the same time can effectively prevent automobile wheel loss and safety accidents.

Owner:NANJING WOYU MECHANICAL & ELECTRICAL EQUIP CO LTD

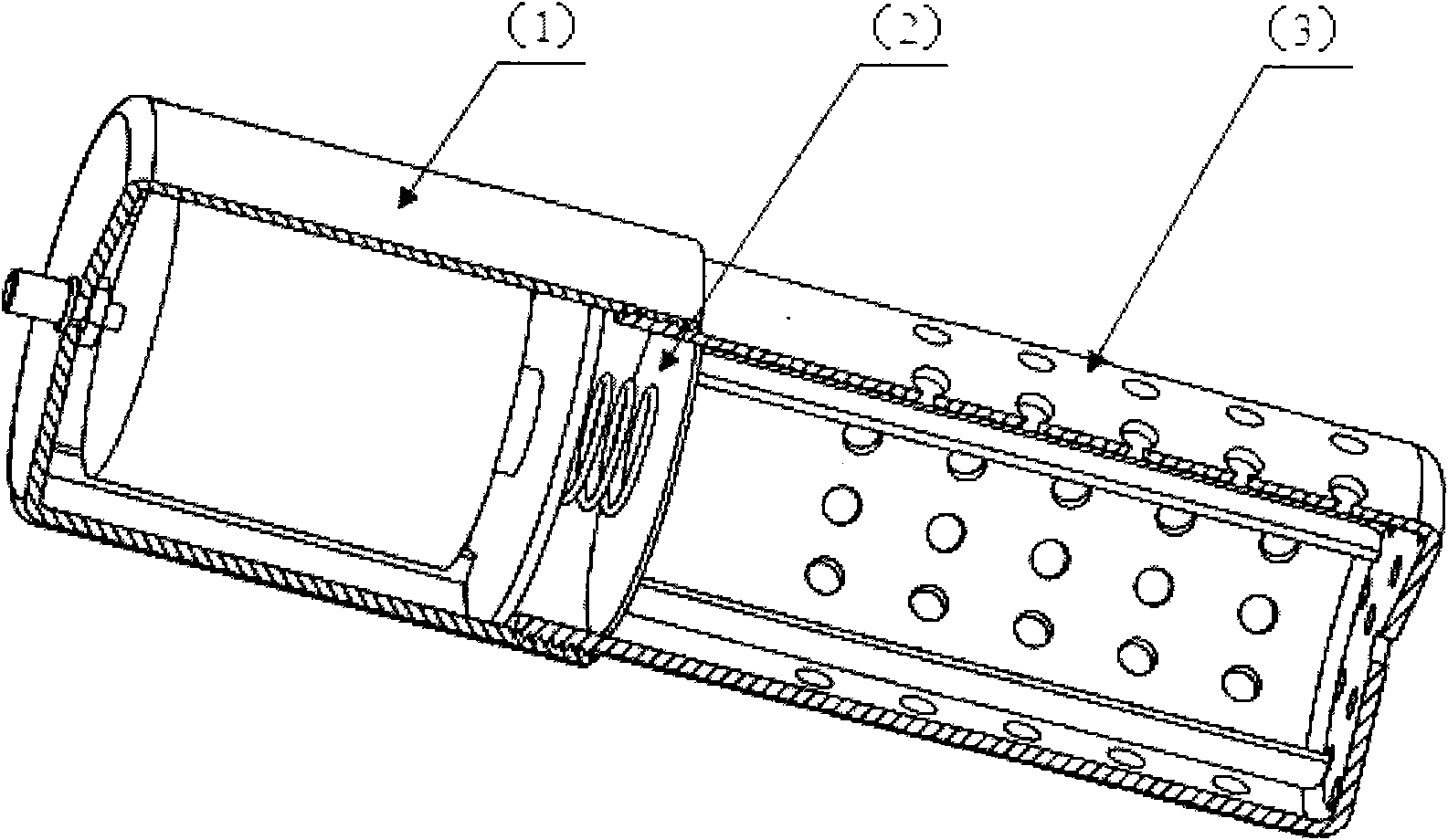

Onboard measuring working cabin convenient to carry and assemble

ActiveCN102837802AEasy to carryEasy to assembleAccommodation for deck loadsVessel partsEngineeringWire rope

Owner:DALIAN SENBIOR SURVEYING INSTR TECH CO LTD

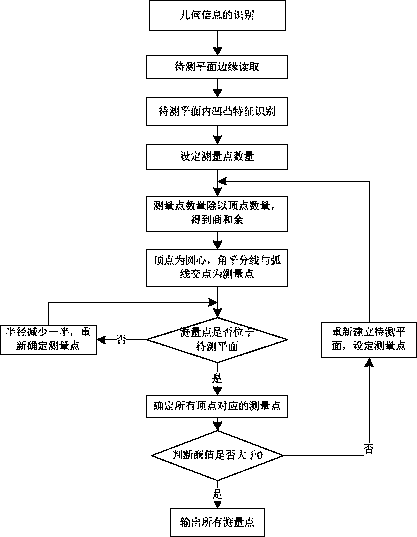

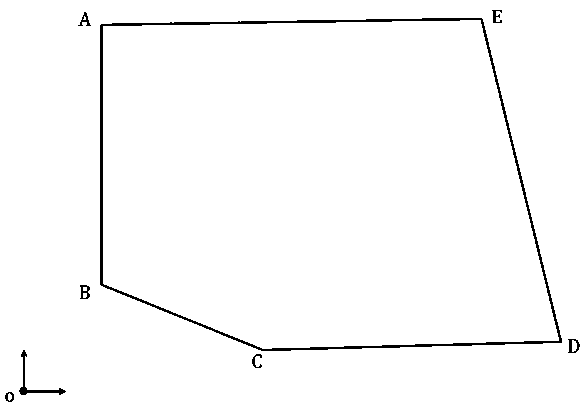

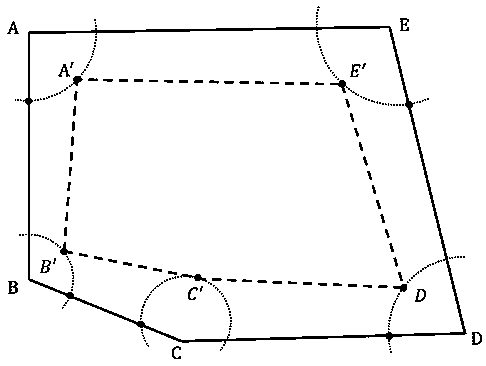

Measuring route planning method for coordinate measuring machine

ActiveCN109059821AQuick tagShort measuring pathMeasurement devicesForecastingMeasurement pointCoordinate-measuring machine

The invention discloses a measuring route planning method for a coordinate measuring machine and is used for the optimum measuring route planning of a complex geometrical plane. The method comprises the steps of identifying geometrical information; reading edges of a to-be-measured plane; identifying concave-convex characteristics in the to-be-measured plane; determining the number and locations of measuring points; computing a result of dividing the number of vertexes by the number of the measuring points, thereby obtaining a quotient value and a remainder value; drawing arcs in the plane bytaking the vertexes as circle centers, wherein intersection points of angle bisectors of vertex angles at which the vertexes are located and the arcs are the locations of the measurement points; generating a measuring route; identifying obstacle avoidance points; and finally determining the measuring route. According to the method, the measuring points can be rapidly marked according to geometrical parameters of the to-be-measured plane and the optimum measuring path is determined according to distribution of the measuring points, so the measuring route of the coordinate measuring machine is enabled to be the shortest and have least measuring time and highest measuring precision, working efficiency and precision are improved, the obtained measuring points are effectively prevented from being located at the exterior of a measuring plane in a route planning process, and the measuring points are enabled to be uniformly distributed in the measuring plane.

Owner:HEFEI UNIV OF TECH

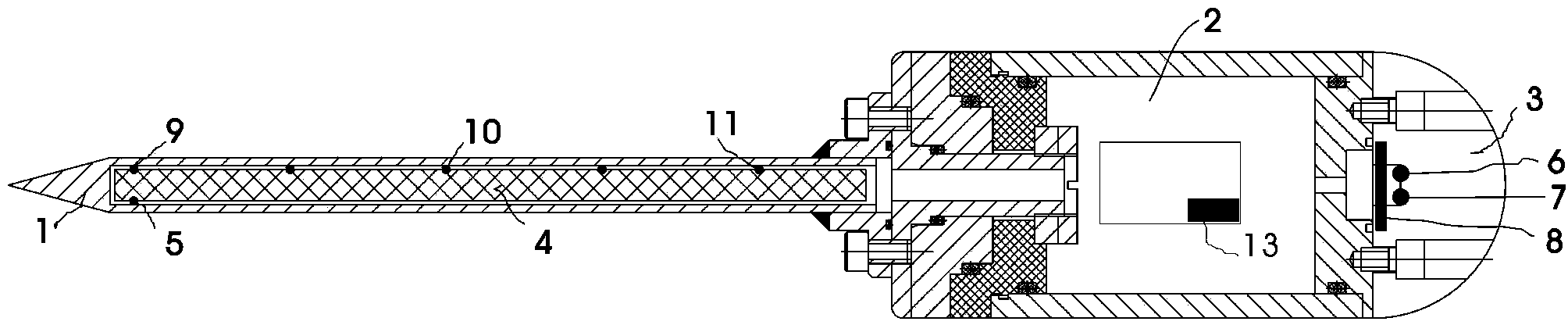

High-precision seabed terrestrial heat flow detection device

InactiveCN104062692ARealize analysisImprove consistencyMaterial heat developmentThermometers using electric/magnetic elementsOcean bottomData acquisition

The invention provides a high-precision seabed terrestrial heat flow detection device. The high-precision seabed terrestrial heat flow detection device comprises a pressure protection pipe, an electronic instrument cabin, a transparent protection cover, a heat insulation rod, a heating element, a two-color LED, a photosensitive element, a charging induction coil and a plurality of thermistors, wherein the pressure protection pipe is installed on one side of the electronic instrument cabin, the heat insulation rod is installed in the pressure protection pipe, and the thermistors are installed on the heat insulation rod. The heating element is installed at the top end of the heat insulation rod, a three-axis acceleration sensor is installed in the electronic instrument cabin, the two-color LED, the photosensitive element and the charging induction coil are installed outside the electronic instrument cabin, and the transparent protection cover is installed outside the two-color LED, the photosensitive element and the charging induction coil. The heating element, the two-color LED, the photosensitive element, the charging induction coil and the three-axis acceleration sensor are connected with a control device through conducting wires, wherein the control device is installed in the electronic instrument cabin. Variation of the angle of inclination of the device is indicated through the two-color LED, operation is facilitated, and data acquisition efficiency is improved.

Owner:GUANGZHOU MARINE GEOLOGICAL SURVEY +1

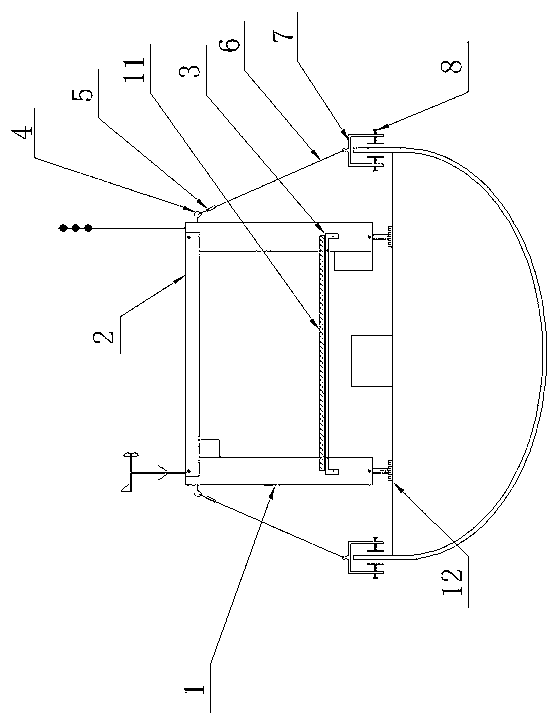

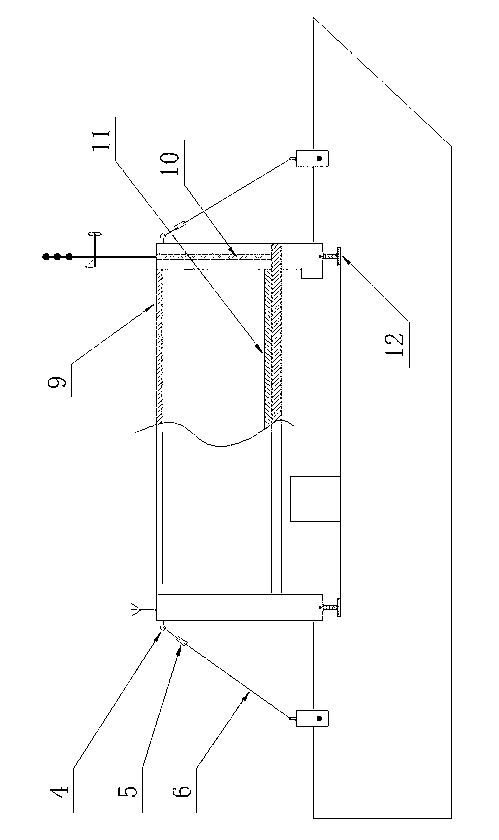

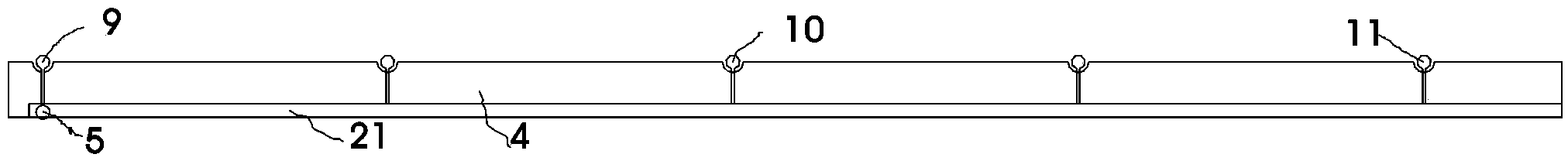

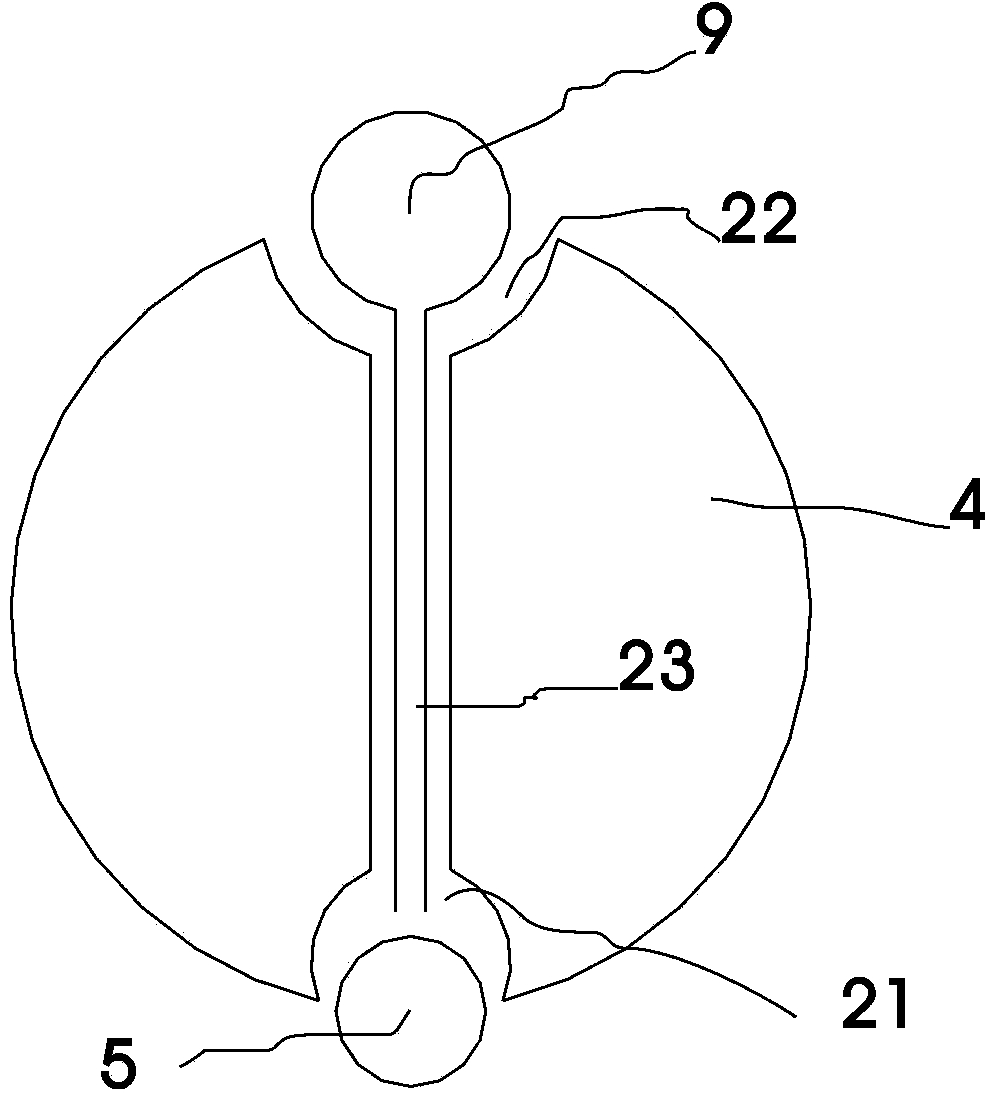

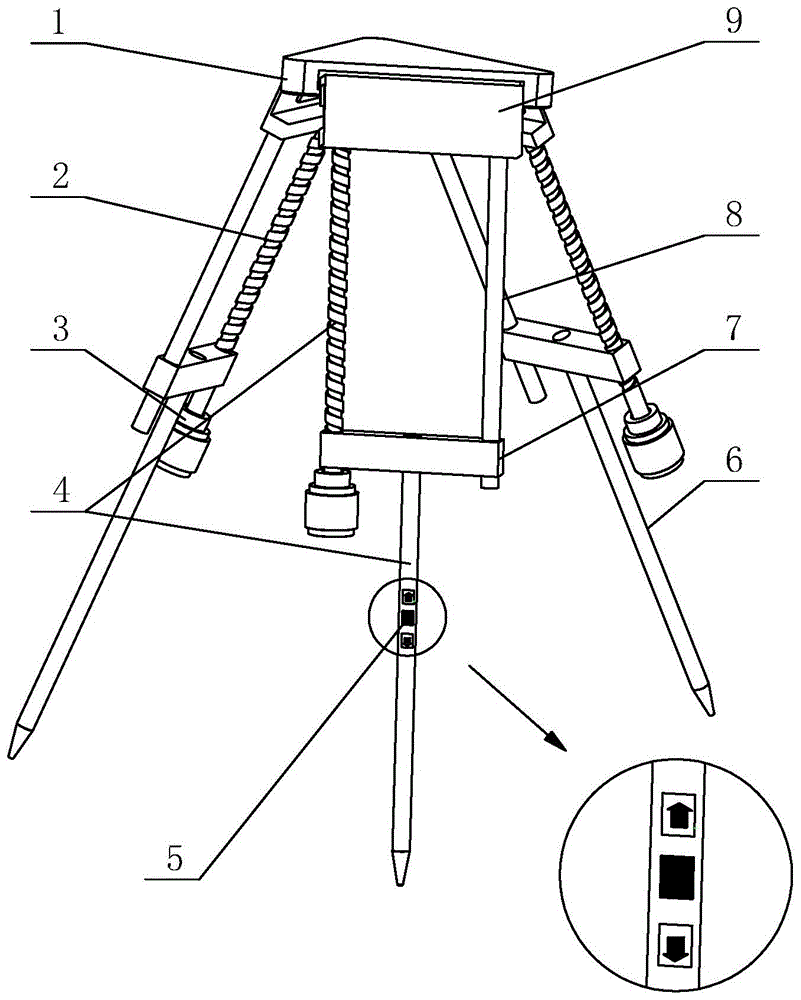

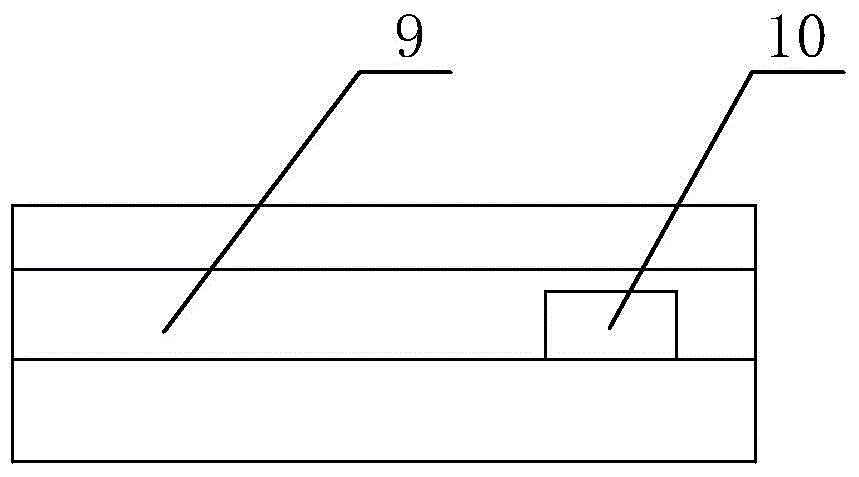

Measuring instrument foot stool capable of automatically ascending, descending and leveling

InactiveCN104677334AFlexible up and down adjustmentReduce alignment timeSurveying instrumentsHeight/levelling measurementMeasuring instrumentEngineering

The invention discloses a measuring instrument foot stool capable of automatically ascending, descending and leveling. The measuring instrument foot stool comprises a work platform (1) and three supporting frames (4) used for supporting the work platform (1), and the supporting frames (4) are connected with the work platform (1) through connection blocks (9). Each supporting frame (4) comprises a screw rod (2), a supporting rod (6), a guide rod (8), a movable block (7) and a direct-current motor (3), wherein three round holes I (7.1) are formed in the movable block (7); the upper end of the screw rod (2) is connected with the corresponding connection block (9), and the lower end of the screw rod (2) penetrates through the round holes I (7.1) to be connected with the direct-current motor (3); the upper end of the guide rod (8) is connected with the corresponding connection block (9), and the lower end of the guide rod (8) is movably connected with the round holes I (7.1); the screw rod (2) is parallel to the guide rod (8). The measuring instrument foot stool can shorten leveling and centering time and improve measurement work efficiency, are easier and more convenient to operate, and can be easily operated by a green hand.

Owner:LIUZHOU RAILWAY VOCATIONAL TECHN COLLEGE

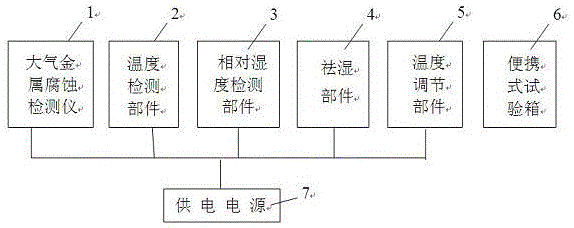

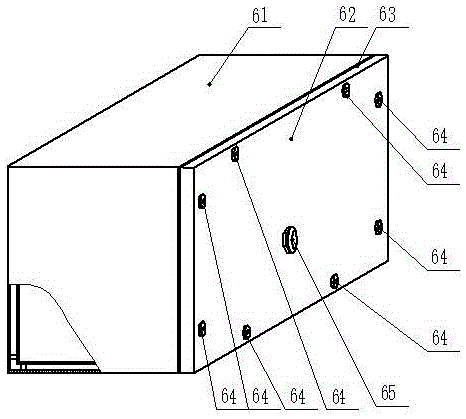

Testing device used for rapid detection of atmosphere environment metal corrosion behavior

PendingCN106610368AImprove measurement productivityEasy to operateWeather/light/corrosion resistanceAtmospheric corrosionCorrosion behavior

The invention discloses a testing device used for rapid detection of atmosphere environment metal corrosion behavior. The testing device is composed of an atmosphere metal corrosion detector (1), a temperature detecting part (2), a relative humidity detecting part (3), a dampness eliminating part (4), a temperature adjusting part (5), a portable test box (6), and a power supply (7). According to the testing device, on testing sites of atmosphere environment, rapid detection of wet atmospheric corrosion behavior and rules of metal in atmosphere with the same content of natural environment atmosphere is realized by testers via increasing and reducing adjusting of the environment temperature in the portable test box and graduate reducing process of the relative humidity, critical humidity at metal corrosion atmosphere environment is determined, and working efficiency is increased. The testing device and the above method can be adopted to study different metal atmosphere corrosion behavior and rules via changing metal corrosion sensors of different materials; operation is simple; cost is low; and application range is wide.

Owner:ZHAOTONG POWER SUPPLYING BUREAU OF YUNNAN POWER GRID +1

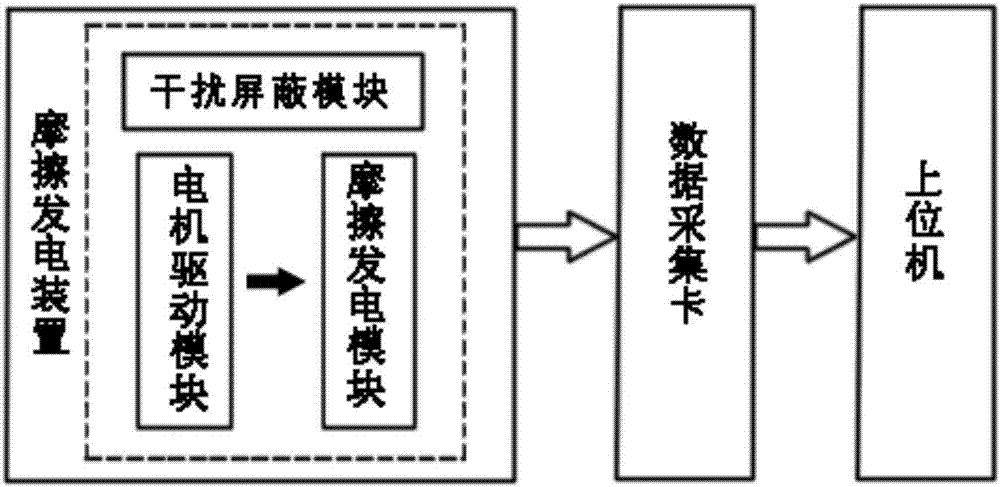

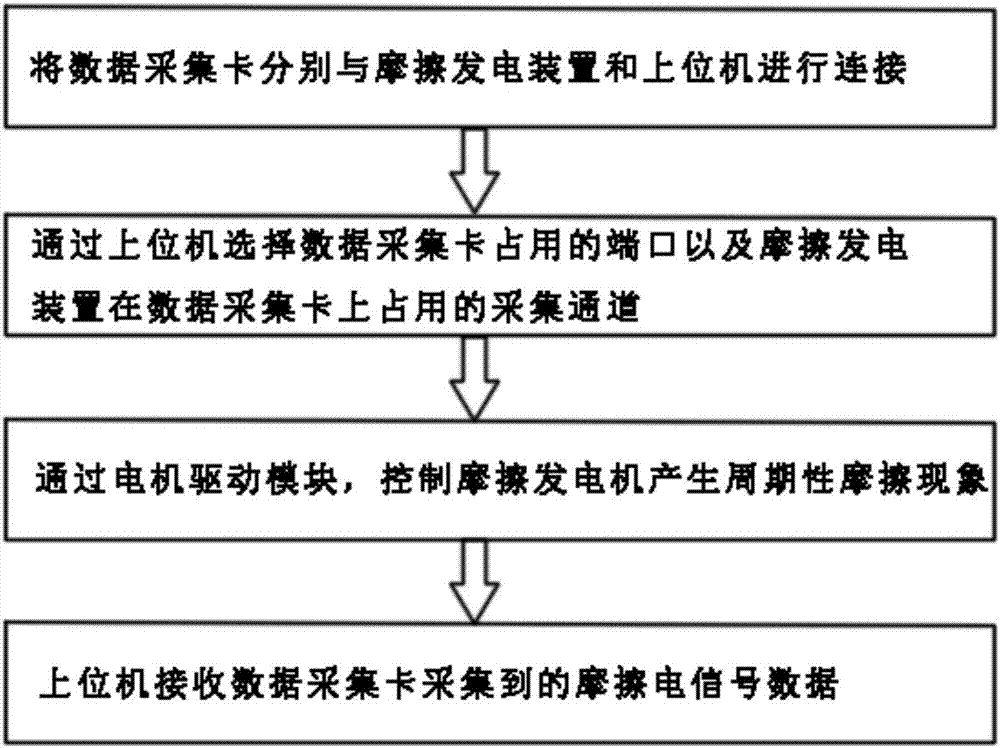

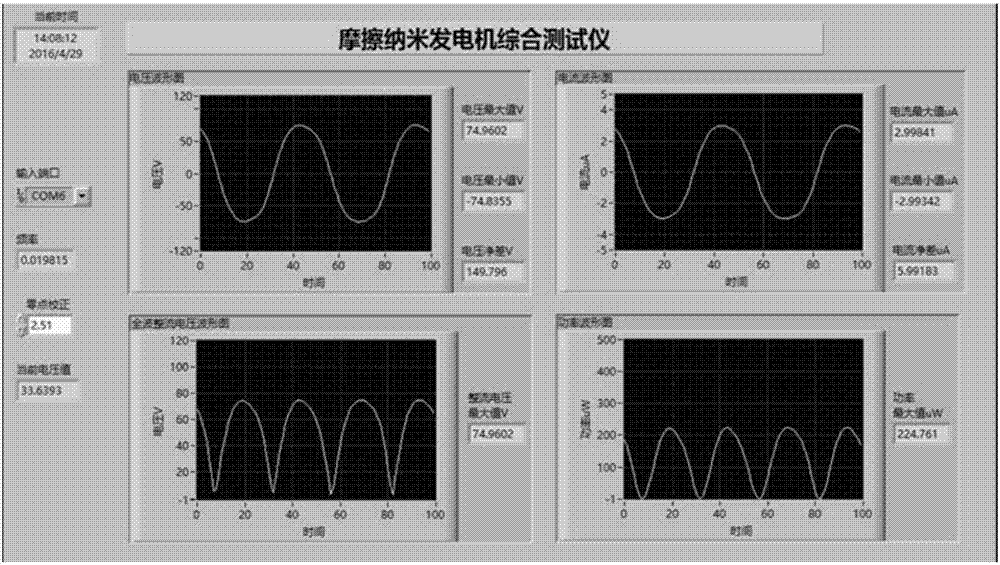

Frictional power generation measurement system based on Labview, and analysis method of frictional power generation measurement system

ActiveCN107102190AReduced business level requirementsSimple and fast operationProgramme controlComputer controlWaveform analysisHuman–machine interface

The invention provides a frictional power generation measurement system based on Labview, and an analysis method of the frictional power generation measurement system, and belongs to the technical field of electronic measurement. The system comprises a frictional power generation device, a data collection card, and an upper computer. A Labview analysis part comprises a man-machine interface program module, a collection control and measurement module, a module filtering module, a waveform analysis module, and a data post-processing module. The method comprises the following steps: enabling a data collection card to be connected with the frictional power generation device and the upper computer; selecting a port occupied by the data collection card and a collection channel occupied by the frictional power generation device on the data collection card through the upper computer after the connection is completed; controlling a frictional power generator to generate a periodic friction phenomenon through a motor drive module; and enabling the upper computer to receive the frictional electric signal data collected by the data collection card. The system can achieve the real-time detection and processing and analysis of the electrical information of a detected frictional power generation device, such as voltage and current.

Owner:DALIAN UNIV OF TECH

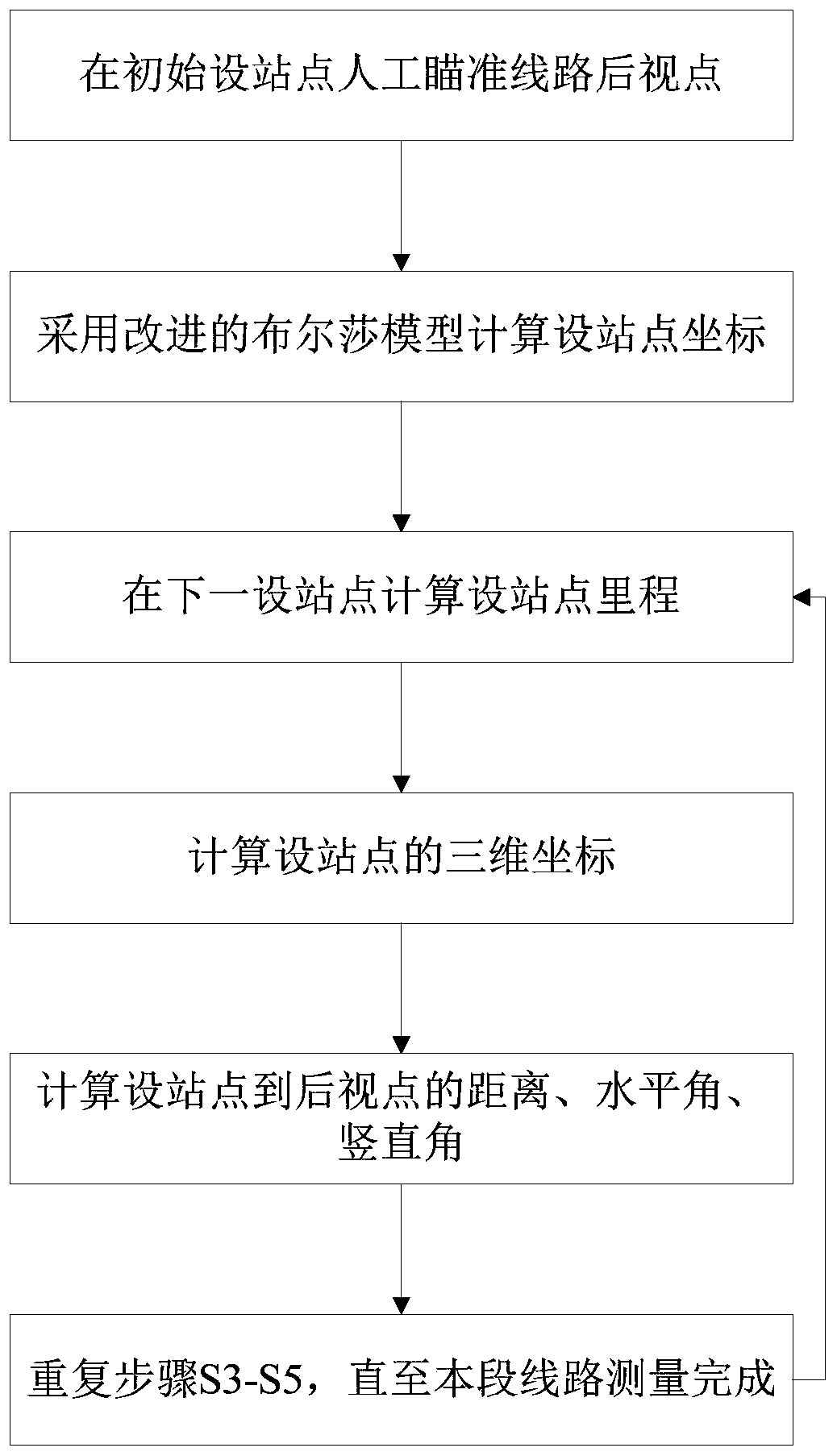

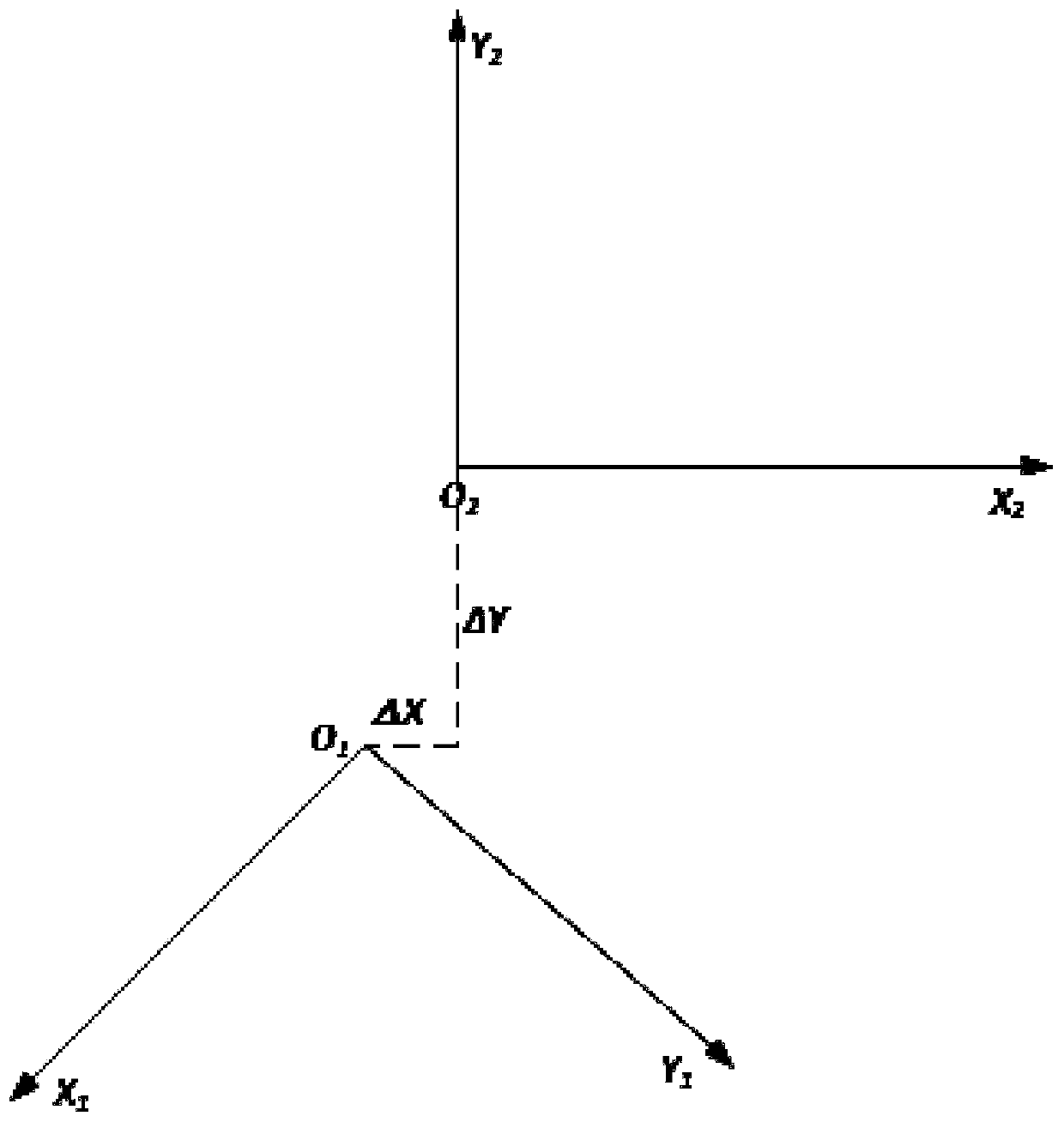

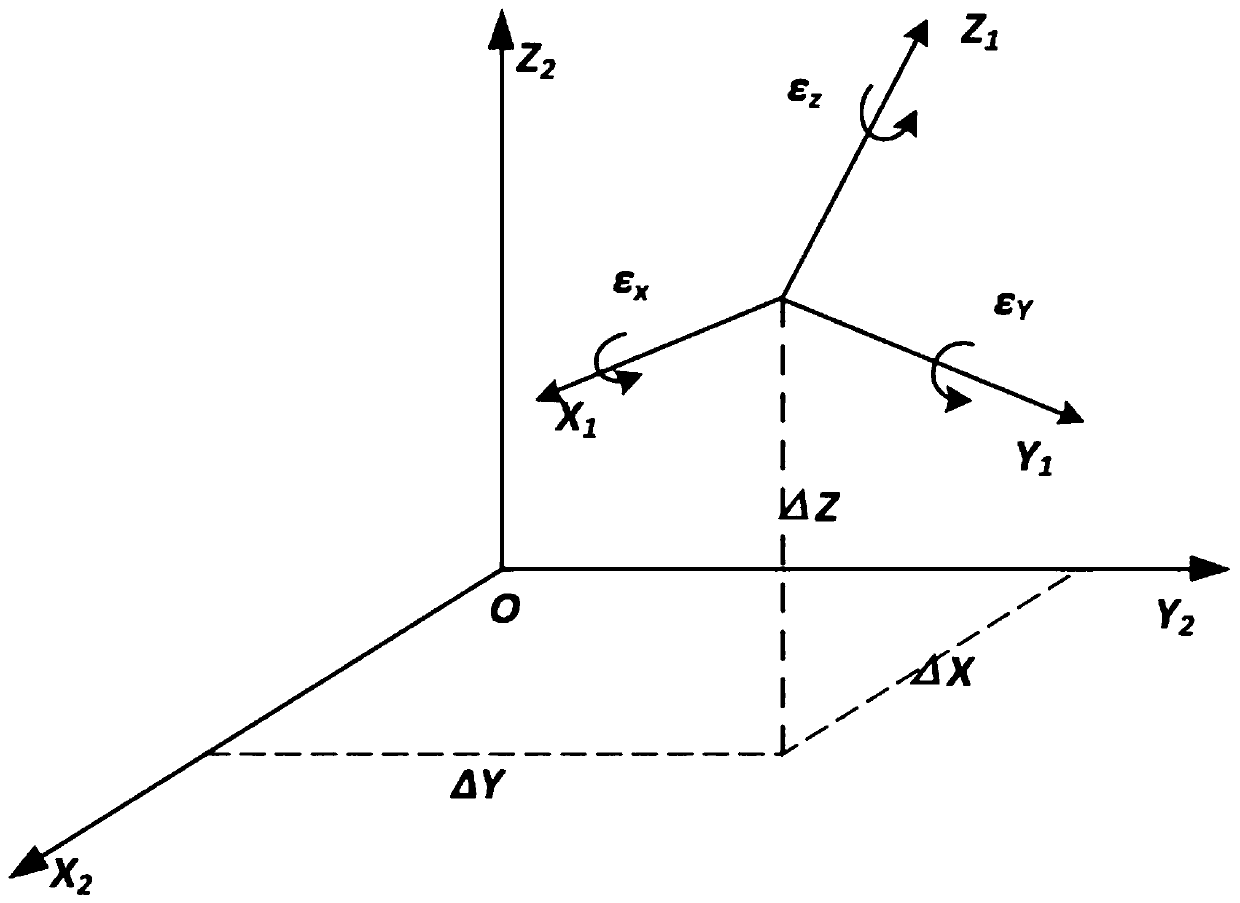

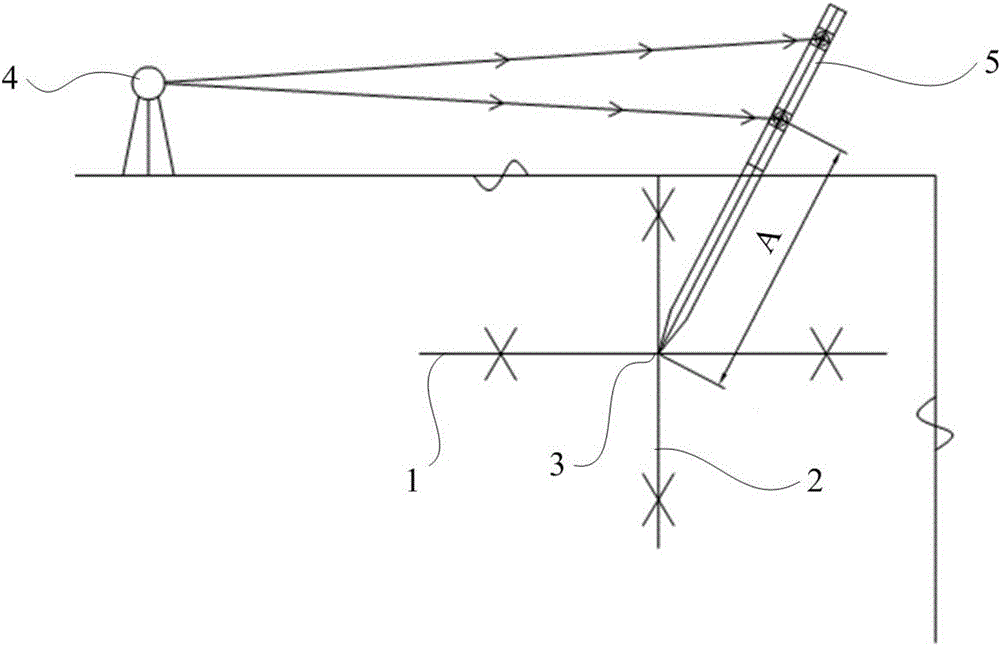

Non-leveling free station establishment method based on improved Bursa model

ActiveCN110345930AReduced measurement workloadImprove measurement productivitySurveying instrumentsOdometerWorkload

The invention discloses a non-leveling free station establishment method based on an improved Bursa model. The method comprises the steps that rearview points on a route are manually aimed at on an initial station establishment point, the improved Bursa model is adopted to calculate coordinates of a current station establishment point, odometer measurement information is utilized to calculate mileage from the current station establishment point to a next station establishment point, then three-dimensional coordinates of the current station establishment point are calculated, the distance, horizontal angle and vertical angle between the current station establishment point and each rearview point are calculated, and the steps are circulated till measurement of the route is completed. According to the method, after the rearview points are aimed at on the initial station establishment point, the three-dimensional coordinates of the current station establishment point and the distance, horizontal angle and vertical angle between the current station establishment point and each rearview point are calculated through the mileage from the current station establishment point, designed over-height, a longitudinal slope and other information by the adoption of the improved Bursa model, therefore, automatic measurement without the need for aiming at a measuring point on a subsequent stationestablishment point is realized, the workload of measurement is reduced, the working efficiency of measurement is improved, and the safety risk is lowered.

Owner:四川铁拓科技有限公司

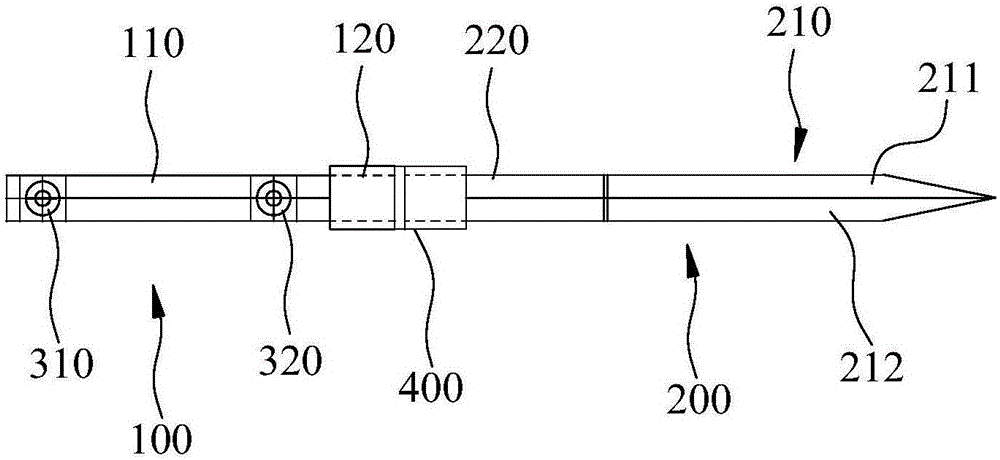

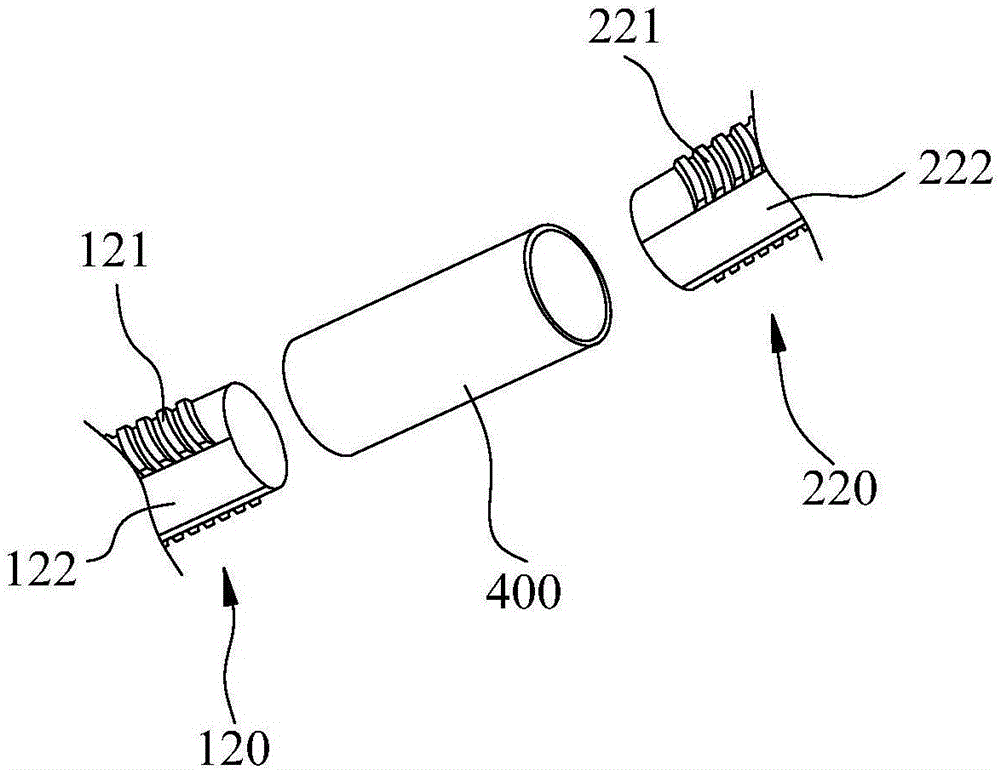

Ship body measurement auxiliary tool and measurement method

ActiveCN105973212AImprove measurement work efficiency and measurement accuracyImprove measurement productivitySurveying instrumentsTotal stationMeasurement precision

The invention discloses a ship body measurement auxiliary tool and a measurement method. The ship body measurement auxiliary tool comprises a retractable supporting rod assembly; the supporting rod assembly comprises a first supporting rod and a second supporting rod which are connected; the first supporting rod is provided with a first reflection sheet and a second reflection sheet, which are arranged at interval along the length direction; the first reflection sheet and the second reflection sheet are located on the same side of the first supporting rod and are located on the same horizontal plane; the first reflection sheet is provided with a first monitoring point; the second reflection sheet is provided with a second monitoring point; the second supporting rod is provided with an abutting point for being abutted against a target point to be detected; and a connection line of the first monitoring point, the second monitoring point and the abutting point is a straight line. The target point to be detected, which cannot be directly measured by a total station, can be accurately measured by adopting the ship body measurement auxiliary tool to assist the total station, and a whole measurement process can be finished by erecting the total station for one time; and compared with the prior art, the measurement working efficiency and the measurement precision are improved.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

Liquid level measuring ruler and liquid level calibration method using same

PendingCN106289454ATimely control the speed of the lower rulerAvoid the problem of inaccurate liquid level measurement dataTesting/calibration apparatusMachines/enginesLiquid level measurementLevel sensor

The invention discloses a liquid level measuring ruler and a liquid level calibration method using the same. The liquid level measuring ruler comprises a steel flexible ruler, a ruler weight, a steel flexible ruler control device and a man-machine interaction device. Measuring personnel and the steel flexible ruler control device can control the ruler discharging speed in time, and meanwhile the problem that liquid level measurement data is inaccurate due the factors of foundation settlement at the bottom of a container, container deformation, accumulation of sediment at the bottom of the container and the like can be solved. The liquid level calibration method is a fixed liquid level meter calibration method based on the liquid measuring ruler and comprises the steps that under different liquid levels of the same container, a fixed liquid level meter and the liquid level measuring ruler are used for measuring the liquid levels of the container two times, errors are calculated with an error formula, the reference height of the container does not need to be obtained in advance, the influence of inaccurate reference height on a measurement result is eliminated, the purpose of calibrating the fixed liquid level meter is achieved, and the efficiency of the measuring work is greatly improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

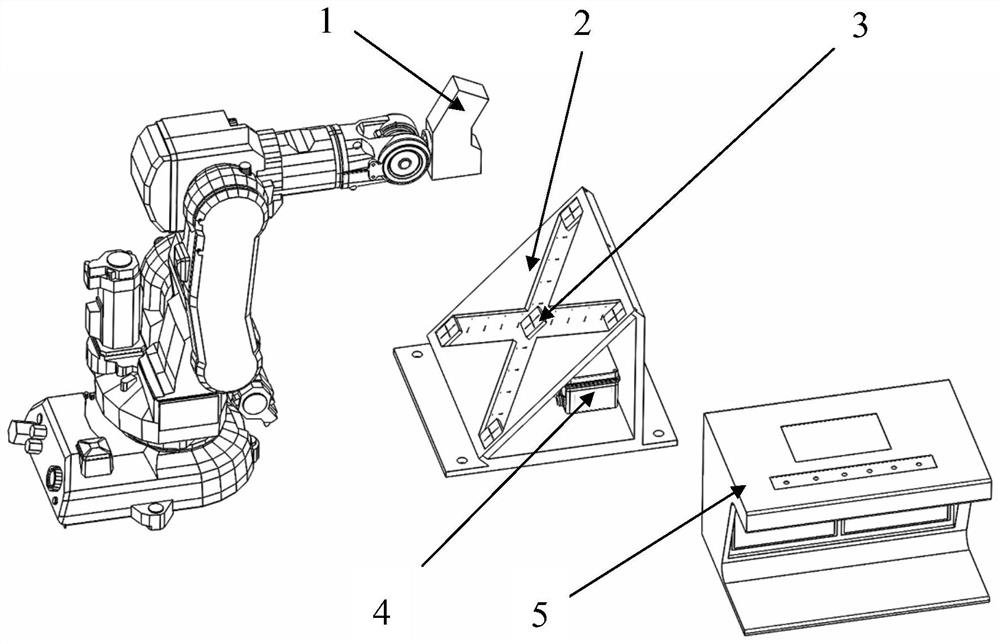

Industrial robot space pose precision test system

PendingCN112917510AAccurate measurementSimulation is accurateManipulatorControl engineeringProcess engineering

The invention discloses an industrial robot space pose precision test system, and belongs to the technical field of industrial robots. The industrial robot space pose precision test system comprises a pose measurement cube assembly, a measurement target, a power supply module, a visual sensor and an operation table. The measurement cube assembly is fixed to the front face of a robot measurement area through bolts. The measurement target is fixed in an X-shaped groove in the surface of a pose measurement cube through a screw, the X-shaped groove is located in the front surface of the pose measurement cube assembly, the total length of the X-shaped groove is 1000 mm, and the requirements of different robot working spaces are met. The power supply module is fixed to the bottom of a base through screws and can supply power to the five measurement targets at the same time; and the visual sensor is fixed to the tail end of a robot and connected with the operation table through a communication cable. The industrial robot space pose precision test system is specially used for testing the space pose precision of the industrial robot, and is convenient to use, high in measurement working efficiency, high in precision and low in cost.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Shafting hot alignment device and shafting hot alignment method

ActiveCN102692180BEliminate time differenceHigh-resolutionUsing electrical meansUltrasound attenuationElectricity

The invention relates to a shafting hot alignment device and a shafting hot alignment method. Horizontal and vertical eddy current sensors are disposed at shafting bearing positions or alignment required positions of a unit around a journal. The horizontal and vertical eddy current sensors are used to measure shafting lateral clearance and vertical clearance respectively. Reflecting paper is adhered to a shaft at the alignment required position, and a revolution speed sensor corresponds to the reflecting paper is used for keyway-phase angle marking. Lateral clearance and vertical clearance value signals of the shafting of the eddy current sensor acquisition unit are processed by an alternating current blocking circuit and a signal attenuation circuit and are then transmitted into an ADC (analog to digital converter) and converted into digital signals, and the digital signals are transmitted to a rear-end ARM (advanced RISC machines) master control chip. When the shafting of the revolution speed sensor acquisition unit rotates to the reflecting paper, a signal of instant phase marking angle value is output, a square signal is output to the ARM master control chip, the signals are subjected to difference calculation by the ARM master control chip through hot alignment software, and data signal of shafting position compensation value required by hot alignment is output to a data output device.

Owner:SHANGHAI HENGTUO IND DEV

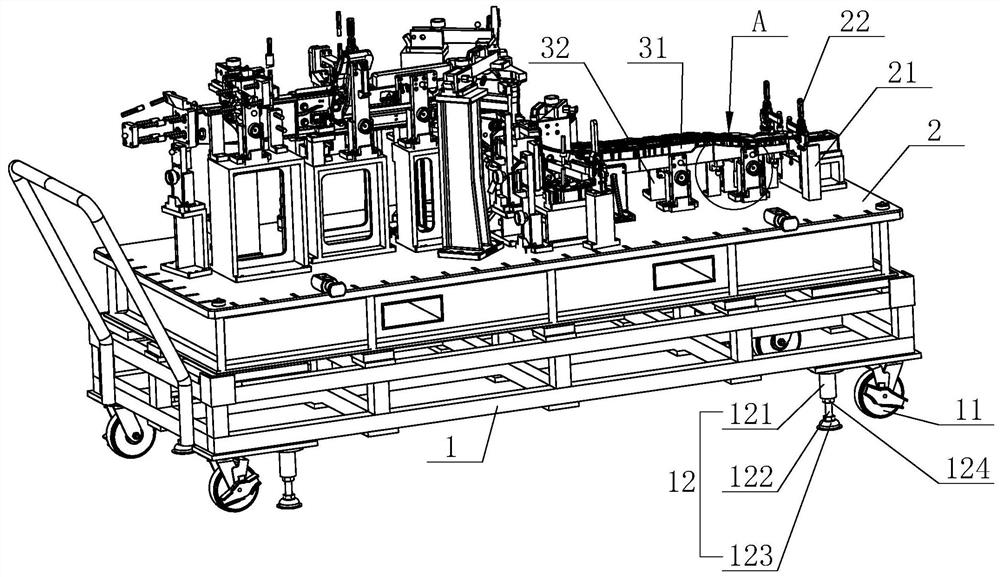

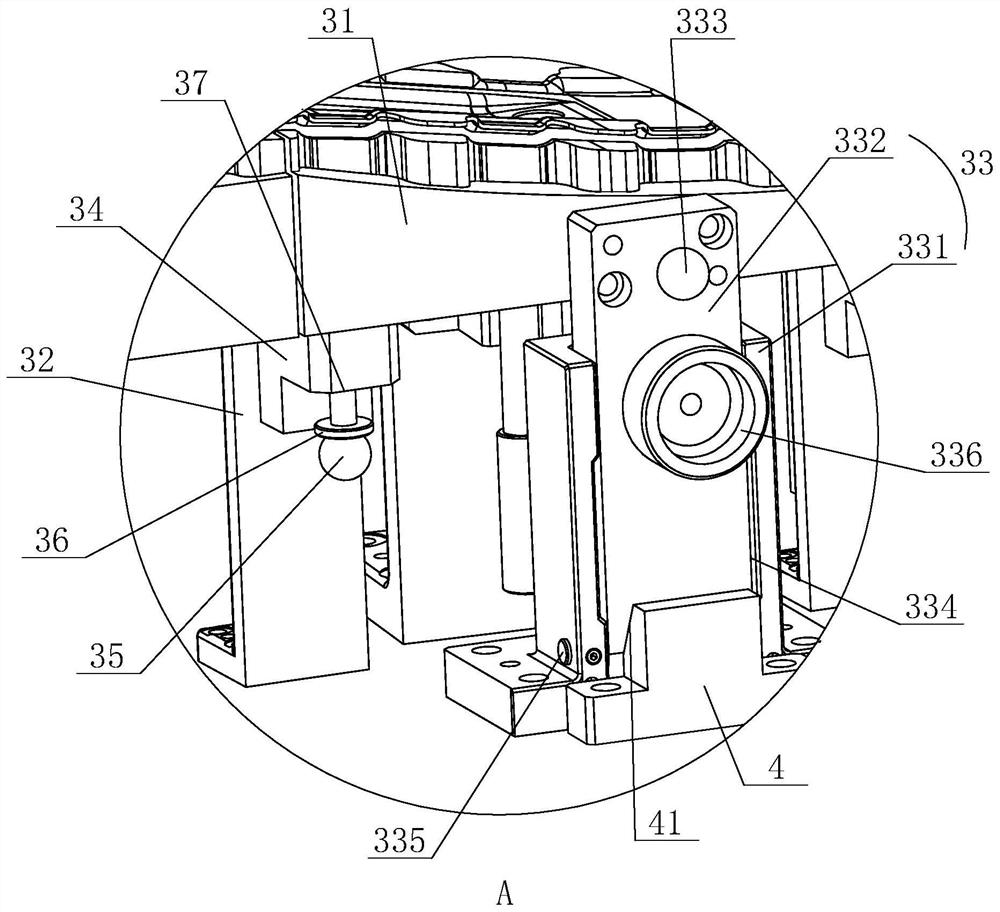

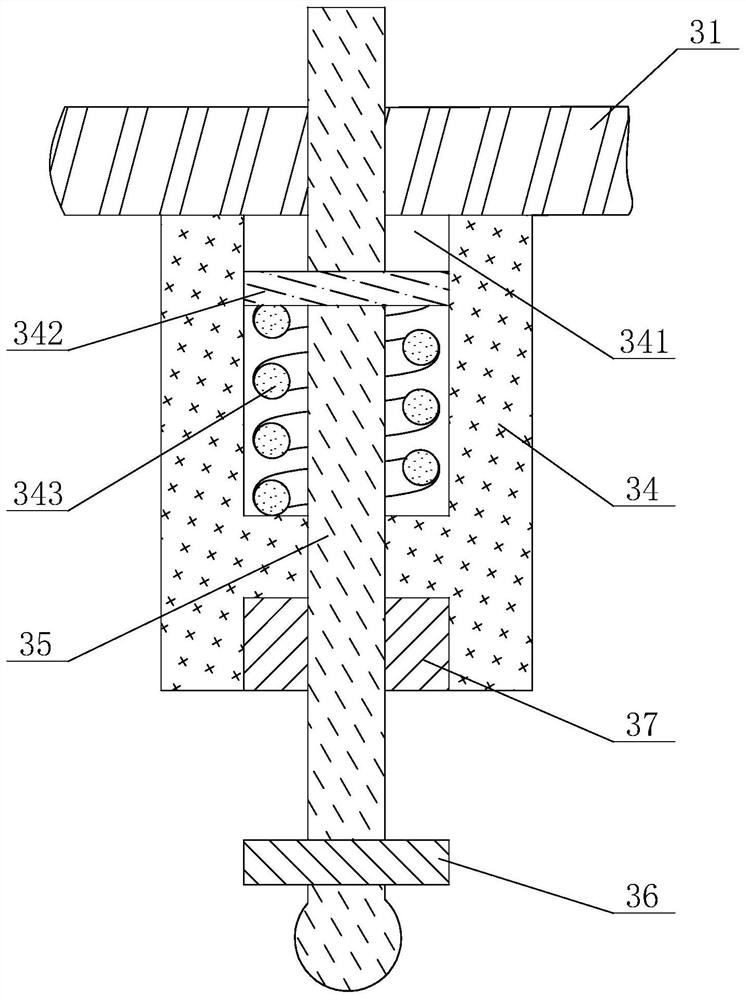

Automobile front longitudinal beam detection table

ActiveCN112212759AShorten the timeAvoid unqualifiedMechanical measuring arrangementsStructural engineeringWorkbench

The invention relates to an automobile front longitudinal beam detection table which comprises a detection tool vehicle, a workbench fixed to the detection tool vehicle and a detection assembly, the detection assembly is detachably fixed to the face, away from the detection tool vehicle, of the workbench, and the detection assembly comprises a simulation block used for installing an automobile front longitudinal beam, a plurality of supporting bases and a positioning module. The positioning module comprises a base and a limiting plate, one end of the limiting plate is rotationally connected tothe base, the other end of the limiting plate is detachably fixed to the base, and a fixing rod is arranged on the limiting plate. A plurality of mounting bases are fixedly connected below the simulation block, positioning pins are elastically arranged in the mounting bases in a sliding mode, one end of the head of each positioning pin is spherical, and the end, away from the head, of each positioning pin penetrates through the corresponding mounting base and the simulation block to be inserted into an assembling hole of the front longitudinal beam. According to the invention, the positioningpins are arranged below the assembly holes, and the matched positioning pins do not need to be found and inserted into the assembly holes when the front longitudinal beam is installed so that the time for installing the front longitudinal beam is saved, and the working efficiency of detection and measurement is improved.

Owner:上海芃佳智能科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com