Method for measuring gap between bearings of roll shafts of pinch rolls

A measurement method and technology of bearing clearance, applied in the direction of mechanical clearance measurement, etc., can solve problems such as failure to truly reflect the deterioration trend of roller bearings and oil film bearings, correct judgment affecting the working state of bearings, large data deviation, etc., and achieve the measurement process. The effect of simplifying, shortening measurement time, and eliminating disturbances in measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

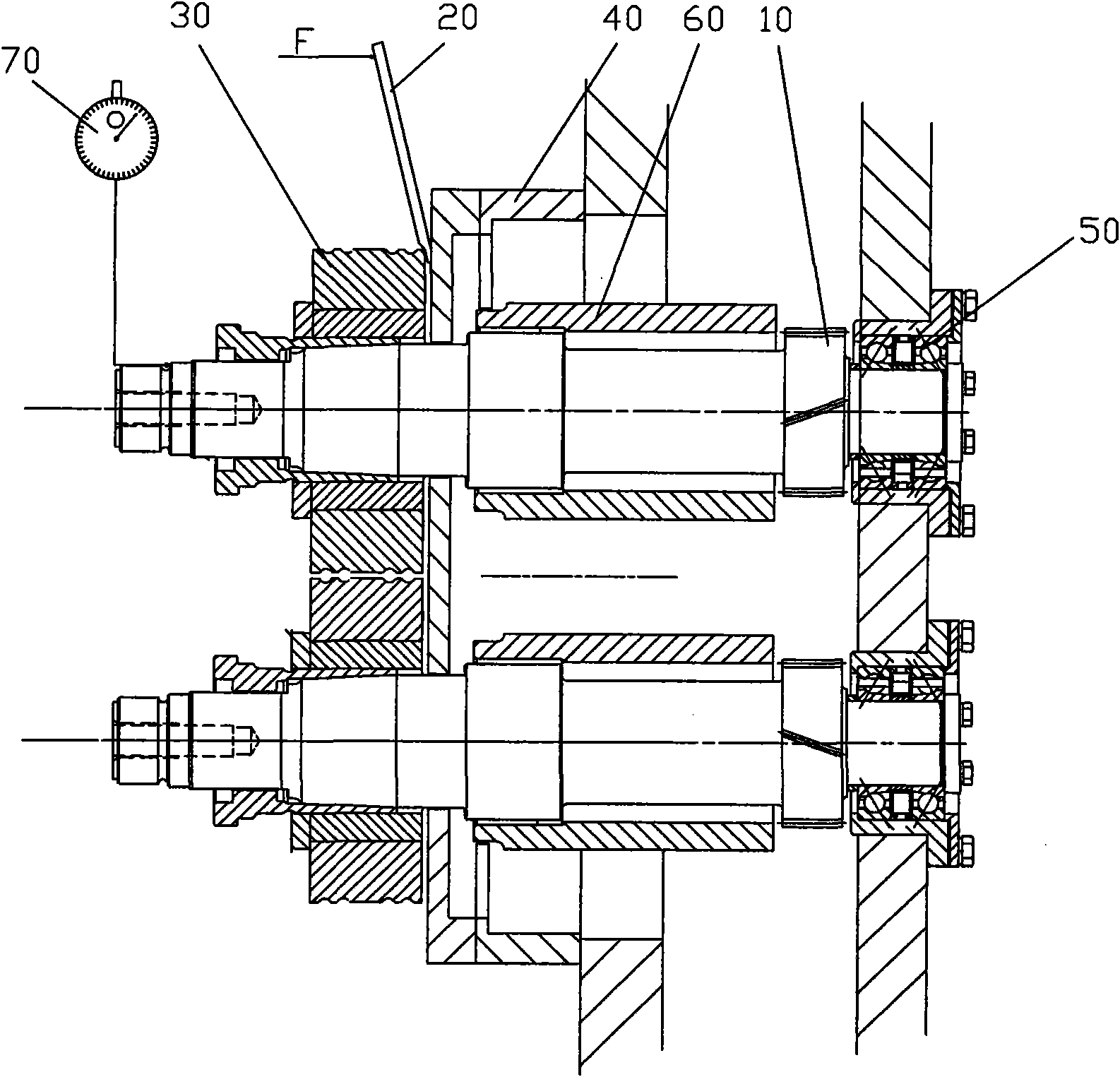

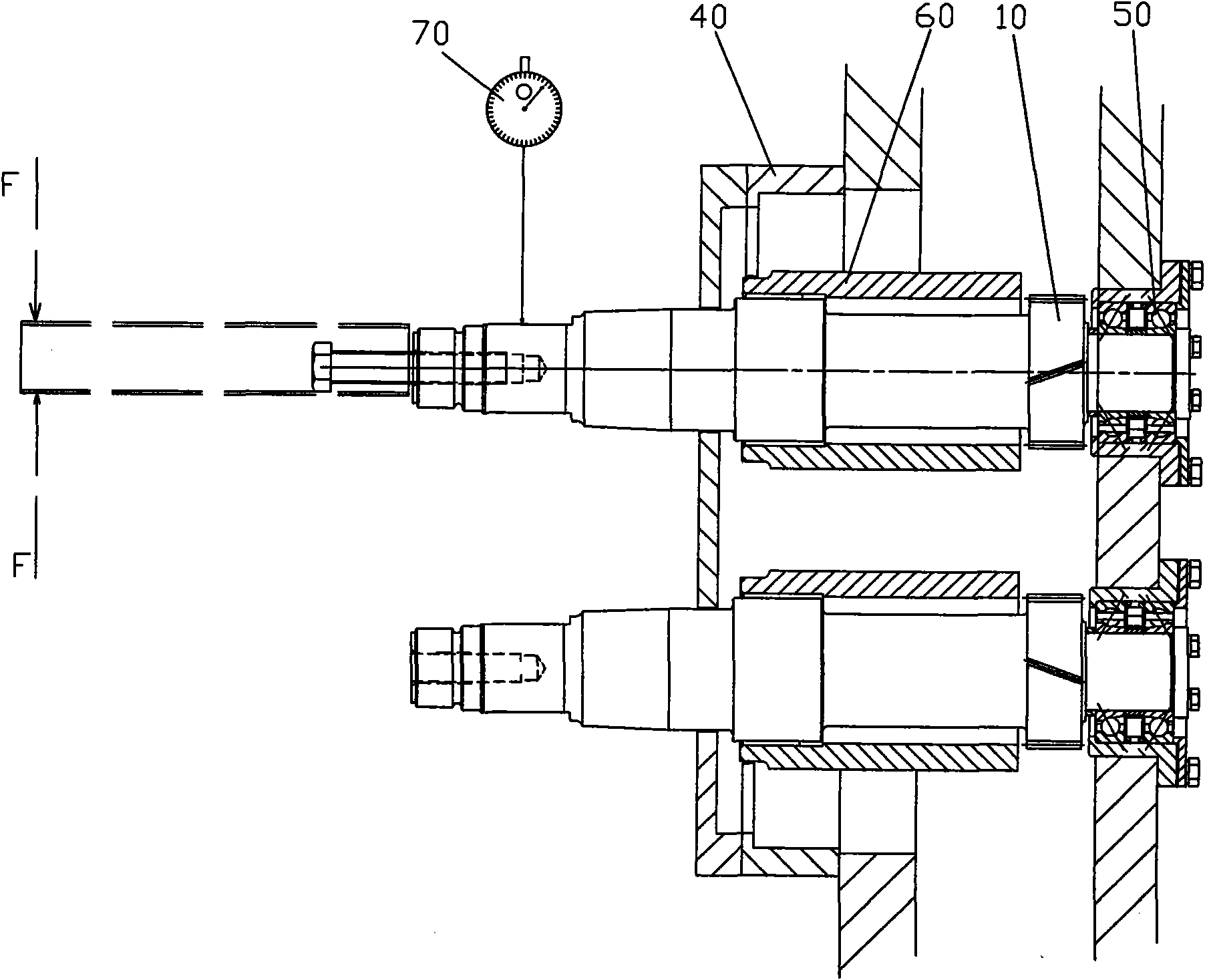

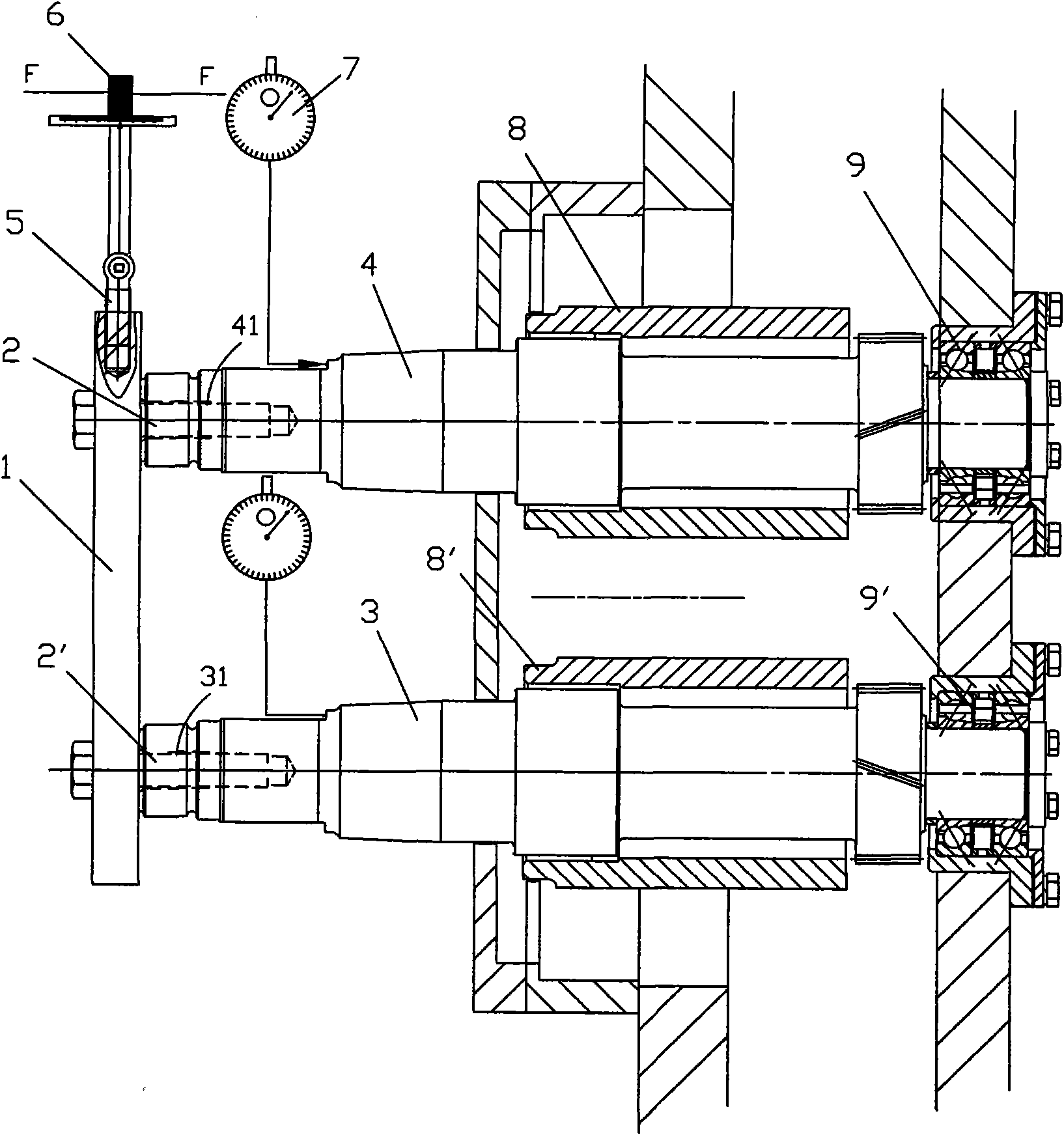

[0040] see image 3 , Figure 5 , Image 6 , the method for measuring the axial gap of the rolling bearing of the present invention comprises the following steps:

[0041]1) Pick up the measuring connecting rod 1 vertically, the upper part of the measuring connecting rod 1 has a waist-shaped hole 101, the lower part has a connecting through hole 102, and the top end is processed with an internal thread hole 103; the measuring connecting rod 1 is connected through the lower part. The hole 102 penetrates the fixing bolt 2 and is screwed into the central threaded hole 31 of the shaft end of the lower roller shaft 3; the upper part of the measuring connecting rod 1 has a waist-shaped hole 101 penetrates the fixing bolt 2' and is screwed into the central threaded hole 41 of the shaft end of the upper roller shaft 4 Inside; at this time, the upper roller shaft 4 and the lower roller shaft 3 are connected with the measuring connecting rod 1 through fixing bolts 2 and 2' respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com