Industrial robot space pose precision test system

An industrial robot, precision testing technology, applied in manipulators, manufacturing tools, etc., can solve the problems of inability to measure the spatial attitude accuracy of the robot end, inability to fully evaluate the robot accuracy index, five-point test evaluation test system, etc., to achieve measurement efficiency. High, simple structure, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

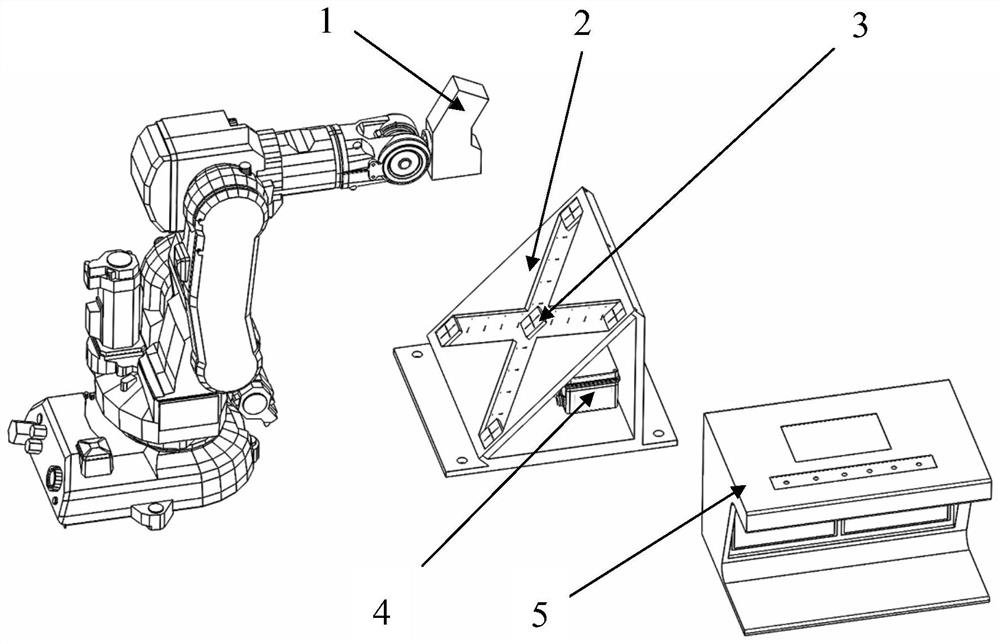

[0022] The invention provides an industrial robot space pose accuracy test system, such as figure 1 shown. The test system includes a pose measurement cube assembly 2, a measurement target 3, a visual sensor 1 and a power supply module 4; the visual sensor 1 is fixed at the end of an industrial robot, and the visual sensor 1 is connected to a terminal controller through a transmission cable, and the terminal control The device is fixed on the console 5. The pose measurement cube assembly 2 is placed in the measurement area of the vision sensor, and the pose measurement cube assembly includes an X-shaped groove 7, and the measurement target 3 is installed in the X-shaped groove.

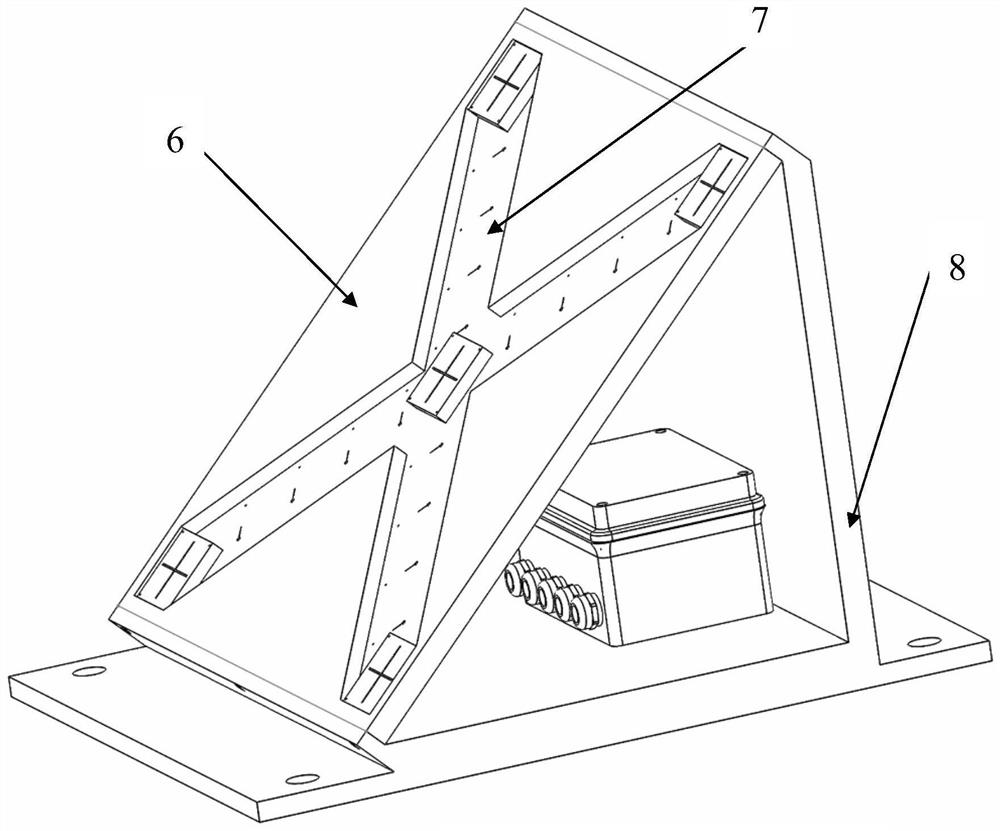

[0023] The pose measurement cube assembly includes a standard test board 6, an X-shaped groove 7 and a mounting bracket 8, the X-shaped groove is opened on the outer surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com