Connecting joint of assembly type concrete prefabricated wallboards and installation method of connecting joint

A technology of prefabricated wall panels and connecting nodes, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of inconvenient transportation, high cost, and many wet operations on site, so as to reduce on-site operation time and improve installation efficiency , a high degree of standardization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

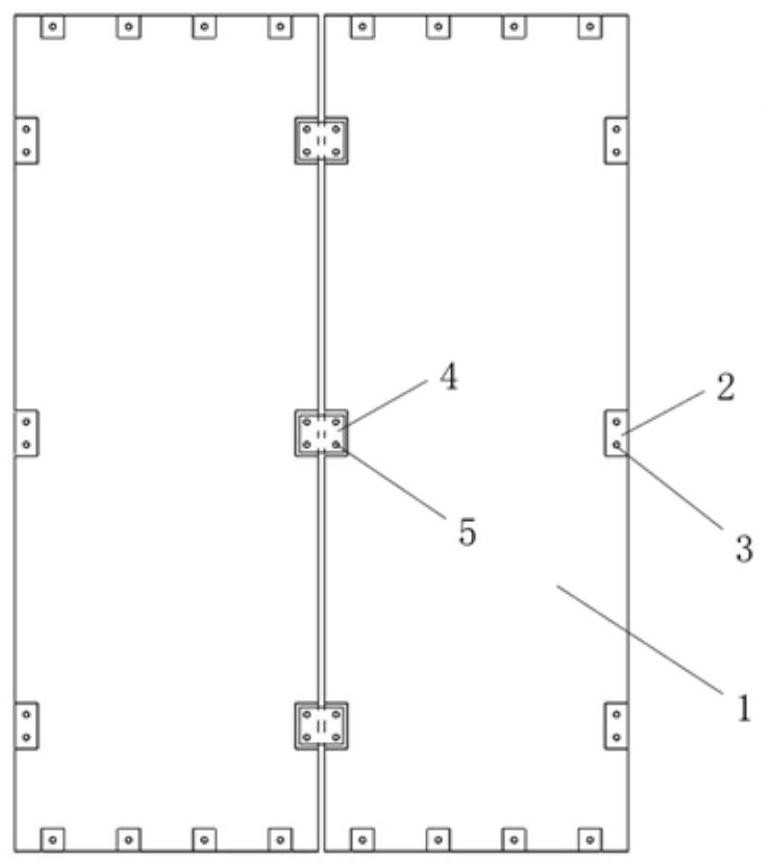

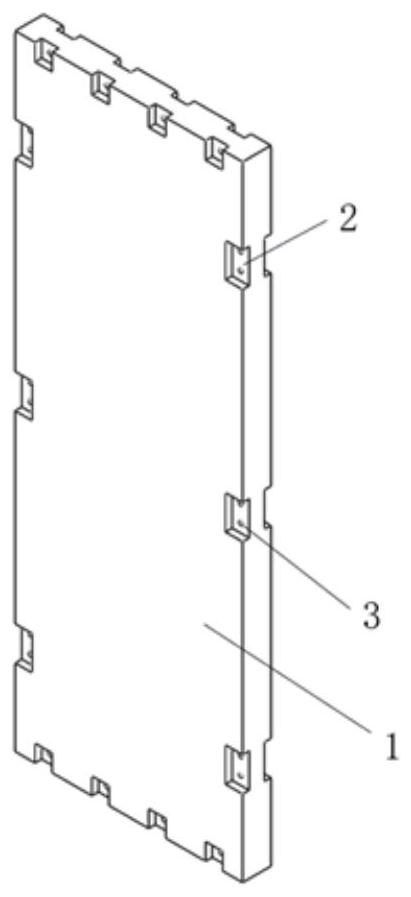

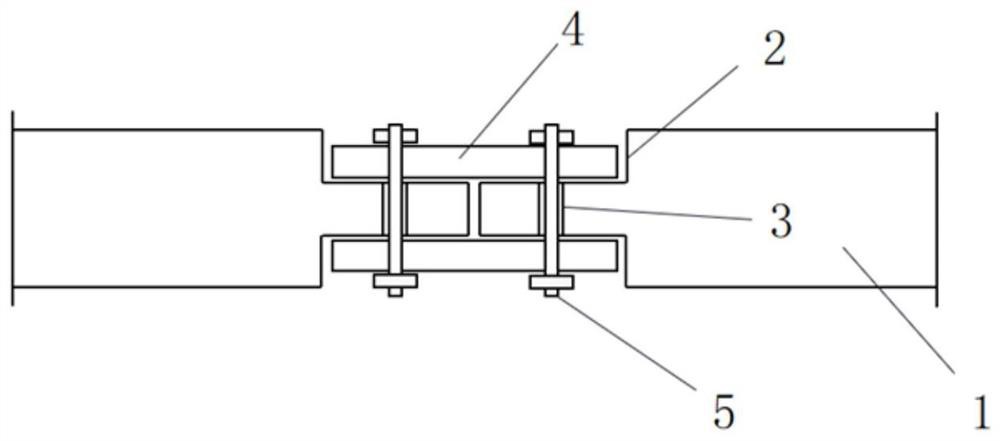

[0021] Below by embodiment, in conjunction with accompanying drawing, the technical scheme of the present invention is described further specifically, as Figure 1-3 As shown, a connection node of an assembled concrete prefabricated wallboard includes several grooves 2 around the prefabricated wallboard 1. The grooves 2 are symmetrically opened on both sides in the thickness direction of the prefabricated wallboard 1. There are several through connecting holes 3, the connecting plate 4 embedded in the groove 2, the connecting plate is provided with a through hole corresponding to the position of the connecting hole 3 in the groove 2, including a number of connecting bolts 5 passing through the prefabricated wallboard 1 In the direction of thickness, two connecting plates 4 in the groove 2 and connecting holes 3 in the groove are provided symmetrically on both sides. The two ends of the connecting bolt 5 are fastened with nuts, and the two prefabricated Connection nodes between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com