Light assembly type steel structure composite floor slab and implementation method thereof

A technology for combining floors and steel structures, applied to floors, floors, building components, etc., can solve the problems of insufficient sound insulation and seismic performance, heavy weight, and heavy wet work, and achieve easy modular manufacturing and production, and easy The effect of transportation and increasing net height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

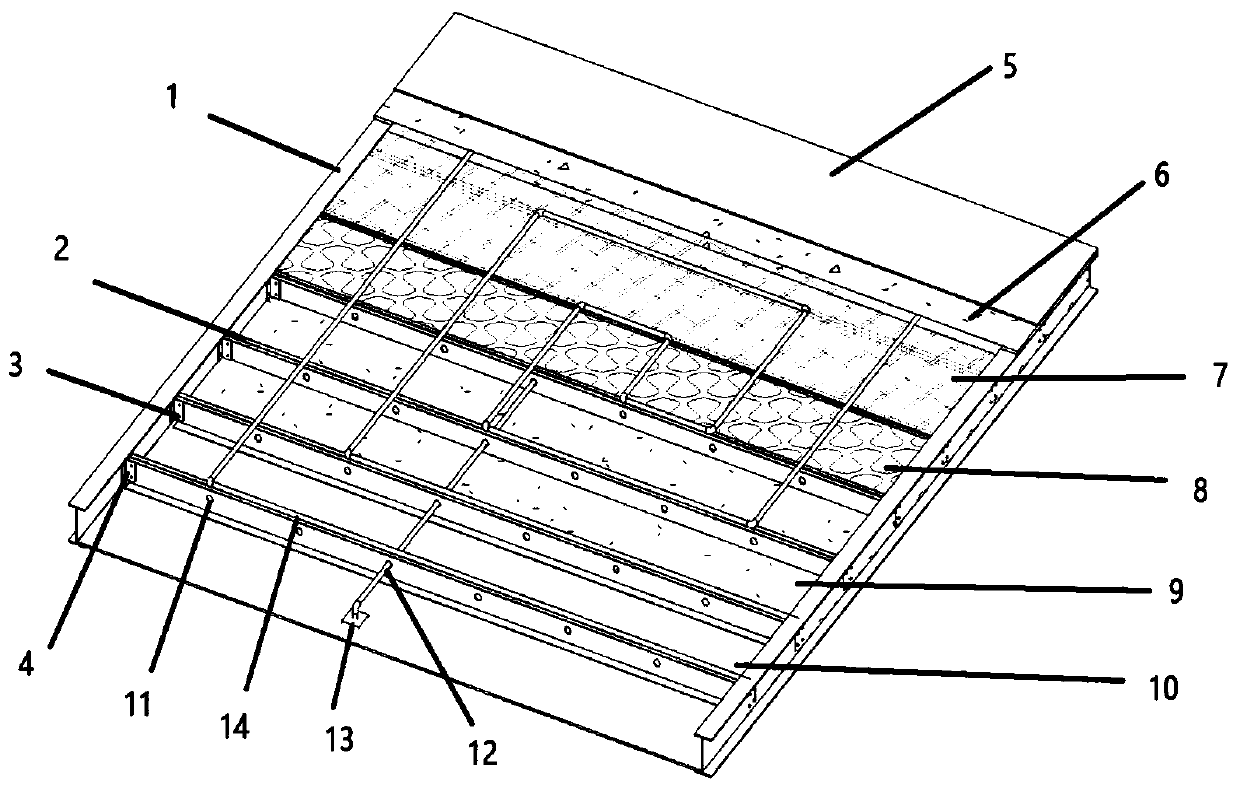

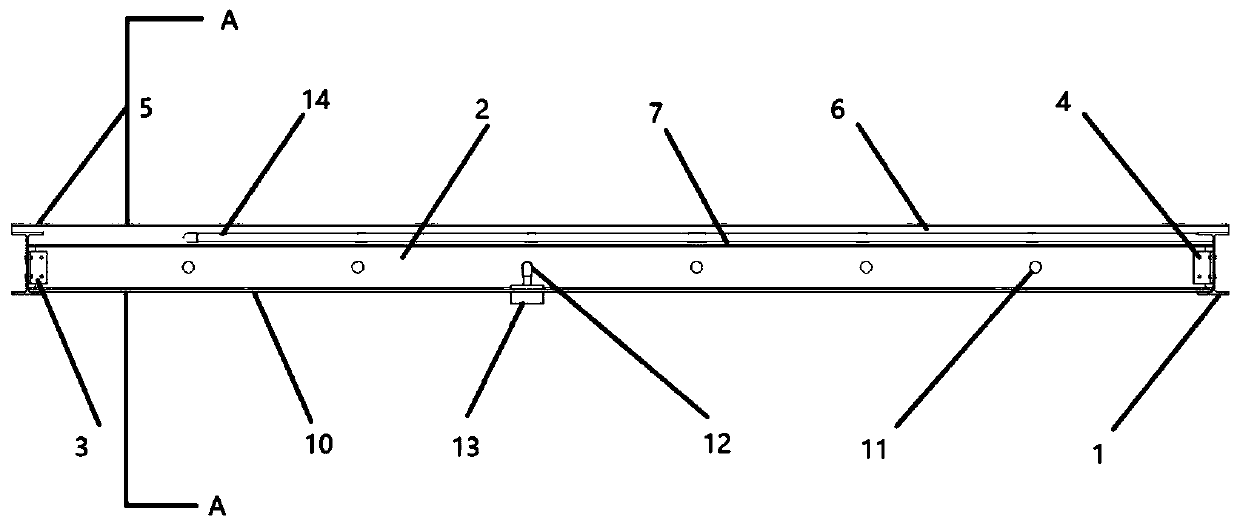

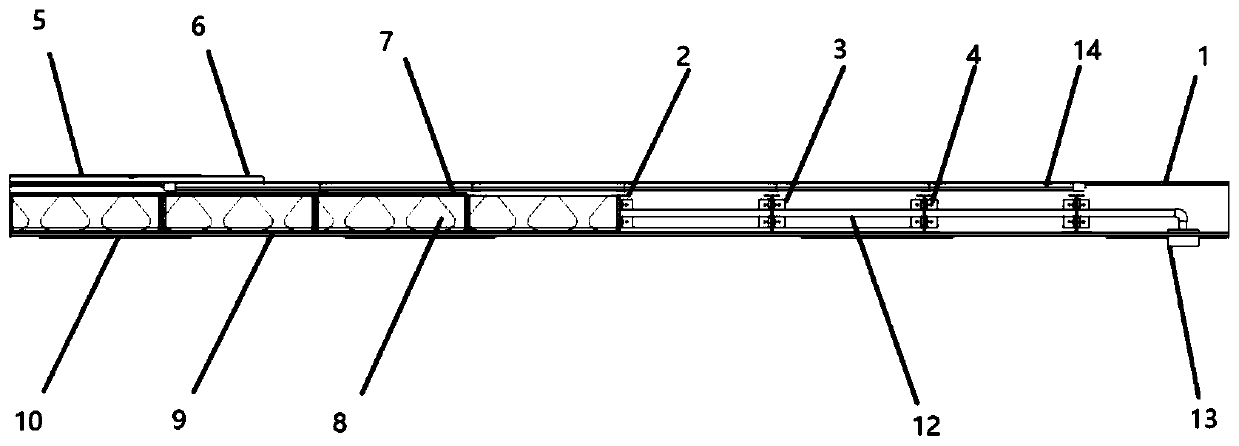

[0040] Embodiment one: by Figure 1 to Figure 6It is given that the light-weight assembled steel structure composite floor used for the assembled steel structure building includes a steel frame, a pipeline 14 and a lightweight concrete layer 6, the steel frame includes a steel beam 1 and a plurality of supporting frames 2, and the supporting frames 2 As the load-bearing skeleton of the composite floor, it plays a supporting role. The bottom surface of each support skeleton 2 is laid with a support plate 9 and the upper surface is laid with a waterproof membrane 7 to form a cavity inside the steel frame. The use of the support plate 9 has the functions of heat preservation and flame retardancy. The board can improve the flame retardancy, heat preservation and waterproof performance of the floor while playing a supporting role. The cavity is filled with a heat insulation and sound insulation layer 8, and the waterproof membrane 7 plays a role in preventing the heat insulation and...

Embodiment 2

[0042] Embodiment 2: On the basis of Embodiment 1, a floor heating pipeline 14 and a lightweight concrete layer 6 are arranged between the waterproof membrane 7 and the ground decoration layer 5. The specific method is: first lay the floor heating pipeline 14, and then pour lightweight concrete , forming a lightweight concrete layer 6 covering the floor heating pipeline 14, the support plate 9 and the heat insulation and sound insulation layer 8 together play the role of supporting formwork for pouring the lightweight concrete layer, and form a horizontal structure together with the cast-in-place lightweight concrete. The anti-instability ability of the support frame 2 is improved, and the waterproof membrane 7 plays a role in preventing the cast-in-place lightweight concrete from eroding the thermal insulation layer 8 .

Embodiment 3

[0043] Embodiment three: on the basis of embodiment two, the position where the waterproof membrane 7 and the beam web are handed over is turned up to form a waterproof structure, which effectively prevents moisture from penetrating downward into the thermal insulation layer 8. Each of the supports The skeleton 2 includes two C-shaped steels arranged with their backs. The flange of the C-shaped steel on which the waterproof membrane 7 is laid is the upper limb flange, and the flange on which the support plate 9 is laid is the lower limb flange, and the width of the upper limb flange is smaller than that of the lower limb flange. Width, each support plate is placed on two opposite C-shaped steel lower limb flanges by laying.

[0044] On the basis of the above-mentioned embodiments, when each support plate 9 is placed on the C-shaped steel, the two can be fixed by gluing, and the glue is applied first, and then placed to form a more effective connection.

[0045] On the basis of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com