Tower-beam thrust connection device and self-anchored suspension bridge rapid construction method

A technology of self-anchored suspension bridges and connecting devices, which is applied in bridge construction, bridges, buildings, etc., can solve the problems of long construction period and difficult synchronous construction of self-anchored suspension bridges, so as to reduce construction costs, save on-site operation time, and resist The effect of high push stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

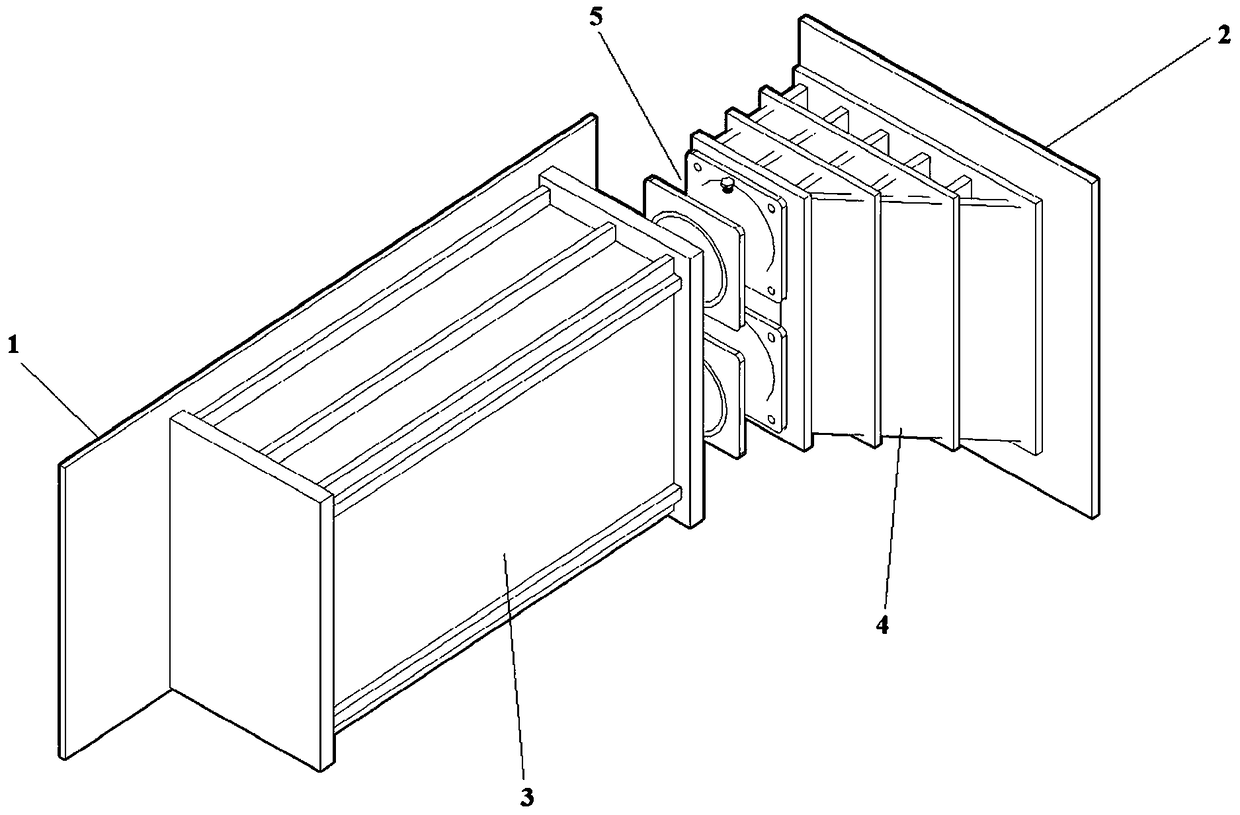

[0065] This embodiment provides a tower beam thrust connection device, such as Figure 1 to Figure 5 As shown, it includes the reserved steel plate 1 at the beam end and the bearing steel plate 2 at the tower end. There is a beam end thruster 3, a tower end thruster 4 is fixedly installed on the tower end pressure steel plate 2, and a thrust conductor 5 is arranged between the beam end thruster 3 and the tower end thruster 4;

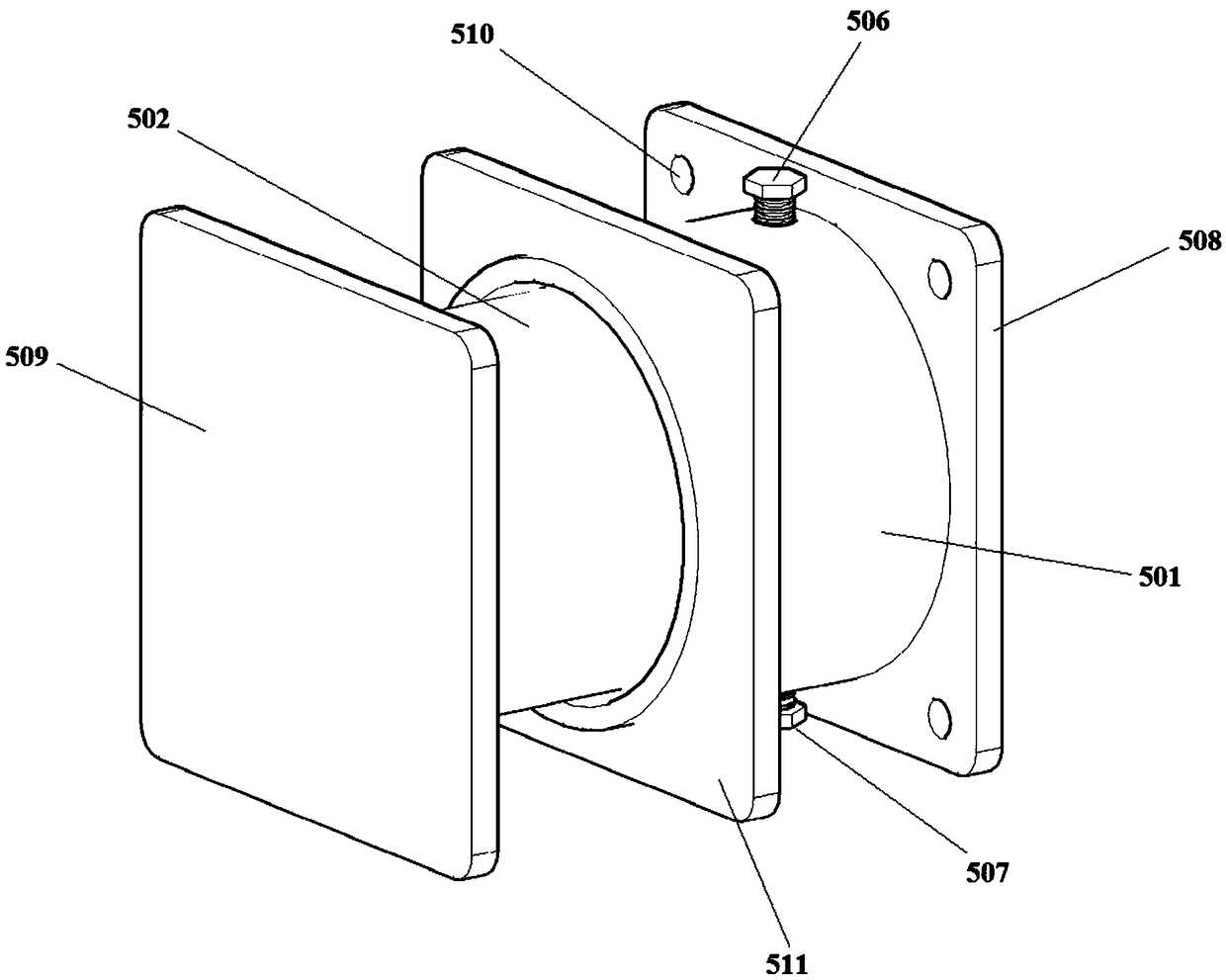

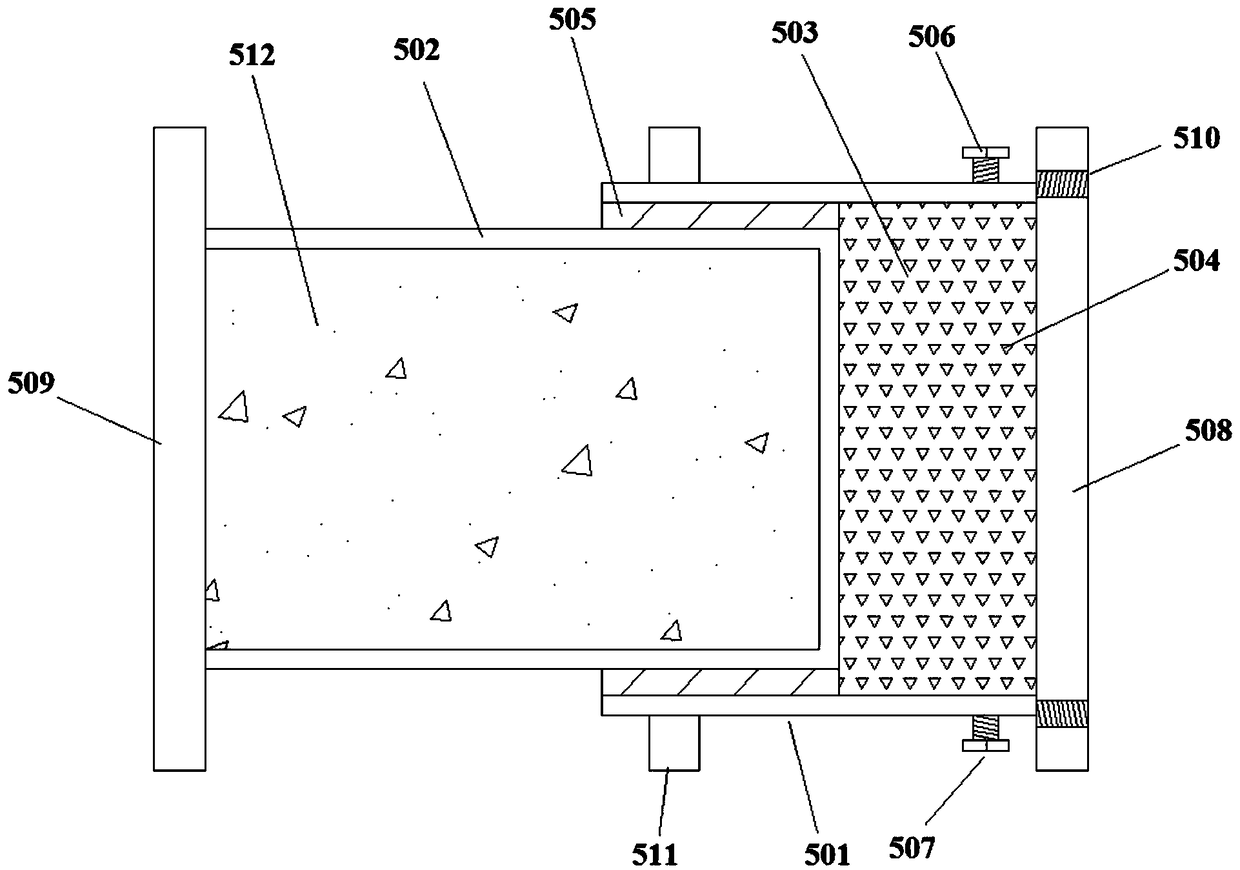

[0066] The thrust conductor 5 includes an outer cylinder 501 and an inner cylinder 502, one end of the outer cylinder 501 is open, and both ends of the inner cylinder 502 are closed, and the closed end of the outer cylinder 501 is installed on the tower end thruster 4, one end of the inner cylinder 502 is installed on the beam end thruster 3, and the other end of the inner cylinder 502 is inserted into the open end of the outer cylinder 501 so that a sand cavity 503 is formed in the outer cylinder 501, and the sand cavity 503 is filled with sand grains ...

Embodiment 2

[0077] This embodiment provides a kind of self-anchored suspension bridge rapid construction construction method, such as Image 6 with Figure 7 As shown, the method adopts the tower beam thrust connection device described in Embodiment 1. The method includes the following steps:

[0078] Step 1, synchronous construction of side span main girder 6 and bridge tower 7;

[0079] Step 1.1, carry out foundation treatment to the foundation of bridge tower 7 and bridge pier 12, construct bridge tower 7 foundation, bridge pier 12 foundation, bridge tower 7 and bridge pier 12;

[0080] Step 1.2, set up the anchor span prestressed concrete main beam and the bracket 11 required for the installation of the side mid span main beam, cast the anchor span concrete beam section on the bracket 11, stretch the prestressed steel beam, and complete the construction of the anchor span main beam;

[0081] Step 1.3, erecting the side-span main girder 6 section by section on the support 11, pourin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com