Integral mounting-dismounting method and platform of circuit breaker

A circuit breaker and platform technology, applied in the direction of switchgear, electrical components, etc., can solve the problems of large power supply load loss, long power outage time, affecting power supply reliability, etc., to reduce load loss, reduce power outage time, and shorten operation time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific embodiment of the present invention is further described below in conjunction with accompanying drawing:

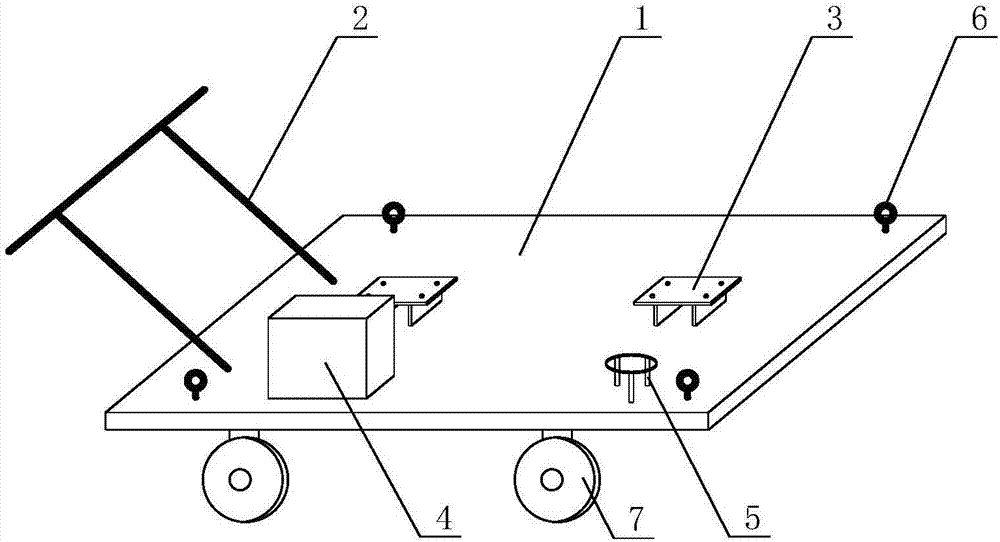

[0033] Such as Figure 1-Figure 4 , a disassembly and assembly platform for circuit breakers, including a platform bottom plate 1, a handle 2, a circuit breaker fixing bracket 3, a power box 4, an inflatable bottle fixing frame 5, a ring buckle 6, universal wheels 7, and a platform bottom plate 1 There is a handle 2 on the top, and two circuit breaker fixing brackets 3 for connecting the circuit breaker 13 are provided in the middle of the platform bottom plate 1. The side of the platform bottom plate 1 close to the handle 2 is provided with a power box 4, and the side away from the handle 2 is provided with a Inflatable bottle fixed frame 5, platform base plate 1 four corners are provided with the ring buckle 6 that is used to fasten safety rope, and platform base plate 1 bottom is provided with universal wheel 7.

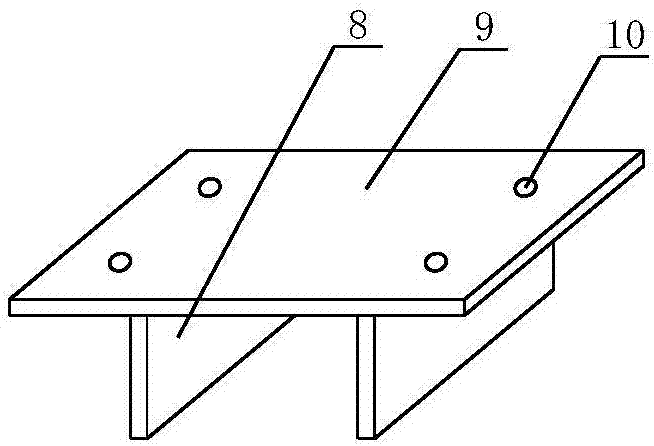

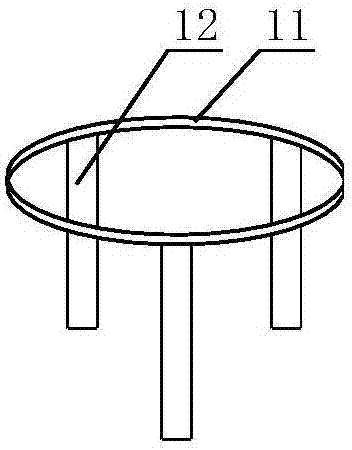

[0034] The circuit breaker fixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com