Method for disassembling DBQ type tower crane machine with small-tonnage crawler crane

A technology for tower cranes and crawler cranes, which is applied in the direction of cranes, etc., can solve the problems of difficult and dangerous demolition work of tower cranes, increasing the amount of high-altitude operations and the number of workers.

Inactive Publication Date: 2011-09-21

CHINA FIRST METALLURGICAL GROUP

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, conventional partial dismantling increases the amount of high-altitude operations and the number of workers, and increases operating costs and operating risks.

For example, the dismantling and dismantling of the 68-ton machine platform of the DBQ3000 tower crane has always been the difficulty and danger of this type of tower crane dismantling work.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment approach

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

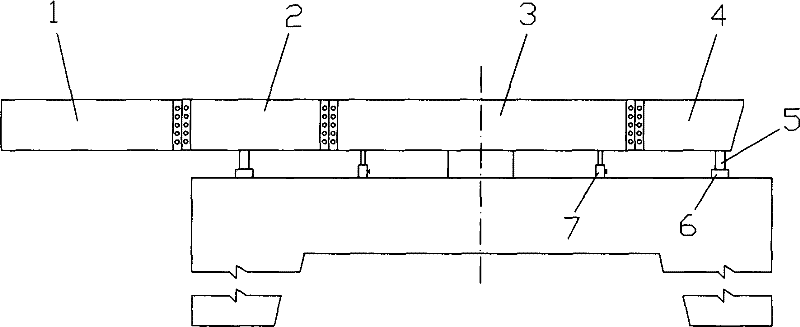

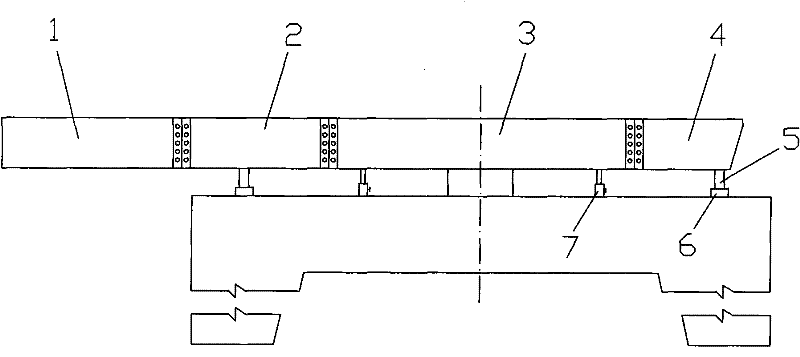

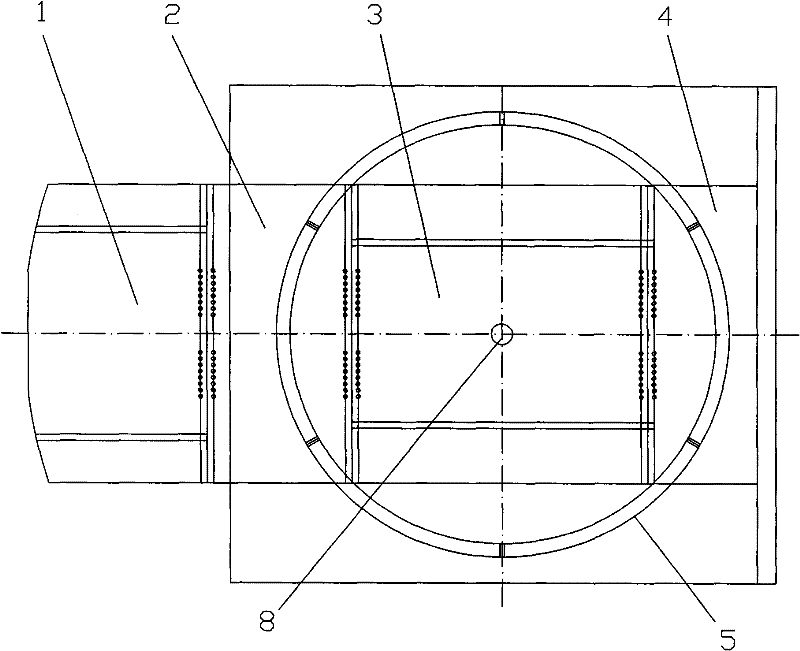

The invention relates to a method for disassembling a DBQ type tower crane machine platform with a small-tonnage crawler crane. The sequence for disassembling the DBQ series tower crane machine platform with the method comprises the following steps of: firstly disassembling the tail part of the machine platform, two sections of rotating rollers, the rear part of the machine platform and the frontpart of the machine platform, and finally disassembling the middle part of the machine platform. By changing and optimizing the disassembly sequence, after simplifying the high-altitude operation process, the method can quickly dissemble the parts of the DBQ series tower crane machine platform by using simple auxiliary equipment, in particular to the parts of a DBQ3000 type tower crane machine platform , thereby being capable of reducing the miscellaneous work amount such as the labeling and the bundling of machine connecting plates and the like. The method has the advantages of saving time and effort, and improving the operation safety and the like.

Description

Method and application of small tonnage crawler crane dismantling DBQ tower crane technical field The invention relates to a tower crane, in particular to a method for dismantling a DBQ tower crane platform by a crawler crane with a small tonnage. Background technique At present, the dismantling of DBQ series tower cranes generally uses 150-ton crawler cranes and other vertical lifting equipment dismantling machines of tonnage above; some are hoisted from high altitude and then dismantled in parts, and some are dismantled locally at high altitude. However, conventional partial dismantling increases the amount of high-altitude operations and the number of operators, increasing operating costs and operating risks. For example, the dismantling and dismantling of the 68-ton machine platform of the DBQ3000 tower crane has always been the difficulty and danger of this type of tower crane dismantling work. Contents of the invention The technical problem to be solved by the pr...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B66C23/26

Inventor 李前国

Owner CHINA FIRST METALLURGICAL GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com