A kind of recoatable ultraviolet light curable coating that can be thick film construction and preparation method thereof

A technology of curing coatings and ultraviolet light, which is applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of increased failure risk, increased production costs, etc., to improve the performance of defective products, prolong the use time, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

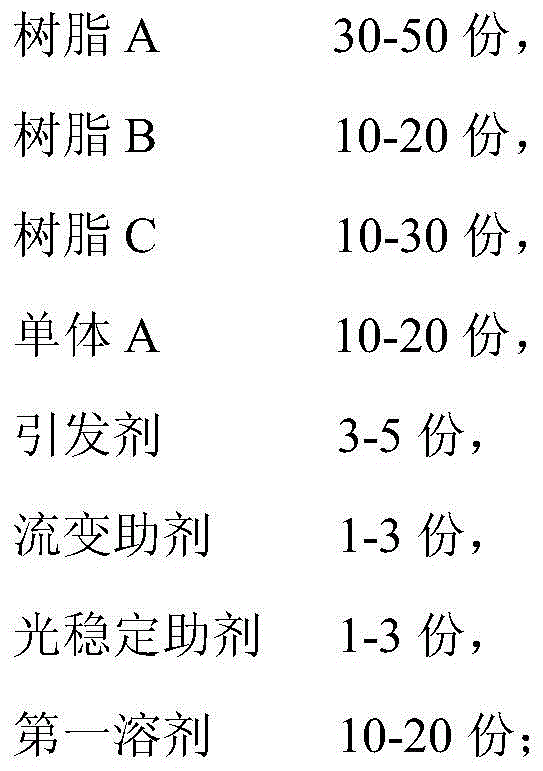

[0022] A thick film applicable recoatable UV curable coating consisting of:

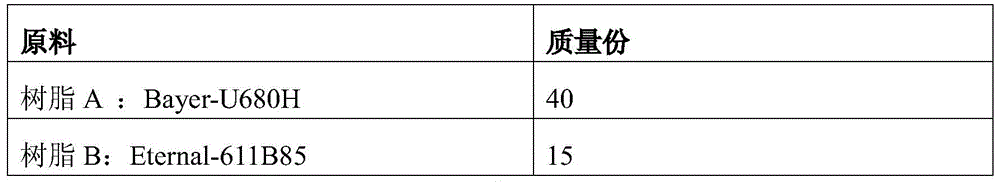

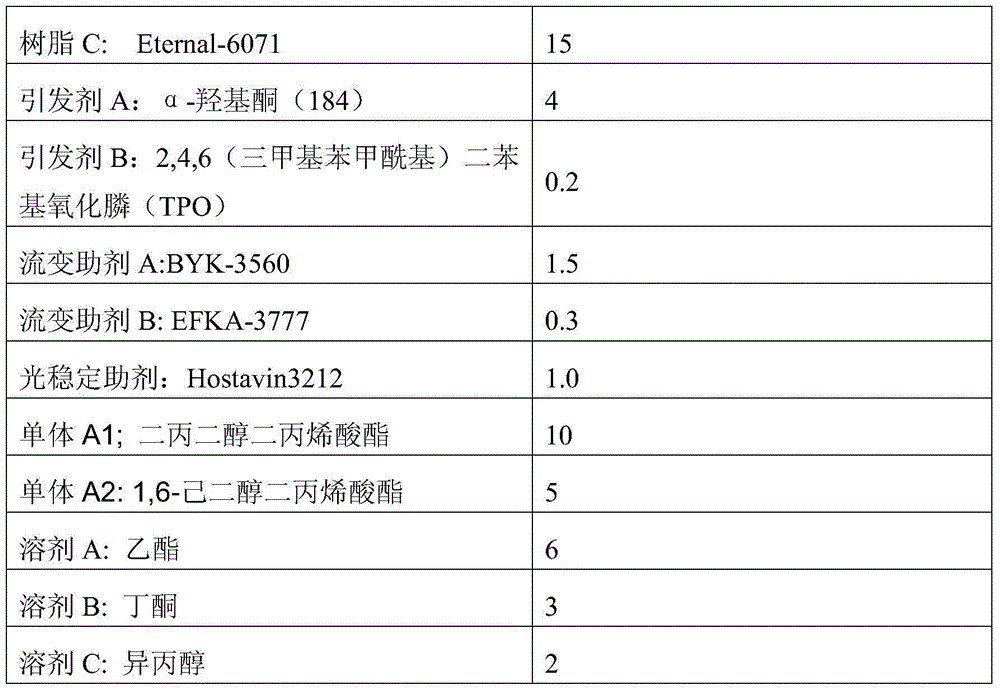

[0023] Table 1: Recoatable UV-curable coatings for thick film application

[0024]

[0025]

Embodiment 2

[0027] A thick film applicable recoatable UV curable coating consisting of:

[0028] Table 2: Recoatable UV-curable coatings for thick film application

[0029]

[0030]

Embodiment 3

[0032] A thick film applicable recoatable UV curable coating consisting of:

[0033] Table 3: Recoatable UV-curable coatings that can be applied in thick film

[0034]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com