Recoat-able polishing-free unsaturated polyester resin for piano lacquer and preparation method of unsaturated polyester resin

A polyester resin, piano paint technology, applied in the direction of coating, can solve the problems of difficult to meet the high hardness requirements of piano topcoat, low surface hardness of piano paint, grinding and polishing, etc., to achieve accelerated dual curing effect and solve surface hardness Low, good adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

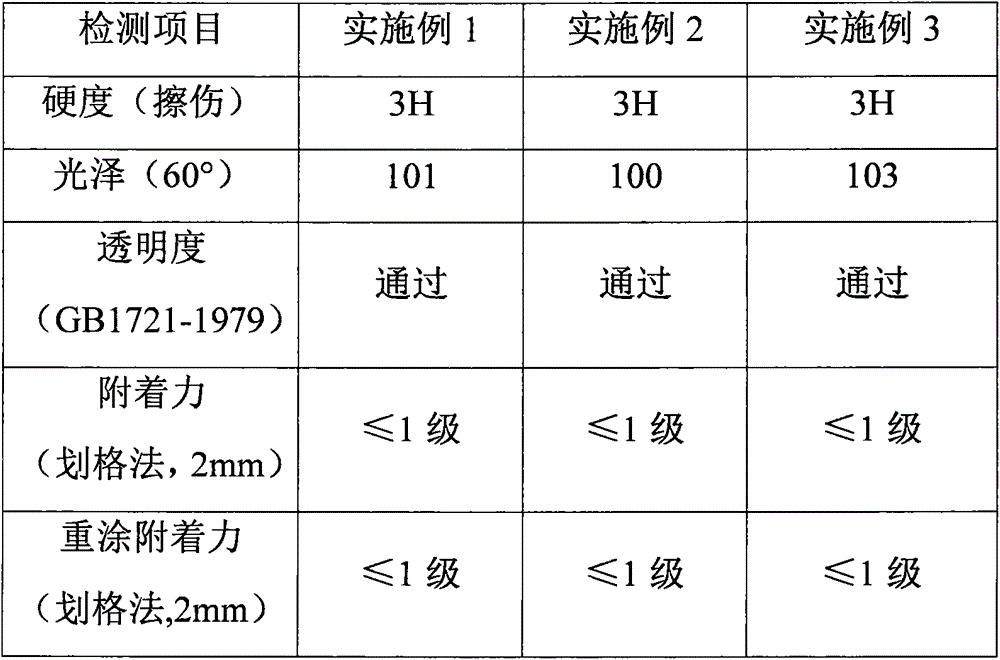

Embodiment 1

[0019] Add 327g maleic anhydride, 49g phthalic anhydride, 200g diethylene glycol, 34g neopentyl glycol, 0.5g Hypophosphorous acid, 0.2g hydroquinone, then start stirring and heating, heat up to 180-200°C, keep warm; continuously check the acid value, when the acid value drops to 120-130mgKOH / g, cool down to 120°C and add pentaerythritol triene Propyl ether 200g, heat up to 200±5°C evenly in 3 hours, keep warm until the viscosity and acid value pass, then cool down to below 120°C, add 300g of styrene to dilute, filter and discharge;

Embodiment 2

[0021] Add 300g maleic anhydride, 100g phthalic anhydride, 250g diethylene glycol, 0.7g hypophosphorous acid, 0.3g para Hydroquinone, then start stirring and heating, heat up to 180-200°C, keep warm; continuously check the acid value, when the acid value drops to 120-130mgKOH / g, cool down to 120°C and add trimethylolpropane diallyl Ether 250g, uniformly heated to 200±5°C in 3 hours, then kept warm until the viscosity and acid value passed, then cooled to below 120°C, added 300g of styrene to dilute, filtered and discharged;

Embodiment 3

[0023] Add 350g of maleic anhydride, 15g of phthalic anhydride, 180g of diethylene glycol, 54g of neopentyl glycol, and 0.6g of hypophosphorous acid in a 2000mL four-necked flask equipped with a stirring device, a thermometer and nitrogen protection in sequence , 0.3g hydroquinone, then start stirring and heating, heat up to 180-200°C, keep warm; continuously check the acid value, when the acid value drops to 120-130mgKOH / g, cool down to 120°C and add trimethylolpropane Diallyl ether 150g, pentaerythritol triallyl ether 150g, take 3 hours to evenly heat up to 200±5°C, keep warm until the viscosity and acid value are qualified, then cool down to below 120°C, add 300g of styrene to dilute, filter and discharge ;

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com