A kind of liquid acid phosphate composition and its preparation method and application

A technology of acid phosphate and composition, which is applied in the field of liquid acid phosphate composition and its preparation, can solve the problems of increasing difficulty, inconvenient feeding, resin precipitation, etc. The effect of coating adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] Another specific embodiment of the present invention provides the preparation method of the liquid acid phosphate composition as described above, comprising the steps of:

[0047] Place the organic acid phosphate at a high temperature and constant temperature until it is in a liquid state;

[0048] Mix propylene glycol butyl ether and dimethylethanolamine evenly in proportion to obtain a mixed solution;

[0049] The organic acid phosphate in liquid state is mixed with the above mixed solution in proportion, and dispersed uniformly to obtain the liquid acid phosphate composition.

[0050] In a preferred example, the temperature of the above-mentioned high temperature and constant temperature storage is about 80°C.

[0051] In yet another preferred example, the mixing of the organic acid phosphate in liquid state and the mixed solution is carried out at normal temperature or low temperature. Preferably 5-35°C.

[0052] In yet another specific embodiment, a water-based ...

Embodiment 1

[0058] A liquid acid phosphate composition is composed of: 75wt% propylene glycol butyl ether, 5wt% dimethylethanolamine and 20wt% dodecyl phosphate.

[0059] The preparation method of above-mentioned liquid acidic phosphate composition, comprises the steps:

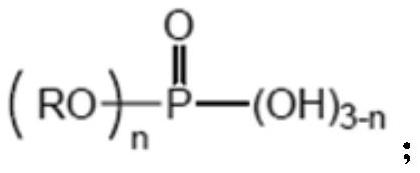

[0060] Store the dodecyl phosphate in a constant temperature storage room at 80°C until it is in a liquid state; wherein, the molecular formula of dodecyl phosphate is: C 12 h 27 o 4 P, the structural formula is as follows:

[0061]

[0062] Mix the propylene glycol butyl ether and dimethylethanolamine, stir and disperse evenly;

[0063] Mix the liquid dodecyl phosphate with the mixture of propylene glycol butyl ether and dimethylethanolamine at 10° C., stir and disperse evenly to obtain the liquid acid phosphate composition. The liquid acid phosphate composition is in a stable liquid state at 10°C, and it is still in a stable liquid state for more than 30 days at low temperature and normal temperature, and its fo...

Embodiment 2

[0065] A liquid acid phosphate composition comprising: 73 wt% propylene glycol butyl ether, 5 wt% dimethylethanolamine and 22 wt% myristyl phosphate.

[0066] The preparation method of above-mentioned liquid acidic phosphate composition, comprises the steps:

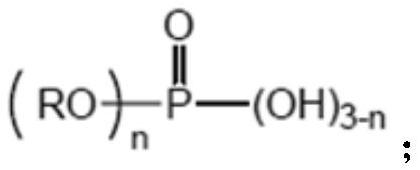

[0067] Store myristyl phosphate in a constant temperature storage room at 80°C until it is in a liquid state. Among them, the structure of myristyl phosphate is similar to that of dodecyl phosphate, and the chemical formula is: C 14 h 31 o 4 P);

[0068] Mix propylene glycol butyl ether and dimethylethanolamine, stir and disperse evenly;

[0069] The tetradecyl phosphate in liquid state was mixed with the aforementioned mixture of propylene glycol butyl ether and dimethylethanolamine at a temperature of 15° C., stirred and dispersed uniformly to obtain the liquid acid phosphate composition. The liquid acid phosphate composition is in a stable liquid state at 15° C., and it is still in a stable liquid state when place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com