Deflecting tractive cotton harvester

A cotton harvesting and traction type technology is applied to the field of yaw traction type cotton harvesters, which can solve the problems of complex machine structure, low cotton picking rate, large cotton loss, etc., and achieves low machine cost, simple operation procedure and long service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

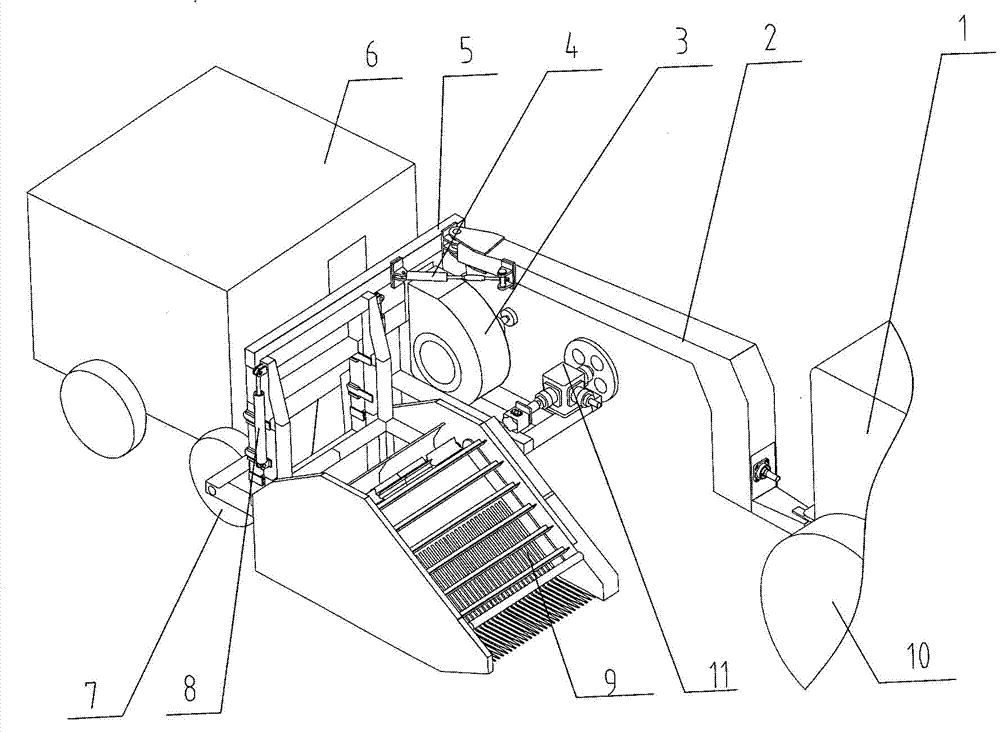

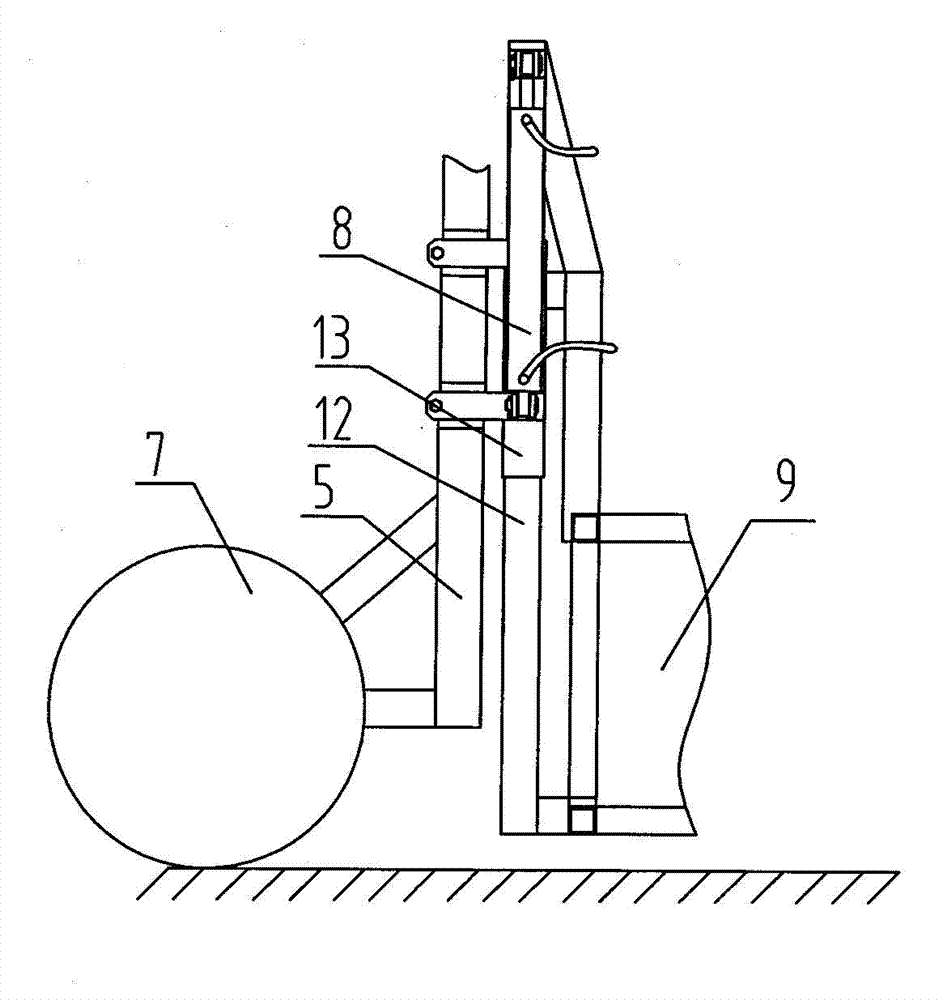

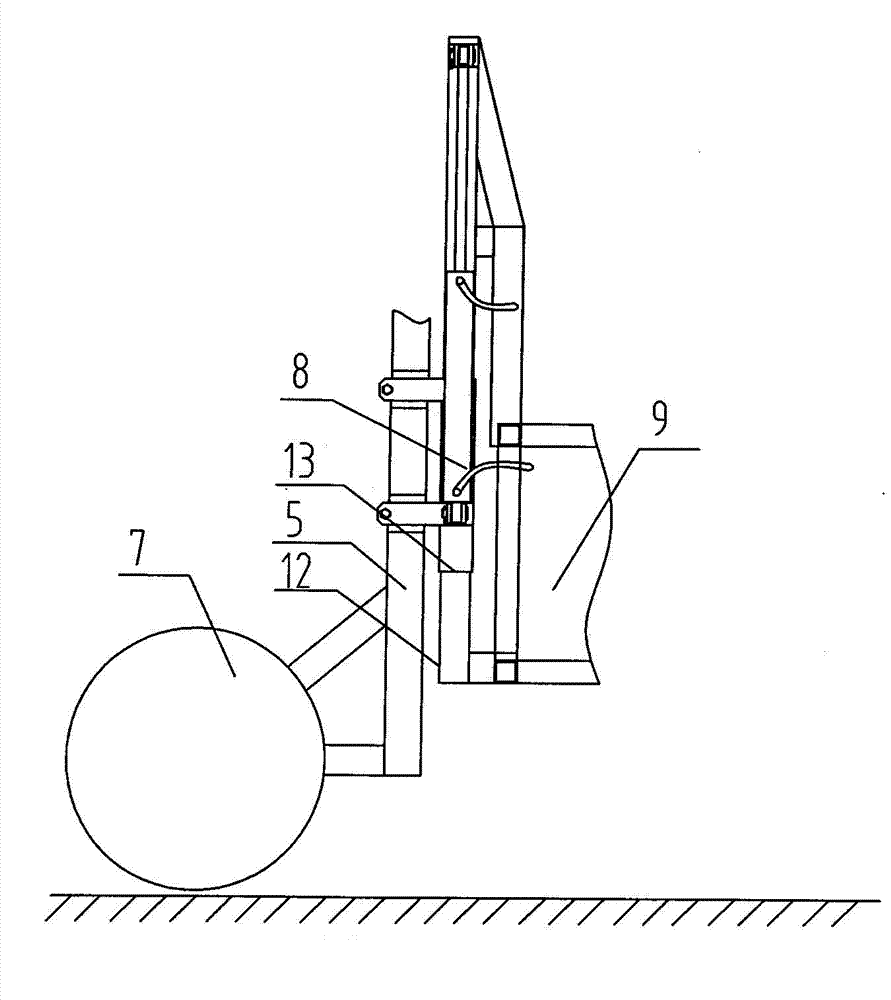

[0017] An eccentric traction cotton harvester, such as figure 1 , figure 2 , image 3 As shown, the comb-toothed cotton picking platform 9 through tractor 1 power transmission is installed on the frame, the bellcrank-shaped traction frame 2 hinged by tractor 1, and the other end is hinged on the picking platform 9 with the lateral support of walking wheels 7 On the upper part of the side of the frame 5, one end of the yaw oil cylinder 4 is hinged on the bellcrank-shaped traction frame 2, and the other end is hinged on the lateral support frame 5. On the lateral support frame 5, inner and outer sleeves 12, 13 The movable guide sleeve is connected to the picking platform 9 through the guide sleeve, wherein the inner sleeve 12 is fixedly connected to the picking platform 9, the outer sleeve 1 is fixedly connected to the transverse support frame 5, and one end of the lifting cylinder 4 is hinged On the outer sleeve 13, the other end is hinged on the inner sleeve 12, and the fan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com