Hoisting vehicle and method for replacing of long and heavy parts of high-speed railway turnout

A technology for replacing parts and hoisting vehicles, which is applied to the superstructure of the track, roads, tracks, etc., can solve the problems of high equipment cost, hidden safety hazards, and long use time, and achieve the effect of saving on-site operation time, easy promotion, and low equipment investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

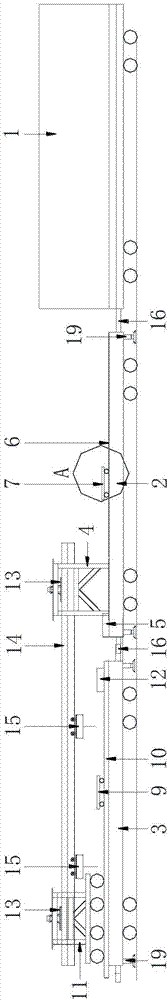

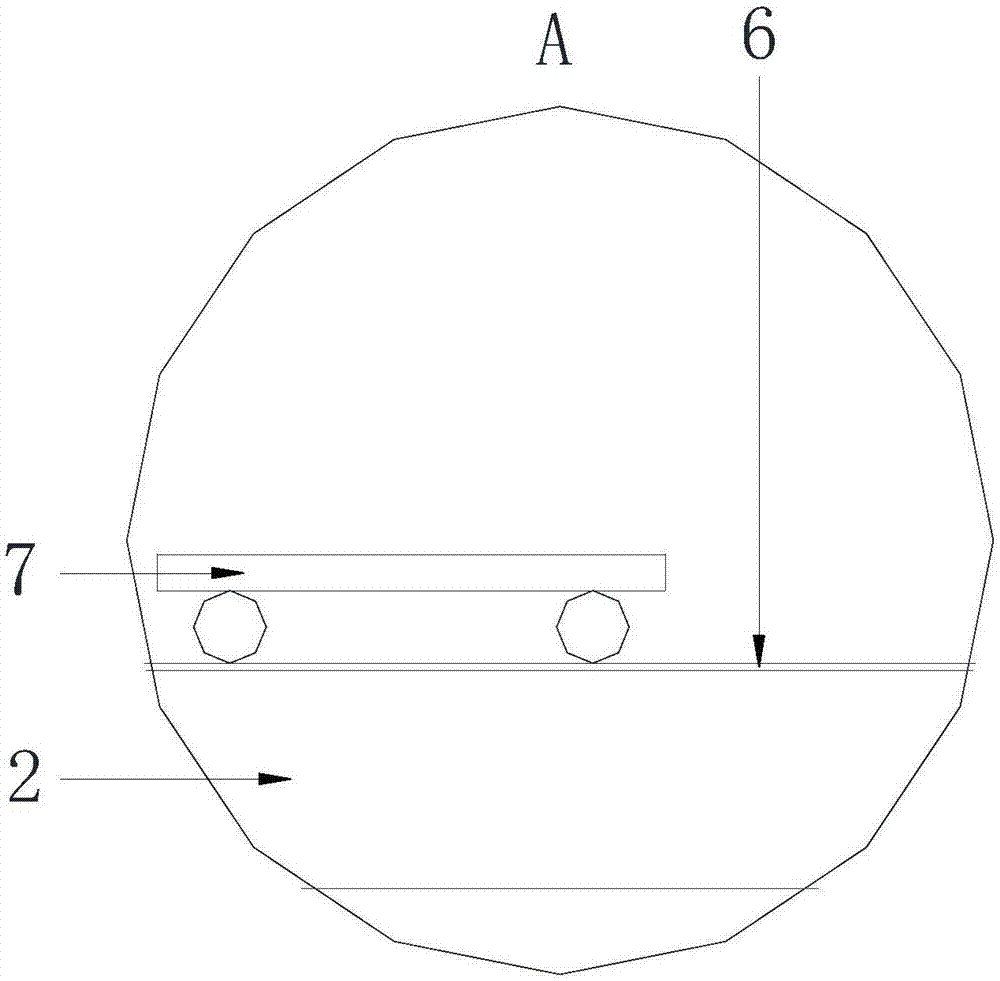

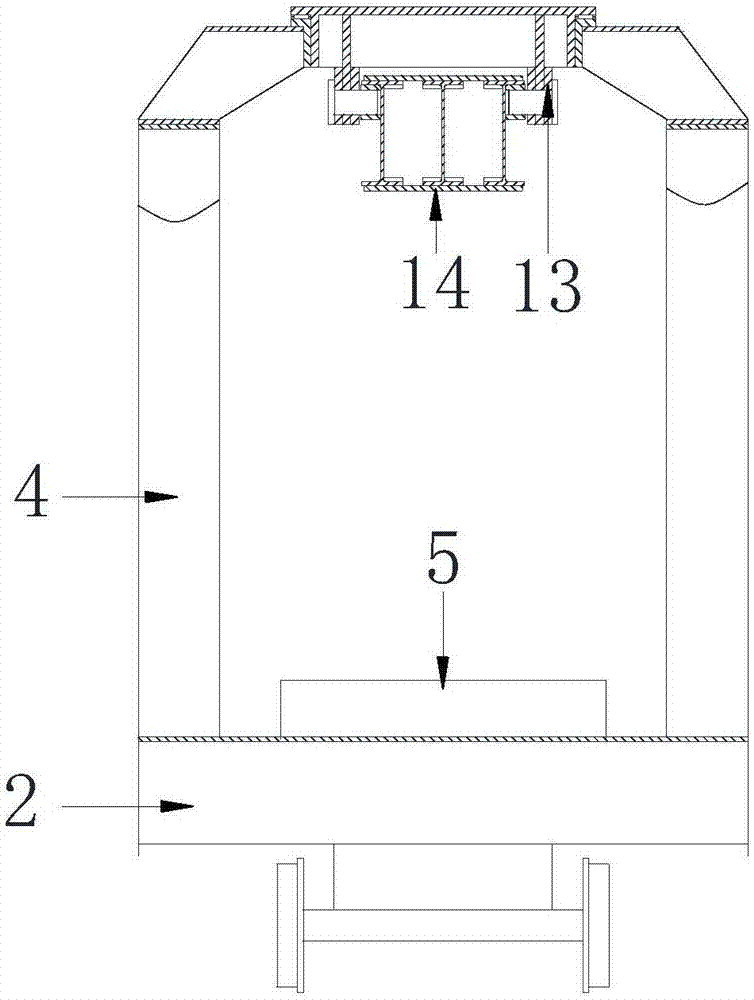

[0028] Embodiment 1: as Figure 1 to Figure 4As shown, the hoisting vehicle for replacing long and heavy parts of high-speed railway turnouts includes rail car 1, fixed gantry flat car 2 and movable gantry flat car 3 connected end to end through hooks 16, and fixed gantry flat car 1 and movable gantry flat car The bottom of both sides of the flat car 2 is vertically provided with a hydraulically telescopic support arm 19; the top of the tail of the fixed gantry flat car 2 is fixedly provided with a fixed gantry 4 and a fixed gantry flat car support frame 5; A pair of fixed gantry flat car tracks 6 are arranged on the top of the fixed gantry flat car 2 on the inner side, and a fixed gantry small flat car 7 that moves back and forth along the fixed gantry small flat car track 6 is arranged on the fixed gantry small flat car track 6; The top surface of the gantry flat car support frame 5 is at the same level as the top surface of the fixed gantry flat car 7; a pair of movable gan...

Embodiment 2

[0029] Embodiment 2: as Figure 5 As shown, the movable center rail switch replacement hoisting vehicle includes a rail car 1, a fixed gantry flat car 2 and a movable gantry flat car 3 connected end-to-end through a hook 16. The difference is that the fixed gantry flat car 2 is composed of two fixed gantry assembly flat cars 2-1, and the bottom of each fixed gantry assembly flat car 2-1 is vertically provided with hydraulic telescopic support arms 19; The fixed gantry assembly flat car 2-1 at the tail end is fixed with a fixed gantry small flat car track 6; the fixed gantry 4 and the fixed gantry flat car support frame 5 are placed on the rearmost fixed gantry assembly flat car 2-1 top of the rear of the car.

[0030] The movable gantry flat car 3 is made up of two movable gantry assembly flat cars 3-1, and the bottom of each movable gantry assembly flat car 3-1 is vertically provided with hydraulic telescopic support arms 19; The top of the component flat car 3-1 is fixedly...

Embodiment 3

[0031] Embodiment 3: a method for replacing long and heavy components of a high-speed rail turnout, which includes the following steps:

[0032] Step 1, hoisting and fixing the long and heavy parts of the new high-speed railway turnout: if Figure 6 Shown, in the rail stock storage yard, the new high-speed rail turnout length and weight part 17 is hoisted on the movable gantry flat car 3 with lifting equipment, and the movable gantry small flat car 9 and the movable gantry flat car on the movable gantry small flat car track 8 and the movable The gantry flat car support frame 12 jointly supports the long and heavy parts 17 of the new high-speed railway turnout.

[0033] Step 2, the fixed gantry flat car and the movable gantry flat car are unfolded and fixed: as Figure 7 As shown, when the long and heavy parts of the high-speed rail turnout are replaced, the rail car 1 is used as the power to run to the place where the long and heavy parts of the high-speed rail turnout are re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com