Multi-layer pipe roof structure based on square jacking pipe and construction method of multi-layer pipe roof structure

A technology of multi-layer pipes and square steel pipes is applied in the field of tunnel pipe curtains, which can solve the problems of high groundwater control risk, large distance between pipes, and large construction area, and achieves reduction in size, construction area, and the effect of risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

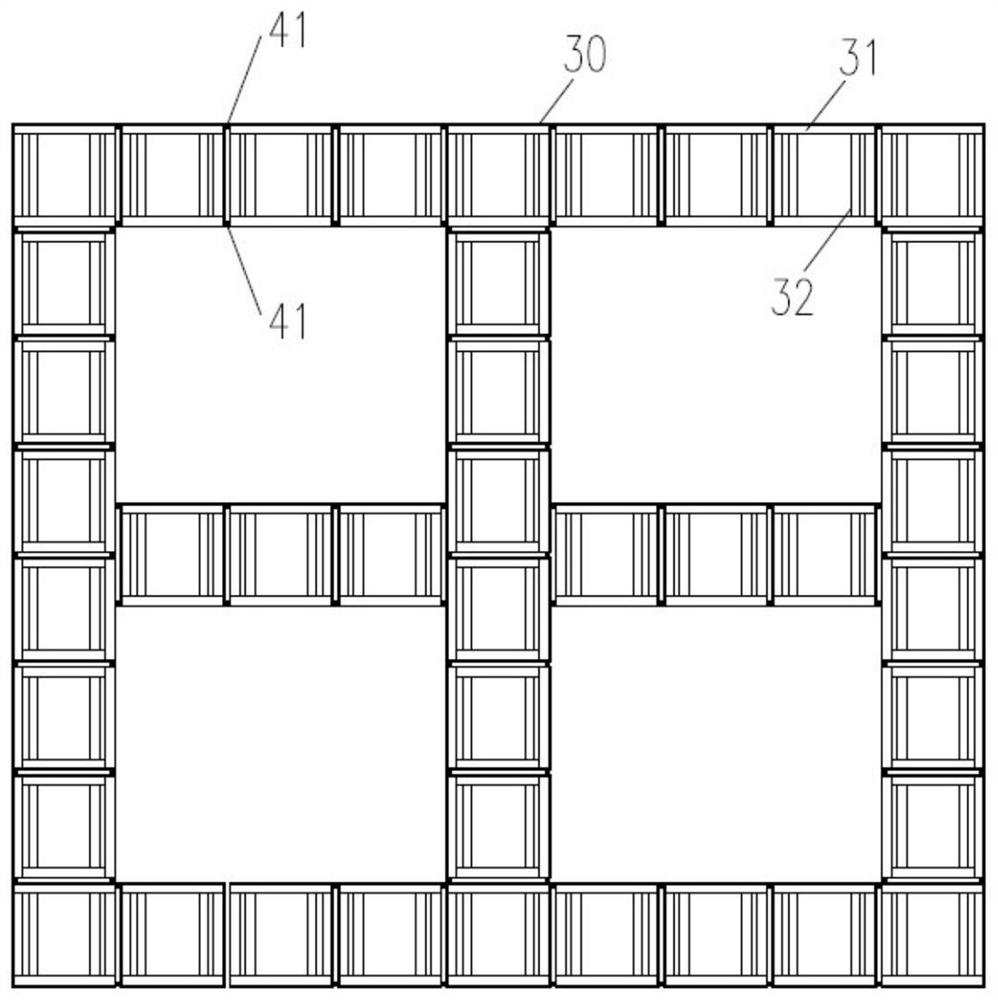

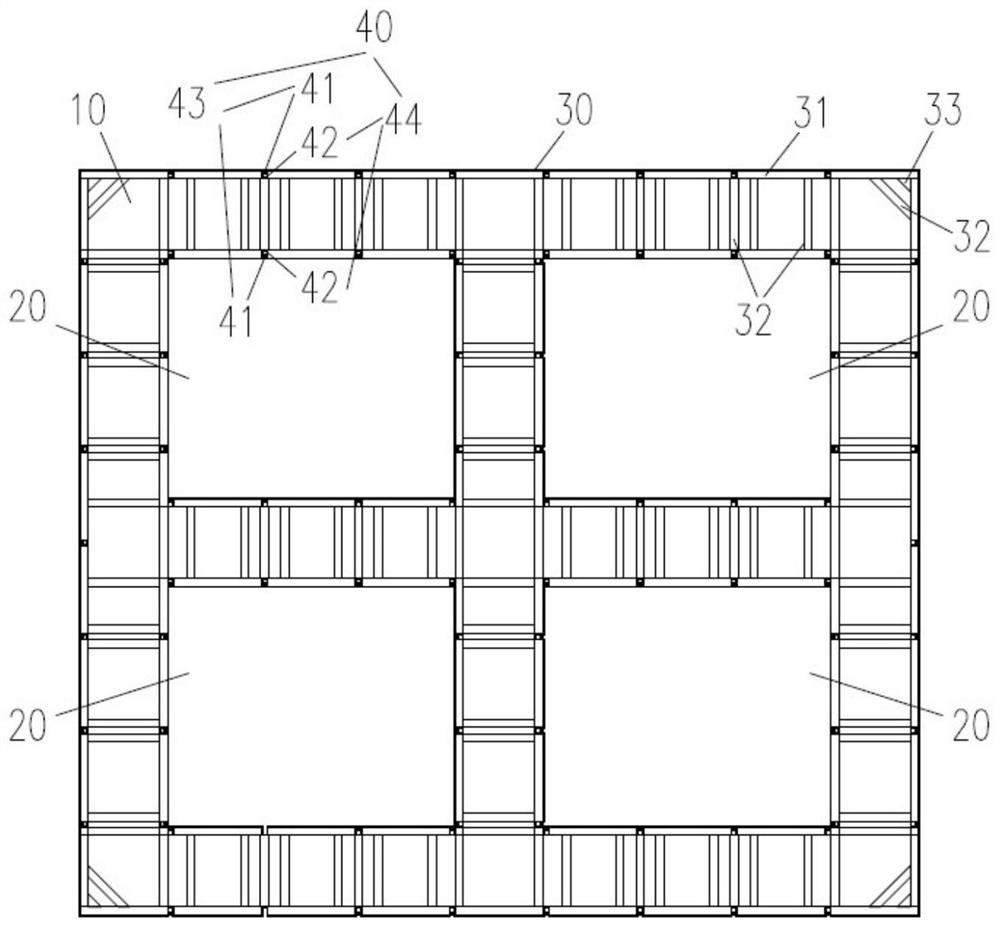

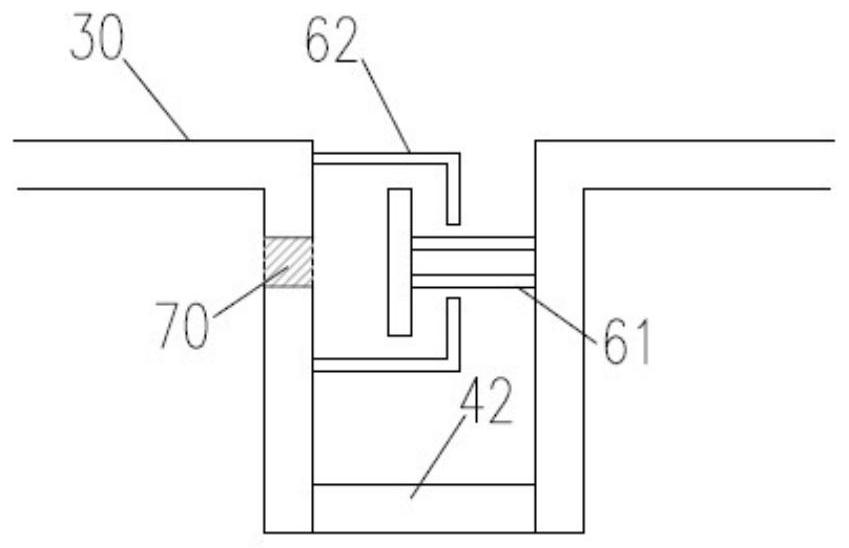

[0061] Such as Figure 1-Figure 5 As shown: this embodiment discloses a multi-layer pipe curtain structure based on square pipe jacking, including: a plurality of square steel pipes 30; two of the plurality of square steel pipes 30 are fixed and communicated with each other by means of connecting components to form a first Closed space 10; a plurality of square steel pipes 30 are combined to form a plurality of second closed spaces 20; the first closed space 10 is used as a construction corridor for pouring reinforced concrete structures; the plurality of second closed spaces 20 For vehicle traffic. Before the jacking of each square steel pipe 30, the inner wall of the steel pipe is welded with a circle of I-shaped steel purlins 31, and the outer flanges of the I-shaped steel purlins 31 are attached to the inner walls of the square steel pipes 30; Two I-shaped steel supports 32 are welded symmetrically between the upper and lower sides of the I-shaped steel purlin 31 , and th...

Embodiment 2

[0078] See attached figure 1 , a structural schematic diagram of a pipe jacking joint based on a square pipe jacking multi-layer pipe curtain structure provided in this embodiment, its main features are: it is a circle of square steel pipes 30 jacked along the outline of the rectangular tunnel structure, and the square steel pipes 30 Not only as a temporary support for the pouring of the tunnel structure, but also as a permanent structure of the tunnel, the water-stop lock 41 is welded between adjacent square steel pipes 30, and the distance between the square steel pipes 30 is set as small as possible, but it should meet the requirements of jacking between the pipes. Deviation requirements, in order to control the risk of water stop between pipes and soil excavation between pipes. I-shaped steel purlins 31 and I-shaped steel supports 32 are welded in the pipe to enhance the stress of the square steel pipe 30 .

[0079] See attached figure 2 , a schematic diagram of the str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com